Introduction

In the ever-evolving world of electronics, understanding the intricacies of printed circuit boards (PCBs) and their assembly (PCBA) is crucial. These components serve as the backbone of modern technology, enabling devices to function seamlessly. This introduction will delve into what PCBs and PCBAs are, the significance of circuit board components, and a brief overview of PCB manufacturing.

Understanding PCB and PCBA

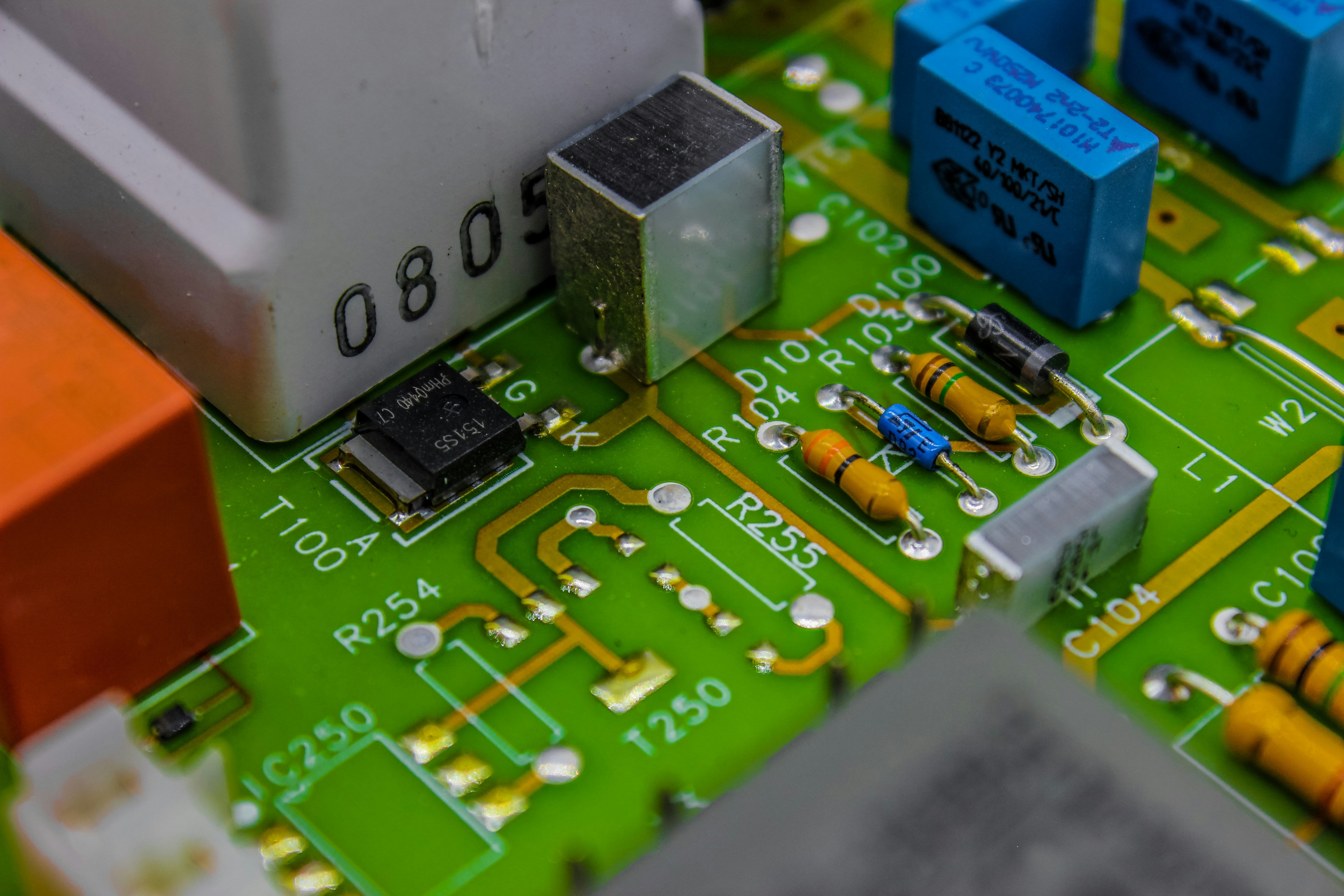

Printed Circuit Boards (PCBs) are essential for connecting electronic components in a compact and efficient manner. They provide a foundation upon which integrated circuits and other components can be mounted, making them vital for any electronic device. On the other hand, PCB Assembly (PCBA) refers to the process of assembling these components onto the PCB itself—transforming a simple circuit board into a fully functional circuit card assembly.

Importance of Circuit Board Components

The individual components on a circuit board play an integral role in determining the overall performance and reliability of electronic devices. From resistors to capacitors, each part contributes to how well a device operates, underscoring their significance in both design and functionality. Without high-quality circuit board components, even the most advanced PCB manufacturing processes would yield subpar results.

Overview of PCB Manufacturing

PCB manufacturing encompasses various techniques that ensure precision and quality in producing circuit boards for numerous applications. This process involves several stages—from design to fabrication—where attention to detail is paramount for achieving optimal results in both PCBs and assembly operations. As technology advances, manufacturers continually refine their methods to enhance efficiency while maintaining high standards in printed circuit assembly.

Defining Printed Circuit Boards

Understanding what a printed circuit board (PCB) entails is crucial for anyone venturing into the world of electronics. A PCB serves as the backbone of virtually all electronic devices, providing the necessary connections between various components. In essence, PCBs are flat boards made from insulating materials that have conductive pathways etched onto them, enabling electrical signals to flow seamlessly throughout a device.

What is a PCB?

A printed circuit board (PCB) is an essential component in modern electronics, acting as a platform for mounting and connecting electronic components like resistors and capacitors. The design of a PCB can vary significantly depending on its application, but it generally consists of layers of materials that include copper traces to facilitate electrical connections. Whether in smartphones or industrial machinery, PCBs are indispensable for ensuring reliable circuit card assembly and efficient operation.

Types of PCB Technologies

There are several types of PCB technologies available today, each tailored to specific requirements and applications. For instance, single-sided PCBs have components mounted on one side only, while double-sided boards allow for more complex designs with components on both sides. Additionally, multilayer PCBs consist of multiple layers stacked together to accommodate intricate circuit designs often seen in high-density applications—making them ideal for advanced printed circuit assembly needs.

Key Role in Electronics

PCBs play a pivotal role in the electronics industry by providing both structural support and electrical connectivity for various components within devices. Without effective circuit board assembly techniques that ensure precision and reliability, many electronic products would simply fail to function correctly or efficiently. As technology continues to advance at breakneck speed, the significance of high-quality PCB manufacturing processes becomes increasingly vital to meet consumer demands and maintain competitive advantage.

Exploring PCB Assembly

PCB assembly is a crucial phase in the lifecycle of electronic devices, transforming a mere printed circuit board (PCB) into a fully functional unit. This process, often referred to as circuit card assembly or printed circuit assembly, involves attaching various electronic components to the PCB, allowing it to perform its intended functions. Without efficient PCB assembly, even the most sophisticated designs would remain inert and useless.

What is PCB Assembly?

At its core, PCB assembly refers to the process of mounting and soldering electronic components onto a printed circuit board. This can include everything from resistors and capacitors to more complex integrated circuits that power modern electronics. The goal of this intricate procedure is to create a reliable and efficient circuit board assembly that meets specific design requirements and operational standards.

The significance of PCBA extends beyond just assembling parts; it encompasses ensuring that each component interacts seamlessly within the overall system. With advancements in technology, techniques like surface mount technology (SMT) have revolutionized how PCBs are assembled, making them smaller and more efficient than ever before. Ultimately, effective PCB assembly is essential for ensuring that electronic devices operate correctly and reliably.

Steps in the PCB Assembly Process

The journey from bare PCB to fully assembled product involves several critical steps that ensure quality and functionality throughout the process. First up is surface preparation, where the clean surface of the circuit board is primed for component placement—think of it as getting your canvas ready before painting! Next comes component placement; this stage can be done manually or through automated pick-and-place machines which accurately position components on designated pads.

After placement comes soldering—either through wave soldering or reflow methods—where heat is applied to create permanent electrical connections between components and the PCB. Once soldered, thorough inspection follows; this often includes automated optical inspection (AOI) systems designed to catch any defects before moving on to testing phases. Each step in this meticulous process contributes significantly towards achieving high-quality printed circuit assemblies that meet industry standards.

Importance of Quality Control

Quality control in PCB assembly cannot be overstated; it's what separates mediocre products from exceptional ones! Ensuring that every aspect of the circuit board assembly meets stringent quality standards helps prevent failures down the line—nobody wants their device malfunctioning due to a poorly assembled PCBA! Implementing rigorous testing protocols throughout every stage not only enhances reliability but also boosts customer confidence in your products.

From visual inspections during soldering processes to functional testing after final assembly, these checks are vital for identifying potential issues early on. Advanced techniques such as X-ray inspection can reveal hidden defects within multi-layered boards that might otherwise go unnoticed until it's too late. By prioritizing quality control in your pcb manufacturing processes, you pave the way for successful electronics with longevity.

Distinguishing PCBA from PCB

When diving into the world of electronics, it's essential to understand the distinction between PCB and PCBA. A printed circuit board (PCB) is essentially the backbone of electronic devices, providing a platform for electrical connections. In contrast, PCB assembly (PCBA) refers to the process of attaching various components onto this board, transforming it into a functional circuit card assembly.

Differences between PCB and PCBA

The primary difference between PCB and PCBA lies in their functionality; a bare PCB is just a flat board with conductive pathways but lacks any components. Once components like resistors, capacitors, and integrated circuits are soldered onto the PCB during the circuit board assembly process, it becomes a fully operational PCBA. This transformation is critical because while all PCBs are essential in electronics manufacturing, not all are assembled into functional assemblies—only those that have undergone the rigorous process of PCB assembly.

The Role of Components in PCBA

Components play a pivotal role in defining what makes up a successful printed circuit assembly (PCBA). Each component contributes specific functions like power regulation or signal processing, which are vital for the overall operation of an electronic device. Without these components properly integrated during circuit card assembly, even the most meticulously manufactured PCB would be rendered useless.

Application Differences in Technology

The applications of PCBs and PCBAs also differ significantly within technology sectors. While bare PCBs can be found in various industries as foundational elements for prototypes or testing purposes, fully assembled PCBAs are crucial for consumer electronics where reliability and functionality are paramount. The demand for high-quality printed circuit assemblies has surged due to advancements in technology that require compact designs with intricate functionalities—making understanding these differences more important than ever.

The Manufacturing Process

The manufacturing process of printed circuit boards (PCBs) and their assembly into functional units, known as PCB assembly (PCBA), is a crucial aspect of modern electronics. This intricate procedure involves various techniques that ensure the reliability and performance of electronic devices. By understanding these processes, manufacturers can optimize circuit card assembly for better efficiency and quality.

Overview of PCB Manufacturing Techniques

PCB manufacturing techniques have evolved significantly over the years, adapting to the growing demands of technology. Traditional methods like subtractive etching are still in use, but advanced techniques such as additive manufacturing and laser direct imaging are gaining traction. These innovations allow for more complex designs and finer features on circuit boards, enhancing overall performance in various applications.

In addition to these methods, the use of multilayer PCBs is becoming increasingly popular due to their ability to accommodate more components in a smaller footprint. This is particularly beneficial for compact electronic devices where space is at a premium. Ultimately, the choice of manufacturing technique impacts not only the cost but also the quality and functionality of the final product.

The Importance of Precision in Circuit Board Assembly

Precision plays a pivotal role in circuit board assembly (CBA), as even minor errors can lead to significant malfunctions in electronic devices. Accurate placement of components during PCB assembly ensures that connections are reliable and that circuits function as intended. This level of precision requires meticulous attention to detail throughout every stage of production.

Moreover, high precision reduces waste by minimizing defects during both PCB manufacturing and assembly processes. With advanced machinery capable of achieving tight tolerances, manufacturers can enhance their production efficiency while maintaining high standards for quality control. In an industry where reliability is paramount, investing in precision translates directly into customer satisfaction and trust.

Advantages of Using Advanced Machinery

Utilizing advanced machinery in PCB manufacturing and assembly brings a host of benefits that can elevate production capabilities significantly. Automated systems improve speed while reducing human error during both printed circuit assembly (PCA) and circuit board fabrication processes. This not only enhances productivity but also allows for consistent quality across large production runs.

Furthermore, advanced machinery enables manufacturers to implement sophisticated inspection systems that ensure each circuit card assembly meets stringent quality standards before reaching consumers. Such technologies include automated optical inspection (AOI) and X-ray inspection systems which detect faults invisible to the naked eye—crucial for maintaining high-quality PCBA outputs. Ultimately, leveraging cutting-edge equipment results in better products that meet evolving market demands efficiently.

Choosing a Manufacturer

Selecting the right manufacturer for your printed circuit assembly (PCA) needs can significantly impact the quality and reliability of your final product. With numerous options available, it’s crucial to evaluate potential partners thoroughly to ensure they align with your project requirements and standards. From assessing their experience in PCB manufacturing to understanding their capabilities in circuit board assembly, every detail matters when it comes to making an informed decision.

Factors to Consider When Selecting a PCB Manufacturer

When choosing a PCB manufacturer, several factors should be top of mind. First and foremost, consider their experience and expertise in both PCB manufacturing and assembly processes; this knowledge is invaluable for ensuring high-quality circuit card assembly. Additionally, you should evaluate their technology stack—advanced machinery often leads to better precision in circuit board production, which is critical for effective PCB assembly.

Another important aspect is the manufacturer's ability to meet your specific volume requirements—whether you need small batches or large-scale production runs can influence who is best suited for your project. Don’t overlook customer service; responsive communication can make or break the relationship between you and your manufacturer during the complex process of printed circuit assembly. Lastly, check for certifications that demonstrate compliance with industry standards; this ensures that they adhere to best practices in PCB manufacturing.

Benefits of Partnering with Bensun Technology

Partnering with Bensun Technology offers several advantages that set them apart from other manufacturers in the market. Their commitment to quality assurance means that every step of the PCB assembly process is meticulously monitored, ensuring that each circuit board meets stringent performance criteria before it reaches you. This level of dedication translates into fewer defects and higher reliability for your electronic products.

Moreover, Bensun Technology boasts a robust portfolio of services tailored specifically to meet diverse client needs—from rapid prototyping to full-scale production runs—making them a versatile partner in your printed circuit assembly journey. Their experienced team not only understands technical specifications but also provides valuable insights into design improvements that can enhance overall product performance. By choosing Bensun Technology as your partner, you gain access to cutting-edge technology and industry expertise that will elevate your projects.

Importance of Customization and Flexibility in Services

In today’s fast-paced electronics market, customization and flexibility are paramount when selecting a suitable manufacturer for PCBA projects. Each electronic device has unique requirements based on its intended application; thus, having a manufacturer capable of tailoring services accordingly can significantly enhance product performance and user satisfaction. The ability to adapt quickly without compromising quality ensures that manufacturers remain competitive while meeting clients' evolving demands.

Bensun Technology excels at offering customized solutions within their PCB manufacturing processes—whether it's modifying existing designs or accommodating special requests during circuit board assembly phases—they have got it covered! Flexibility also extends beyond just production capabilities; quick turnaround times on orders allow businesses like yours to stay agile amidst changing market conditions while maintaining high standards throughout all stages of printed circuit assembly.

Conclusion

In wrapping up our exploration of printed circuit boards (PCBs) and their assembly (PCBA), it's essential to highlight the distinctions between the two. While a PCB serves as the foundational structure for electronic components, PCBA encompasses the entire process of integrating those components onto the circuit board. Understanding these differences is crucial for anyone involved in electronics, as it enables better decision-making when selecting manufacturing processes and partners.

Recap of PCB and PCBA Differences

To put it simply, a PCB is like the canvas, while PCBA is the completed artwork that brings an electronic device to life. The primary difference lies in functionality; PCBs are bare boards designed to connect electronic components, whereas PCBA includes those components soldered onto the board for operational use. This distinction is vital in understanding how circuit card assembly impacts overall product performance and reliability.

Highlighting the Importance of Quality PCBA

Quality in printed circuit assembly cannot be overstated; it directly influences a product's lifespan and reliability. When manufacturers focus on high-quality PCB assembly practices, they ensure that each component functions harmoniously within its designated role on the circuit board. Investing in quality control during this phase not only reduces failures but also enhances customer satisfaction and brand reputation.

Future of Printed Circuit Assembly in Electronics

Looking ahead, the future of printed circuit assembly seems bright with advancements in technology paving new pathways for innovation. As industries increasingly demand smaller, more efficient devices, innovations in PCB manufacturing techniques will play a pivotal role in meeting these challenges head-on. The integration of smart technologies into circuit board assembly processes promises to revolutionize how we design and produce electronic devices, making them more adaptable and efficient than ever before.