Introduction

In the fast-paced world of electronics manufacturing, the selective soldering process has emerged as a pivotal technique for ensuring high-quality connections on printed circuit boards (PCBs). Unlike traditional wave soldering machines that apply solder to entire boards, selective soldering machines target specific areas, making them ideal for complex PCB to PCB soldering tasks. This precision not only enhances the reliability of electronic products but also optimizes production efficiency.

Understanding the Selective Soldering Process

Selective soldering is a specialized method used in PCB assembly that allows for targeted application of molten solder to designated areas of a circuit board. This process is particularly beneficial when dealing with sensitive components that could be damaged by the broader application of wave soldering equipment. By focusing solely on critical joints, selective soldering machines ensure that each connection is secure while minimizing thermal stress on surrounding components.

Benefits of Using a Selective Soldering Machine

One of the standout benefits of using selective soldering equipment lies in its precision; it allows manufacturers to achieve reliable and repeatable results without compromising component integrity. Additionally, this method reduces wastage by applying only the necessary amount of solder at precise locations, ultimately leading to cost savings during production runs. With these advantages in mind, many companies are shifting their focus from traditional wave soldering methods to more advanced selective solutions.

Key Features to Look for in Soldering Machines

When selecting a suitable soldering machine for your operations, several key features should be considered to ensure optimal performance and reliability. Look for machines equipped with advanced vision systems that enhance accuracy during placement and inspection processes—this feature is particularly vital in SMT soldering machines where tight tolerances are required. Furthermore, consider models with user-friendly interfaces and customizable settings to streamline operations and adapt easily to various PCB designs and layouts.

What is a Selective Soldering Machine?

Selective soldering machines are specialized devices designed to join electronic components to printed circuit boards (PCBs) with precision and efficiency. Unlike traditional soldering methods, these machines focus on specific areas of the board, applying solder only where needed. This targeted approach not only enhances the quality of connections but also minimizes waste and reduces thermal stress on sensitive components.

Definition and Purpose

A selective soldering machine is an automated system that applies molten solder to designated areas of a PCB, ensuring reliable electrical connections without affecting adjacent components. The primary purpose of this equipment is to provide high-quality solder joints while maintaining the integrity of other parts of the board. By using a selective approach, manufacturers can achieve better results in complex assemblies where precision is critical.

How It Differs from Wave Soldering Machines

The key distinction between selective soldering machines and wave soldering equipment lies in their application method. While wave soldering involves submerging an entire PCB into a wave of molten solder, which can lead to potential damage or bridging between components, selective soldering precisely targets only specific areas for connection. This difference not only improves component safety but also makes selective systems more suitable for modern PCBs with dense layouts and mixed technologies.

Applications in Modern PCB Manufacturing

Selective soldering machines play a crucial role in various applications within modern PCB manufacturing environments. They are particularly effective for pcb to pcb soldering tasks, where multiple layers or complex geometries require careful handling to ensure connectivity without compromising quality. Additionally, these machines are commonly employed in industries such as automotive electronics, telecommunications, and consumer electronics—where reliability and performance are paramount.

Advantages of Selective Soldering Equipment

When it comes to soldering technology, selective soldering equipment stands out for several compelling reasons. This method enhances the quality and efficiency of the soldering process, especially in complex PCB to PCB soldering applications. Let’s explore the advantages that make selective soldering machines a preferred choice over traditional wave soldering machines.

Precision in Soldering Board Connections

One of the most significant advantages of a selective soldering machine is its unmatched precision in creating reliable connections on a circuit board. Unlike wave soldering equipment that floods an entire board with molten solder, selective machines target specific areas, ensuring that only designated joints receive the necessary treatment. This level of accuracy not only improves connection quality but also minimizes excess solder, reducing cleanup and rework time.

Reduced Risk of Component Damage

Selective soldering equipment is designed with component protection in mind, which is crucial when dealing with sensitive electronic parts. The focused application of heat means that nearby components are less likely to be affected by thermal stress compared to processes like wave soldering, where heat can inadvertently affect adjacent areas. This reduction in risk translates into fewer damaged components and lower overall costs associated with repairs or replacements.

Cost-Effectiveness for Production Runs

Investing in a selective soldering machine can lead to significant cost savings during production runs, particularly for small to medium-sized batches where flexibility is key. The efficiency gained from precise targeting allows manufacturers to optimize their material usage and reduce waste, making it an economically sound choice compared to traditional wave soldering methods that may lead to excess material use and higher operational costs. Moreover, as production scales up or down based on demand, having versatile selective soldering equipment ensures that manufacturers can adapt without incurring substantial additional expenses.

Selecting the Right Soldering Machine

Choosing the right soldering machine can feel like navigating a maze, especially with so many options available. Whether you're looking for a selective soldering machine or considering wave soldering equipment, understanding your specific needs is crucial. This section will guide you through key factors to consider during selection, compare different types of machines, and highlight a top player in the market.

Factors to Consider During Selection

When selecting a soldering machine, there are several factors that come into play to ensure it meets your production requirements. First and foremost is the type of soldering process you intend to use; for instance, if precision in pcb to pcb soldering is essential, a selective soldering machine might be your best bet. Additionally, consider the size and complexity of your circuit boards—selective soldering equipment excels in handling intricate designs while wave soldering machines may be better suited for simpler layouts.

Another important aspect is throughput; how quickly do you need your boards processed? If speed is critical in your production line, look for features like automated loading and unloading capabilities in an SMT soldering machine that can significantly enhance efficiency. Lastly, don't overlook after-sales support and warranty options; investing in reliable maintenance services can save you from unexpected downtime.

Comparing Selective Soldering vs Wave Soldering Equipment

When it comes down to choosing between selective and wave soldering equipment, each has its unique advantages tailored to different manufacturing needs. Selective soldering machines are renowned for their precision; they apply solder only where needed on specific components without affecting surrounding areas—ideal for complex board designs with sensitive components. In contrast, wave soldering machines offer high-speed processing ideal for bulk production runs but may pose a risk of damaging delicate parts during the immersion process.

Moreover, cost-effectiveness plays a significant role in this decision-making process. While wave soldering equipment tends to have lower initial costs due to its simplicity and speed for large batches, selective processes can save money over time by reducing rework caused by component damage or poor connections on densely populated boards. Ultimately, the choice boils down to balancing precision against volume needs based on your unique PCB manufacturing scenarios.

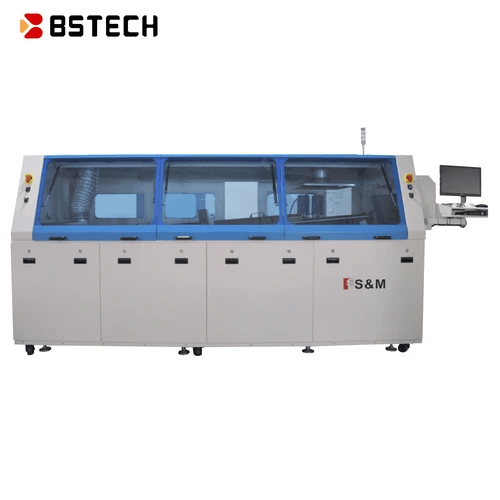

Top Brands in the Market: Bensun Technology Co., Ltd.

In today’s competitive landscape of selective soldering machines and related technologies, Bensun Technology Co., Ltd stands out as a leading brand worth considering. Known for their innovative designs and robust performance metrics, Bensun's products cater specifically to those who prioritize quality in their PCB manufacturing processes—especially when it comes to selective applications where precision matters most. Their range includes various models suited for different scales of operation from small workshops up to large-scale factories needing high-volume output.

Bensun’s commitment extends beyond just selling equipment; they provide comprehensive support including training programs that help operators get familiar with their sophisticated SMT soldering machines quickly and effectively. This level of customer service ensures that clients not only invest wisely but also maximize their returns through efficient operations over time. So if you're venturing into purchasing new selective or wave soldering equipment, keeping an eye on what Bensun has to offer could lead you toward making an informed decision that enhances productivity.

Maintenance Tips for Your Soldering Machine

Maintaining your selective soldering machine is crucial to ensure optimal performance and longevity. Regular upkeep can prevent costly downtimes, improve solder quality, and enhance the overall efficiency of your PCB to PCB soldering processes. Here are some key maintenance tips to keep your equipment running smoothly.

Regular Cleaning and Inspection

Regular cleaning is essential for any soldering machine, including selective soldering equipment and wave soldering machines. Dust, flux residues, and other contaminants can accumulate on the soldering board and components over time, leading to potential malfunctions or poor-quality joints. Schedule routine inspections to check for wear and tear on critical parts like nozzles and pumps; this proactive approach can save you from unexpected breakdowns.

In addition to cleaning the external surfaces of your selective soldering machine, pay special attention to internal components as well. Use appropriate cleaning solutions that won't damage sensitive parts; a clean environment fosters better performance in SMT soldering machines. By keeping everything spick-and-span, you'll not only maintain functionality but also extend the lifespan of your equipment.

Troubleshooting Common Issues

Even with diligent maintenance, issues can occasionally arise with your selective soldering equipment or wave soldering machines. Common problems include inconsistent heating, clogged nozzles, or misaligned boards during the pcb to pcb soldering process. When troubleshooting these issues, start by consulting the user manual for guidance on specific error codes or symptoms.

If you encounter persistent problems that basic troubleshooting can't resolve, consider checking connections and settings on your soldering machine's control panel. Sometimes a simple recalibration can work wonders! Don't forget that online forums or manufacturer support can be invaluable resources when seeking solutions from fellow users who may have faced similar challenges.

Scheduling Professional Servicing

While regular maintenance tasks are manageable in-house, certain aspects of maintaining a selective soldering machine require professional expertise. Scheduling periodic professional servicing ensures that your wave soldering equipment receives thorough checks beyond what you might perform yourself—think of it as an annual check-up for your machinery! Technicians will have specialized tools and knowledge necessary to address deeper issues effectively.

Professional servicing typically involves comprehensive inspections of all critical systems within the selective soldering machine—this includes evaluating electrical components and fine-tuning settings for optimal performance during production runs. It’s wise to keep a service log documenting past inspections so you can track recurring issues over time—this insight could help technicians diagnose problems faster during future visits!

Invest in regular professional care; it pays off by minimizing downtime while maximizing productivity in PCB manufacturing processes.

Future Trends in Selective Soldering Technology

The landscape of selective soldering technology is rapidly evolving, driven by innovations that enhance efficiency and precision. As manufacturers strive for higher quality in PCB to PCB soldering, advancements in SMT soldering machines are leading the charge. These innovations not only improve the performance of selective soldering equipment but also expand their applications across various industries.

Innovations in SMT Soldering Machines

Recent breakthroughs in SMT soldering machines have introduced features that significantly enhance their capabilities. For instance, new models now incorporate advanced algorithms that optimize the soldering process, ensuring perfect connections on every board. Additionally, these machines are designed with improved thermal management systems to prevent overheating and damage during operation, making them a preferred choice over traditional wave soldering equipment.

Moreover, innovations such as modular designs allow for easy upgrades and maintenance of selective soldering machines, extending their lifespan and adaptability to changing production needs. Manufacturers can now customize their setups based on specific requirements without investing in entirely new systems. The integration of high-resolution cameras for real-time monitoring further elevates the precision of the solder joints produced by these advanced machines.

The Role of Automation and AI

Automation is taking center stage in modern manufacturing processes, including those involving selective soldering equipment. By integrating AI into the operation of these machines, manufacturers can achieve unprecedented levels of accuracy and consistency in PCB to PCB soldering tasks. Automated systems can quickly adapt to variations in component types or board designs, reducing downtime and increasing overall productivity.

AI-driven analytics also play a crucial role by providing valuable insights into production efficiency and potential areas for improvement. This data helps operators make informed decisions about maintenance schedules and operational adjustments needed to optimize performance further. As automation continues to evolve, we can expect even smarter selective soldering machines that anticipate issues before they arise.

Sustainable Practices in Soldering Processes

Sustainability is becoming an essential consideration within the electronics manufacturing industry, including selective soldering processes. Manufacturers are increasingly focused on reducing waste generated during PCB assembly while ensuring high-quality results from their soldering machines. This shift has led to the development of eco-friendly materials and methods that minimize environmental impact without compromising performance.

Selective soldering equipment is being designed with energy efficiency in mind; newer models consume less power while maintaining optimal performance levels compared to older wave soldering machines. Furthermore, practices such as recycling used materials from production lines are gaining traction among companies committed to sustainability goals. By adopting these practices, manufacturers not only contribute positively to the environment but also appeal to a growing market segment that values eco-conscious products.

Conclusion

In summary, the selective soldering machine stands out as a vital tool in modern PCB manufacturing. Its precision and efficiency make it an excellent choice for applications where traditional wave soldering machines may fall short. With the right selective soldering equipment, manufacturers can enhance their production capabilities while minimizing risks and costs.

Key Takeaways About Selective Soldering Machines

Selective soldering machines offer unparalleled precision in soldering board connections, making them ideal for complex PCB to PCB soldering tasks. Unlike wave soldering equipment, which floods the entire assembly with molten solder, selective machines target specific areas, thus reducing the risk of damage to sensitive components. This targeted approach not only improves quality but also boosts overall productivity by streamlining the manufacturing process.

How to Choose the Best Equipment for Your Needs

When selecting a soldering machine, consider factors such as production volume, component types, and specific application requirements. Comparing selective soldering vs wave soldering equipment will help determine which technology aligns best with your operational goals. Look for key features like programmable profiles and ease of maintenance in your chosen selective soldering equipment to ensure you get the most value from your investment.

The Future of PCB Manufacturing Technologies

The future of PCB manufacturing technologies is bright, with innovations in SMT soldering machines paving the way for even greater efficiencies and capabilities. Automation and AI are set to revolutionize how we approach selective soldering processes by enhancing accuracy and reducing human error significantly. Additionally, sustainable practices are becoming increasingly important; manufacturers are focusing on eco-friendly materials and processes that align with global sustainability goals.