Introduction

In the fast-paced world of electronics, enhancing efficiency in PCB manufacturing is not just a goal; it’s a necessity. With the increasing complexity of printed circuit assembly, manufacturers are constantly seeking ways to streamline processes and minimize errors. One such innovation making waves in this domain is the PCB handling conveyor, which plays a pivotal role in optimizing workflow during PCB production and assembly.

Enhancing Efficiency in PCB Manufacturing

Efficiency in PCB manufacturing directly impacts product quality and time-to-market. By utilizing advanced technologies like the PCB handling conveyor, companies can significantly reduce bottlenecks associated with traditional methods of circuit board movement. This not only speeds up the printed circuit board assembly process but also ensures that each pcb board is handled with precision, minimizing defects and enhancing overall productivity.

Unpacking the PCB Handling Conveyor

The PCB handling conveyor is designed specifically for the unique needs of printed circuit board assembly lines. Unlike conventional conveyors, these systems are tailored to accommodate various sizes and types of pcb boards while ensuring safe transport throughout the production process. Understanding its functionality reveals how it seamlessly integrates into existing workflows to enhance efficiency and support high-volume production demands.

Why Workflow Matters in Electronics

Workflow efficiency is crucial in electronics manufacturing as it affects everything from lead times to product reliability. In an industry where precision is paramount, optimizing processes through tools like pcb handling conveyors can lead to significant improvements in both speed and accuracy during pcb board assembly. Ultimately, a well-designed workflow not only boosts productivity but also positions companies competitively within a rapidly evolving market landscape.

Understanding PCB Handling Conveyors

In the world of electronics, particularly in printed circuit assembly, efficiency is key. One of the unsung heroes in this domain is the PCB handling conveyor, a specialized system designed to transport circuit boards seamlessly through various stages of production. By optimizing workflow and reducing manual handling, these conveyors play a pivotal role in enhancing overall productivity.

Definition and Functionality

A PCB handling conveyor is specifically engineered to move printed circuit boards (PCBs) through different processes in assembly lines. Unlike standard conveyors that might be used for general materials, these systems are tailored to accommodate the unique dimensions and fragility of circuit boards. They often feature adjustable speeds and configurations that ensure a smooth transition from one stage of PCB production and assembly to another.

The functionality of a PCB handling conveyor extends beyond mere transportation; it integrates with other machinery like soldering stations and inspection units. This integration allows for automated processes that significantly reduce manual labor requirements while increasing accuracy during printed circuit board assembly. Ultimately, this technology serves as a backbone for efficient PCB board assembly operations.

How They Fit into the PCB Production Process

PCB handling conveyors are integral to the entire lifecycle of printed circuit board production, from initial fabrication to final testing. These systems facilitate the movement of PCBs between various workstations where critical processes such as soldering, component placement, and quality control occur. By ensuring that each board reaches its destination without delay or damage, they help maintain a steady workflow throughout the entire assembly line.

Moreover, these conveyors can be programmed to synchronize with other automated equipment within the production environment. This synergy not only enhances speed but also minimizes bottlenecks commonly experienced during traditional manufacturing setups. The result is an efficient ecosystem where each element works harmoniously toward successful PCB board assembly.

Key Differences from Traditional Conveyors

While traditional conveyors serve their purpose well in many industries, they lack specific features necessary for effective PCB handling. Standard systems typically do not account for the delicate nature of printed circuit boards or their varying sizes and shapes; thus they may inadvertently cause damage during transport. In contrast, dedicated PCB handling conveyors are equipped with features such as soft-touch mechanisms and adjustable widths that cater specifically to the needs of electronic components.

Another notable difference lies in their automation capabilities; while traditional conveyors may require manual intervention at various points along their path, modern PCB handling solutions facilitate continuous flow without human oversight wherever possible. This leads not only to increased accuracy but also significant reductions in labor costs associated with manual handling tasks during PCB production and assembly processes. The enhanced compatibility with advanced technologies makes these specialized conveyors indispensable for today’s high-speed manufacturing environments.

Benefits of Implementing a PCB Handling Conveyor

The implementation of a PCB handling conveyor can revolutionize the printed circuit assembly process, offering numerous advantages that streamline operations and enhance overall productivity. By automating the movement of circuit boards during production, manufacturers can significantly reduce bottlenecks and improve workflow efficiency. This not only leads to faster turnaround times but also allows for better resource allocation within the PCB production and assembly environment.

Streamlined Workflow in Printed Circuit Assembly

A well-designed PCB handling conveyor integrates seamlessly into the printed circuit board assembly line, ensuring that each step in the process is coordinated and efficient. With automated transportation of PCB boards from one station to another, workers can focus on value-added tasks rather than moving components manually. This streamlined workflow minimizes downtime and enhances operational efficiency, making it easier to meet tight production schedules while maintaining high-quality standards.

Reduction in Manual Errors and Improved Accuracy

One of the standout benefits of utilizing a PCB handling conveyor is its ability to drastically reduce manual errors associated with traditional methods of PCB board assembly. By automating the movement and positioning of circuit boards, the risk of human error—such as misalignment or misplaced components—is significantly diminished. Consequently, this leads to improved accuracy in printed circuit assembly, ensuring that each board meets stringent quality requirements before moving on to subsequent stages.

Enhanced Productivity Through Automation

Automation through a PCB handling conveyor not only reduces errors but also enhances overall productivity across the entire manufacturing process. As machines take over repetitive tasks such as transporting PCBs between stations, human operators are free to engage in more complex activities that require skill and creativity—ultimately driving innovation within the industry. Additionally, with faster processing times afforded by automated systems, companies can increase their output without compromising quality or safety standards.

The Role of Bensun Technology in PCB Solutions

In the ever-evolving world of electronics, Bensun Technology has carved a niche for itself as a leader in PCB solutions. With a focus on innovation and efficiency, Bensun has developed specialized equipment that enhances the workflow in printed circuit assembly. Their expertise extends beyond mere manufacturing; they understand the nuances of PCB production and assembly, ensuring that every solution is tailored to meet industry demands.

Overview of Bensun’s Expertise

Bensun Technology boasts years of experience in the field of electronic manufacturing solutions, specifically designed for PCB handling conveyor systems. Their team comprises skilled professionals who are well-versed in the latest advancements in circuit board technology and automation. This depth of knowledge allows them to create products that not only streamline processes but also elevate overall productivity within printed circuit board assembly environments.

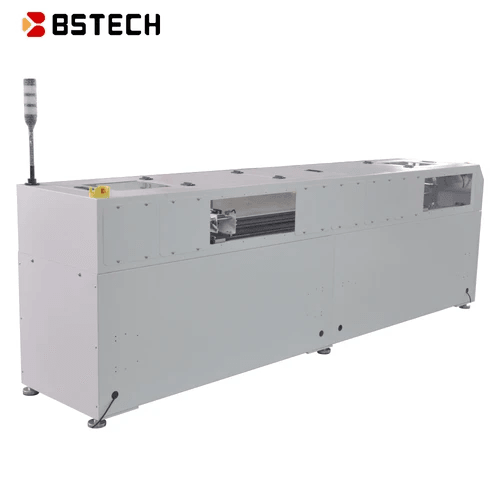

Features of Bensun's PTK-350/460/550 Intelligent Shuttle Conveyor

The PTK-350/460/550 Intelligent Shuttle Conveyor is a standout product from Bensun, equipped with features tailored for optimal PCB handling conveyor performance. This advanced system offers precise control over the movement and positioning of circuit boards throughout the assembly process, significantly reducing wait times and enhancing workflow efficiency. Additionally, its modular design allows for easy integration into existing PCB board assembly lines without major disruptions.

Real-World Applications in PCB Assembly

Bensun's intelligent shuttle conveyors have found their way into various real-world applications across different sectors involved in PCB production and assembly. From automotive electronics to consumer gadgets, these conveyors facilitate seamless transitions between stages in printed circuit board assembly, minimizing manual handling and errors along the way. Companies leveraging this technology report substantial improvements not only in accuracy but also in turnaround times—proving that investing in a quality pcb handling conveyor pays off handsomely.

Integration Challenges and Solutions

Integrating a PCB handling conveyor into existing production lines can be a game-changer, but it doesn’t come without its hurdles. The complexities of printed circuit assembly often lead to various obstacles that can impede the smooth transition to automated systems. Understanding these challenges is crucial for manufacturers looking to enhance their PCB production and assembly processes.

Common Obstacles in PCB Board Assembly

One of the primary obstacles in PCB board assembly is the compatibility of new conveyor systems with current machinery. Older equipment may not easily interface with modern PCB handling conveyors, leading to potential bottlenecks in workflow. Additionally, resistance to change from staff accustomed to traditional methods can create friction during the integration process.

Another common challenge is ensuring that the layout of the workspace accommodates new equipment without disrupting existing operations. Poorly planned integration can lead to inefficiencies, causing delays in printed circuit board assembly and increasing operational costs. Moreover, issues related to supply chain logistics and parts availability can further complicate efforts to streamline PCB production.

Finally, there’s often a learning curve associated with new technologies that can hinder productivity during the initial implementation phase. Staff may require time to adapt their skills for effective use of advanced automation tools like the PCB handling conveyor. This transition period might result in temporary declines in output until everyone is on board with the changes.

Strategies for Seamless Integration

To overcome these integration challenges, manufacturers should start by conducting a thorough analysis of their current systems and identifying compatibility requirements for new equipment like a PCB handling conveyor. This analysis should include assessing existing machinery and determining how best to modify or replace outdated components that could slow down printed circuit assembly processes.

Next, involving employees early in the planning phase fosters buy-in and minimizes resistance when changes are implemented. Offering demonstrations or pilot programs showcasing how a PCB handling conveyor enhances workflow efficiency can help alleviate concerns among staff members about adopting new technology.

Lastly, developing a comprehensive implementation plan that includes step-by-step timelines will ensure all aspects of integration are managed effectively. This plan should also account for any necessary downtime during installation while providing strategies for maintaining productivity levels throughout the transition period—ensuring smooth sailing into enhanced PCB board assembly operations.

Training for Staff and Maintenance Requirements

Once integrated, proper training becomes paramount for maximizing efficiency with a newly installed PCB handling conveyor system. Manufacturers must invest time and resources into educating staff on operation protocols specific to printed circuit board assembly processes involving automation technologies. This training ensures everyone understands how to leverage these tools effectively while minimizing manual errors associated with traditional methods.

In addition to operational training, ongoing maintenance education is vital for sustaining long-term performance of both conveyors and other automated equipment within production lines. Regular workshops highlighting best practices for upkeep will empower employees with knowledge on troubleshooting common issues before they escalate into costly downtime scenarios—keeping your PCB production running smoothly.

Finally, creating an environment where feedback is encouraged allows staff members engaged in daily operations to share insights on improving workflows further over time as they become more familiar with integrated systems like those offered by Bensun Technology’s intelligent shuttle conveyors—ultimately driving continuous improvement across all facets of printed circuit board assembly.

Future Trends in PCB Handling Technology

The landscape of PCB handling technology is evolving rapidly, driven by innovations that aim to enhance efficiency and adaptability in printed circuit assembly processes. As the demand for more complex circuit boards increases, manufacturers are seeking solutions that not only streamline production but also integrate seamlessly into existing workflows. This evolution is characterized by a focus on automation, real-time data analytics, and user-friendly interfaces that simplify the operation of PCB handling conveyors.

Innovations on the Horizon

One of the most exciting trends in PCB handling technology is the development of smart conveyors equipped with advanced sensors and AI capabilities. These intelligent systems can monitor production lines in real-time, identifying bottlenecks and optimizing workflow to ensure that every printed circuit board assembly moves smoothly through each stage of production. Additionally, innovations such as modular conveyor designs allow for greater flexibility in adapting to specific needs within PCB board assembly processes, making it easier to scale operations up or down based on market demands.

Another promising innovation is the integration of IoT (Internet of Things) technologies into PCB handling conveyors. By connecting production equipment to a centralized network, manufacturers can gain insights into performance metrics and maintenance needs, allowing for proactive adjustments before issues arise. This connectivity not only enhances productivity but also ensures that printed circuit assembly remains efficient even as complexities increase.

Sustainability in PCB Production and Assembly

Sustainability has become a key focus area within the electronics industry, prompting manufacturers to adopt greener practices throughout their PCB production and assembly processes. The use of eco-friendly materials and energy-efficient equipment is on the rise as companies strive to reduce their environmental impact while still meeting high-quality standards for circuit boards. Implementing sustainable practices not only helps protect our planet but can also lead to cost savings over time by reducing waste and improving resource management.

Moreover, advancements in recycling technologies are enabling better recovery of materials from old PCBs, turning what was once considered e-waste into valuable resources for new products. By investing in sustainable solutions like these within their PCB handling conveyor systems, manufacturers can contribute positively to environmental conservation while enhancing their brand reputation among eco-conscious consumers.

Adaptive Solutions for Evolving Industry Needs

As consumer preferences shift towards more customized electronic products, flexibility becomes crucial in PCB board assembly processes. Manufacturers are now looking towards adaptive solutions that allow them to quickly adjust their workflows without significant downtime or costly reconfigurations of their existing systems. The implementation of programmable logic controllers (PLCs) within pcb handling conveyors offers such adaptability by enabling users to modify settings easily according to varying product specifications.

Additionally, training programs focused on upskilling staff are essential as new technologies emerge within the realm of printed circuit board assembly. Ensuring employees are well-versed in operating advanced machinery will facilitate smoother transitions when integrating innovative solutions into existing workflows while minimizing disruptions during changes in production demands.

In conclusion, staying ahead with future trends in pcb handling technology will empower manufacturers not just to keep pace with industry changes but also thrive amid competition through enhanced efficiency and sustainability efforts.

Conclusion

In the fast-paced world of electronics, the efficiency of printed circuit assembly is paramount. The integration of a PCB handling conveyor can significantly enhance workflow by minimizing manual errors and streamlining processes in PCB production and assembly. As the industry evolves, embracing these technologies not only improves productivity but also positions companies for future success.

Key Takeaways on Workflow Efficiency

The adoption of a PCB handling conveyor is a game-changer for circuit board manufacturing, providing numerous advantages that translate into smoother operations. By automating tasks within the PCB board assembly process, manufacturers can reduce bottlenecks and ensure a consistent flow of materials. Ultimately, this leads to higher accuracy in printed circuit board assembly and allows teams to focus on more complex tasks.

The Future of PCB Production and Assembly

Looking ahead, the future of PCB production and assembly is bright with innovations on the horizon that promise to revolutionize how we think about circuit board manufacturing. Advances in technology will likely lead to even more sophisticated PCB handling conveyors that adapt to changing production needs, making it easier for companies to scale operations efficiently. As sustainability becomes increasingly important, we can expect eco-friendly solutions integrated into these systems, further enhancing their value in the marketplace.

Embracing Technology for Competitive Advantage

To maintain a competitive edge in the electronics industry, organizations must embrace technology like advanced PCB handling conveyors as essential tools for growth and efficiency. By investing in modern solutions for printed circuit assembly, businesses can not only improve their operational workflows but also respond more adeptly to market demands. In an era where agility matters most, those who leverage innovative technologies will undoubtedly stand out from the crowd.