Introduction

In the world of electronics manufacturing, the efficiency and precision of soldering techniques play a pivotal role in ensuring high-quality products. Selective soldering has emerged as a preferred method for PCB assembly, particularly when dealing with complex designs and delicate components. This process utilizes specialized selective soldering equipment to apply solder & flux precisely where needed, minimizing waste and maximizing reliability.

Understanding Selective Soldering Machines

Selective soldering machines are designed to target specific areas on a printed circuit board (PCB) for solder application, unlike traditional wave soldering machines that inundate entire boards with molten solder. These advanced machines feature precise nozzles that deliver controlled amounts of solder & flux directly onto the joints that require bonding, making them ideal for intricate PCB to PCB soldering tasks. By understanding how these selective soldering machines operate, manufacturers can better appreciate their advantages over conventional methods.

Importance of Selective Soldering in PCB Assembly

The importance of selective soldering in PCB assembly cannot be overstated; it allows for greater control over the manufacturing process and significantly reduces the risk of damaging sensitive components. In industries such as automotive and medical devices, where reliability is paramount, selective soldering ensures that every connection is secure without compromising surrounding parts. As technology continues to advance, the demand for efficient and effective methods like selective soldering will only increase.

The Role of Solder & Flux in the Process

Solder & flux are crucial elements in any soldering operation, but their roles become even more pronounced within selective soldering processes. The right type of flux helps prevent oxidation during heating while promoting better adhesion between surfaces—key factors when using selective soldering equipment on intricate designs. Furthermore, choosing appropriate solders can enhance joint strength and conductivity, ultimately leading to improved performance in electronic devices.

What is Selective Soldering?

Selective soldering is a specialized process used in the assembly of printed circuit boards (PCBs). It allows for precise application of solder to specific areas, making it an ideal choice for complex assemblies where traditional methods may fall short. By utilizing selective soldering equipment, manufacturers can achieve high-quality connections while minimizing the risk of damage to surrounding components.

Definition and Overview

Selective soldering refers to a technique that applies molten solder only to designated areas on a PCB, typically where through-hole components are located. This method contrasts sharply with wave soldering, which inundates the entire board in molten solder, potentially causing issues with sensitive surface-mounted devices. The precision of selective soldering ensures that only the intended joints receive the necessary solder & flux, enhancing overall reliability.

Differences Between Selective Soldering and Wave Soldering

The primary distinction between selective and wave soldering lies in their approach to applying solder. While wave soldering machines immerse entire PCBs into a wave of molten metal, selective soldering machines target specific locations on the board—ideal for mixed-technology assemblies. This targeted approach not only reduces the amount of waste but also enhances quality control by preventing overheating or damaging heat-sensitive components.

The Need for Selective Soldering Equipment

In today's fast-paced manufacturing environment, having efficient and effective selective soldering equipment is crucial for maintaining production standards and meeting market demands. As electronic devices become increasingly complex, traditional methods like wave soldering often cannot keep up with precision requirements or component sensitivity. Thus, investing in advanced selective soldering technology allows manufacturers to perform PCB to PCB soldering more effectively while ensuring high-quality results without compromising on efficiency or cost-effectiveness.

Applications of Selective Soldering Machines

Selective soldering machines have carved out a significant niche in various industries, showcasing their versatility and precision. These machines are particularly beneficial for complex assemblies where traditional wave soldering may fall short. From automotive applications to consumer electronics and medical devices, the need for efficient PCB to PCB soldering has never been more apparent.

PCB to PCB Soldering in Automotive

In the automotive sector, selective soldering is crucial for ensuring robust connections in electronic control units (ECUs) and other critical components. The use of selective soldering equipment allows manufacturers to achieve high precision while minimizing thermal stress on sensitive parts, something that a wave soldering machine might struggle with due to its broader application method. With the increasing complexity of automotive electronics, the ability to selectively apply solder & flux is vital for reliability and performance.

Automotive PCBs often require multiple layers and intricate designs that demand accurate placement of components. Selective soldering enables precise PCB to PCB soldering without compromising surrounding elements, reducing the risk of defects significantly. As electric vehicles gain traction, this technology becomes even more essential for meeting stringent safety standards.

Consumer Electronics and Selective Soldering

The consumer electronics industry thrives on innovation and efficiency, making selective soldering an ideal fit for modern production lines. In this fast-paced market, products must be assembled quickly without sacrificing quality; selective soldering equipment excels at achieving this balance by allowing targeted application of solder & flux only where needed. This results in cleaner boards with fewer defects compared to traditional methods like wave soldering.

Selective soldering not only improves the quality but also enhances the overall aesthetic appeal of consumer products by reducing excess material around components. Manufacturers can achieve higher yields while minimizing waste—a win-win situation when it comes to cost-effectiveness in PCB manufacturing. Additionally, as devices become smaller and packed with more features, selective techniques enable intricate designs that meet consumer demands.

Medical Devices and Their Unique Requirements

In the medical field, precision is paramount; even minor errors can have serious implications for patient safety. Selective soldering machines are tailored to meet these stringent requirements by providing exceptional accuracy during assembly processes such as connecting sensors or integrating circuit boards within medical devices. The careful application of specialized solders & flux ensures reliable connections that comply with regulatory standards.

Medical devices often involve complex circuitry where traditional wave soldering could lead to overheating or damage sensitive components—issues easily avoided with selective techniques that focus on specific areas without affecting others. Moreover, given the rapid advancements in medical technology, having flexible manufacturing solutions like selective soldering allows companies to adapt quickly while maintaining high-quality standards across their product lines.

Key Components of Selective Soldering Equipment

In the world of PCB assembly, understanding the key components of selective soldering equipment is essential for achieving optimal results. These machines are designed to deliver precision and efficiency, making them a preferred choice over traditional wave soldering methods. By breaking down the integral parts, we can appreciate how they contribute to successful pcb to pcb soldering.

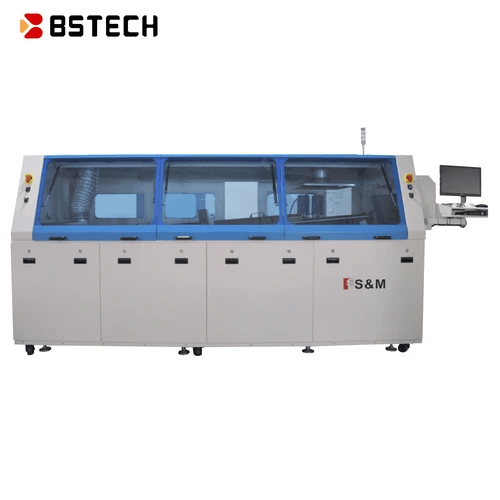

Understanding the Selective Soldering Machine

A selective soldering machine is engineered to target specific areas on a printed circuit board (PCB) for solder application, allowing manufacturers to avoid unnecessary exposure of components to heat. This precision minimizes damage and enhances reliability, particularly when dealing with sensitive electronic components that cannot withstand the rigors of a wave soldering machine. With various models available, businesses can select a machine that best suits their production needs while ensuring high-quality results.

The operation of these machines involves several stages, including preheating the PCB and applying solder through specialized nozzles. This targeted approach not only improves efficiency but also reduces waste by limiting excess solder application. As a result, manufacturers experience lower material costs and improved product quality when utilizing selective soldering equipment.

Role of Solder & Flux in Efficiency

Solder & flux play pivotal roles in enhancing the efficiency of selective soldering processes. The right combination ensures strong connections between electronic components while preventing oxidation during assembly—a critical factor for long-lasting performance in various applications like automotive electronics or medical devices. Choosing high-quality materials tailored for selective soldering can significantly impact overall production effectiveness.

Flux acts as an intermediary that cleans surfaces and promotes better adhesion during the heating process; thus, its selection should not be taken lightly. Different types of flux are available depending on the specific requirements of your project; some may be more suited for high-speed operations while others excel in delicate applications requiring meticulous attention to detail. Ultimately, effective use of solder & flux directly correlates with reduced defects and increased throughput in PCB assembly lines.

Importance of Accurate Printer PCB Boards

Accurate printer PCB boards are fundamental to successful selective soldering operations because they ensure precise alignment during assembly processes. If PCBs are misaligned or inaccurately printed, it can lead to poor connections or even total failure—issues that can be costly both in terms of time and resources spent rectifying errors after production has commenced. Therefore, investing in high-quality printing technology is essential for maximizing efficiency when using selective soldering equipment.

Moreover, accuracy in printing contributes significantly to overall workflow optimization within manufacturing facilities by minimizing rework rates associated with faulty connections or misaligned components post-soldering phase. This level of precision not only enhances product quality but also builds trust among clients who rely on consistent performance from their electronic devices across industries like consumer electronics or medical technology sectors where reliability is paramount.

In conclusion, understanding these key components—selective soldering machines themselves, the critical roles played by solder & flux, and ensuring accurate printer PCB boards—can greatly enhance your manufacturing capabilities while setting you apart from competitors still relying heavily on outdated wave soldering techniques.

The Advantages of Selective Soldering

Selective soldering has carved out a niche in the world of PCB assembly, and for good reason. Its unique advantages over traditional methods like wave soldering make it an attractive option for manufacturers looking to enhance their production processes. From precision to cost-effectiveness, selective soldering equipment is becoming a go-to choice for industries ranging from automotive to consumer electronics.

Enhanced Precision Over Wave Soldering

One of the standout features of selective soldering is its enhanced precision compared to wave soldering. While wave soldering machines apply molten solder uniformly across a board, selective soldering machines target specific areas, ensuring that only designated components receive the necessary solder & flux. This level of control minimizes the risk of bridging and other defects, resulting in higher quality assemblies—especially critical in complex PCB to PCB soldering applications.

The ability to focus on individual joints allows manufacturers to work with smaller components and denser layouts without compromising on quality. In fact, this precision not only improves product reliability but also reduces rework rates significantly. With selective soldering equipment, businesses can achieve tighter tolerances and maintain higher standards in their manufacturing processes.

Cost-Effectiveness in PCB Manufacturing

Cost-effectiveness is another compelling advantage of selective soldering that cannot be overlooked. By utilizing selective soldering machines, companies can optimize their use of materials such as solder & flux, which leads to lower overall costs during production runs. Unlike wave soldering where excess material often goes to waste, selective processes allow for precise application—reducing both material waste and expenses.

Moreover, the reduced need for rework due to fewer defects translates directly into savings on labor and time—a win-win scenario for any manufacturer aiming for efficiency. As businesses strive to maintain competitive pricing while improving quality standards, adopting selective soldering becomes a financially sound decision that pays dividends long-term.

Reduced Scrap and Waste Benefits

One significant benefit that comes with using selective soldering equipment is the reduction in scrap and waste generated during the manufacturing process. Traditional wave soldering often results in excess material being applied beyond what is necessary; however, with selective methods, only required areas are targeted—leading to less wasted resources overall. This efficient use of materials not only helps lower costs but also aligns with growing sustainability goals within the industry.

Additionally, fewer defects mean less product scrapping; therefore manufacturers can enjoy higher yields from each batch produced using selective techniques compared to conventional methods like wave soldering machines. Companies committed to minimizing their environmental impact will find that implementing selective processes supports these efforts effectively while enhancing profitability at the same time.

Bensun Technology's Solutions in Selective Soldering

When it comes to selective soldering, Bensun Technology stands out with its cutting-edge solutions designed for modern assembly lines. The innovative equipment we offer is tailored to meet the unique demands of various industries, ensuring high-quality results in PCB to PCB soldering applications. Our selective soldering machines are engineered with precision, allowing for efficient use of solder & flux while minimizing waste.

Innovative Equipment for Modern Assembly

Bensun Technology's selective soldering equipment is at the forefront of industry advancements, combining speed and accuracy that traditional wave soldering machines simply can't match. Our machines are designed to handle complex PCB layouts and delicate components, making them ideal for sectors like automotive and medical devices where precision is paramount. With features that enhance usability and efficiency, our selective soldering machines empower manufacturers to achieve superior quality in their assemblies.

After-Sales Support and Training

Investing in selective soldering equipment from Bensun Technology means you’re not just getting top-notch machinery; you’re also gaining a partner committed to your success. We provide comprehensive after-sales support that includes training your staff on best practices for using our selective soldering machines effectively. This ensures optimal performance while reducing the learning curve associated with new technology—because a well-trained team is key to maximizing the benefits of advanced equipment.

Flexible Options: Sales, Rentals, and Contract Manufacturing

Understanding that every business has unique needs, Bensun Technology offers flexible options when it comes to acquiring our state-of-the-art selective soldering equipment. Whether you're looking to purchase outright or prefer rental arrangements during peak production times, we've got you covered! Additionally, our contract manufacturing services allow companies without their own facilities to leverage our expertise in PCB assembly using advanced selective soldering techniques—making us a versatile ally in your manufacturing journey.

Conclusion

In the ever-evolving world of PCB assembly, selective soldering stands out as a game-changer. With its ability to precisely target solder connections without affecting surrounding components, it offers unparalleled advantages over traditional methods like wave soldering. By investing in selective soldering equipment, businesses can enhance their production efficiency while ensuring high-quality results.

Why Choose Selective Soldering for Your Business

Selective soldering provides a level of precision that is hard to achieve with wave soldering machines. This technology allows for targeted application of solder & flux, making it ideal for complex assemblies and minimizing the risk of damage to sensitive components. Additionally, the reduced scrap and waste associated with selective processes translate into cost savings, making it an attractive option for businesses looking to optimize their PCB to PCB soldering operations.

Future Trends in PCB Assembly Technology

As technology continues to advance, we can expect further innovations in selective soldering techniques and equipment. The integration of automation and AI into selective soldering machines will likely enhance efficiency and accuracy even more. Furthermore, as industries demand more compact and complex designs, the need for high-precision selective soldering will only grow stronger.

Bensun Technology's Commitment to Quality and Innovation

Bensun Technology is at the forefront of providing cutting-edge solutions in selective soldering equipment. Our dedication extends beyond just selling machines; we offer comprehensive after-sales support and training to ensure your team is well-versed in using our products effectively. With flexible options such as sales, rentals, and contract manufacturing services tailored to your needs, Bensun remains committed to quality and innovation in every aspect of PCB assembly.