Introduction

In the rapidly evolving world of electronics, the significance of PCB manufacturers has surged, particularly in China. The country has become a powerhouse for printed circuit assembly (PCA), leading the charge in innovation and production capabilities. As businesses seek reliable partners for their electronic needs, understanding the intricacies of circuit card assembly becomes paramount.

The Rise of PCB Manufacturers in China

China's ascent as a leader in PCB manufacturing and assembly can be attributed to its robust infrastructure and skilled workforce. With countless electronics manufacturers flocking to this region, the landscape is ripe for competition and technological advancement. This boom not only enhances production efficiency but also drives down costs, making PCBA in China an attractive option for businesses worldwide.

Understanding PCB Assembly and Its Importance

Printed circuit assembly (PCBA) is a critical process that transforms bare circuit boards into fully functional electronic devices. This involves intricate steps such as soldering components onto a printed board assembly, ensuring that each connection is precise and reliable. As modern electronics become more complex, the importance of quality PCBA cannot be overstated—it directly impacts product performance and longevity.

Meet Bensun Technology: Your Go-To Partner

Enter Bensun Technology, a distinguished player in the realm of PCB manufacturing and assembly. With a commitment to excellence and customer satisfaction, Bensun offers tailored solutions that cater to diverse electronic needs. Whether you require advanced printed circuit assy services or efficient contract processing options, Bensun Technology stands ready to support your journey toward success in the competitive electronics market.

What is PCB Assembly?

PCB assembly, or printed circuit board assembly, is the process of connecting electronic components to a circuit board to create a functional electronic device. This intricate procedure involves various steps that ensure all parts are securely placed and properly connected, forming the backbone of modern electronics. Understanding PCB assembly is crucial for anyone involved in electronics manufacturing, especially when considering options like PCBA in China.

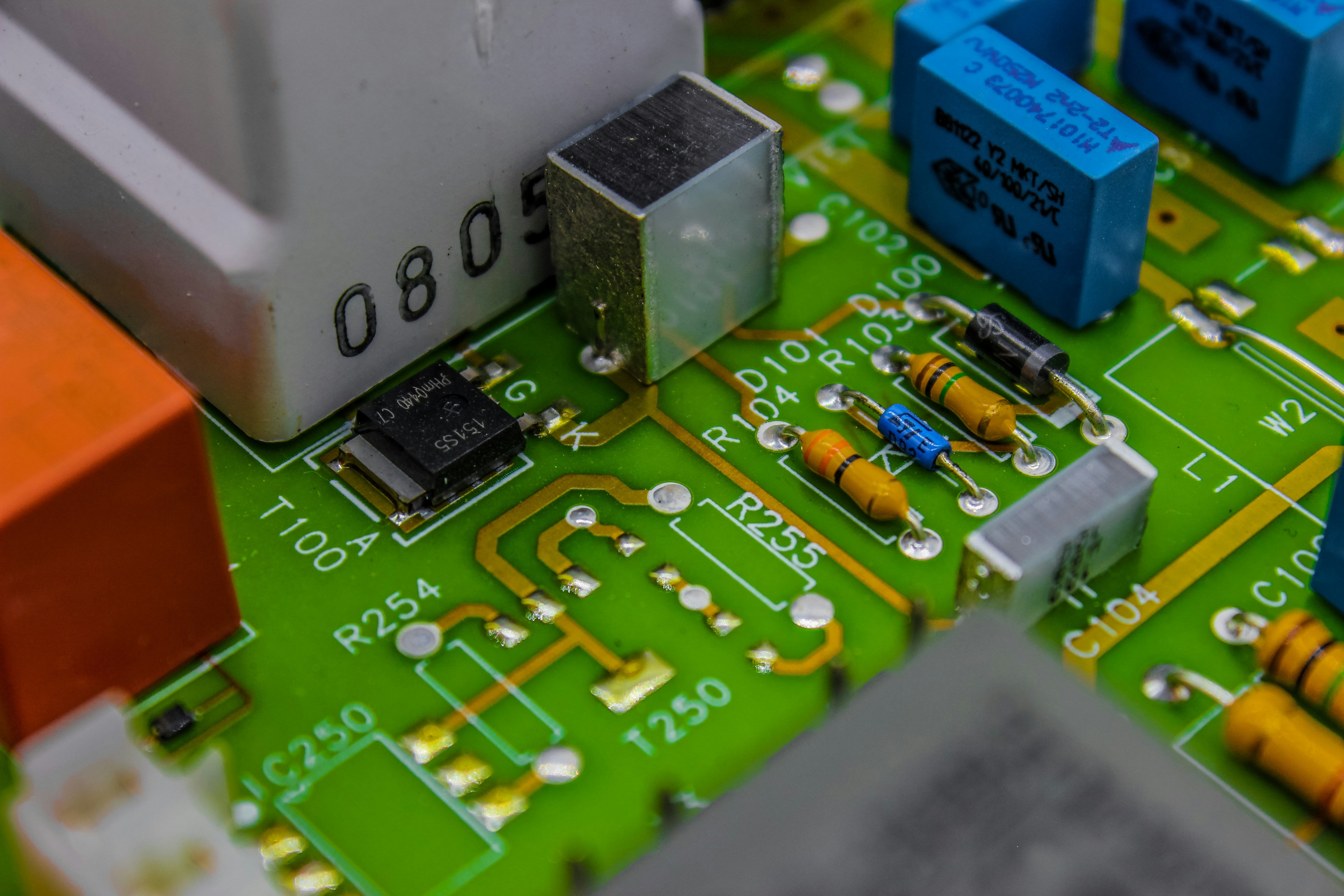

Defining Printed Circuit Assembly

Printed circuit assembly (PCA) refers to the method of assembling electronic components onto a printed circuit board (PCB). This process transforms raw boards into fully functional circuit card assemblies capable of powering everything from smartphones to complex industrial machines. In essence, PCA is what turns an empty circuit board into a vibrant hub of electronic activity.

The Process of Circuit Card Assembly

The process of circuit card assembly involves several key stages: component placement, soldering, and inspection. Initially, components are strategically placed on the printed board before being soldered—either manually or through automated systems—to ensure solid electrical connections. Following this, thorough inspections are conducted to confirm that each connection meets quality standards before moving on to testing and final integration.

Importance in Modern Electronics

The importance of PCB assembly in modern electronics cannot be overstated; it’s the heart that keeps devices alive and functioning efficiently. As technology advances at breakneck speed, the demand for reliable and efficient printed board assemblies grows exponentially. Choosing an experienced electronics manufacturer specializing in PCB manufacturing and assembly ensures that devices not only meet but exceed performance expectations while maintaining cost-effectiveness.

Bensun Technology: An Overview

Bensun Technology stands at the forefront of the PCB manufacturing and assembly industry in China, embodying innovation and reliability. With a commitment to excellence, Bensun has rapidly emerged as a trusted partner for businesses seeking high-quality printed circuit assembly (PCA) solutions. Their vision is to revolutionize electronics manufacturing by providing cutting-edge services that cater to the evolving needs of their clients.

Company Background and Vision

Founded with a passion for technology and a dedication to quality, Bensun Technology has carved out a niche in the competitive landscape of PCBA in China. The company’s mission revolves around delivering exceptional printed board assembly services while fostering long-term partnerships with its customers. By investing in advanced technologies and skilled personnel, Bensun aims to lead the charge in transforming how circuit card assembly is perceived within the electronics manufacturing sector.

Services Offered by Bensun Technology

Bensun Technology offers an extensive range of services tailored to meet diverse client needs within PCB manufacturing and assembly. From prototype development to mass production, their capabilities encompass every stage of printed circuit assy, ensuring seamless integration into various electronic applications. Additionally, they provide specialized solutions such as surface mount technology (SMT) assembly and customized contract processing that cater specifically to unique project requirements.

Commitment to Quality in PCB Manufacturing and Assembly

Quality is at the heart of everything Bensun Technology does; it’s not just a buzzword but a fundamental principle guiding their operations. Rigorous quality control measures are implemented throughout the entire production process, from initial design reviews through final inspections of circuit boards. This unwavering commitment ensures that every product meets stringent industry standards while also exceeding customer expectations for reliability and performance.

Advantages of Choosing PCBA in China

When it comes to printed circuit assembly (PCBA), China has become a powerhouse in the electronics manufacturing landscape. The advantages of choosing PCB manufacturing and assembly services in this region are numerous, making it an attractive option for businesses worldwide. From cost savings to technological prowess, the benefits are hard to ignore.

Cost-Effectiveness of PCB Manufacturing

One of the most compelling reasons to opt for PCBA in China is the cost-effectiveness associated with its PCB manufacturing processes. Labor costs are significantly lower compared to Western countries, which translates into reduced overall production expenses for circuit board assembly. This affordability allows companies to allocate their budgets more efficiently, investing in research and development rather than exorbitant manufacturing costs.

Moreover, China's robust supply chain infrastructure ensures that raw materials and components are readily available at competitive prices. The economies of scale achieved by large-scale electronics manufacturers further drive down costs, making high-quality printed circuit assy accessible even for startups and small businesses. In essence, choosing PCB manufacturing and assembly services from China can lead to substantial savings without compromising quality.

Access to Advanced Technology and Expertise

China's position as a leader in electronics manufacturing is not just about low costs; it also offers unparalleled access to advanced technology and expertise in printed board assembly. Many Chinese manufacturers invest heavily in state-of-the-art machinery and innovative production techniques that enhance efficiency and precision during the circuit card assembly process. This commitment to technological advancement means that clients benefit from cutting-edge solutions tailored to their specific needs.

Additionally, many companies specializing in PCBA have skilled engineers and technicians who possess extensive knowledge of industry standards and best practices. Their expertise ensures that every aspect of PCB manufacturing meets international quality benchmarks while maintaining compliance with various regulations. By partnering with an experienced electronics manufacturer like Bensun Technology, businesses can leverage this wealth of knowledge for superior product development.

Scalability and Flexibility in Production

Another significant advantage of choosing PCBA services from China is the scalability and flexibility offered by local manufacturers. Whether you’re looking for small-batch prototypes or large-scale production runs, Chinese electronics manufacturers can adapt quickly to meet fluctuating demands without sacrificing quality or speed. This versatility is crucial for businesses navigating rapidly changing markets where consumer preferences can shift overnight.

Furthermore, many manufacturers provide customization options tailored specifically for unique project requirements during circuit board assembly processes. Companies can collaborate closely with their chosen partner on design modifications or special features that set their products apart from competitors’. This adaptability not only fosters innovation but also enhances customer satisfaction through personalized solutions.

The PCB Manufacturing and Assembly Process

The PCB manufacturing and assembly process is a crucial component in the creation of modern electronics, ensuring that printed circuit assemblies (PCBA) are produced with precision and efficiency. This intricate process involves several stages, each designed to contribute to the final product's reliability and performance. Understanding these stages helps highlight why choosing a reputable electronics manufacturer is essential for successful circuit card assembly.

Overview of Printed Board Assembly Stages

Printed board assembly comprises several key stages that transform raw materials into fully functional circuit boards. Initially, the process begins with design validation, where engineers ensure that the schematic aligns with production requirements. Following this, the fabrication stage produces bare PCBs, which are then populated with electronic components during the assembly phase through techniques like surface mount technology (SMT) or through-hole mounting.

After component placement, the next step involves soldering to secure components onto the circuit board effectively. This is typically achieved through reflow or wave soldering methods tailored to different types of assemblies. Finally, rigorous testing ensures that each printed circuit assy meets quality standards before it moves on to packaging and delivery.

Role of SMT and MI in Production

Surface Mount Technology (SMT) plays a pivotal role in modern PCB manufacturing and assembly processes by allowing for higher density component placement on smaller boards. This technology enables manufacturers to produce compact designs without compromising functionality, which is especially critical in today's miniaturized electronics landscape. Meanwhile, Manual Insertion (MI) remains relevant for larger components that require careful handling during installation.

Both SMT and MI contribute significantly to efficiency in production lines while maintaining high-quality standards throughout the assembly process. By integrating these techniques into their workflows, manufacturers can achieve both speed and accuracy when producing complex printed circuit assemblies (PCBA). As a result, businesses can respond quickly to market demands while ensuring reliable performance from their products.

Quality Control Measures in Place

Quality control measures are paramount in ensuring that every step of PCB manufacturing and assembly yields products capable of meeting stringent industry standards. Comprehensive inspections occur at multiple points throughout production—from initial design reviews to post-assembly testing—guaranteeing adherence to specifications at every stage of printed board assembly. Manufacturers often employ automated optical inspection (AOI) systems alongside manual checks for enhanced reliability.

In addition to visual inspections, functional testing assesses whether assembled circuits perform as intended under various conditions. These quality assurance practices help mitigate risks associated with faulty products reaching consumers, which could harm brand reputation or lead to costly recalls later on. By prioritizing quality control within their operations, electronics manufacturers not only safeguard their products but also build trust with clients seeking dependable PCBA solutions from China.

Bensun's Comprehensive Services

When it comes to printed circuit assembly (PCA), Bensun Technology is a powerhouse in the industry, offering a range of services designed to meet the diverse needs of electronics manufacturers. From cutting-edge equipment solutions for PCB assembly to tailored contract processing and exceptional after-sales support, Bensun ensures that every step of the printed board assembly process is seamless and efficient. By choosing Bensun, clients can rest assured they are partnering with a leader in PCBA China.

Equipment Solutions for PCB Assembly

Bensun Technology prides itself on providing state-of-the-art equipment solutions for printed circuit assembly. Our advanced machinery is specifically designed to enhance the efficiency and precision of circuit card assembly, ensuring that every circuit board produced meets stringent quality standards. With an emphasis on innovation, we continuously upgrade our equipment, allowing us to stay ahead in the competitive landscape of PCB manufacturing and assembly.

Our automated systems streamline processes such as surface mount technology (SMT) placement and inspection, which significantly reduce production times while maintaining accuracy. This means faster turnaround times for our clients without compromising on quality or performance. Whether you need low-volume runs or large-scale production, our equipment solutions are adaptable to your specific requirements.

Contract Processing and Customization Options

At Bensun Technology, we understand that no two projects are alike; that's why we offer comprehensive contract processing options tailored to your unique specifications. Our team works closely with clients to customize their printed circuit assy according to their designs and functional needs, ensuring that each product is perfectly suited for its intended application. This level of personalization sets us apart from other electronics manufacturers who may not offer such flexibility.

In addition to customization, we provide full-service solutions ranging from prototyping through mass production. Our capabilities extend beyond simple PCB manufacturing; we can integrate additional components into your design seamlessly during the circuit board assembly process. This approach not only saves time but also enhances overall product performance.

After-Sales Support and Customer Service

Bensun Technology believes that exceptional customer service doesn't end once a product leaves our facility; it’s just as important afterward! Our dedicated after-sales support team is always ready to assist with any questions or concerns regarding your printed board assembly products. We take pride in building long-term relationships with our clients by providing ongoing support throughout their project lifecycle.

From troubleshooting technical issues to offering guidance on maintenance practices, our customer service representatives are knowledgeable about all aspects of PCB manufacturing and assembly processes. We also gather feedback from clients post-delivery to continually improve our services and address any evolving needs they may have in future projects. Choosing Bensun means you’re not just getting a supplier; you’re gaining a partner committed to your success.

Conclusion

In the rapidly evolving landscape of electronics manufacturing, PCB assembly plays a pivotal role in ensuring the functionality and reliability of devices we use every day. As we navigate this intricate world, understanding the nuances of printed circuit assembly and the value it brings to modern technology becomes essential. With a multitude of options available, choosing the right partner for your circuit card assembly needs can significantly impact your project's success.

Navigating the World of Electronics Manufacturing

The journey through electronics manufacturing can often feel like traversing a labyrinth filled with complex processes and technical jargon. From selecting components to managing production timelines, each step in printed board assembly demands careful consideration and expertise. By partnering with a reliable electronics manufacturer, businesses can streamline their operations and focus on innovation rather than getting bogged down by logistical challenges.

Why Bensun Technology Stands Out

Bensun Technology distinguishes itself in the crowded field of PCB manufacturing and assembly through its unwavering commitment to quality and customer satisfaction. With state-of-the-art facilities located in China, they harness advanced technology to deliver top-notch printed circuit assy solutions tailored to specific client needs. Their extensive experience not only ensures cost-effectiveness but also fosters trust among clients seeking reliable circuit board solutions.

Future Trends in PCB Manufacturing and Assembly

As technology continues to advance at breakneck speed, future trends in PCB manufacturing and assembly are set to reshape how electronic devices are produced. Innovations such as smart manufacturing processes, automation, and sustainable practices will lead the charge toward more efficient production methods while maintaining high-quality standards in PCBA China. Embracing these trends will allow companies like Bensun Technology to stay ahead of the curve, delivering cutting-edge solutions that meet evolving market demands.