Introduction

In the fast-paced world of electronics, the role of PCBA manufacturers has never been more critical. These suppliers provide essential electronic manufacturing services that bridge the gap between raw materials and functional devices. As technology continues to evolve, understanding PCB manufacturing and assembly becomes crucial for anyone involved in the electronics industry.

Overview of PCBA Manufacturer Solutions

PCBA manufacturer solutions encompass a wide range of services designed to facilitate efficient production processes. From design assistance to full-scale pcb fabrication and assembly, these solutions ensure that products meet stringent quality standards while being cost-effective. By partnering with a reliable pcb assembly manufacturer, companies can streamline their operations and focus on innovation.

Importance of PCB Assembly in Electronics

PCB assembly is a cornerstone of modern electronics, integrating various components into a single functional unit. This process not only enhances performance but also impacts the overall reliability and lifespan of electronic devices. As such, selecting an experienced pcba supplier is vital for ensuring high-quality pcb manufacturing assembly that meets market demands.

Key Players in the PCBA Industry

The PCBA industry features several key players who shape its landscape through innovation and quality assurance. Established electronics manufacturers often dominate this space, leveraging advanced technologies to deliver superior products efficiently. Understanding who these key players are helps businesses make informed decisions when choosing their pcb fab and assembly partners.

Understanding PCB Manufacturing and Assembly

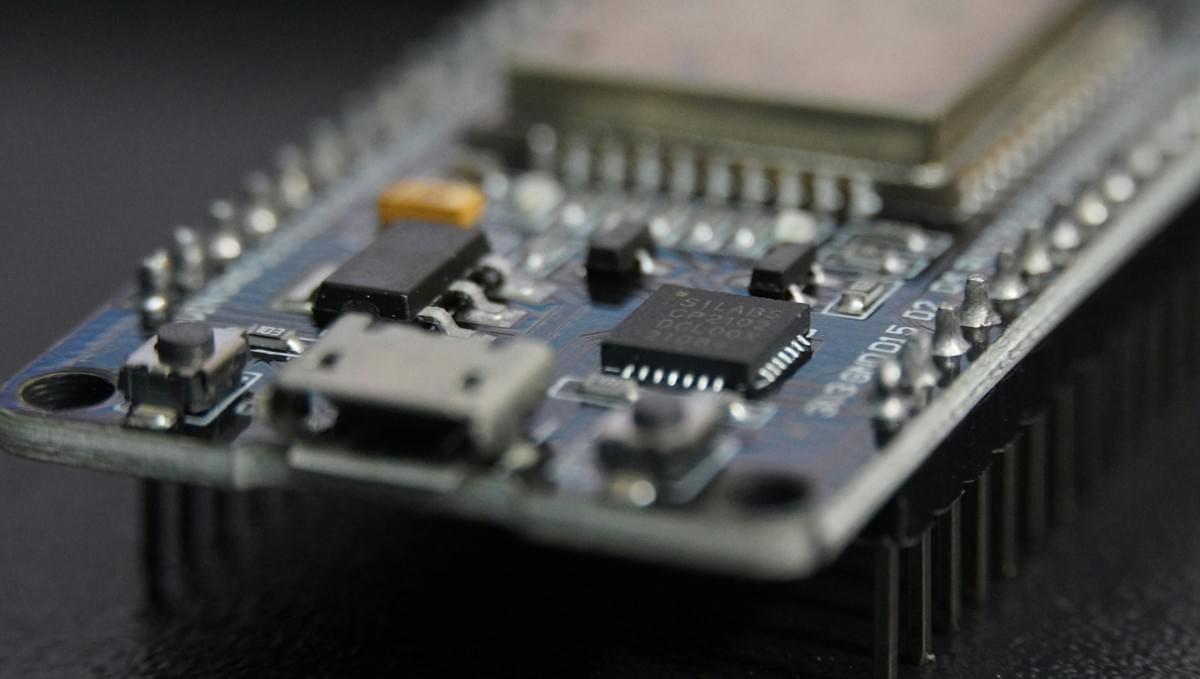

When diving into the world of electronics, one cannot overlook the significance of Printed Circuit Boards (PCBs). These essential components serve as the backbone for virtually every electronic device, enabling connections between various electronic elements. The intricate nature of PCB manufacturing and assembly is crucial, as it directly impacts the performance and reliability of devices produced by any electronics manufacturer.

Definition of PCB and Its Importance

A Printed Circuit Board (PCB) is a flat board that physically supports and connects electronic components using conductive pathways. These pathways are etched from copper sheets laminated onto a non-conductive substrate, forming a reliable platform for circuit assembly. The importance of PCBs in modern electronics cannot be overstated; they allow for compact designs, improved functionality, and enhanced durability in devices ranging from smartphones to complex medical equipment.

Steps Involved in PCB Fabrication and Assembly

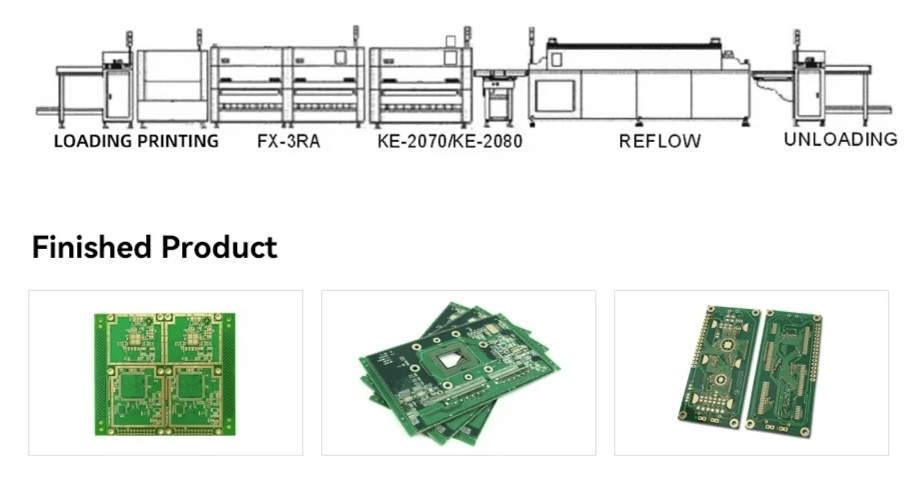

The journey from raw materials to a fully functional PCB involves several critical steps in both fabrication and assembly. Initially, the design phase utilizes specialized software to create schematics that dictate the layout of circuits. Following this, the process includes etching copper layers, drilling holes for component placement, applying solder mask layers, screen printing legends, and finally assembling components through processes like surface mount technology (SMT) or through-hole mounting.

Once these steps are completed during PCB fabrication and assembly, rigorous testing ensures that all connections function correctly before moving on to packaging. Each stage requires precision to maintain quality standards set by reputable pcba suppliers in the industry. With advancements in technology, automation has further streamlined these processes while enhancing accuracy—making it easier for electronics manufacturers to deliver high-quality products efficiently.

Role of a PCB Assembly Manufacturer

A PCB assembly manufacturer plays a pivotal role in transforming fabricated boards into complete electronic assemblies ready for use in various applications. These manufacturers specialize not only in assembling PCBs but also managing supply chains effectively to ensure timely delivery of components required for production. By collaborating closely with pcba suppliers and leveraging their expertise in electronic manufacturing services, they can optimize production timelines while maintaining high standards.

Moreover, an experienced pcb assembly manufacturer understands the nuances involved in different types of assemblies—whether it’s low-volume prototypes or high-volume mass production runs—tailoring their approach accordingly. Their ability to adapt ensures that clients receive products that meet specific requirements without compromising on quality or performance standards essential for success in today’s competitive market landscape.

Choosing the Right PCBA Supplier

When it comes to selecting a PCBA supplier, the stakes are high. The right choice can make or break your product's success in the competitive electronics market. With numerous options available, understanding what to look for is crucial in ensuring quality and reliability in your PCB manufacturing and assembly process.

Factors to Consider When Selecting a Supplier

First and foremost, consider the supplier's experience and expertise in PCB fabrication and assembly. An established PCB assembly manufacturer will have a proven track record of delivering high-quality products on time, which can save you headaches down the line. Additionally, evaluate their technology and equipment; advanced capabilities often translate to better precision and efficiency in PCB manufacturing assembly.

Another critical factor is communication and customer service. You want a partner who is responsive and willing to collaborate throughout the entire process of PCB fab and assembly. A strong relationship with your electronic manufacturing services provider fosters transparency, which is essential for addressing any issues that may arise during production.

Lastly, do not overlook certifications and compliance with industry standards when choosing a PCBA supplier. Certifications like ISO 9001 ensure that your chosen electronics manufacturer adheres to stringent quality management practices, giving you confidence in their ability to deliver exceptional results consistently.

Benefits of Working with Established Electronics Manufacturers

Partnering with an experienced PCBA supplier offers several advantages that can significantly impact your project’s outcome. Established electronics manufacturers typically have robust supply chains that ensure timely procurement of materials necessary for efficient PCB fabrication and assembly processes. This reliability allows you to maintain production schedules without unnecessary delays.

Moreover, working with seasoned professionals means accessing their wealth of knowledge regarding best practices in PCB manufacturing assembly techniques. Their insights can lead to improved designs or alternative solutions that enhance performance while reducing costs—something every business seeks!

Additionally, established suppliers often invest heavily in research and development to stay ahead of industry trends, allowing you access to cutting-edge technologies like automation in PCB fab and assembly processes. By leveraging these advancements, you can improve product quality while streamlining production efficiency.

How Bensun Technology Stands Out in the Industry

Bensun Technology distinguishes itself from other PCBA suppliers through its commitment to innovation paired with unparalleled customer service. As an industry leader in electronic manufacturing services, they utilize state-of-the-art equipment combined with skilled technicians who ensure meticulous attention during each stage of PCB fabrication and assembly projects.

What truly sets Bensun apart is their dedication to sustainability within their operations; they actively implement eco-friendly practices throughout their PCB manufacturing assembly processes without compromising quality or performance standards. This forward-thinking approach resonates well with businesses looking for responsible partners who prioritize environmental stewardship alongside technological advancement.

In addition, Bensun Technology emphasizes collaboration by maintaining open lines of communication throughout every project phase—this ensures alignment on goals while fostering trust between teams working together towards shared success! Their comprehensive support system guarantees that clients receive tailored solutions specific to their unique needs within the complex landscape of modern electronics manufacturing.

Innovative Electronic Manufacturing Services

In the rapidly evolving world of electronics, innovative electronic manufacturing services are essential for staying competitive. As technology advances, so too do the techniques and methodologies employed by PCB assembly manufacturers. This section will delve into advanced techniques in PCB manufacturing and assembly, highlight the importance of automation and precision, and showcase real-world examples of innovative solutions in the industry.

Advanced Techniques in PCB Manufacturing and Assembly

To keep pace with technological advancements, PCBA suppliers are increasingly adopting advanced techniques in PCB manufacturing and assembly. Techniques such as surface mount technology (SMT) allow for higher component density on smaller boards, optimizing space without sacrificing performance. Additionally, processes like automated optical inspection (AOI) ensure that each PCB fabrication and assembly meets stringent quality standards before leaving the factory floor.

Another significant advancement is the integration of 3D printing technologies into PCB fabrication and assembly processes. This allows electronics manufacturers to create prototypes quickly while reducing material waste significantly. Moreover, innovations such as flexible PCBs are becoming more prevalent, enabling new designs that cater to modern consumer electronics' demands for lightweight and compact devices.

Importance of Automation and Precision in PCB Fab and Assembly

Automation plays a pivotal role in enhancing both efficiency and accuracy within the realm of PCB fab and assembly. By utilizing automated systems for soldering, component placement, and inspection processes, electronic manufacturing services can achieve remarkable consistency across production runs. This level of precision not only reduces human error but also accelerates production timelines—essential factors for any competitive PCBA supplier.

Moreover, precision engineering is crucial when dealing with high-frequency applications where even minor deviations can lead to performance issues or failures in functionality. Advanced machinery equipped with laser-guided systems ensures that components are placed accurately on PCBs during manufacturing assembly processes. As a result, manufacturers can deliver products that meet or exceed customer specifications while maintaining high reliability.

Real-World Examples of Innovative Solutions

Several leading electronics manufacturers have embraced innovative solutions to enhance their PCB manufacturing assembly processes dramatically. For instance, a notable automotive manufacturer integrated machine learning algorithms into its production line to predict potential failures before they occur—reducing downtime significantly while improving product quality across their range of electronic components.

Another example involves a tech startup specializing in wearable devices that utilized flexible printed circuit boards (FPCBs) combined with IoT technology to create ultra-slim health monitoring gadgets capable of tracking vital signs seamlessly throughout daily activities. This innovation showcases how advancements in PCB fabrication can lead to entirely new product categories that resonate with consumers seeking convenience without compromising on functionality.

These real-world applications illustrate how adopting advanced techniques not only solves current challenges but also paves the way for future innovations within the industry—ensuring that companies remain at the forefront as leaders among PCBA suppliers.

Challenges in PCB Fabrication and Assembly

The journey of PCB manufacturing and assembly is not without its bumps in the road. Manufacturers often encounter a variety of challenges that can impact the efficiency and quality of their products. Understanding these issues is crucial for any electronics manufacturer looking to optimize their processes and deliver top-notch products.

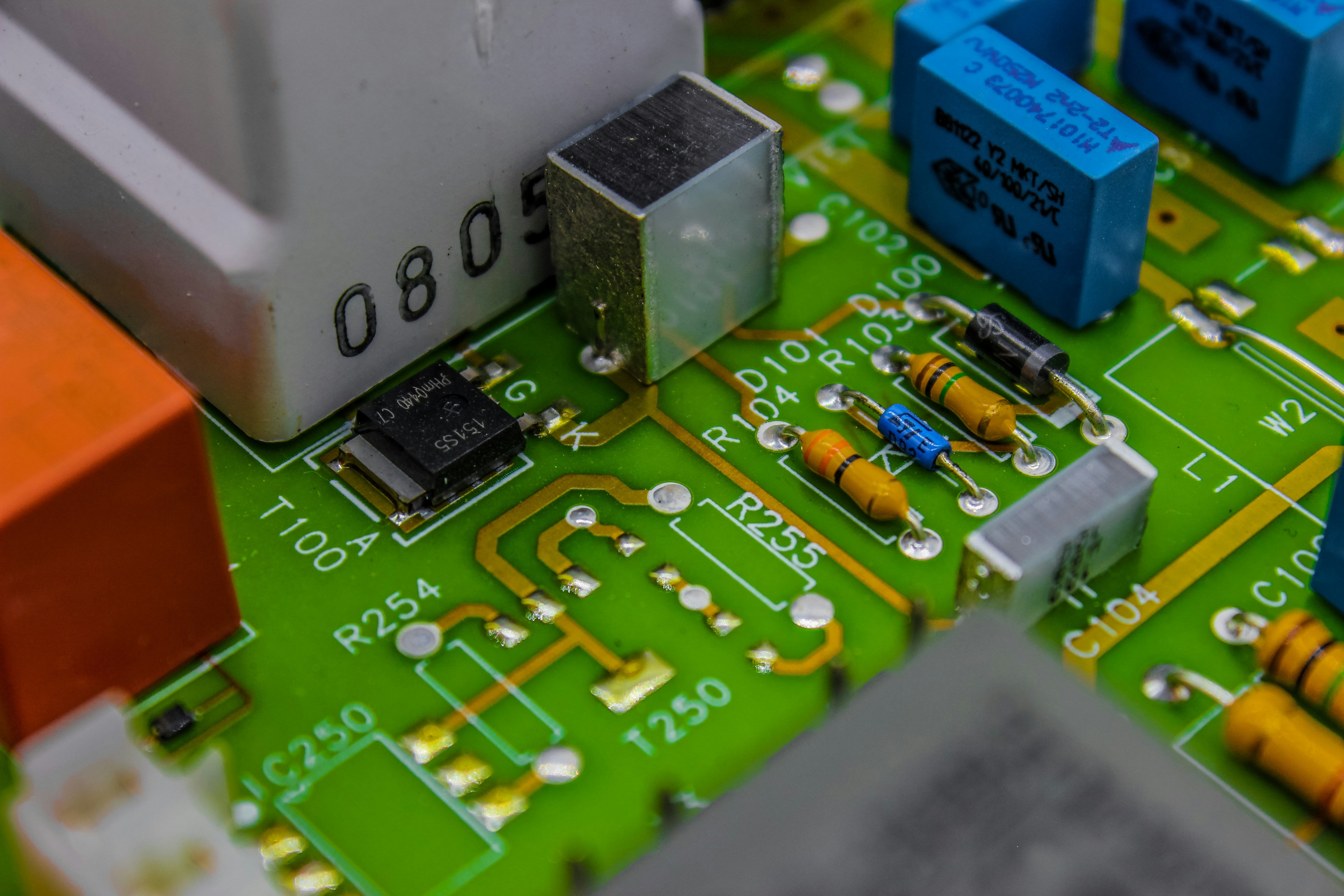

Common Issues Faced by Manufacturers

One of the most prevalent issues in PCB fabrication and assembly is component misalignment during the soldering process. This can lead to faulty connections, which ultimately affects product performance, making it a nightmare for any pcba supplier trying to maintain quality standards. Additionally, supply chain disruptions can result in delays or shortages of essential components, causing bottlenecks that hinder production timelines.

Another common challenge is managing thermal stress during the soldering process, which can warp PCBs or damage sensitive components. This issue not only affects the integrity of individual boards but also raises concerns about long-term reliability in end-use applications. Moreover, manufacturers must contend with strict regulations regarding materials used in PCB manufacturing, as compliance with environmental standards has become increasingly important.

Strategies to Overcome Challenges

To tackle these challenges effectively, manufacturers need to adopt several proactive strategies. Implementing advanced automation techniques in pcb fab and assembly processes can significantly reduce human error related to component placement and soldering accuracy. By leveraging state-of-the-art technology, electronics manufacturers can streamline operations while enhancing precision.

Furthermore, building strong relationships with reliable pcba suppliers ensures access to high-quality components even during supply chain disruptions. Diversifying sources for critical materials allows manufacturers to mitigate risks associated with shortages or price fluctuations effectively. Regular training sessions for staff on best practices in pcb manufacturing assembly can also enhance skill sets and improve overall production quality.

The Importance of Quality Control

Quality control cannot be overstated when it comes to pcb fabrication and assembly; it's the backbone that supports a successful manufacturing operation. Establishing stringent quality assurance protocols helps detect defects early on, preventing costly recalls or rework later down the line—a nightmare scenario for any electronics manufacturer!

Moreover, employing automated inspection systems ensures that every single board meets industry standards before leaving the factory floor, thereby safeguarding brand reputation and customer trust. Ultimately, prioritizing quality control not only enhances product reliability but also positions a pcba supplier as a leader within an increasingly competitive market.

Future Trends in PCBA Manufacturing

The landscape of PCB manufacturing and assembly is evolving rapidly, driven by technological advancements and changing market demands. As industries increasingly rely on electronic manufacturing services, the need for innovative solutions from a reliable PCBA supplier becomes paramount. This section delves into the emerging technologies, sustainability practices, and future predictions that are shaping the PCB fabrication and assembly sector.

Emerging Technologies Shaping the Industry

Emerging technologies are revolutionizing how PCB manufacturing assembly is approached, with automation and artificial intelligence leading the charge. Smart factories equipped with IoT devices enable real-time monitoring of production processes, enhancing efficiency while reducing waste. Furthermore, advancements in materials science are paving the way for more flexible circuits and high-frequency applications that push the boundaries of traditional PCB capabilities.

Another significant trend is the integration of 3D printing into PCB fabrication and assembly processes. This technology allows for rapid prototyping and customization, enabling electronics manufacturers to respond swiftly to market demands without compromising quality or performance. As a result, partnering with an innovative PCB assembly manufacturer can provide companies with a competitive edge in this dynamic environment.

Sustainability and Eco-Friendly Practices in PCB Assembly

Sustainability is no longer just a buzzword; it’s a necessity in today’s electronics industry. Leading PCBA suppliers are adopting eco-friendly practices throughout their manufacturing processes to minimize environmental impact. This includes using recyclable materials in PCB fabrication and assembly as well as implementing energy-efficient production techniques that reduce carbon footprints.

Additionally, many electronics manufacturers are embracing closed-loop systems that recycle waste generated during production back into new products. By prioritizing sustainability, these companies not only meet regulatory requirements but also appeal to environmentally-conscious consumers who favor brands committed to green practices. Ultimately, investing in sustainable electronic manufacturing services can enhance brand reputation while contributing positively to global environmental goals.

Predictions for the PCBA Market

Looking ahead, several key predictions will likely influence the direction of the PCBA market over the next few years. The increasing demand for smart devices will drive innovation in both consumer electronics and industrial applications—creating opportunities for growth among established PCB assembly manufacturers as well as new entrants into the field. Moreover, as 5G technology becomes more widespread, there will be an urgent need for advanced PCB fabrication solutions capable of supporting higher frequencies.

Furthermore, globalization will continue to shape supply chains within electronic manufacturing services as companies seek cost-effective production locations without sacrificing quality or reliability from their chosen PCBA supplier. In this context, maintaining strong partnerships across borders will be crucial for navigating potential challenges such as tariffs or trade restrictions effectively.

In summary, understanding these future trends enables businesses to align their strategies accordingly—ensuring they remain competitive in an ever-evolving marketplace focused on innovation and sustainability.

Conclusion

In the ever-evolving landscape of electronics, understanding the nuances of PCB manufacturing and assembly is crucial for success. The insights shared throughout this discussion highlight the importance of selecting a reliable PCBA supplier, navigating the complexities of PCB fabrication and assembly, and recognizing the key players in the industry. As we look to the future, it’s clear that innovative electronic manufacturing services will continue to shape how we approach design and production.

Recap of Key Insights on PCBA Solutions

Throughout our exploration of PCBA solutions, we've underscored their vital role in modern electronics manufacturing. From understanding basic definitions to delving into advanced techniques in PCB fab and assembly, these insights reveal how integral a PCB assembly manufacturer is to product development. Moreover, recognizing challenges such as quality control ensures that manufacturers can deliver reliable products consistently.

The Role of Bensun in Modern Electronics Manufacturing

Bensun Technology stands out as a leading electronics manufacturer by providing comprehensive electronic manufacturing services tailored to meet diverse client needs. Their commitment to quality and innovation in PCB manufacturing and assembly positions them as a trusted partner for businesses seeking efficient solutions. By leveraging advanced technologies and maintaining strict quality control measures, Bensun exemplifies excellence in PCB fabrication and assembly.

Choosing the Right Partner for PCB Manufacturing Assembly

Selecting the right PCBA supplier is paramount for any organization aiming to succeed in today’s competitive market. Factors like technological capability, experience in PCB fab and assembly processes, and customer support should guide your decision-making process. In an industry where precision matters greatly, partnering with an established electronics manufacturer like Bensun can provide peace of mind while ensuring high-quality results.