Introduction

In the ever-evolving world of electronics, understanding what is a SMT (Surface Mount Technology) is essential for anyone involved in the design and manufacturing of electronic devices. SMT has revolutionized the way printed circuit assembly (PCA) is conducted, allowing for smaller, lighter, and more efficient products. Its significance cannot be overstated, as it forms the backbone of modern circuit board production.

What is a smt and its significance

So, what is a SMT? In simple terms, it's a method that allows electronic components to be mounted directly onto the surface of a circuit board rather than being inserted into holes as in traditional methods. This innovation not only streamlines the manufacturing process but also enhances performance and reliability in electronic devices by reducing space and weight.

The role of SMT in electronics

The role of SMT in electronics cannot be overlooked; it has become integral to the design and functionality of contemporary products. By enabling higher component density on circuit boards, SMT supports advanced features like miniaturization and improved heat dissipation. As manufacturers strive to create more compact devices with greater capabilities, SMT stands out as a pivotal technology driving this transformation.

Key benefits of using SMT technology

The key benefits of using SMT technology are numerous and impactful for manufacturers and consumers alike. Firstly, it reduces the size and weight of electronic devices significantly while maintaining or even enhancing performance levels. Additionally, because printed circuit assembly processes can be automated more easily with SMT, production times are shortened—leading to cost savings that can be passed on to consumers.

Defining SMT in Simple Terms

Surface Mount Technology (SMT) has revolutionized the way we think about electronic devices and their assembly. At its core, SMT involves mounting electronic components directly onto the surface of a circuit board, making it distinct from traditional methods that often require drilling holes for component leads. This innovation not only streamlines the manufacturing process but also enhances the overall efficiency of printed circuit assembly.

Explanation of surface mount technology

So, what is a SMT? Simply put, it’s a method where electronic components are attached directly to the surface of a circuit board instead of being inserted through holes. This technique allows for a higher density of components on a circuit board, which means more functionality in less space—a critical factor in today’s compact electronic devices. Moreover, SMT enables automated assembly processes that significantly reduce production time and costs.

Comparison with traditional methods

When comparing SMT to traditional through-hole technology, several key differences emerge. Traditional methods involve inserting component leads into holes drilled into a circuit board, which can be cumbersome and time-consuming during assembly. In contrast, SMT eliminates this step by allowing components to sit flat against the PCB surface—resulting in a lighter and slimmer design for modern electronic devices while simplifying the entire PCB assembly process.

Importance in modern electronics

The importance of SMT in modern electronics cannot be overstated; it is foundational to creating smaller, more efficient devices that we use every day. As consumer demand grows for sleek gadgets packed with features, manufacturers turn to SMT as an essential solution for optimizing both performance and space on circuit boards. In essence, without this innovative technology, our beloved smartphones and laptops would be bulkier and less capable than they are today.

Components of SMT

When diving into the world of surface mount technology (SMT), understanding the components and materials involved is crucial. SMT relies on a variety of electronic components that are designed to be mounted directly onto the surface of a circuit board, allowing for compact and efficient designs. This section will explore the essential components used in SMT, the types of circuit boards employed, and provide insights into printed circuit assembly.

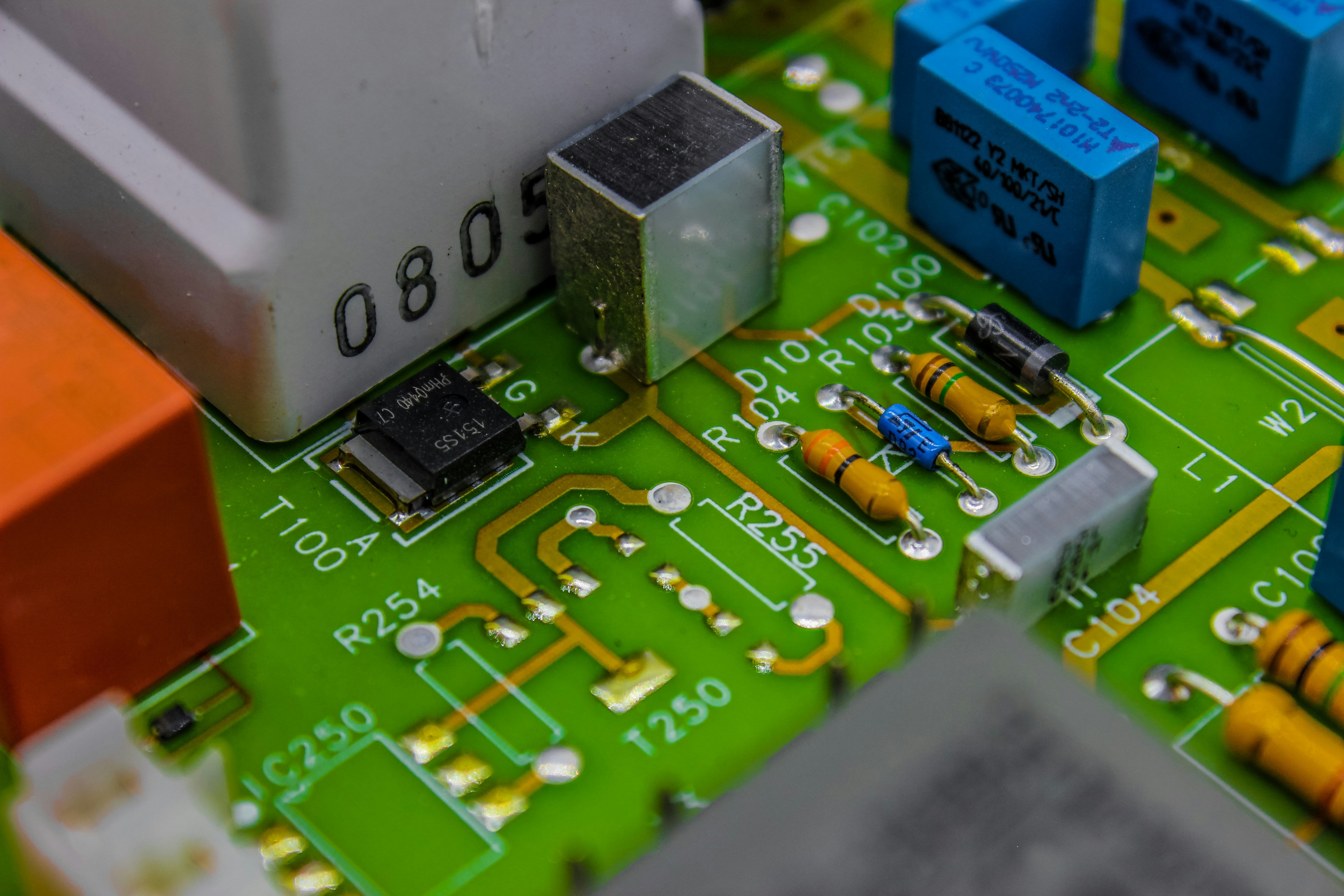

Overview of electronic components used

In SMT, electronic components come in various shapes and sizes, each serving specific functions within a circuit board. Commonly used components include resistors, capacitors, diodes, and integrated circuits (ICs), all designed to optimize space on a circuit board while ensuring high performance. The ability to use smaller electronic components not only contributes to reducing the overall size of devices but also enhances their functionality by enabling more complex designs.

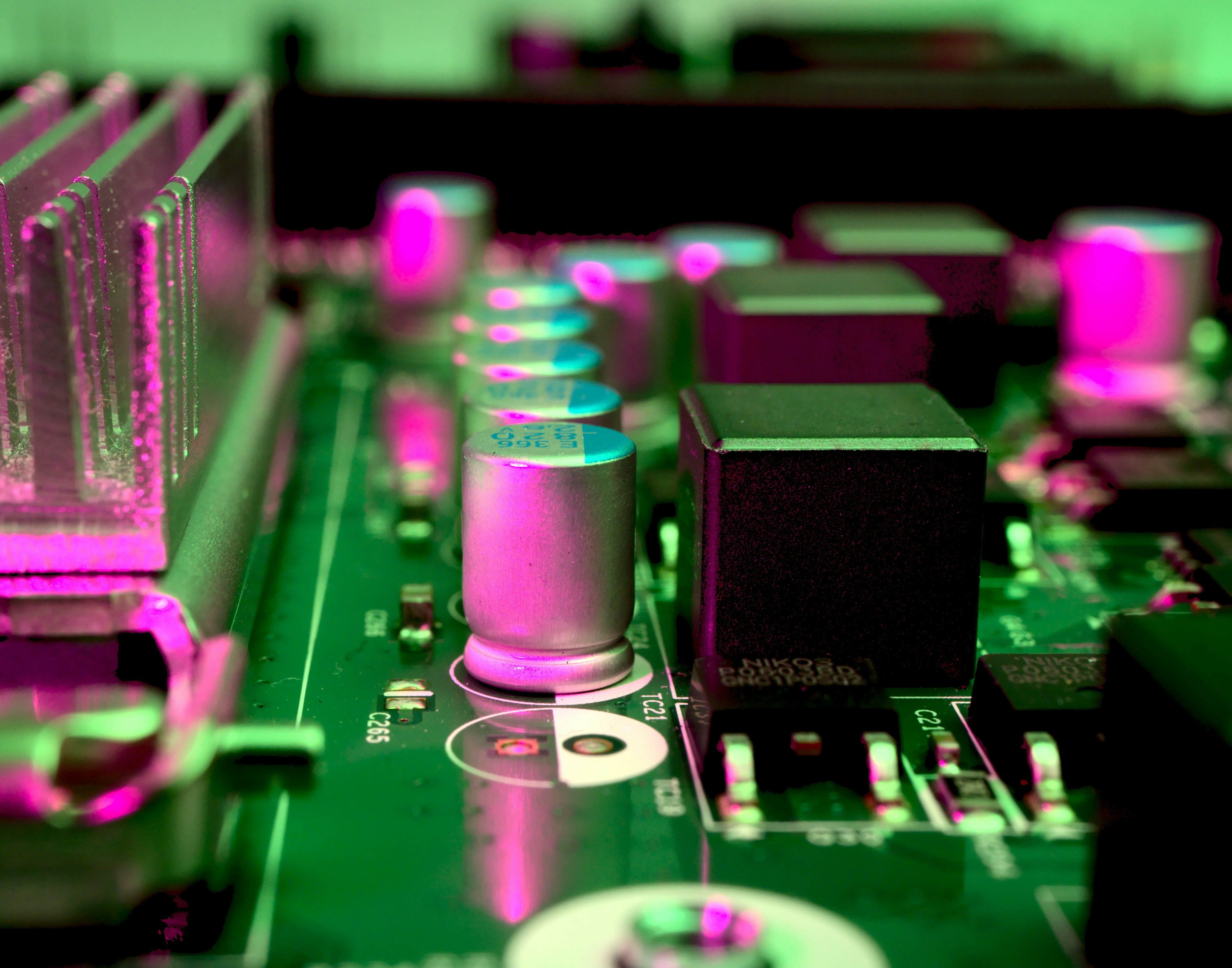

Types of circuit boards employed

The types of circuit boards employed in SMT play a significant role in determining how effectively electronic devices operate. Typically, printed circuit boards (PCBs) are utilized due to their ability to accommodate multiple layers and intricate designs that support various electronic components. Additionally, flexible PCBs have gained popularity in modern electronics because they can bend and twist without compromising functionality, making them ideal for compact or portable devices.

Insights into printed circuit assembly

Printed circuit assembly (PCA) is a critical step in the SMT process where all those tiny electronic components come together on a circuit board. This process involves soldering these components onto the PCB with precision to ensure optimal connectivity and performance within electronic devices. A well-executed PCA not only improves reliability but also enhances manufacturing efficiency by streamlining production processes—making it an indispensable part of modern electronics.

The SMT Process Explained

Surface Mount Technology (SMT) has revolutionized the way we assemble electronic devices, making the process more efficient and effective. Understanding this process is essential for anyone involved in electronics, from engineers to manufacturers. Let’s dive into the intricacies of SMT assembly and its significance in printed circuit assembly.

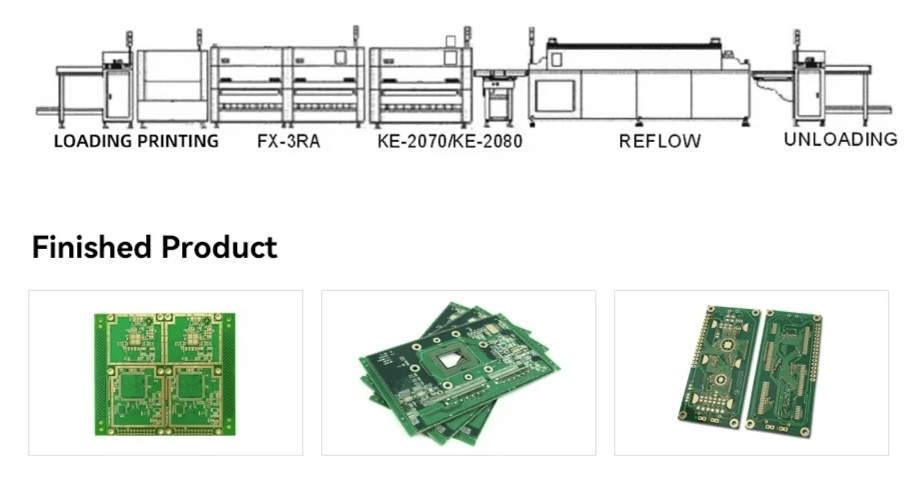

Step-by-step breakdown of SMT assembly

The SMT assembly process begins with the careful design of a circuit board, which lays out where each electronic component will be placed. Next, solder paste is applied to specific areas on the PCB using a stencil, ensuring that only the designated spots are coated for optimal adhesion. Following this, components are placed onto the circuit board using pick-and-place machines, which accurately position each electronic component based on pre-programmed coordinates.

After placement, the circuit board undergoes reflow soldering where it is heated in an oven to melt the solder paste, creating strong electrical connections between components and PCB pads. Once cooled, inspection takes place—often through automated optical inspection—to catch any defects or misalignments before moving on to further testing. This meticulous step-by-step approach ensures that every aspect of printed circuit assembly meets high standards for quality and reliability.

The role of PCB assembly in the process

PCB assembly serves as a critical backbone in the SMT process; without it, there would be no platform for mounting electronic components effectively. A well-designed PCB not only accommodates various types of components but also optimizes signal integrity and thermal management within electronic devices. Essentially, PCB assembly transforms raw materials into fully functional products ready for market deployment.

Moreover, effective PCB design can significantly reduce manufacturing costs by minimizing material waste and improving production efficiency during surface mount technology processes. As manufacturers strive for smaller and more complex designs in their products, a robust PCB becomes even more vital to accommodate these evolving requirements without compromising performance or reliability. In short, effective PCB assembly is where innovation meets practicality in modern electronics.

Importance of precision in circuit board assembly

Precision plays a pivotal role throughout every stage of circuit board assembly; even minor inaccuracies can lead to significant failures down the line. Given that electronic components are often tiny and densely packed on a circuit board, precise placement ensures that connections remain intact while avoiding short circuits or other malfunctions during operation. In SMT processes specifically designed for high-density applications like smartphones or wearables, this precision becomes absolutely crucial.

Furthermore, in today’s competitive landscape where consumers demand high-performance devices with minimal errors or malfunctions, maintaining precision directly correlates with customer satisfaction and brand reputation. Manufacturers who prioritize precision not only enhance product quality but also streamline their production processes by reducing rework rates associated with faulty assemblies. Thus, investing time and resources into achieving accuracy during circuit board assembly pays off substantially over time.

Advantages of SMT for Electronic Devices

Surface Mount Technology (SMT) has revolutionized the way electronic devices are manufactured, making it a favored choice among manufacturers. With the ability to place electronic components directly onto the surface of a circuit board, SMT streamlines the printed circuit assembly process. This efficiency not only reduces production time but also enhances overall product quality, making SMT a go-to solution in modern electronics.

Why manufacturers prefer SMT

Manufacturers prefer SMT primarily due to its compactness and efficiency in production. Unlike traditional through-hole methods, where components are inserted into drilled holes on a circuit board, SMT allows for greater flexibility in design and layout. This means that more electronic components can be placed on a smaller area of a circuit board, leading to innovative designs that cater to consumer demands for sleek and lightweight devices.

Moreover, the automation involved in PCB assembly using SMT significantly reduces labor costs and human error during production. The precision placement of components ensures consistent quality across batches, which is crucial for maintaining brand reputation in competitive markets. Ultimately, the combination of speed, reliability, and cost-effectiveness makes SMT an attractive option for manufacturers looking to stay ahead in the electronics game.

Impact on product size and weight

One of the most noticeable impacts of using SMT is the reduction in product size and weight—an essential factor in today’s tech-savvy world where consumers crave portability. By utilizing smaller electronic components mounted directly onto a circuit board's surface, manufacturers can create slimmer products without compromising functionality or performance. This shift allows devices like smartphones and laptops to become increasingly lightweight while packing powerful capabilities.

Additionally, this miniaturization opens up new possibilities for design innovation; engineers can explore unique form factors that were previously impractical with traditional methods. The result? A surge of sleek gadgets that fit seamlessly into our fast-paced lifestyles while delivering high performance levels expected from modern electronic devices. As consumers continue to demand more from their technology, this trend toward compactness will likely persist.

Enhanced performance in electronic components

The enhanced performance offered by SMT contributes significantly to improved functionality across various electronic devices. By minimizing lead lengths between components on a circuit board assembly, signal integrity is preserved—leading to faster data transfer rates and reduced electromagnetic interference (EMI). This is particularly important as devices become more complex with advanced features requiring reliable communication between parts.

Furthermore, because SMT allows for higher component density on printed circuit assemblies (PCAs), engineers can incorporate more functionalities into smaller packages without sacrificing quality or reliability. As technology advances at breakneck speed, having robust yet compact designs becomes imperative—not just for aesthetics but also for ensuring optimal device performance under demanding conditions. In essence, adopting what is a smt leads to smarter designs that elevate user experiences across countless applications.

Choosing the Right SMT Service Provider

In the world of electronics, selecting the right SMT service provider can make or break your project. With numerous options available, it’s crucial to identify a partner that aligns with your specific needs for printed circuit assembly and electronic components. A well-chosen PCB assembly partner not only ensures quality but also enhances the efficiency of your circuit board assembly process.

What to look for in a PCB assembly partner

When searching for a PCB assembly partner, start by assessing their experience with surface mount technology (SMT). Look for companies that have a solid track record in handling various electronic devices and can demonstrate proficiency in assembling complex circuit boards. Additionally, consider their capabilities in terms of quality control, equipment used for SMT processes, and their ability to meet tight deadlines without compromising on quality.

Another key factor is their flexibility to adapt to your specific requirements. Whether you need low-volume prototypes or high-volume production runs, your chosen provider should be able to accommodate these needs seamlessly. Moreover, ensure they have robust communication practices in place; clear dialogue throughout the project can significantly reduce errors and enhance collaboration during printed circuit assembly.

Lastly, don’t overlook customer reviews and testimonials; they can provide valuable insights into a provider's reliability and performance history. A good service provider will be transparent about their processes and willing to share previous success stories involving SMT projects similar to yours. This level of openness is critical in establishing trust as you embark on your electronic journey.

Bensun Technology’s offerings in SMT

Bensun Technology stands out as a leading choice when considering an SMT service provider due to its comprehensive range of offerings tailored specifically for printed circuit assembly needs. They specialize in advanced surface mount technology solutions that cater to various industries—from consumer electronics to automotive applications—ensuring that every electronic device meets stringent performance standards.

What sets Bensun apart is their state-of-the-art facilities equipped with cutting-edge machinery designed for efficient circuit board assembly. Their team comprises skilled professionals who are well-versed in handling diverse electronic components while maintaining precision throughout the PCB assembly process. This commitment not only enhances product quality but also optimizes production timelines, allowing clients to bring their products to market faster.

Additionally, Bensun Technology prides itself on its customer-centric approach; they work closely with clients from concept through production phases, ensuring all specifications are met precisely as intended. This partnership model fosters innovation and encourages feedback loops that help refine processes continually—an essential aspect when dealing with complex electronic devices requiring meticulous attention.

The significance of experience and technology

An experienced team understands common pitfalls associated with printed circuit assemblies and has developed strategies to mitigate risks effectively during circuit board manufacturing processes. This expertise translates into fewer errors and higher-quality outcomes for electronic components used across various applications.

Moreover, leveraging advanced technology is equally vital; modern equipment enhances precision during PCB assembly while accommodating intricate designs typical of today’s compact electronic devices. Providers who invest in innovative technologies often yield better results regarding speed, accuracy, and overall efficiency within their operations—elements critical for staying competitive in the fast-paced electronics market.

Ultimately, selecting an experienced partner equipped with cutting-edge tools ensures that you receive top-notch service tailored specifically for your unique needs within surface mount technology projects. With such considerations at play, making informed choices becomes significantly easier as you navigate through potential partners who will help bring your vision into reality seamlessly.

Conclusion

In wrapping up our exploration of surface mount technology (SMT), it's clear that this innovative approach has revolutionized the way we design and manufacture electronic devices. By allowing for a more compact layout on circuit boards, SMT not only optimizes space but also enhances performance and reliability of electronic components. The significance of SMT in printed circuit assembly cannot be overstated; it is indeed the backbone of modern electronics.

Summarizing the importance of SMT

So, what is a SMT? It’s a game-changer in the world of electronics, enabling manufacturers to create smaller, lighter, and more efficient products. The precision involved in circuit board assembly ensures that electronic components are placed accurately, reducing errors and improving overall functionality. As we’ve seen throughout this discussion, embracing SMT technology is essential for staying competitive in today’s fast-paced market.

Future trends in surface mount technology

Looking ahead, the future trends in surface mount technology promise even greater advancements. With ongoing innovations such as automation and artificial intelligence being integrated into PCB assembly processes, we can expect enhanced efficiency and reduced costs for manufacturers. Additionally, as electronic devices become increasingly complex, the demand for more sophisticated SMT techniques will likely rise to meet these challenges head-on.

Making informed choices in electronic assembly

When it comes to making informed choices in electronic assembly, selecting the right partner is crucial. Look for a PCB assembly provider that understands what is a SMT and has experience with various types of circuit boards and electronic components. By prioritizing expertise and technological capabilities, businesses can ensure their products are built to last while keeping pace with industry standards.