Introduction

In the ever-evolving world of electronics, SMD chip mounters have become indispensable tools for efficient printed circuit assembly (PCA). These machines are designed to place electronic components on chip boards with unparalleled precision and speed, making them essential for modern PCB assembly. Understanding how they work and their significance in the production process can greatly enhance your ability to create reliable and high-quality electronic parts.

Understanding SMD Chip Mounters

At the heart of any successful PCB circuit is the SMD chip mounter, a sophisticated machine that automates the placement of surface-mounted devices (SMDs). These machines can handle a wide variety of electronic components, ensuring that each part is placed accurately on the board. By utilizing advanced technology, SMD chip mounters streamline the assembly process, reducing both time and labor costs while improving overall product quality.

Importance of Efficient PCB Assembly

Efficient PCB assembly is crucial for maintaining competitiveness in today's fast-paced electronics market. A well-functioning SMD chip mounter significantly reduces production time and minimizes errors associated with manual placement methods. As manufacturers strive to produce more complex circuits within tighter deadlines, optimizing the assembly process becomes vital for meeting customer demands and ensuring product reliability.

Key Techniques in SMT Mounting

Mastering key techniques in SMT mounting is essential for maximizing the performance of your SMD chip mounter during printed circuit assembly. Techniques such as proper setup procedures, effective loading of electronic components, and fine-tuning placement accuracy can make all the difference in achieving high-quality results. By honing these skills, you not only enhance your efficiency but also ensure that your PCB circuits meet industry standards.

The Basics of SMD Chip Mounters

Understanding the fundamentals of SMD chip mounters is crucial for anyone involved in printed circuit assembly (PCA). These devices are essential for efficiently placing electronic components onto chip boards, which form the backbone of modern electronics. By mastering the basics, you can significantly improve your PCB assembly processes and elevate the quality of your final products.

What is an SMD Chip Mounter?

An SMD chip mounter is a sophisticated machine designed to automate the placement of surface mount devices (SMDs) onto PCB circuits. Unlike traditional methods that require manual labor, these machines utilize advanced technology to ensure precision and speed in mounting electronic parts. In essence, they streamline the process of SMT mounting, enabling manufacturers to meet high-volume production demands with consistent accuracy.

Components of a Chip Mounter

A typical SMD chip mounter consists of several key components that work in harmony to achieve optimal performance. These include a feeder system that holds and supplies electronic components, a vision system for accurate placement verification, and a placement head that executes the mounting process with pinpoint precision. Each component plays a vital role in ensuring that every electronic part is placed correctly on the PCB circuit without any errors.

How SMD Technology Benefits PCB Assembly

SMD technology revolutionizes PCB assembly by enhancing efficiency and reducing production costs. With faster placement speeds and improved accuracy compared to manual methods, manufacturers can produce more complex designs without sacrificing quality. Furthermore, utilizing an SMD chip mounter allows for higher density layouts on chip boards, leading to smaller and lighter electronic devices—a significant advantage in today’s compact tech landscape.

Selecting the Right Equipment

Choosing the right equipment is crucial for successful PCB assembly, especially when it comes to SMD chip mounters. With a plethora of options available, it's essential to focus on features that enhance efficiency and accuracy in mounting electronic components. This section will guide you through the key features of SMD chip mounters, compare popular brands, and explain why Bensun Technology stands out in the crowded market.

Key Features of SMD Chip Mounters

When selecting an SMD chip mounter, several key features should be at the forefront of your decision-making process. Firstly, speed is a significant factor; high-speed placement capabilities can dramatically increase your printed circuit assembly output. Additionally, look for machines with advanced vision systems that ensure precise alignment of electronic components on PCB circuit boards, reducing errors during SMT mounting.

Another critical feature is flexibility; a good chip mounter should handle various electronic parts and sizes without compromising performance. Automated feeders are also essential for minimizing downtime and maximizing productivity while loading electronic components efficiently into the machine. Finally, consider user-friendly interfaces that simplify operation and reduce training time for your team.

Comparing Popular Chip Mounter Brands

In the world of SMD chip mounters, several brands have established themselves as industry leaders worth considering for your PCB assembly needs. Companies like Panasonic and Yamaha are renowned for their reliability and advanced technology in SMT mounting solutions. However, they often come with a hefty price tag that may not fit every budget.

On the other hand, brands such as Juki offer competitive pricing along with impressive performance metrics suitable for small to medium-sized enterprises focused on printed circuit assembly efficiency. When comparing these brands, it's vital to assess not just initial costs but also long-term support services and availability of replacement parts for maintenance purposes. Ultimately, finding a balance between quality and cost will lead you to the best choice for your specific requirements.

Why Bensun Technology Stands Out

Bensun Technology has carved out a niche in the competitive landscape of SMD chip mounters by offering exceptional value without sacrificing quality or performance in PCB assembly processes. Their machines boast innovative features such as real-time monitoring systems that enhance placement accuracy while minimizing errors during SMT mounting operations. This attention to detail ensures that each electronic component aligns perfectly on chip boards.

Moreover, Bensun’s commitment to customer service sets them apart from competitors; they provide extensive training resources and responsive technical support tailored specifically for their users’ needs in printed circuit assembly environments. Their equipment is designed with flexibility in mind—allowing seamless integration with various types of electronic parts—making them an attractive option whether you're scaling up production or optimizing current workflows.

In conclusion, selecting the right equipment involves evaluating key features across different brands while keeping an eye out for standout companies like Bensun Technology that prioritize both innovation and customer satisfaction in their offerings.

Techniques for Optimizing SMT Mounting

When it comes to achieving flawless printed circuit assembly (PCA), optimizing the SMT mounting process is key. Efficient techniques can drastically improve the performance of your SMD chip mounter, ensuring that electronic components are placed accurately and securely on chip boards. Let’s dive into some essential setup procedures, best practices for loading electronic parts, and methods for fine-tuning placement accuracy.

Essential Setup Procedures

Before you even think about starting your SMD chip mounter, proper setup is crucial. This includes calibrating the machine to ensure that it aligns perfectly with the PCB circuit design specifications. Additionally, setting up a clean workspace free from dust and debris will prevent contamination of electronic components during assembly.

Another important step is to familiarize yourself with the software interface of your chip mounter. Make sure all necessary parameters are configured correctly, including component dimensions and placement coordinates, as these details significantly impact the efficiency of your PCB assembly process. Lastly, don’t forget to perform a thorough inspection of your equipment before running any production jobs; this can save you time and headaches down the line.

Best Practices for Loading Electronic Components

Loading electronic components into an SMD chip mounter may seem straightforward, but there are best practices that can make a world of difference in your PCB assembly outcomes. First off, always ensure that components are oriented correctly before loading them onto the machine; misalignment at this stage can lead to costly errors later in the process.

Moreover, it's wise to organize electronic parts systematically according to their types and sizes—this not only speeds up loading but also minimizes confusion during assembly runs. Utilizing trays or reels designed specifically for SMD components will help maintain order and streamline operations when working with various types of chip boards.

Finally, keep an eye on inventory levels for critical electronic components; running out mid-production can halt progress and create delays in project timelines. By following these best practices while loading components into your SMD chip mounter, you’ll set yourself up for smoother operations throughout the entire printed circuit assembly process.

Fine-Tuning Placement Accuracy

Placement accuracy is paramount when it comes to effective SMT mounting—after all, even a slight misalignment can lead to significant performance issues in electronic devices. To achieve optimal placement precision with your SMD chip mounter, start by regularly calibrating both mechanical parts and vision systems within the machine itself.

Utilizing high-quality fiducial marks on each PCB circuit can also enhance alignment during component placement; these marks serve as reference points that guide accurate positioning of electronic parts on chip boards. Additionally, consider implementing real-time feedback systems within your mounting equipment; they allow operators to make instant adjustments if discrepancies occur during production runs.

Lastly, conducting periodic testing using sample PCBs will help identify any recurring issues related to placement accuracy early on—this proactive approach ensures that problems are addressed before they escalate into larger challenges affecting overall productivity in PCB assembly processes.

Troubleshooting Common Issues

When working with an SMD chip mounter, encountering issues is part of the journey in printed circuit assembly (PCA). The efficiency of your PCB assembly can be significantly impacted by placement errors, misalignment, or equipment malfunctions. Understanding how to troubleshoot these common challenges will not only enhance your workflow but also improve the quality of electronic components on your chip boards.

Identifying Placement Errors

Placement errors are a frequent headache in SMT mounting and can arise from various factors such as incorrect programming or component misalignment. These errors manifest themselves as misplaced electronic parts on the PCB circuit, leading to potential failures in functionality. Regularly inspecting and verifying the placement accuracy during production can help identify these issues early on, ensuring that your assembly process remains smooth and efficient.

Solutions for Common SMD Challenges

Once you've identified a placement error, it's crucial to have effective solutions at hand to rectify it. First, recalibrating your SMD chip mounter may resolve alignment discrepancies; this ensures that all components are placed correctly on the PCB assembly. Additionally, implementing a more rigorous quality control process during component loading can prevent many common challenges associated with electronic components and their placements on chip boards.

Maintaining Your Chip Mounter

Proper maintenance of your SMD chip mounter is essential for its longevity and performance in printed circuit assembly tasks. Regular cleaning of the machine's nozzles and surfaces helps prevent dust buildup that could affect placement accuracy over time. Furthermore, keeping an eye on wear-and-tear parts will ensure that your equipment functions smoothly when handling delicate electronic parts—ultimately enhancing productivity and reducing downtime in SMT mounting operations.

Future Trends in SMD Technology

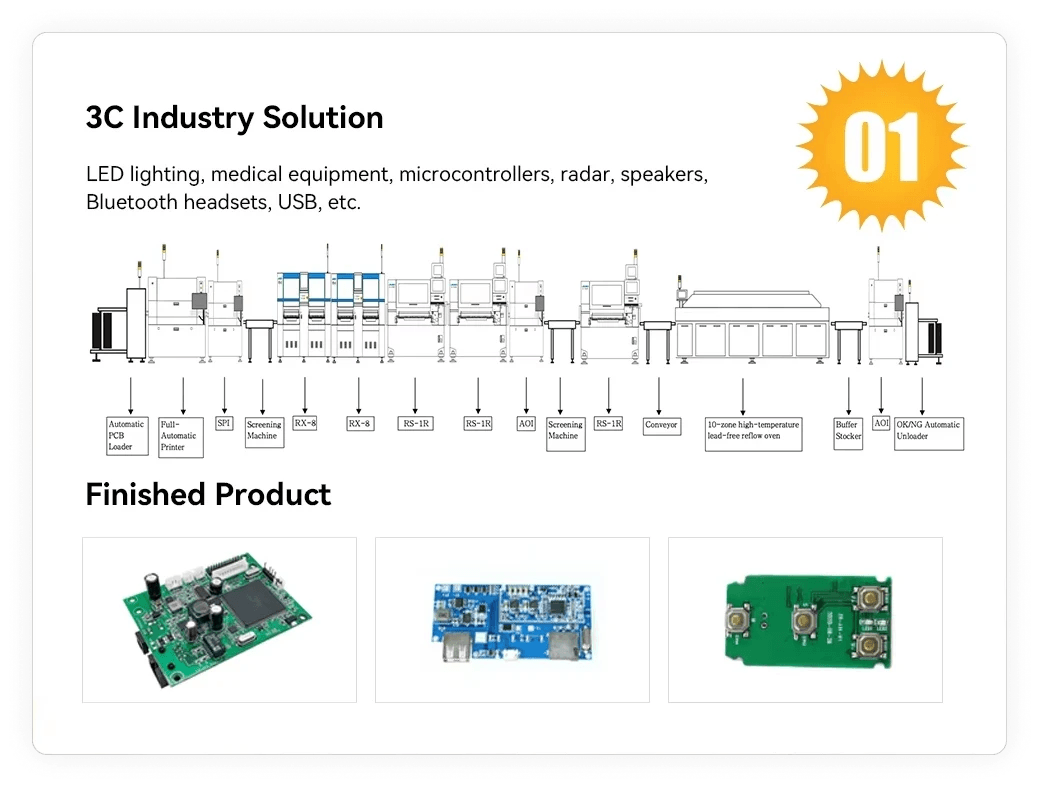

The landscape of SMD technology is evolving rapidly, with innovations that promise to revolutionize printed circuit assembly (PCA) processes. As manufacturers strive for greater efficiency and accuracy, the integration of cutting-edge techniques into PCB assembly becomes essential. This section explores the future trends that are reshaping how electronic components are assembled on chip boards.

Innovations in PCB Assembly

One of the most exciting innovations in PCB assembly is the development of advanced materials and techniques that enhance performance and reliability. New soldering processes, such as selective soldering and low-temperature soldering, allow for better thermal management of electronic parts while reducing stress on sensitive components. Additionally, improvements in surface finishes for PCB circuits are enabling better adhesion and overall durability, crucial for high-performance applications.

Another notable trend is the miniaturization of electronic components, which allows designers to create more compact chip boards without sacrificing functionality. This shift necessitates more precise SMT mounting techniques to accommodate smaller sizes while maintaining placement accuracy. With these innovations, manufacturers can produce lighter, more efficient devices that meet consumer demands for portability and performance.

Finally, enhanced inspection technologies have emerged to ensure quality control throughout the PCB assembly process. Automated optical inspection (AOI) systems are being integrated into production lines to detect defects early on, minimizing costly rework later in the manufacturing cycle. These advancements not only streamline operations but also significantly improve product reliability.

The Rise of Automated Solutions

Automation has become a game-changer in SMD technology and PCB assembly practices. The increasing complexity of electronic components demands systems capable of performing tasks with minimal human intervention while maintaining high precision levels. Fully automated SMD chip mounters are now equipped with features like vision systems that enable them to identify component types and adjust placements accordingly.

Moreover, automated solutions reduce labor costs and increase throughput by allowing manufacturers to scale production without compromising quality or speed. As industries continue embracing automation trends, we can expect a rise in collaborative robots (cobots) working alongside human operators to enhance productivity further while ensuring safety on the factory floor.

In addition to traditional automation methods, cloud-based solutions are gaining traction within the industry as they enable real-time monitoring of production metrics across multiple facilities worldwide. This connectivity fosters a data-driven approach to decision-making that enhances operational efficiency throughout the entire printed circuit assembly process.

Impact of AI on SMT Mounting

Artificial Intelligence (AI) is poised to transform SMT mounting practices by introducing sophisticated algorithms capable of analyzing vast amounts of data generated during PCB assembly operations. One major application is predictive maintenance; AI systems can anticipate equipment failures before they occur by analyzing usage patterns from smd chip mounters over time—saving manufacturers from unexpected downtimes.

Furthermore, AI-driven analytics can optimize placement strategies by assessing historical performance data on electronic components during production runs—enabling continuous improvement efforts tailored specifically for each type of chip board produced. This level of insight empowers engineers with actionable recommendations designed not only for immediate gains but also long-term strategic planning within their operations.

Lastly, machine learning models will likely play an increasingly significant role in quality assurance practices by identifying potential defects earlier than conventional methods could achieve alone—enhancing overall product reliability while reducing waste associated with faulty assemblies or misaligned parts during SMT mounting processes.

Conclusion

As we wrap up our exploration of SMD chip mounters and their pivotal role in printed circuit assembly, it's clear that mastering these techniques is essential for anyone involved in PCB assembly. The ability to efficiently mount electronic components onto chip boards can drastically improve production timelines and product reliability. With the right knowledge and practices, you can ensure your PCB circuit designs come to life flawlessly.

Mastering SMD Chip Mounter Techniques

To truly excel in SMT mounting, one must understand the intricacies of SMD chip mounter techniques. This involves not only learning how to operate the equipment but also honing skills related to component placement and alignment on chip boards. By focusing on precision and efficiency during the setup process, you can minimize errors and enhance the overall quality of your printed circuit assembly.

The Role of Quality Equipment in Success

Quality equipment plays a monumental role in achieving success within PCB assembly operations. Investing in a reliable SMD chip mounter ensures that you have the necessary tools to handle various electronic parts with ease and accuracy. When you choose high-quality machines, you're not just buying a piece of equipment; you're investing in improved workflow, reduced downtime, and ultimately, better end products.

Embracing the Future of PCB Assembly

The future of PCB assembly is bright, with innovations constantly reshaping how we approach SMT mounting. Automated solutions are becoming more prevalent, allowing for increased efficiency while reducing human error during component placement on chip boards. Furthermore, advancements like AI integration promise to revolutionize how we manage electronic components throughout the entire manufacturing process.