Introduction

In the fast-paced world of electronics manufacturing, the importance of choosing the right PCB shuttle conveyor cannot be overstated. This critical piece of conveyor equipment plays a vital role in ensuring efficient movement and handling of printed circuit boards (PCBs) throughout the production process. Selecting an appropriate conveyor system tailored to your specific needs can significantly enhance productivity and streamline operations in your SMT line.

Importance of Choosing the Right PCB Shuttle Conveyor

The right PCB shuttle conveyor serves as the backbone of your production line, affecting everything from speed to reliability. A well-chosen conveyor not only optimizes workflow but also minimizes downtime, which is crucial for meeting tight deadlines in PCB production. With various options available, making an informed decision can lead to substantial long-term benefits for your manufacturing efficiency.

Factors to Consider in Your Decision

When selecting a PCB shuttle conveyor, several factors warrant careful consideration to ensure compatibility with existing SMT machines and other equipment like PCB ovens. Assessing capacity and speed requirements is essential; you want a system that can handle your production demands without bottlenecks or inefficiencies. Additionally, understanding integration capabilities with other machinery will help create a seamless workflow across your entire line SMT.

Overview of PCB Shuttle Conveyor Types

PCB shuttle conveyors come in various types designed for different applications within the electronics manufacturing sector. From modular systems that allow for flexibility in layout to high-speed conveyors tailored for rapid throughput, each type offers unique advantages depending on your operational needs. Familiarizing yourself with these options will empower you to make choices that align perfectly with your production goals and machinery setup.

Understanding PCB Shuttle Conveyors

PCB shuttle conveyors are essential components in modern electronics manufacturing, specifically designed to transport printed circuit boards (PCBs) efficiently through various stages of production. These conveyor systems are tailored for high precision and reliability, making them indispensable for any PCB production setup. By understanding the key features, functions, and applications of these conveyors, you can make informed decisions that enhance your production line.

What is a PCB Shuttle Conveyor?

A PCB shuttle conveyor is a specialized type of conveyor equipment designed to move PCBs between different machines in the assembly line, such as SMT machines and PCB ovens. Unlike traditional belt conveyors that continuously transport materials, shuttle conveyors operate on a stop-and-go basis, allowing for precise positioning and transfer of PCBs at various stages of production. This makes them particularly effective in environments where timing and accuracy are critical.

Key Features and Functions

One standout feature of PCB shuttle conveyors is their ability to integrate seamlessly with other conveyor systems and machinery within the SMT line. They often come equipped with adjustable speeds and programmable controls to optimize workflow based on specific production needs. Additionally, many models feature sensors for detecting board presence, ensuring that each PCB is processed at the right moment without delays or errors.

Applications in PCB Production

PCB shuttle conveyors play a pivotal role in several applications within the realm of PCB production machines. They facilitate the movement of boards between soldering processes, inspection stations, and final assembly areas while maintaining high levels of accuracy throughout each step. Their versatility also allows them to be used in conjunction with other equipment like reflow ovens or pick-and-place machines, enhancing overall efficiency in complex manufacturing environments.

Assessing Your Production Needs

Evaluating Your Conveyor System Requirements

First things first: evaluate the specific requirements of your conveyor system. Consider factors like the size and weight of the PCBs you'll be transporting, as well as the overall layout of your production area. A well-chosen PCB shuttle conveyor should seamlessly integrate into your existing workflow without causing bottlenecks or disruptions.

Additionally, think about the types of materials you'll be handling and any potential environmental conditions they may encounter during transport. For instance, if you're using a PCB oven in conjunction with your line SMT setup, you'll want a conveyor that can withstand heat and provide adequate cooling times for sensitive components. Remember, an effective assessment leads to smarter decisions regarding your conveyor equipment.

Integrating with SMT Machines

Integrating a PCB shuttle conveyor with SMT machines is another critical consideration for streamlined operations. Your chosen conveyor should work harmoniously with machines like pick-and-place systems to ensure smooth transitions between processes. This integration not only enhances productivity but also minimizes downtime caused by misalignments or mechanical issues.

Moreover, consider how various SMT machines interact within the entire production line; this will help determine where best to position your PCB shuttle conveyor for optimal performance. Efficient integration means fewer interruptions and a more cohesive flow from one stage of production to another—ultimately leading to higher quality outputs from your PCB production machine.

Capacity and Speed Considerations

Capacity and speed are pivotal when assessing your PCB shuttle conveyor needs; after all, time is money in manufacturing! You’ll need to establish how many PCBs you expect to move through the system per hour while maintaining quality standards throughout the process. The selected conveyor equipment should meet or exceed these capacity requirements without sacrificing performance.

Think about how speed impacts not just output but also product integrity—too fast might lead to errors or damage during transport. Balancing capacity with appropriate speed settings ensures that you're not only meeting demands but doing so efficiently and reliably across all stages of production.

Comparing Conveyor Equipment Options

When it comes to selecting the right PCB shuttle conveyor, understanding the various types available can make all the difference. The market is brimming with options, each designed to cater to specific needs in PCB production. From basic models suitable for small-scale operations to advanced systems that seamlessly integrate with SMT machines, knowing your choices is key to optimizing your conveyor system.

Types of PCB Shuttle Conveyors Available

PCB shuttle conveyors are available in several configurations tailored for different manufacturing processes. Standard models typically feature a simple belt design that transports PCBs from one station to another, while more sophisticated versions include automated features for enhanced efficiency. Additionally, some conveyors are designed specifically for integration with other equipment like PCB ovens and SMT machines, ensuring a smooth workflow throughout the entire production line.

Another noteworthy option is the modular conveyor system, which allows manufacturers to customize their setup according to space constraints and production demands. These systems can be easily expanded or reconfigured as needed, making them ideal for businesses anticipating growth or changes in PCB production requirements. Ultimately, assessing your specific needs will guide you toward the type of PCB shuttle conveyor that best fits your operation.

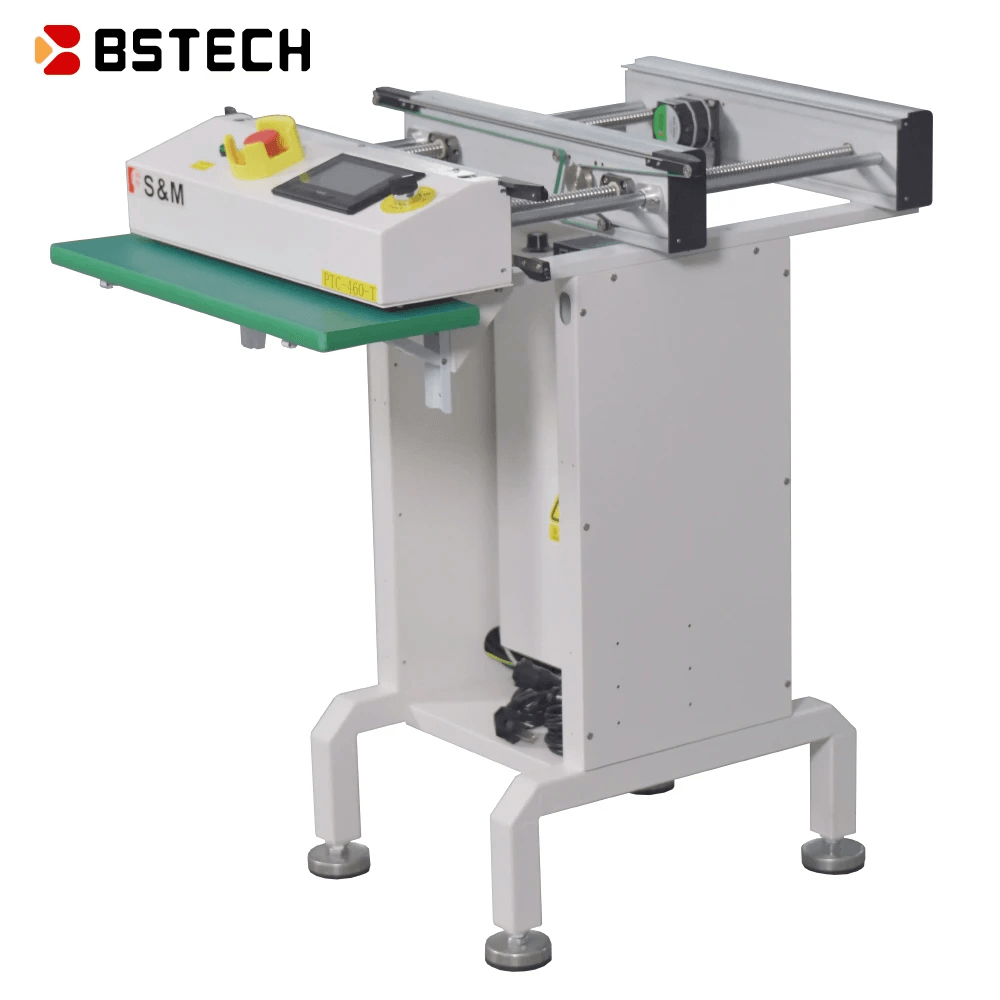

JUKI and Bensun Technology Solutions

Two prominent players in the PCB shuttle conveyor market are JUKI and Bensun Technology Solutions, each offering unique advantages tailored to different manufacturing environments. JUKI is known for its high-quality equipment that integrates seamlessly with SMT machines while providing exceptional reliability and performance in demanding production settings. Their conveyors often come equipped with advanced features such as real-time monitoring capabilities and user-friendly interfaces that enhance overall operational efficiency.

On the other hand, Bensun Technology Solutions focuses on providing cost-effective yet robust solutions that do not compromise on quality or functionality. Their range of PCB shuttle conveyors caters well to smaller manufacturers who require reliable systems without breaking the bank. By comparing these two brands based on your specific requirements—such as compatibility with existing equipment or particular applications—you can make an informed decision about which supplier aligns best with your goals.

Cost vs. Value Analysis

When weighing options for a new PCB shuttle conveyor system, it's essential to conduct a thorough cost versus value analysis rather than simply opting for the lowest price tag available on conveyor equipment. While initial costs may seem appealing at first glance, consider factors such as durability, maintenance requirements, and long-term operational efficiency before making a final decision. Investing in high-quality machinery often translates into fewer breakdowns and lower repair costs over time—ultimately saving both money and headaches down the line.

Moreover, consider how well each option integrates into your existing line SMT setup; an efficient integration can significantly enhance productivity by reducing downtime during transitions between processes like assembly and soldering within your PCB production machine environment. By focusing on value rather than just upfront costs—factoring in aspects like support services provided by suppliers—you'll ensure that you choose a solution that truly meets your business needs today while also being prepared for tomorrow's challenges.

Space and Layout Considerations

When it comes to optimizing your PCB production line, space and layout play a pivotal role in ensuring that your operations run smoothly. A well-designed line SMT can significantly enhance the efficiency of your conveyor system, allowing for seamless integration with various equipment like SMT machines and PCB ovens. By carefully planning your layout, you can minimize bottlenecks and maximize productivity, which is essential in today’s fast-paced manufacturing environment.

Designing Your Line SMT Efficiently

Efficient design of your line SMT involves strategically placing the PCB shuttle conveyor and other equipment to facilitate smooth workflow. Consider the flow of materials from one stage to another, ensuring that each component—be it a PCB production machine or an SMT machine—is positioned for optimal accessibility. Additionally, incorporating features such as adjustable heights or modular designs can further enhance flexibility in your layout, accommodating future changes without significant overhauls.

Compatibility with Existing Equipment

Ensuring compatibility between new conveyor equipment and existing systems is crucial for maintaining operational continuity. When selecting a PCB shuttle conveyor, take into account the specifications of your current SMT machines and any other related machinery you have in place. This compatibility not only streamlines integration but also reduces downtime during installation, allowing you to hit the ground running with minimal disruption to ongoing production processes.

Planning for Future Expansion

As businesses grow, so do their production needs; thus, planning for future expansion is vital when designing your layout. When setting up your line SMT, consider how additional PCB shuttle conveyors or other equipment might fit into the existing space without causing chaos. By leaving room for growth—whether it's adding more PCB ovens or upgrading to faster SMT machines—you ensure that scalability is built into your operations from day one.

Maintenance and Support Factors

When investing in a PCB shuttle conveyor, understanding maintenance and support factors is crucial for ensuring the longevity and efficiency of your conveyor system. A well-maintained conveyor equipment can significantly reduce downtime, which is vital in high-paced environments like PCB production. Regular service and reliable support from manufacturers or suppliers can make all the difference in keeping your SMT machines running smoothly.

Importance of Reliable Service and Support

Reliable service and support are essential components of any successful PCB shuttle conveyor operation. When something goes awry with your conveyor system, having access to prompt assistance can minimize disruptions in your production line SMT. Manufacturers that offer excellent customer service not only help you troubleshoot issues but also provide valuable insights on optimizing the performance of your PCB oven and other associated equipment.

Furthermore, a strong support network ensures that you receive timely updates about software or hardware enhancements related to your PCB production machine. This ongoing relationship can lead to better maintenance practices, ultimately improving the overall efficiency of your manufacturing process. Remember, a well-supported system is more likely to perform consistently over time.

Choosing Equipment with Easy Maintenance

Selecting a PCB shuttle conveyor designed for easy maintenance can save you time and money in the long run. Look for features such as modular designs that allow for quick access to parts needing repair or replacement without dismantling large sections of the equipment. Additionally, conveyors that require minimal specialized tools for upkeep will make it easier for your team to perform routine checks.

Another important aspect is how user-friendly the maintenance procedures are; intuitive designs mean less training time for staff responsible for maintaining the conveyor system. You want a solution that integrates seamlessly with existing SMT machines while allowing efficient cleaning processes—after all, cleanliness is key when working with sensitive electronics!

Choosing equipment with straightforward maintenance requirements not only keeps operations running smoothly but also extends the life expectancy of your investment in conveyor equipment.

Understanding Warranty and Lifespan

A thorough understanding of warranty terms and expected lifespan should be part of your decision-making process when selecting a PCB shuttle conveyor. Most manufacturers provide warranties that cover parts or labor for specific durations; knowing these details helps you gauge potential future costs associated with repairs or replacements down the line.

It’s also wise to consider how long various components are expected to last under normal operating conditions; this knowledge enables you to budget effectively while planning upgrades or replacements as necessary within your production workflow involving SMT machines and other related setups like a PCB oven.

Ultimately, investing time into comprehending warranty options alongside lifespan expectations will empower you to make an informed choice regarding which PCB production machine best meets both current needs and future growth plans.

Conclusion

In the fast-paced world of PCB production, making an informed decision on the right PCB shuttle conveyor can significantly impact your operational efficiency. With a plethora of options available, it's essential to carefully evaluate your needs and align them with the capabilities of various conveyor systems. By understanding the intricacies of these systems, you can enhance your production line and ensure seamless integration with SMT machines.

Making an Informed Decision on PCB Conveyors

Choosing the right PCB shuttle conveyor is not merely about picking a piece of equipment; it’s about selecting a partner in your production journey. Assessing factors such as capacity, speed, and compatibility with existing SMT machines will help you make an educated choice that aligns with your unique requirements. Remember that investing in quality conveyor equipment today can lead to significant cost savings and enhanced productivity tomorrow.

The Role of Quality in Production Efficiency

Quality plays a pivotal role in ensuring that your PCB production machine operates at peak efficiency. A high-quality PCB shuttle conveyor minimizes downtime and maximizes throughput, allowing for smoother transitions between processes like soldering and inspection—especially when paired with reliable PCB ovens. When every component works harmoniously within your line SMT, you create an environment ripe for innovation and growth.

Partnering with the Right Suppliers

Establishing strong relationships with reliable suppliers can make all the difference in navigating the complexities of selecting conveyor systems for your operations. Look for suppliers who not only provide high-quality products but also offer robust support services to ensure that your equipment remains operational over time. By partnering with trusted providers, you can secure peace of mind knowing that you have access to expertise when it comes to maintaining and optimizing your PCB shuttle conveyors.