Introduction

In today's fast-paced technological landscape, the demand for innovative and efficient circuit solutions has never been higher. Understanding flex and rigid-flex circuits is crucial for anyone involved in electronics, as these components are integral to modern devices. Choosing the right manufacturer can significantly impact the performance and reliability of a circuit board, making it essential to partner with experienced flexible circuit board manufacturers who understand your needs.

Understanding Flex and Rigid-Flex Circuits

Flexible circuit boards are designed to bend and twist while maintaining functionality, offering unparalleled versatility in design. Rigid-flex circuits combine both rigid and flexible elements, allowing for more complex layouts that can fit into tighter spaces without sacrificing performance. These advancements have opened doors for applications in various fields such as consumer electronics, automotive technology, and medical devices.

The Importance of Choosing the Right Manufacturer

The right manufacturer not only guarantees high standards but also offers expertise that can help navigate challenges during production stages. When you choose a reliable partner for your PCB assembly and manufacturing needs, you set the foundation for successful product development.

Overview of BSTECH’s Capabilities

BSTECH stands out among flexible circuit board manufacturers with its comprehensive offerings in PCB fabrication assembly. Their commitment to quality ensures that every board for circuit meets rigorous industry standards while providing innovative solutions tailored to client specifications. With state-of-the-art technology and specialized expertise, BSTECH is well-equipped to support diverse projects across high-tech industries.

What are Flex and Rigid-Flex Circuit Boards

Understanding flex and rigid-flex circuit boards is essential in today’s technology-driven world. These innovative circuit solutions offer unique advantages that cater to various applications, from consumer electronics to medical devices. Let’s dive into what makes flexible circuits and rigid-flex circuits stand out in the realm of PCB fabrication assembly.

Defining Flexible Circuit Boards

Flexible circuit boards are designed with materials that allow them to bend, twist, and conform to various shapes without compromising functionality. Unlike traditional rigid boards, these circuits can be integrated into compact spaces, making them ideal for modern electronics where size matters. Flexible circuit board manufacturers utilize advanced materials like polyimide or polyester to create circuits that can withstand dynamic movements while maintaining electrical integrity.

These flexible circuits can be single-sided, double-sided, or multi-layered based on the complexity of the design required for a specific application. The ability to create a lightweight board for circuit applications opens doors for innovation across industries such as automotive and aerospace. Ultimately, flexible circuit boards represent a leap forward in PCB production and assembly techniques.

Features of Rigid-Flex Circuits

Rigid-flex circuits combine the best aspects of both rigid and flexible technologies, offering versatility without sacrificing durability. These hybrid configurations feature sections that remain rigid while others can flex, allowing for intricate designs in compact spaces. This adaptability makes them perfect for applications requiring both stability and mobility—think smartphones or medical devices where space is at a premium.

One notable feature of rigid-flex circuits is their ability to reduce interconnects between different components by integrating multiple layers into one cohesive unit. This not only streamlines assembly but also enhances reliability by minimizing potential points of failure during operation. As a result, many PCB assembly board projects now favor this innovative approach over traditional methods.

Applications in Modern Technology

The applications of flexible and rigid-flex circuit boards are vast and varied across numerous industries—each benefiting from unique characteristics tailored through careful PCB fab and assembly processes. In consumer electronics like smartphones or wearables, flexibility allows designers to create sleek devices without bulky components getting in the way. Meanwhile, sectors such as aerospace leverage these technologies for lightweight systems that demand high performance under challenging conditions.

Furthermore, automotive advancements rely heavily on these innovations as vehicles become more sophisticated with integrated electronic systems controlling everything from navigation to safety features. Thus, choosing the right flexible circuit board manufacturers can significantly impact product success across diverse fields.

The Role of Flexible Circuit Board Manufacturers

Why Quality Matters in PCB Manufacturing

Quality in PCB manufacturing is paramount because it directly impacts the functionality and longevity of electronic devices. Flawed boards can lead to malfunctions, increased costs, and dissatisfied customers—nobody wants that! Flexible circuit board manufacturers understand this and prioritize rigorous testing methods throughout the pcb fab and assembly process to ensure that each pcb assembly board meets industry standards.

Moreover, high-quality production processes reduce the risk of failures down the line. This is especially critical in sectors like aerospace or medical technology where reliability is non-negotiable. By selecting a manufacturer committed to quality, companies can rest assured that their products will perform optimally.

Key Processes in PCB Fab and Assembly

The journey from concept to a fully functional circuit board involves several key processes in pcb fabrication assembly. Initially, design files undergo meticulous review before moving into prototyping—a crucial step where initial versions are tested for functionality and design accuracy. Following prototyping, the actual production begins with processes such as etching, layering, and soldering components onto the pcb assembly board.

Another essential aspect is surface mount technology (SMT), which allows for efficient placement of tiny components on flexible circuits. This method enhances both speed and precision during production while minimizing human error—something every manufacturer strives for! In short, understanding these key processes helps businesses appreciate what goes into creating reliable products.

Selecting a Manufacturer for Your Needs

Choosing the right flexible circuit board manufacturers involves assessing various factors tailored to your specific requirements. Start by evaluating their experience within your industry; specialized knowledge often translates into better outcomes when it comes to custom projects or unique applications of a circuit board. Additionally, consider their capabilities regarding pcb production and assembly—do they offer quick turnaround times without compromising quality?

It's also wise to ask about their commitment to innovation; after all, staying ahead in technology requires continuous improvement in manufacturing techniques and equipment used during pcb fab and assembly. Finally, don't forget about customer support; responsive communication can make all the difference when navigating complex projects or unexpected challenges.

BSTECH: Your Go-To Source for PCB Solutions

When it comes to flexible circuit board manufacturers, BSTECH stands out as a premier choice for all your PCB assembly and manufacturing needs. With a robust portfolio that spans various industries, BSTECH is committed to delivering high-quality solutions tailored to meet the unique demands of its clients. Whether you require a circuit board for circuit applications or intricate designs, BSTECH has the expertise and resources to bring your vision to life.

Comprehensive Offerings in PCB Assembly and Manufacturing

BSTECH offers an extensive range of services in PCB fab and assembly, ensuring that every client finds exactly what they need under one roof. From flexible circuit boards to rigid-flex options, their capabilities encompass everything from initial design consultation through to final production and assembly. The company's focus on providing complete solutions means you can rely on them for every step of your project, making the process seamless and efficient.

Their state-of-the-art facilities are equipped with cutting-edge technology that enhances the quality of their pcb fabrication assembly processes. This commitment ensures that each pcb assembly board meets stringent industry standards while also allowing for customization based on specific project requirements. With BSTECH's comprehensive offerings, clients can rest assured knowing they have partnered with a manufacturer who understands the intricacies of modern PCB production and assembly.

Specialization in High-Tech Industries

BSTECH specializes in serving high-tech industries where precision and reliability are paramount. Their experience working with sectors such as aerospace, medical devices, automotive electronics, and telecommunications showcases their versatility as flexible circuit board manufacturers. Each industry has distinct requirements; thus, BSTECH tailors its services accordingly to ensure optimal performance of every board for circuit application.

By focusing on high-tech industries, BSTECH stays at the forefront of technological advancements in pcb production and assembly methods. This specialization not only enhances their manufacturing capabilities but also positions them as leaders in innovation within the field of flexible circuits. Clients can trust that their projects will benefit from cutting-edge techniques designed specifically for demanding applications.

Commitment to Quality and Innovation

At BSTECH, quality is not just an afterthought; it is woven into every aspect of their operations as part of a steadfast commitment to excellence in pcb fabrication assembly. The company employs rigorous testing protocols throughout the manufacturing process to ensure each product meets or exceeds customer expectations before leaving the facility. This dedication helps solidify their reputation among top flexible circuit board manufacturers globally.

Innovation drives progress at BSTECH; hence they continually invest in research and development initiatives aimed at improving production efficiency while maintaining exceptional quality standards. Their proactive approach allows them to adapt quickly to changing market demands while delivering advanced solutions tailored specifically for today’s technological landscape. Choosing BSTECH means aligning with a partner who prioritizes both innovation and quality in every aspect of pcb assembly board creation.

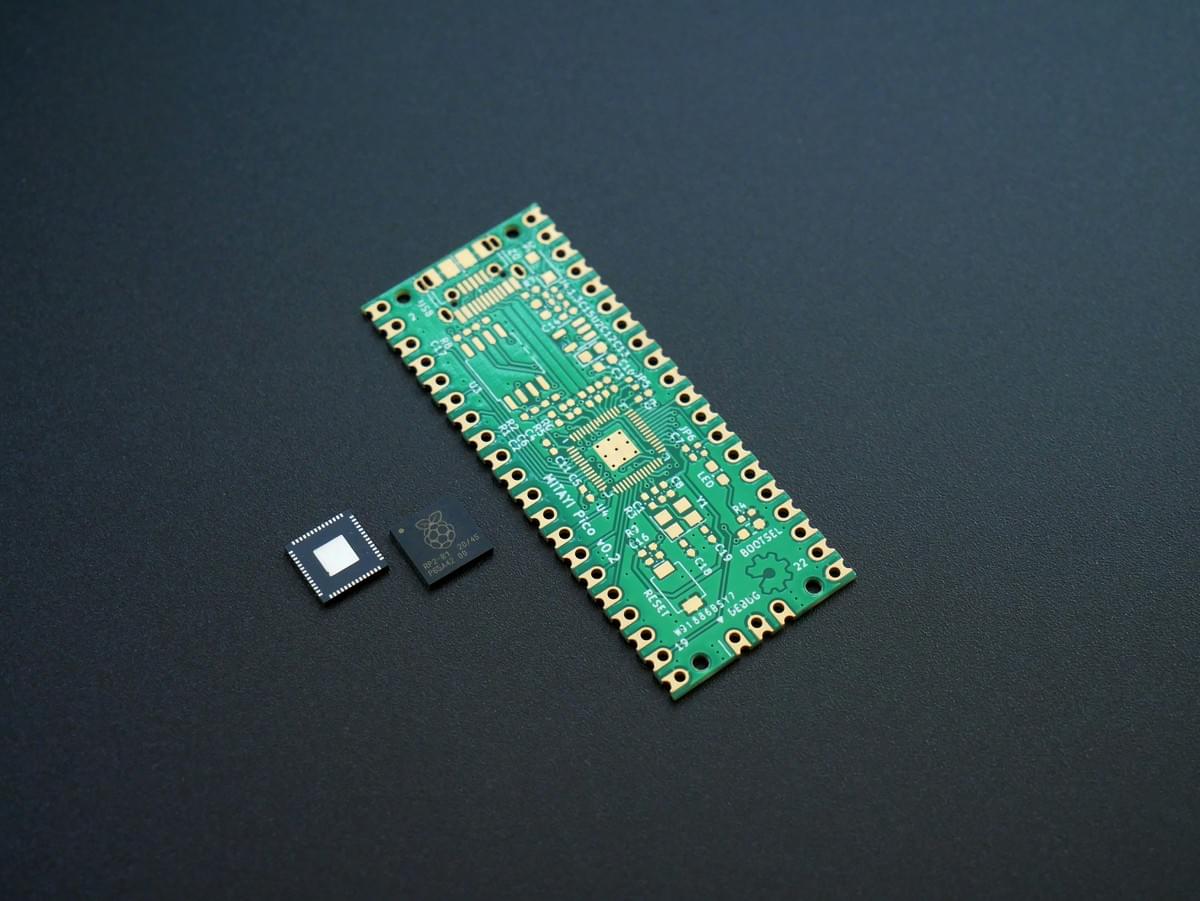

Exploring Bensun Technology’s Equipment

When it comes to the world of flexible circuit board manufacturers, Bensun Technology stands out with its state-of-the-art equipment designed for superior PCB production and assembly. Their advanced machinery not only enhances the efficiency of manufacturing processes but also ensures that every board for circuit meets stringent quality standards. This commitment to excellence is crucial in an industry where precision and reliability are paramount.

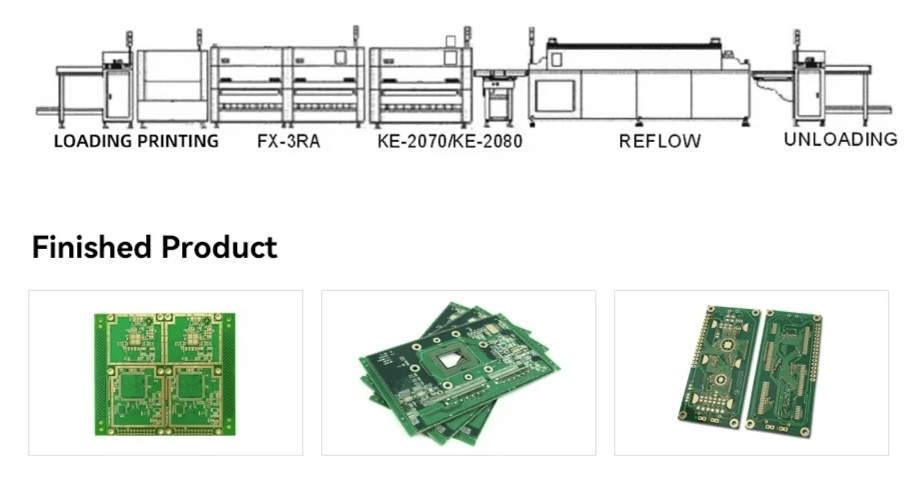

Overview of SMT and MI Production Equipment

Surface Mount Technology (SMT) and Manual Insertion (MI) production equipment are vital components in the PCB fabrication assembly process. SMT allows for the efficient placement of components directly onto the surface of a circuit board, streamlining production while maintaining high accuracy levels. Meanwhile, MI provides flexibility for complex assemblies that require human touch, ensuring that even intricate designs can be executed flawlessly by skilled technicians.

Bensun's investment in cutting-edge SMT and MI technology means they can handle a wide range of projects, from simple PCB assembly boards to more complex designs needed in high-tech industries. This versatility makes them a go-to choice among flexible circuit board manufacturers looking to deliver innovative solutions tailored to specific needs. With such advanced equipment at their disposal, Bensun sets itself apart as a leader in PCB fab and assembly.

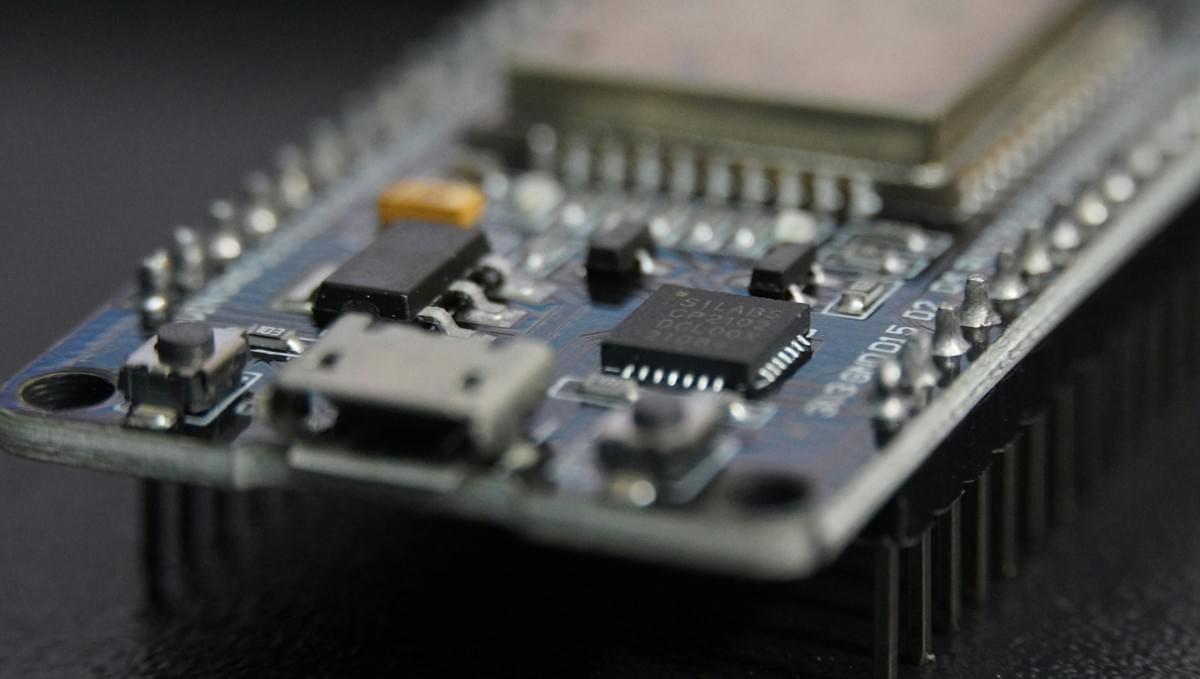

The Importance of JUKI Pick and Place Machines

One standout feature of Bensun's production line is their use of JUKI pick and place machines, which play an essential role in modern PCB assembly and manufacturing processes. These machines excel at quickly placing thousands of components accurately on boards for circuits, significantly reducing manufacturing time while enhancing precision. The automation provided by JUKI technology not only boosts productivity but also minimizes human error during the critical assembly phase.

Moreover, JUKI pick and place machines are known for their adaptability across various projects, making them ideal for both small-batch runs and large-scale productions alike. For flexible circuit board manufacturers like Bensun, this means they can meet diverse customer demands without compromising on quality or speed. Investing in such reliable equipment underscores their dedication to delivering top-notch PCB production and assembly services.

How Bensun Supports Circuit Board Production

Bensun Technology’s comprehensive support system plays a pivotal role in optimizing circuit board production from start to finish. They offer extensive technical assistance throughout the entire process—from initial design consultations through to final inspection—helping clients navigate challenges associated with PCB fabrication assembly effectively. Their team works closely with customers to ensure that each aspect aligns with specific project requirements while adhering to industry standards.

Additionally, by leveraging advanced equipment like SMT lines equipped with JUKI machines alongside skilled workforce expertise, Bensun guarantees efficient turnaround times without sacrificing quality or performance on any pcb assembly board project undertaken. This holistic approach not only reinforces their reputation as leading flexible circuit board manufacturers but also builds lasting partnerships based on trust and reliability within various industries requiring innovative electronic solutions.

The Benefits of Choosing Flexible Circuit Board Solutions

Flexible circuit boards have transformed the landscape of PCB production and assembly, offering a multitude of advantages that can benefit various industries. By opting for flexible circuit board solutions, businesses can optimize their design processes and reduce overall manufacturing costs. This flexibility not only enhances product functionality but also ensures that manufacturers can meet the ever-evolving demands of modern technology.

Cost-Effective PCB Production and Assembly

These boards often require fewer materials than traditional rigid boards, leading to significant savings in both raw materials and labor during the pcb fab and assembly process. Additionally, flexible circuit board manufacturers typically use advanced techniques that streamline production, further reducing costs while maintaining high-quality standards.

Moreover, the compact nature of flexible circuits allows for more efficient use of space within electronic devices, which can lead to lower shipping costs and reduced carbon footprints during transportation. As companies increasingly prioritize sustainability alongside cost-effectiveness, choosing a circuit board that minimizes waste becomes essential in today’s market. Thus, investing in flexible circuits not only makes financial sense but also aligns with broader environmental goals.

Enhanced Design Flexibility

One of the standout benefits of flexible circuit boards is their enhanced design flexibility compared to traditional options. These circuits can be bent or shaped to fit into tight spaces without compromising performance or functionality—a crucial factor for modern electronics where space is often at a premium. This adaptability opens up new avenues for innovation as engineers explore unique designs that were previously impossible with rigid pcbs.

Furthermore, flexible circuits allow for multi-layer designs that integrate various functionalities into a single board for circuit solutions. This integration reduces assembly time and complexity while enhancing performance reliability across different applications—from wearables to automotive systems. With the ability to create custom shapes tailored specifically to product requirements, businesses gain a competitive edge by delivering innovative solutions faster than ever before.

Meeting Diverse Industry Needs

Flexible circuit board solutions are versatile enough to cater to diverse industry needs—from consumer electronics to medical devices and aerospace applications. As industries evolve rapidly due to technological advancements, having a reliable partner among flexible circuit board manufacturers becomes crucial for meeting specific requirements effectively. The expertise offered by these manufacturers ensures that every pcb assembly board produced meets stringent industry standards without sacrificing quality or performance.

Moreover, with specialized capabilities in high-tech industries such as telecommunications and automotive sectors emerging constantly, these manufacturers are well-equipped to handle unique challenges presented by each field's demands on pcb fabrication assembly processes. They provide tailored support throughout production cycles while ensuring compliance with regulatory guidelines necessary for safety-critical applications like those found in healthcare settings or aviation systems.

In summary, choosing flexible circuit board solutions offers substantial benefits including cost-effectiveness through streamlined production methods; enhanced design flexibility allowing innovative product development; and the capability to meet diverse industry needs efficiently—all vital components driving success in today’s fast-paced technological landscape.

Conclusion

In the ever-evolving landscape of technology, the significance of advanced PCB fabrication assembly cannot be overstated. As industries seek to innovate and enhance their products, the demand for high-quality flexible circuit board manufacturers has surged. By leveraging cutting-edge techniques in PCB production and assembly, businesses can achieve unparalleled performance and reliability in their electronic devices.

Leveraging Advanced PCB Fabrication Assembly

Advanced PCB fabrication assembly processes are pivotal for producing robust circuit boards that meet modern technological demands. With a focus on precision and efficiency, flexible circuit board manufacturers utilize state-of-the-art equipment to ensure that each board for circuit adheres to stringent quality standards. This commitment to excellence not only enhances product longevity but also contributes to overall cost-effectiveness in pcb assembly and manufacturing.

The Future of Circuit Board Manufacturing

The future of circuit board manufacturing looks promising with the continuous advancements in materials and technologies. Flexible circuits are becoming increasingly popular due to their ability to fit into compact spaces while maintaining functionality, making them ideal for a variety of applications. As more companies recognize the benefits of flexible solutions, we can expect a surge in demand for innovative designs and enhanced capabilities in pcb fab and assembly.

Why BSTECH Stands Out in the Industry

BSTECH distinguishes itself among flexible circuit board manufacturers through its unwavering commitment to quality and innovation. With comprehensive offerings in PCB assembly board services, they cater to diverse industry needs while ensuring exceptional performance across all products. Their expertise not only streamlines pcb production and assembly but also positions them as a trusted partner for businesses looking to elevate their technological solutions.