Introduction

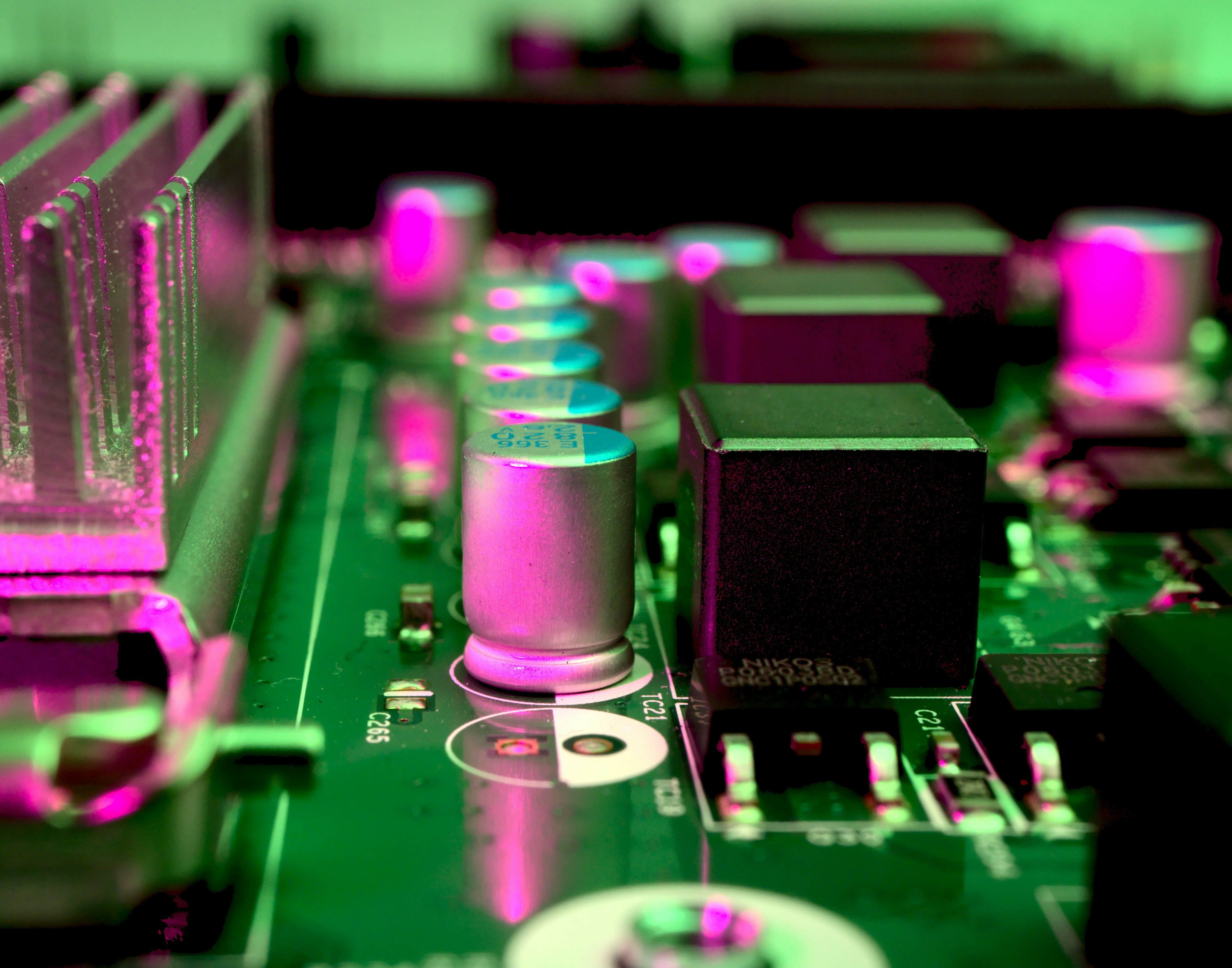

In the fast-paced world of electronics, surface-mount technology (SMT) has emerged as a game-changer in printed circuit board assembly (PCBA). This innovative method allows components to be mounted directly onto the surface of a circuit board, streamlining the manufacturing process and enhancing overall efficiency. With the increasing demand for compact and efficient electronic devices, understanding SMT is more crucial than ever.

Understanding Surface Mount Technology

Surface-mount technology revolutionizes how we think about circuit board assembly. Unlike traditional methods that require drilling holes for components, SMT employs a more streamlined approach where components are soldered directly onto the PCB's surface. This not only simplifies the manufacturing process but also opens up new possibilities for design and functionality in printed circuit board assembly.

The Importance of PCB Assembly

Printed circuit board assembly is at the heart of modern electronics, serving as the backbone for countless devices we use daily. From smartphones to medical equipment, effective PCB assembly ensures reliability and performance in every application. As technology continues to evolve, so does the importance of adopting advanced techniques like surface-mount technology to meet growing demands.

Why Choose Surface Mount Technology

Choosing surface-mount technology over traditional methods can significantly impact your production efficiency and product quality. SMT allows for higher component density on PCBs, leading to smaller designs without sacrificing performance. Furthermore, this method facilitates faster production times and reduced labor costs—making it an attractive option for businesses looking to stay competitive in today's market.

Overview of Surface Mount Technology

Surface mount technology (SMT) has revolutionized the world of printed circuit board assembly (PCB assembly) by providing a more efficient and compact way to mount electronic components. Unlike traditional methods, SMT allows components to be placed directly onto the surface of a circuit board, eliminating the need for holes. This not only enhances the design possibilities but also contributes to improved performance metrics in electronic devices.

Definition and Basics of SMT

At its core, surface mount technology refers to a method where electronic components are soldered directly onto the surface of a PCB rather than being inserted into holes as with through-hole technology. This technique allows for higher component density and smaller overall circuit board designs, which is essential in today’s compact electronics landscape. The process involves using specialized equipment to ensure precise placement and soldering, making it a cornerstone in modern printed circuit assembly.

Comparison with Through-Hole Technology

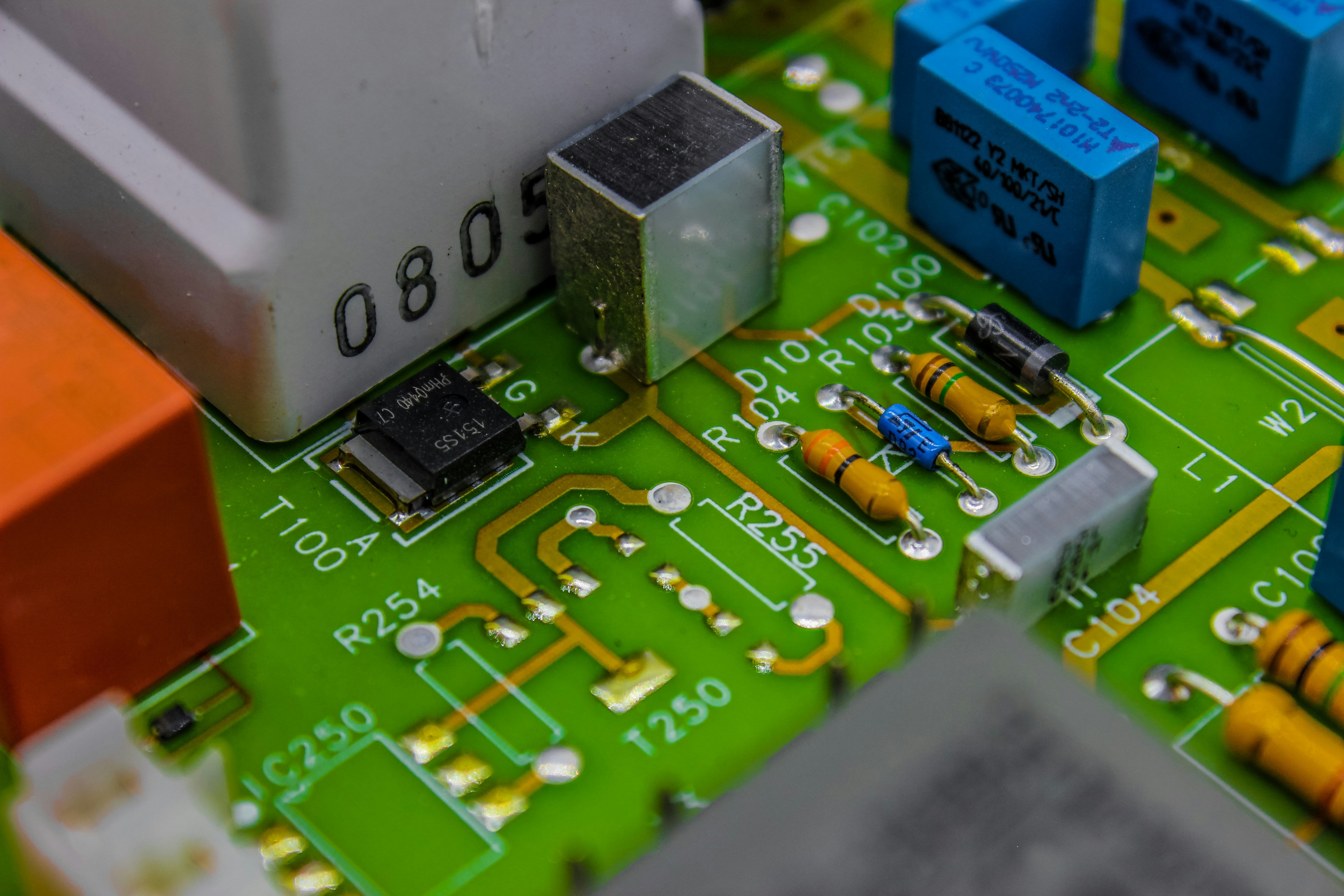

When comparing surface mount technology with through-hole technology, several key differences emerge that highlight SMT's advantages. Through-hole technology requires drilling holes into the PCB for component leads, which can take up valuable space and complicate design layouts. In contrast, SMT enables more efficient use of space by allowing components to be mounted on both sides of the circuit board, leading to reduced size and weight while maintaining or enhancing performance.

Typical Applications of SMT

Surface mount technology is widely used across various industries due to its versatility and efficiency in PCB assembly processes. Common applications include consumer electronics like smartphones and tablets, automotive systems requiring compact yet reliable circuitry, and medical devices where precision is critical. As manufacturers continue to push boundaries in miniaturization and functionality, SMT remains at the forefront of innovation in circuit board assembly.

Advantages of Surface Mount Technology

When it comes to printed circuit board assembly, surface-mount technology (SMT) has carved out a niche that’s hard to ignore. This innovative approach offers numerous advantages that enhance both the design and functionality of circuit boards. From saving space to boosting performance metrics, SMT is leading the charge in modern PCB assembly.

Space-Saving Benefits

One of the most significant advantages of surface-mount technology is its ability to maximize space on a printed circuit board. Unlike traditional through-hole technology, where components require more room due to their leads extending through the board, SMT components are mounted directly onto the surface. This compact design not only allows for smaller PCB board assemblies but also enables engineers to create sleeker devices that can fit into tighter spaces.

Moreover, this space-saving capability opens up new avenues for design innovation, paving the way for more complex and feature-rich products. With less real estate consumed by components, designers can allocate more space for additional functionalities or even reduce the overall size of their devices. Ultimately, this leads to lighter and more portable products that meet consumer demands for convenience and efficiency.

Increased Component Density

Another compelling advantage of surface-mount technology is its remarkable ability to increase component density on a circuit board. By utilizing smaller components and placing them closer together, SMT allows engineers to pack more functionality into a given area without compromising performance. This increased density is particularly beneficial in industries such as telecommunications and consumer electronics, where high-performance devices are essential.

Higher component density also translates into improved electrical performance due to shorter trace lengths between components—resulting in reduced signal loss and enhanced speed capabilities in printed circuit assembly processes. Additionally, with fewer layers required in multilayer boards thanks to SMT's efficiency, manufacturers can streamline production while maintaining quality standards in their PCB assembly operations.

Enhanced Performance Metrics

Surface-mount technology doesn’t just stop at saving space or increasing component density; it also delivers enhanced performance metrics that elevate circuit board functionality. The shorter connections between components lead to faster signal transmission speeds and lower electromagnetic interference—two critical factors in ensuring reliable operation across various applications. As a result, devices utilizing SMT often exhibit superior performance compared to those built with traditional methods.

Furthermore, advancements in materials used alongside SMT have contributed significantly to overall reliability and durability within printed circuit board assembly processes. These enhancements ensure that circuits can withstand harsher conditions without sacrificing integrity or function over time—a crucial consideration for industries like automotive and aerospace where failure isn’t an option.

In summary, when looking at the myriad benefits offered by surface-mount technology—from spatial efficiency and increased component density to improved performance metrics—it’s clear why this approach has become so popular among manufacturers today.

Efficiency in Printed Circuit Board Assembly

In the fast-paced world of electronics, efficiency in printed circuit board assembly is paramount. Surface-mount technology (SMT) has revolutionized how we approach PCB assembly, leading to significant improvements in production processes. By integrating SMT into circuit board assembly, manufacturers can achieve faster turnaround times and more streamlined operations.

Faster Production Times

One of the standout benefits of surface-mount technology is its ability to accelerate production times dramatically. With components mounted directly onto the surface of a PCB, rather than inserted through holes as in traditional methods, the assembly process becomes much quicker. This reduction in time not only enhances productivity but also allows companies to respond swiftly to market demands and customer needs.

Moreover, SMT facilitates automated assembly techniques that further contribute to speed. Advanced machines can place components with remarkable precision and at high speeds, minimizing human error and maximizing output. As a result, businesses can churn out more printed circuit boards in less time while maintaining high-quality standards.

Reduced Labor Costs

Implementing surface-mount technology also leads to reduced labor costs associated with printed circuit board assembly. The automation capabilities inherent in SMT mean fewer manual processes are required, freeing up skilled labor for other critical tasks within the production line. This shift not only lowers direct labor expenses but also enhances overall operational efficiency by allowing teams to focus on areas that require more human oversight.

Additionally, since SMT allows for smaller components and denser layouts on PCBs, it reduces the need for extensive handling during manufacturing processes. Less handling translates into lower risk of damage or errors during assembly—further driving down costs associated with rework or repairs. Ultimately, embracing surface-mount technology can lead to substantial savings that positively impact a company's bottom line.

Simplified Assembly Processes

The transition to surface-mount technology simplifies many aspects of the printed circuit board assembly process. For starters, the design flexibility offered by SMT means fewer constraints when arranging components on a PCB layout; this results in cleaner designs with improved signal integrity and performance metrics. Furthermore, simplified designs often lead to shorter assembly times as there are fewer steps involved.

Another advantage is that many SMT components come pre-assembled or packaged together, which streamlines inventory management during PCB board assembly projects. This ease of use means companies can quickly switch between different products without overhauling their entire setup or supply chain logistics each time an order changes—saving both time and resources along the way.

In conclusion, adopting surface-mount technology significantly enhances efficiency within printed circuit board assemblies through faster production times, reduced labor costs, and simplified processes that promote better organization and output quality.

Reliability and Quality Control

In the world of printed circuit assembly, reliability and quality control are paramount. Surface-mount technology (SMT) has revolutionized the way circuit board assembly is conducted, ensuring that each PCB assembly meets rigorous standards. With consistent processes and advanced techniques, manufacturers can deliver high-quality products that stand the test of time.

Consistency in Circuit Board Assembly

One of the standout features of surface-mount technology is its ability to provide consistency in circuit board assembly. Unlike traditional methods, SMT minimizes human error through automation and precise placement of components on the PCB board assembly. This level of consistency not only improves manufacturing efficiency but also enhances product reliability, leading to fewer defects in the final printed circuit board assembly.

Advanced Inspection Techniques

To maintain high standards in printed circuit board assembly, advanced inspection techniques are employed throughout the manufacturing process. Automated Optical Inspection (AOI) systems scan PCB assemblies for defects at various stages, ensuring that any issues are identified early on. These cutting-edge inspection methods bolster confidence in surface-mount technology by catching potential problems before they escalate into costly failures.

Long-Term Performance Advantages

Investing in surface-mount technology translates into long-term performance advantages for circuit boards and their applications. SMT components tend to be more robust due to their smaller size and lower profile, which reduces stress on solder joints during thermal cycling or mechanical vibrations. This durability means that products utilizing SMT can operate reliably over extended periods, making them a favorite choice for industries where performance is critical.

Bensun Technology’s Role in SMT

Bensun Technology stands at the forefront of surface-mount technology, offering comprehensive solutions for printed circuit assembly that cater to a diverse range of industries. Their expertise in PCB assembly ensures that clients receive high-quality circuit board assemblies tailored to their specific needs. With a focus on innovation and efficiency, Bensun Technology is committed to enhancing the overall performance of circuit board manufacturing processes.

Comprehensive Solutions for PCB Assembly

At Bensun Technology, the focus is on providing end-to-end solutions for printed circuit board assembly that streamline the entire process from design to production. Their extensive services include everything from prototyping to full-scale manufacturing, ensuring that every aspect of PCB board assembly is covered. This holistic approach not only saves time but also enhances the reliability and quality of each circuit board produced.

Equipment and Services Offered

Bensun Technology offers state-of-the-art equipment designed specifically for surface-mount technology applications, ensuring precision and efficiency in every printed circuit assembly project. Their advanced machinery supports high-speed placement and soldering processes, which are crucial for maintaining quality standards in PCB assembly. Additionally, they provide a range of services including testing and inspection to guarantee that every circuit board meets industry specifications before reaching the customer.

Commitment to Customer Needs

One of Bensun Technology's standout qualities is its unwavering commitment to understanding and fulfilling customer needs within the realm of surface-mount technology. They prioritize client collaboration throughout the printed circuit board assembly process, ensuring that feedback is integrated into production strategies. This customer-centric approach not only fosters long-lasting partnerships but also drives continuous improvement in their services and offerings.

Conclusion

In wrapping up our exploration of surface-mount technology (SMT), it’s clear that this innovation is not just a passing trend but a cornerstone of modern electronics. The evolution of printed circuit assembly has paved the way for more compact, efficient, and reliable circuit boards. As we look to the future, SMT will undoubtedly continue to shape the landscape of PCB assembly.

The Future of Surface-Mount Technology

The future of surface-mount technology looks incredibly promising, with ongoing advancements in materials and processes enhancing its capabilities. Innovations in automation and artificial intelligence are set to revolutionize printed circuit board assembly, making it faster and more precise than ever before. As industries demand higher performance from their electronic devices, SMT will be at the forefront, adapting to meet these challenges head-on.

Impact on Circuit Board Manufacturing

Surface-mount technology has significantly transformed circuit board manufacturing by allowing for greater complexity in design without compromising space or cost efficiency. This shift enables manufacturers to produce smaller and more powerful devices that cater to consumer demands for portability and functionality. The integration of SMT into standard practices has also streamlined PCB assembly processes, resulting in reduced production times and enhanced overall quality.

Why SMT is Here to Stay

Surface-mount technology is here to stay because it addresses key challenges faced by today’s electronics industry—compactness, efficiency, and reliability are all hallmarks of modern design principles. As long as there is a need for high-performance electronic devices that can fit into smaller spaces without sacrificing quality, SMT will remain an essential part of printed circuit board assembly practices. With its proven track record and continuous improvements on the horizon, it's safe to say that surface-mount technology will remain a mainstay in circuit board assembly for years to come.