Introduction

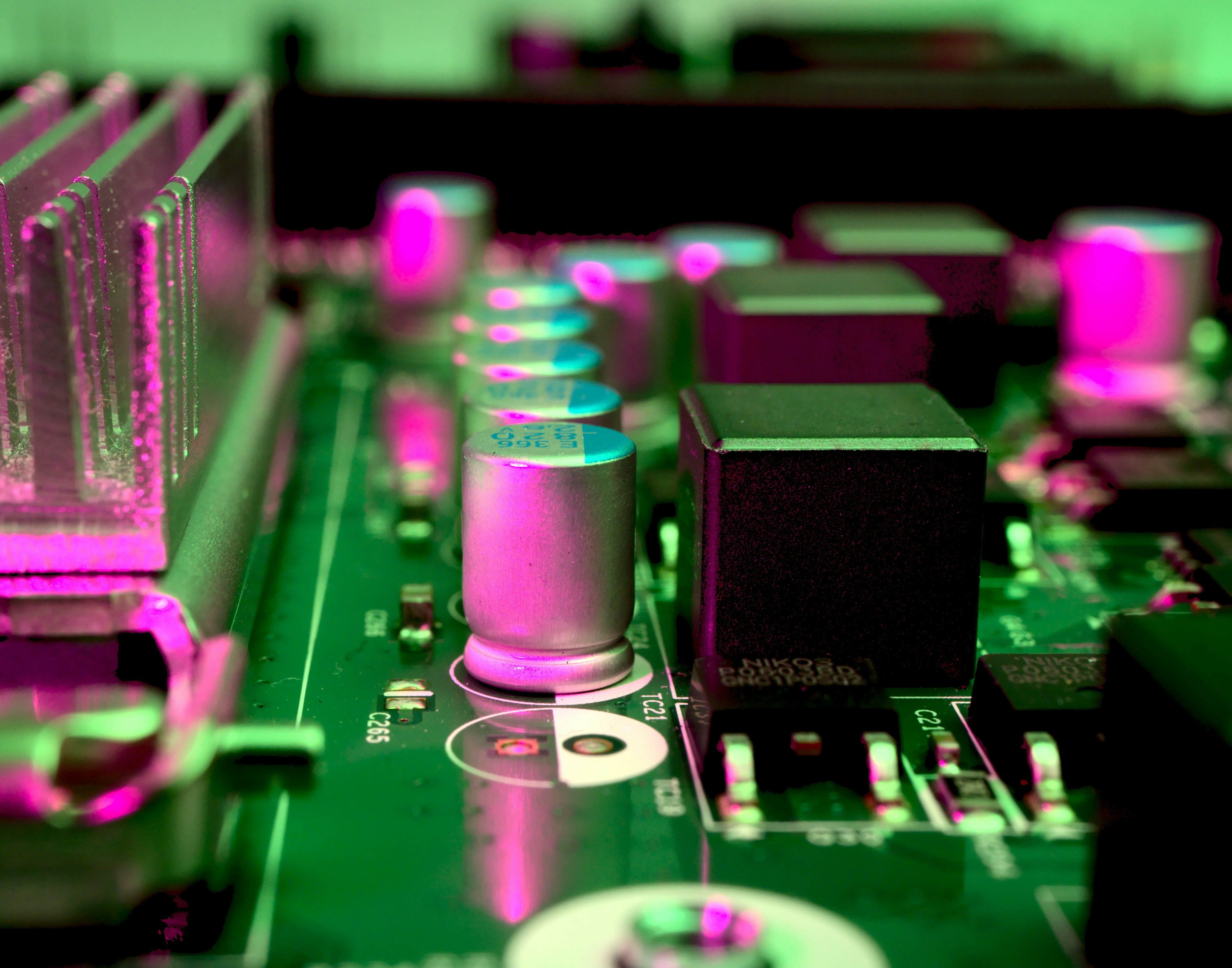

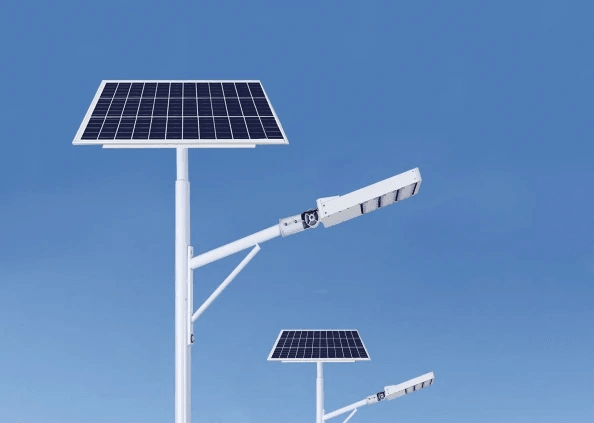

In the ever-evolving world of electronics, LED PCB assembly stands out as a critical component in modern lighting solutions. The integration of LED technology into printed circuit boards has revolutionized how we design and utilize light sources, offering energy-efficient and versatile options for various applications. This introduction will explore the significance of LED light circuit boards, emphasizing their impact on industries ranging from consumer electronics to automotive.

Overview of LED PCB Assembly

LED PCB assembly refers to the process of integrating light-emitting diodes (LEDs) onto printed circuit boards (PCBs) to create efficient lighting solutions. An LED PCB board is specifically designed to accommodate the thermal management and electrical requirements unique to LEDs, ensuring optimal performance and longevity. With advancements in surface mount technology, manufacturers can produce custom LED circuit boards that cater to diverse needs while maintaining high-quality standards.

Importance of LED Light Circuit Boards

The importance of LED light circuit boards cannot be overstated; they are essential for creating innovative lighting designs that save energy and reduce costs. These boards enable a compact design while maximizing brightness and minimizing heat generation, making them ideal for applications ranging from home lighting to intricate medical devices. Furthermore, the rise of smart technology has increased demand for advanced features in LEDs, further highlighting the need for specialized led board pcb designs.

Role of Bensun in the Industry

Bensun plays a pivotal role in the LED PCB assembly industry by providing high-quality manufacturing services tailored to meet customer specifications. With expertise in designing surface mount led pcbs and an emphasis on quality control throughout their processes, Bensun ensures that every custom led circuit board meets rigorous industry standards. As a trusted partner in this fast-paced sector, Bensun is committed to driving innovation and excellence in LED solutions worldwide.

What is LED PCB Assembly?

LED PCB assembly is a specialized process that involves the integration of light-emitting diodes (LEDs) onto printed circuit boards (PCBs) designed specifically for lighting applications. This assembly technique merges electrical engineering with innovative design, resulting in efficient and effective LED light circuit boards. Understanding the nuances of LED PCB assembly is essential for anyone looking to harness the full potential of LED technology.

Definition of LED PCB Board

An LED PCB board is essentially a substrate that supports and connects various electronic components, primarily LEDs, through conductive pathways etched into the board material. These boards are designed to efficiently dissipate heat generated by the LEDs while providing structural integrity and electrical connectivity. In essence, an LED printed circuit board serves as the backbone of any lighting solution, ensuring reliable performance and longevity.

Components of LED Printed Circuit Boards

The primary components of an LED printed circuit board include LEDs themselves, resistors for current regulation, capacitors for smoothing voltage fluctuations, and traces that connect these elements together. Additionally, thermal pads may be incorporated to enhance heat dissipation from high-power LEDs during operation. The combination of these elements allows custom LED circuit boards to deliver optimal performance tailored to specific applications.

Advantages of Custom LED Circuit Boards

Custom led circuit boards offer several advantages over standard designs; they can be tailored to meet unique specifications such as size constraints or specific thermal management needs. This customization not only enhances efficiency but also contributes to improved aesthetics in products where form matters just as much as function. Furthermore, custom designs can lead to cost savings in production by optimizing material usage and reducing waste during manufacturing processes like surface mount led pcb assembly.

Key Considerations in LED Light Circuit Board Design

When it comes to LED light circuit board design, several key considerations can significantly impact both performance and efficiency. The interplay between functionality, aesthetics, and manufacturability is crucial in creating an effective LED PCB assembly. Designers must also account for the specific requirements of the application to ensure optimal operation of the custom LED circuit boards.

Factors Influencing Design Choices

Several factors influence the design choices for LED printed circuit boards. First, the intended application plays a vital role; whether it's for consumer electronics or industrial use, each has unique demands that dictate component selection and layout. Additionally, cost constraints can affect material choices and production methods, leading designers to explore options like surface mount LED PCBs for their compactness and efficiency.

Another consideration is the target lifespan of the product; longer lifespans may require more robust materials and designs that prevent premature failure. Moreover, environmental factors such as temperature variations can also influence design decisions—designers often have to strike a balance between performance and durability in various conditions. Ultimately, these factors converge to create a well-rounded LED board PCB that meets both functional and commercial needs.

Thermal Management for LED Boards

Thermal management is one of the most critical aspects of designing an effective LED PCB board. LEDs generate heat during operation, which can lead to decreased performance or even failure if not properly managed; thus, incorporating efficient thermal management strategies is essential in any led light circuit board design. Techniques such as using thermal vias or heat sinks are often employed to dissipate heat effectively.

Moreover, selecting materials with better thermal conductivity can significantly enhance heat dissipation capabilities in custom LED circuit boards. Designers must also consider airflow within enclosures; ensuring proper ventilation can further mitigate overheating issues associated with high-density surface mount technology components on led printed circuit boards. In summary, prioritizing thermal management ensures longevity and reliability in any LED PCB assembly project.

Compliance with Industry Standards

Compliance with industry standards is another essential consideration when designing an LED light circuit board. Adhering to established guidelines ensures not only safety but also compatibility across different applications—this is particularly important when integrating multiple components into an overall system involving led PCB assembly. Standards such as IPC-A-610 provide benchmarks for quality assurance throughout the manufacturing process.

Additionally, many regions have specific regulations regarding electromagnetic interference (EMI) which must be considered during design stages; this is where custom led circuit boards shine by allowing tailored solutions that meet local compliance requirements without sacrificing performance or aesthetics. Furthermore, certifications from organizations like UL or CE signal a commitment to quality that enhances marketability while assuring customers of product safety standards met by your led board PCB designs.

The Manufacturing Process of LED Boards

The manufacturing process of LED boards is a sophisticated blend of technology and precision, crucial for producing high-quality LED PCB assemblies. From initial design to final assembly, each step is vital to ensure that the LED printed circuit board performs optimally in its intended application. Understanding this process can help stakeholders appreciate the intricacies involved in creating custom LED circuit boards that meet specific needs.

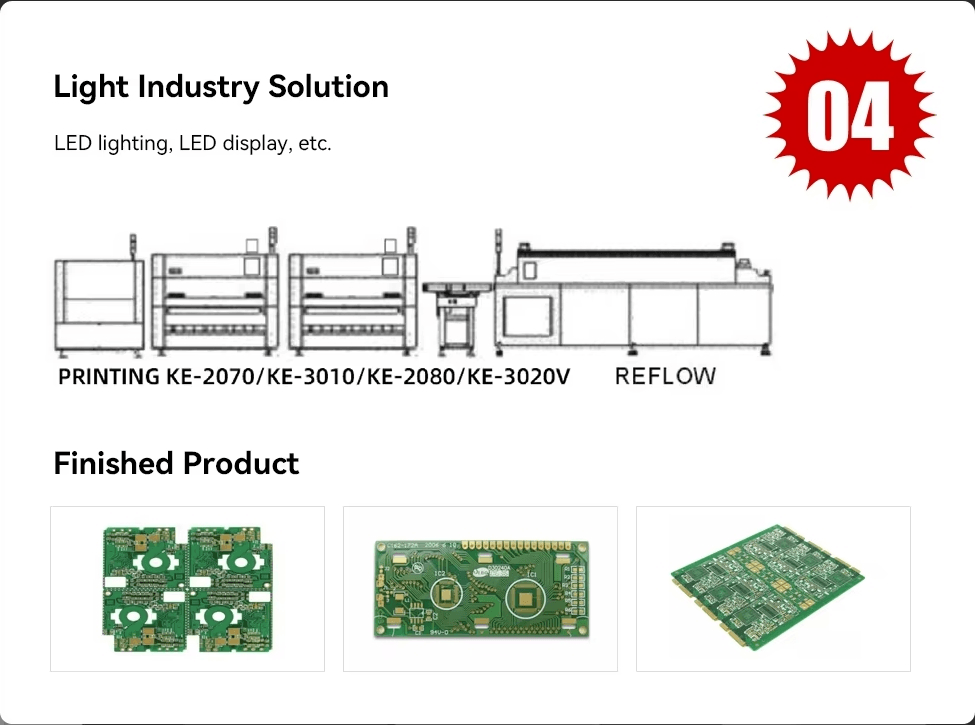

Surface Mount Technology Explained

Surface Mount Technology (SMT) is a pivotal method used in the assembly of LED PCBs, allowing for efficient and compact designs. This technique involves mounting electronic components directly onto the surface of a led board PCB, eliminating the need for through-hole mounting and significantly reducing space requirements. SMT not only enhances production speed but also improves performance due to shorter electrical paths, making it ideal for modern led light circuit board designs.

Role of Bensun in Assembly Techniques

Bensun stands at the forefront of innovative assembly techniques in the realm of LED PCB assembly, leveraging advanced machinery and skilled labor to ensure top-notch quality. Their expertise allows them to handle various types of surface mount led PCBs with precision and efficiency, catering to diverse customer requirements. By partnering with Bensun, clients gain access to cutting-edge technology and customizable options that enhance their custom LED circuit boards.

Quality Control in LED PCB Assembly

Quality control is an essential component of the manufacturing process for led printed circuit boards, ensuring that each product meets rigorous industry standards before reaching consumers. Bensun employs a robust quality assurance system that includes thorough testing at multiple stages—right from material inspection to post-assembly evaluations—guaranteeing reliability and performance in every led light circuit board design they produce. This commitment to quality not only minimizes defects but also fosters trust among clients seeking dependable solutions for their lighting needs.

Applications of LED PCB Assembly

LED PCB assembly has revolutionized various industries by providing efficient, compact, and versatile lighting solutions. From consumer electronics to automotive lighting and medical devices, the applications of LED printed circuit boards are vast and impactful. This section will delve into these use cases, showcasing how custom LED circuit boards enhance functionality and performance.

Use Cases in Consumer Electronics

In the realm of consumer electronics, LED PCB assembly is a game-changer. Devices like televisions, smartphones, and laptops utilize LED light circuit board designs to deliver vibrant displays while conserving energy. The integration of surface mount LED PCBs allows for sleek designs without compromising on brightness or efficiency, making them essential in modern gadgets.

Moreover, custom LED circuit boards enable manufacturers to tailor lighting solutions specific to their product needs. For instance, smart home devices often incorporate programmable LEDs that can change colors or intensity based on user preferences. This adaptability not only enhances user experience but also sets products apart in a competitive market.

As technology continues to advance, the importance of high-quality led PCB boards becomes even more apparent. With consumers increasingly seeking energy-efficient options that do not sacrifice performance, manufacturers rely heavily on innovative led light circuit board design techniques to meet these demands. The future looks bright for consumer electronics powered by advanced LED technologies.

LED Boards in Automotive Lighting

Automotive lighting has undergone a significant transformation thanks to advancements in led PCB assembly technology. Modern vehicles now feature intricate lighting systems that utilize led printed circuit boards for headlights, taillights, and interior illumination. These systems not only improve visibility but also contribute to the overall aesthetic appeal of cars.

The use of surface mount led PCBs in automotive applications allows for greater design flexibility and reduced weight compared to traditional lighting methods. Custom led circuit boards can be engineered for specific vehicle models or functions, ensuring optimal performance under varying conditions such as rain or fog. This level of customization enhances safety while offering drivers an enhanced driving experience.

Furthermore, as the automotive industry shifts towards electric vehicles (EVs), the demand for efficient lighting solutions continues to grow. Manufacturers are increasingly turning to advanced led board PCBs that provide superior thermal management and energy efficiency—key factors for battery-powered vehicles striving for longer ranges. The future is undoubtedly bright with LEDs leading the way in automotive innovation.

Medical Devices and Their LED Circuit Boards

In healthcare settings, precision matters—and so does reliable illumination provided by led PCB assembly solutions within medical devices. From surgical lights to diagnostic equipment like endoscopes and imaging machines, led printed circuit boards play a crucial role in ensuring procedures are conducted safely and effectively under optimal lighting conditions.

The benefits of using custom led circuit boards extend beyond just functionality; they also enhance patient care through improved visibility during critical operations or examinations. Surface mount led PCBs allow designers to create compact yet powerful light sources that fit seamlessly into various medical devices without taking up excessive space—an essential consideration in design-heavy environments like hospitals.

Moreover, as telemedicine gains traction post-pandemic—where remote diagnostics become more prevalent—the need for reliable illumination remains paramount across all platforms involving patient interaction or monitoring via video calls or mobile apps utilizing medical-grade cameras equipped with advanced LEDs becomes vital too! Thus highlighting how integral these technologies have become across diverse applications within healthcare settings!

Choosing the Right Manufacturer for LED PCBs

When it comes to LED PCB assembly, selecting the right manufacturer is crucial to ensure quality and performance. The right partner can significantly influence the success of your projects, especially when dealing with intricate designs like custom LED circuit boards. Here, we’ll explore key factors that will help you make an informed decision.

Evaluating Expertise and Experience

Expertise and experience are paramount when choosing a manufacturer for your LED printed circuit board needs. Look for companies that have a proven track record in the industry, particularly in handling various types of LED board PCB projects. A manufacturer with extensive experience will not only understand the complexities of LED light circuit board design but also bring valuable insights into optimizing your product for efficiency and cost-effectiveness.

In addition, consider their familiarity with surface mount technology (SMT) as it plays a vital role in modern LED PCB assembly processes. Manufacturers who have successfully executed SMT will likely deliver higher-quality results while minimizing production errors. Ultimately, expertise translates to reliability; you want a partner who can navigate challenges smoothly while delivering consistent outcomes.

Importance of Customization Options

Customization options are essential when it comes to LED PCB assembly because one size rarely fits all in this field. Your project may require specific dimensions, unique layouts, or special components tailored to your application—custom led circuit boards excel in meeting these needs. A manufacturer that offers flexible customization options ensures that you can achieve the precise specifications necessary for optimal performance.

Moreover, having access to various design choices allows you to innovate without being constrained by standard offerings. This flexibility can lead to more efficient designs and ultimately better-performing products tailored for specific markets such as automotive lighting or consumer electronics. In short, choosing a manufacturer that prioritizes customization empowers you to push boundaries and create standout solutions.

Benefits of Partnering with Bensun

With years of experience under their belt, they specialize in creating high-quality led printed circuit boards tailored specifically for diverse applications—from medical devices to automotive lighting solutions. Their commitment to excellence means you'll receive top-notch support throughout every stage of the manufacturing process.

Bensun also excels at offering custom led circuit boards designed precisely according to client specifications while adhering strictly to industry standards—this ensures compliance without compromising on creativity or functionality. Furthermore, their advanced surface mount led pcb techniques guarantee precision and reliability in every product they create, making them an ideal choice for those seeking cutting-edge technology combined with expert craftsmanship.

In conclusion, selecting the right manufacturer is critical for successful LED PCB assembly projects; prioritize expertise, customization options, and reliable partners like Bensun who understand your unique needs fully.

Conclusion

In conclusion, LED PCB assembly is revolutionizing the way we think about lighting solutions, offering a myriad of benefits that enhance efficiency and performance. From custom LED circuit boards tailored to specific applications to the reliability of surface mount LED PCBs, these technologies are paving the way for innovative designs. As industries continue to embrace LED light circuit board design, the importance of high-quality assembly processes cannot be overstated.

Summary of LED PCB Assembly Benefits

LED PCB assembly provides several advantages that make it a preferred choice for modern electronics. Custom LED circuit boards enable designers to optimize space and functionality while ensuring effective thermal management—a crucial aspect in maintaining performance and longevity. Moreover, the durability and energy efficiency of an LED printed circuit board contribute significantly to reduced operational costs over time.

Future Trends in LED Circuit Board Technology

The future of LED circuit board technology looks bright, with advancements poised to enhance both functionality and sustainability. Innovations such as flexible LED boards and integration with smart technologies are becoming more commonplace, allowing for versatile applications across various sectors. Additionally, as energy efficiency regulations tighten globally, we can expect a surge in demand for high-performance LED PCB assemblies that meet rigorous compliance standards.

Why Bensun is Your Best Partner in LED Solutions

With extensive expertise in manufacturing custom led circuit boards tailored to diverse applications, they ensure quality at every stage—from design through production. Their commitment to innovation and customer satisfaction makes Bensun an invaluable ally for businesses seeking reliable solutions in the ever-evolving world of LED technology.