Introduction

In the rapidly evolving world of technology, LED PCB solutions have become a cornerstone of modern electronic design and manufacturing. These specialized boards are crucial for powering everything from vibrant LED PCB strips to intricate SMD LED PCB boards, providing efficiency and versatility in various applications. As the demand for innovative lighting solutions grows, understanding the nuances of LED PCBs is essential for manufacturers and consumers alike.

Understanding LED PCB Solutions

LED PCBs, or printed circuit boards designed specifically for light-emitting diodes, are integral to a wide range of electronic devices. They support the effective operation of LEDs by ensuring optimal heat dissipation and electrical connectivity. With advancements in technology, these boards can be customized to meet specific requirements, making them an invaluable asset for any LED PCB manufacturer looking to stay competitive.

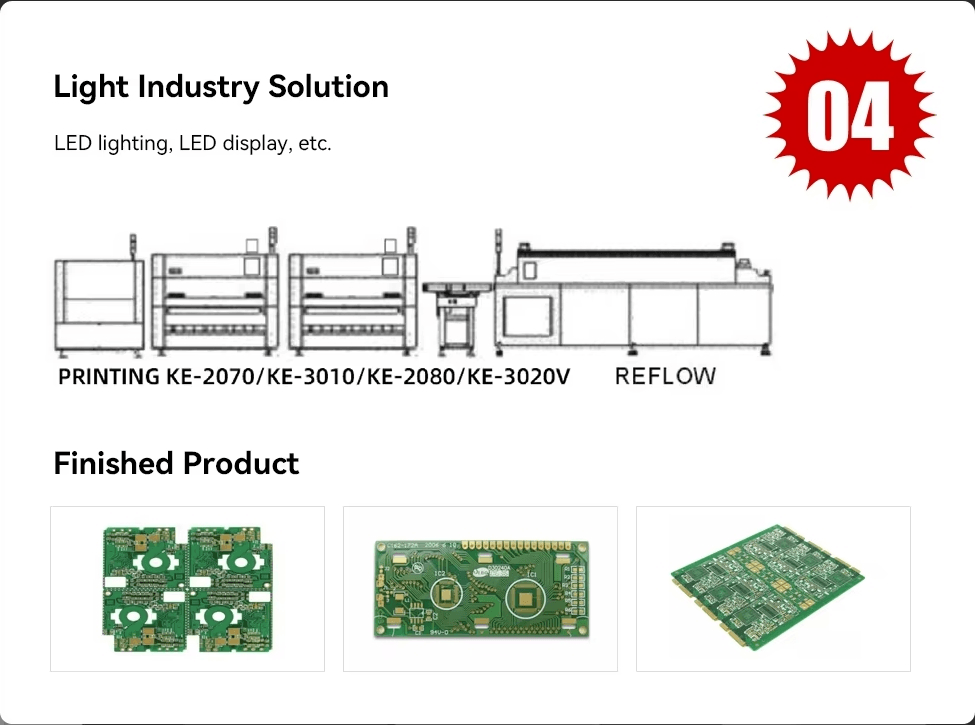

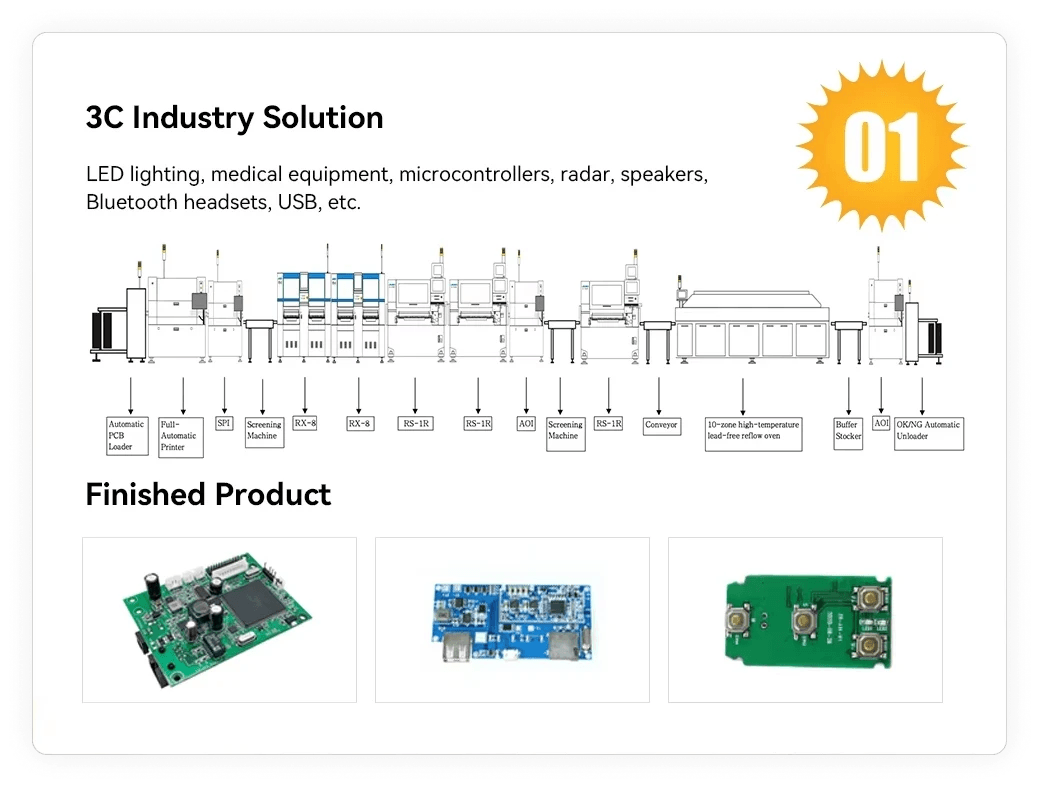

Importance of Pick and Place Machines

Pick and place machines play a pivotal role in the assembly process of LED PCBs by automating the placement of components with precision and speed. This automation not only enhances productivity but also reduces human error, ensuring that each SMD LED PCB board is manufactured to exact specifications. For manufacturers aiming to produce high-quality custom LED PCBs efficiently, investing in advanced pick and place technology is essential.

Benefits of Custom LED PCBs

Custom LED PCBs offer numerous advantages over standard designs, allowing businesses to tailor their products according to unique specifications and requirements. This customization can lead to improved performance, reduced costs through optimized layouts, and enhanced aesthetics that cater directly to consumer preferences—think sleek designs on your favorite LED PCB strip! By collaborating with experienced manufacturers who specialize in custom solutions, companies can unlock new potential in their lighting applications.

Overview of LED PCB Technology

In the vibrant world of electronics, LED PCBs stand out as a crucial component in modern lighting solutions. These specialized circuit boards are designed to host light-emitting diodes (LEDs), providing an efficient and effective way to deliver illumination. Understanding the ins and outs of LED PCB technology is essential for anyone involved in lighting design, manufacturing, or innovation.

What is a LED PCB

A LED PCB, or light-emitting diode printed circuit board, is a substrate that supports and connects multiple LEDs while also dissipating heat generated during operation. This unique combination allows for high-density arrangements of LEDs without compromising performance or lifespan. In essence, a well-designed LED PCB ensures that your lighting solutions shine bright and last longer, making it a favorite among manufacturers looking for reliable components.

Types of LED PCBs

When it comes to types of LED PCBs, variety is the spice of life! There are several forms available, including standard rigid boards, flexible circuits for custom applications, and even aluminum-backed designs for enhanced thermal management. Each type serves distinct purposes; for instance, an SMD LED PCB board allows surface-mounted devices to be easily placed and soldered on the board's surface—perfect for compact designs like LED PCB strips used in decorative lighting.

Applications of LED PCBs

The versatility of LED PCBs means they find their way into countless applications across various industries. From residential lighting solutions that enhance ambiance to industrial applications requiring robust illumination systems, these boards do it all! Additionally, with the rise in smart technology integration—think smart homes with customizable lighting—Custom LED PCBs have become increasingly popular as manufacturers seek tailored solutions that meet specific consumer needs.

The Role of Pick and Place Machines

In the world of LED PCB manufacturing, pick and place machines play a pivotal role in ensuring precision and efficiency. These machines automate the assembly process, placing components like SMD LED PCB boards onto printed circuit boards with remarkable accuracy. By eliminating manual errors, they significantly enhance the quality and speed of production for custom LED PCBs.

How Pick and Place Machines Work

Pick and place machines operate through a series of well-coordinated steps that ensure each component is placed accurately on the LED PCB. Initially, these machines use vision systems to identify the correct position for each SMD LED or other components based on pre-programmed layouts. Once identified, robotic arms equipped with suction cups or grippers pick up these parts from a feeder system and precisely place them onto the designated spots on the PCB.

The process is highly efficient; it can handle thousands of placements per hour while maintaining consistency across all units produced. This level of automation not only speeds up production times but also allows manufacturers to scale their operations without sacrificing quality. For companies looking to produce high volumes of LED PCB strips or custom LED PCBs, investing in a reliable pick and place machine becomes essential.

Advantages for LED PCB Manufacturing

The advantages offered by pick and place machines in LED PCB manufacturing are manifold. First off, they drastically reduce labor costs since fewer human operators are needed to oversee assembly lines filled with SMD LED PCB boards. Additionally, these machines minimize human error—ensuring that every component is correctly placed—leading to higher yield rates and less waste during production.

Another significant benefit lies in their ability to handle various component sizes and types seamlessly, making them perfect for manufacturers who specialize in diverse product lines including custom LED PCBs or specialized LED PCB strips. Furthermore, modern pick and place machines often come equipped with advanced software that allows for quick adjustments between different board designs without extensive downtime—a game-changer in today’s fast-paced manufacturing environment.

Key Features to Look For

When selecting a pick and place machine for your manufacturing needs, certain key features should be prioritized to ensure optimal performance in assembling your LED PCBs. First, consider the machine's placement accuracy; high precision is crucial when dealing with tiny SMD LEDs on compact boards like those found in custom designs or strips.

Next up is speed; look for models that can handle multiple placements per minute while maintaining quality control standards—this will enhance overall productivity significantly. Lastly, flexibility should be at the forefront; choose equipment capable of accommodating various component sizes as well as easy programming options that allow quick changes between different types of SMD LED PCB boards.

Selecting the Right SMD LED PCB Board

Choosing the right SMD LED PCB board is crucial for achieving optimal performance in your LED projects. A well-selected LED PCB can enhance efficiency, reduce heat, and extend the lifespan of your lighting solutions. With a plethora of options available, understanding what to prioritize is essential for both hobbyists and industry professionals alike.

Factors to Consider for SMD LED PCB

When selecting an SMD LED PCB, several factors should be at the forefront of your decision-making process. First and foremost, consider the thermal management capabilities; effective heat dissipation is vital for maintaining performance and longevity in any LED application. Additionally, evaluate the layout design—an efficient design can significantly impact light distribution and overall aesthetics of your LED PCB strip.

Another critical aspect is compatibility with various components; ensure that your chosen board supports the specific types of LEDs you plan to use. Pay attention to the size and dimensions as well; a compact design may be necessary for tighter spaces or intricate installations. Finally, don't overlook the importance of manufacturing quality—partnering with a reputable LED PCB manufacturer ensures reliability and durability in your final product.

Popular SMD LED PCB Manufacturers

Navigating through numerous manufacturers can feel overwhelming when searching for high-quality SMD LED PCBs. However, some names stand out due to their commitment to innovation and customer satisfaction. Companies like Bensun Technology have earned a reputation for producing exceptional custom LED PCBs that cater to diverse applications.

Others include established players such as OSRAM and Cree, known for their cutting-edge technology in lighting solutions and reliable products. Each manufacturer offers unique features; thus, it's wise to compare them based on your specific needs—whether you're looking for cost-effectiveness or advanced capabilities in your selected SMD LED PCB board.

Customization Options Available

Customization plays a pivotal role in ensuring that your SMD LED PCB meets all project requirements effectively. Many manufacturers provide tailored solutions that allow you to specify dimensions, layer counts, copper thicknesses, and even surface finishes on your custom LED PCBs. This flexibility not only enhances functionality but also allows designers greater freedom in creating innovative lighting solutions.

Moreover, some companies offer design assistance services where experienced engineers help refine specifications based on technical feasibility and cost-efficiency—making it easier than ever to bring creative ideas to life! Don't hesitate to explore these options when selecting an SMD LED PCB board; after all, customization can often mean the difference between ordinary illumination and extraordinary brilliance.

Bensun Technology: Your LED PCB Partner

When it comes to LED PCB solutions, Bensun Technology stands out as a reliable partner for businesses seeking high-quality products and services. With a focus on innovation and customer satisfaction, Bensun offers a range of services tailored to meet the diverse needs of the LED industry. Whether you are in search of custom LED PCBs or efficient manufacturing processes, Bensun has you covered.

Services Offered by Bensun Technology

Bensun Technology provides an impressive array of services designed specifically for the LED PCB market. From designing custom LED PCBs to manufacturing SMD LED PCB boards, they ensure that each product meets stringent quality standards. Additionally, their expertise extends to creating flexible LED PCB strips that cater to various applications, making them a go-to choice for many businesses.

Furthermore, their comprehensive prototyping services allow clients to test designs before full-scale production begins. This not only saves time but also ensures that the final product aligns perfectly with client specifications. With an emphasis on collaboration and communication, Bensun works closely with customers throughout the entire process to deliver exceptional results.

Quality Assurance Practices

Quality is paramount at Bensun Technology; they employ rigorous quality assurance practices at every stage of production. Each LED PCB undergoes thorough testing and inspection to guarantee reliability and performance in real-world applications. Their commitment to excellence means that customers can trust their SMD LED PCB boards will function flawlessly in any setting.

Bensun utilizes advanced technology and methodologies such as IPC standards compliance and automated inspection systems to maintain high-quality outputs consistently. By prioritizing quality assurance, they minimize defects and ensure that every custom LED PCB meets or exceeds industry expectations. This dedication not only enhances customer satisfaction but also solidifies Bensun's reputation as a leading LED PCB manufacturer.

Customer Success Stories

Bensun Technology has built a strong portfolio of success stories showcasing their impact on various industries through innovative LED solutions. One notable example involves partnering with an automotive company looking for efficient lighting solutions; through customized SMD LED PCBs, they significantly improved energy efficiency while reducing costs. The result was a state-of-the-art lighting system that enhanced both functionality and aesthetic appeal.

Another success story features collaboration with a smart home technology firm in need of flexible LED PCB strips for its products. By leveraging their expertise in custom designs, Bensun delivered tailored solutions that seamlessly integrated into the client's existing systems while providing superior performance and reliability. Such examples demonstrate how partnering with an experienced LED PCB manufacturer like Bensun can lead to remarkable outcomes across diverse applications.

Future Trends in LED PCB Assembly

The world of LED PCB assembly is on the brink of remarkable transformations, driven by continuous innovation and evolving consumer demands. As we look ahead, we can expect to see advancements that not only enhance the functionality and efficiency of LED PCBs but also redefine how they are used in various applications. This section explores the exciting future trends shaping the landscape of LED technology and its implications for manufacturers and consumers alike.

Innovations in LED Technology

Innovations in LED technology are paving the way for more efficient and versatile solutions, particularly in custom LED PCBs. One notable trend is the development of high-density SMD LED PCB boards that allow for compact designs without sacrificing performance. These advancements mean that manufacturers can create slimmer, more powerful products—think ultra-thin LED PCB strips that fit seamlessly into any design.

Moreover, new materials and techniques are enhancing thermal management capabilities within these boards, which is crucial for maintaining optimal performance over time. With improved heat dissipation methods, manufacturers can produce higher wattage LEDs while ensuring longevity and reliability. This innovation not only benefits product lifespan but also opens doors to applications previously deemed impractical due to heat constraints.

Lastly, integrating smart features into LEDs is becoming increasingly common—think dimming capabilities or color-changing options controlled via mobile apps. These features offer users unparalleled flexibility while creating opportunities for custom LED PCB designs tailored to specific needs or preferences.

The Rise of Smart Lighting Solutions

The rise of smart lighting solutions marks a significant shift in how we think about illumination—and it all starts with advanced LED PCBs. These systems utilize interconnected SMD LED PCB boards that communicate with one another through IoT technology, allowing users to control lighting remotely or set schedules based on their preferences. This level of control not only enhances convenience but also promotes energy efficiency by ensuring lights are only on when needed.

Furthermore, smart lighting solutions often incorporate sensors that adjust brightness based on ambient light conditions or occupancy detection—making them ideal for both residential and commercial spaces alike. Such innovations require high-quality manufacturing from reputable LED PCB manufacturers who understand the complexities involved in producing these sophisticated systems reliably.

As urban areas continue to evolve into smart cities, expect an increased demand for integrated lighting solutions powered by cutting-edge custom LED PCBs designed specifically for this purpose. The ability to customize each board will play a pivotal role in meeting diverse requirements across various environments—from streetlights to office buildings.

Predictions for the LED PCB Market

Looking ahead at predictions for the LED PCB market reveals a bright future filled with opportunities driven by technological advancements and growing consumer awareness regarding energy efficiency. Analysts forecast continued growth as industries adopt more sustainable practices—particularly as regulations surrounding energy consumption become stricter worldwide.

Additionally, with an increasing number of companies investing heavily in research and development focused on innovative SMD technologies, we can anticipate even greater efficiencies from future generations of led pcbs—resulting in lower costs per unit without compromising quality or performance standards expected from top-tier manufacturers.

Finally, customization will remain a key trend as businesses seek tailored solutions that meet specific needs rather than one-size-fits-all products available today—a shift likely supported by leading players like Bensun Technology who specialize in offering bespoke services alongside their standard offerings.

Conclusion

In the ever-evolving world of technology, maximizing efficiency in LED assembly is crucial for staying ahead of the competition. Utilizing advanced techniques like SMD LED PCB board design and custom LED PCB solutions can lead to enhanced performance and reduced production costs. By embracing these innovations, businesses can streamline their processes and improve product quality.

Maximizing Efficiency in LED Assembly

To maximize efficiency in LED assembly, manufacturers need to focus on integrating high-quality components with optimized designs. The use of a well-designed LED PCB strip can significantly enhance light output while minimizing energy consumption. Additionally, leveraging automated pick and place machines ensures precision placement of components on SMD LED PCB boards, further increasing production speed and accuracy.

The Evolution of LED PCB Manufacturing

The evolution of LED PCB manufacturing has been marked by rapid advancements in both technology and materials used. From traditional designs to more sophisticated custom LED PCBs that cater to specific applications, manufacturers are continuously innovating to meet market demands. As new technologies emerge, such as flexible circuits and improved thermal management solutions, the landscape of LED PCBs will continue to change dramatically.

Partnering with Experts in the Field

Partnering with an experienced LED PCB manufacturer is essential for businesses looking to thrive in this competitive market. These experts not only provide high-quality products but also offer valuable insights into design optimization and industry trends. By collaborating with specialists who understand the intricacies of SMD LED PCB boards and custom designs, companies can ensure they are making informed decisions that lead to successful outcomes.