Introduction

In the ever-evolving world of electronics, LED technology stands out as a beacon of innovation and efficiency. With various types of LEDs available, understanding the distinctions between them is crucial for designers and engineers alike. This guide will delve into the fascinating universe of surface mount devices (SMD) LED and through-hole LEDs, shedding light on their applications and advantages.

Understanding LED Types and Applications

LEDs come in various forms, each tailored for specific uses in electronic devices. Surface Mount LEDs (SMD LEDs) are compact, versatile components that are ideal for high-density PCB layouts, while traditional through-hole LEDs offer robust connections suitable for prototyping and DIY projects. By grasping the nuances of these types of SMD LED, you can make informed decisions that optimize both performance and design.

Why Choose Between Through-hole and Surface-mount

The choice between through-hole and surface-mount technologies can significantly impact your project's success. While through-hole LEDs provide ease of handling during assembly due to their larger size, Surface Mount LED options allow for more efficient use of space on a PCB—perfect for modern electronics demanding miniaturization without sacrificing functionality. Understanding these differences is key to selecting the right type for your specific application.

The Role of Bensun Technology in LED Solutions

Bensun Technology emerges as a leader in providing innovative LED solutions tailored to diverse needs across industries. With a wide array of products including various types of SMD LED, Bensun ensures that customers have access to cutting-edge technology coupled with expert support. By choosing Bensun Technology, you gain not only quality products but also valuable insights into optimizing your designs with both surface mount device LEDs and traditional options.

Overview of Through-hole LEDs

Through-hole LEDs have been a staple in the electronics industry for decades, providing reliable performance and ease of use. Unlike their sleek surface mount counterparts, these LEDs feature long leads that are inserted into holes on a printed circuit board (PCB) and soldered in place. This traditional design not only makes them easy to handle but also allows for robust connections that can withstand mechanical stress.

Definition and Characteristics

Through-hole LEDs are characterized by their cylindrical shape and protruding leads, which facilitate straightforward installation onto a PCB. These LEDs come in various sizes and colors, making them versatile for different applications. Their construction typically includes a plastic housing that protects the internal components while allowing light to emit effectively.

Common Uses in Electronics

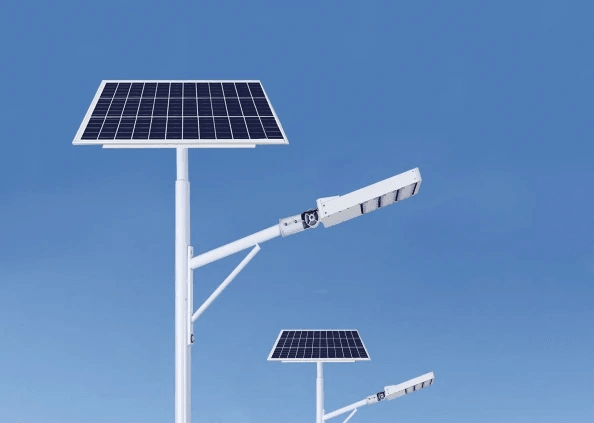

You’ll find through-hole LEDs lighting up everything from simple electronic devices to complex machinery. They are commonly used in indicator lights, displays, and even as backlighting solutions due to their visibility from various angles. Their ability to handle higher power levels also makes them suitable for applications requiring brighter illumination.

Advantages Over Surface Mount

One of the standout advantages of through-hole LEDs is their durability; they are less prone to damage during handling or assembly compared to surface mount devices like Surface Mount LED options. Additionally, they provide easier access for repairs or replacements due to their size and lead structure—ideal for prototyping or DIY projects where adjustments may be necessary. Furthermore, through-hole technology allows for better thermal management since they can dissipate heat more effectively than many Types of SMD LED configurations.

Exploring Surface Mount LEDs

Surface Mount LEDs have revolutionized the lighting and electronics industries, offering a compact and efficient alternative to traditional lighting methods. These tiny powerhouses are designed to be mounted directly onto the surface of printed circuit boards (PCBs), making them ideal for modern electronic devices that demand space efficiency and performance. With various types of SMD LED available, they cater to a wide range of applications, from consumer electronics to industrial lighting solutions.

Definition and Characteristics

A Surface Mount LED is a type of light-emitting diode that is soldered directly onto the surface of a PCB rather than through holes like traditional LEDs. This design allows for a much smaller footprint, enabling more flexibility in circuit design and layout. The characteristics of SMD LEDs include high brightness levels, low power consumption, and excellent thermal management properties, which contribute to their growing popularity in various applications.

Benefits of Surface Mount Technology

One of the standout benefits of Surface Mount Technology (SMT) is its ability to save space without sacrificing performance. By utilizing smaller components like Surface Mount LEDs, manufacturers can create sleeker designs while also increasing component density on PCBs. Furthermore, SMT allows for automated assembly processes, reducing labor costs and production times—an attractive proposition for businesses looking to optimize their operations.

Ideal Applications for SMD LEDs

Surface Mount LEDs are incredibly versatile and can be found in an array of applications across multiple industries. They are commonly used in automotive lighting systems due to their durability and efficiency; think dashboard indicators or headlight assemblies that require reliable illumination under varying conditions. Additionally, you’ll find these tiny luminaries in consumer electronics like smartphones and televisions where space is at a premium—proving that sometimes good things come in small packages!

Comparing Performance Metrics

When it comes to choosing between through-hole and surface mount LEDs, performance metrics play a pivotal role in the decision-making process. Factors such as brightness, efficiency, heat dissipation, longevity, and reliability can significantly influence which type of LED is best suited for your specific application. In this section, we’ll dive deep into these aspects to help you make an informed choice.

Brightness and Efficiency Differences

Brightness levels in LEDs can vary widely based on the type of LED technology employed. Surface Mount LEDs (SMD LEDs) are often designed to emit higher lumens per watt compared to their through-hole counterparts due to their compact size and efficient light extraction techniques. This increased efficiency translates into better performance in applications that require high brightness without consuming excessive power—an essential consideration for any lighting project.

Furthermore, the types of SMD LED available provide varying brightness options that cater to different needs—from subtle ambient lighting to intense task illumination. The ability of surface mount device LEDs to integrate seamlessly into a variety of designs also enhances their appeal; they can often be placed closer together on a Surface Mount LED PCB for uniform light distribution without sacrificing efficiency or brightness levels. Ultimately, if you're after superior brightness and energy savings, SMDs are hard to beat.

Heat Dissipation Considerations

Heat management is crucial when discussing LED performance metrics because excessive heat can significantly shorten an LED's lifespan and affect its output quality. Through-hole LEDs typically have larger thermal masses that allow them to dissipate heat more effectively than surface mount device LEDs at first glance; however, advancements in SMD technology have led to improved thermal management solutions tailored for these compact components.

In many cases, modern Surface Mount LED PCBs are designed with integrated heat sinks or thermal vias that facilitate better heat dissipation than older models did. This means that while traditional through-hole designs might initially seem more robust in terms of heat management, many contemporary SMD solutions offer comparable—or even superior—heat dissipation capabilities when properly engineered.

Longevity and Reliability

Longevity is another critical metric when comparing through-hole versus Surface Mount LEDs; generally speaking, both types boast impressive lifespans due to their solid-state nature. However, surface mount device LEDs tend to show greater resilience against environmental factors like vibrations or shocks due to their low profile and soldered connections directly onto the PCB surface—reducing mechanical stress points compared with through-hole variants.

Moreover, the manufacturing processes used for Types of SMD LED often lead to improved reliability since they minimize potential failure points associated with traditional leads found in through-hole designs. With proper design considerations taken into account—such as appropriate thermal management strategies—Surface Mount LEDs can offer exceptional longevity along with consistent performance over time.

Cost Analysis: Through-hole vs Surface-mount

When evaluating the cost implications of through-hole versus surface-mount LEDs, it's essential to consider both initial investments and long-term value. While through-hole LEDs may have a lower upfront cost, the advantages of a Surface Mount LED can lead to significant savings over time. Understanding these financial dynamics helps in making informed decisions for your electronic projects.

Initial Investment vs Long-term Value

The initial investment for a surface mount device LED is often higher than that for traditional through-hole options due to the advanced technology and materials involved. However, this upfront cost can be offset by the long-term benefits that come with using Surface Mount LEDs, such as reduced power consumption and longer lifespans. Over time, these factors contribute to lower operational costs, making Surface Mount LED PCB applications more economically viable in many scenarios.

In contrast, while through-hole LEDs are generally less expensive initially, they may not be as efficient or durable as their surface mount counterparts. The longevity of Surface Mount LEDs means fewer replacements and maintenance costs down the line. Therefore, when considering total cost of ownership, investing in high-quality surface mount devices often proves more beneficial.

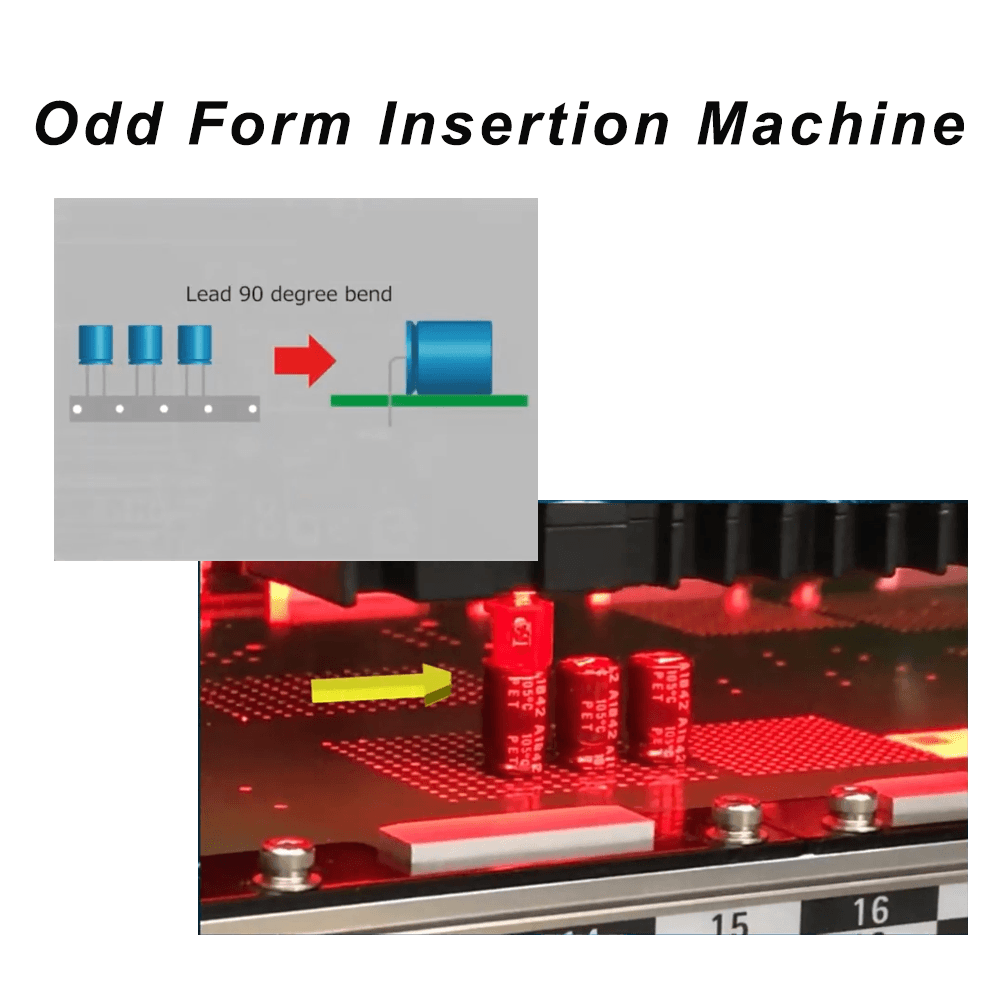

Production and Assembly Cost Differences

Production costs also vary significantly between through-hole and surface-mount technologies due to differences in manufacturing processes. Surface Mount LED PCBs allow for automated assembly techniques that streamline production lines, which can drastically reduce labor costs compared to manual soldering required for through-hole components. This efficiency not only speeds up production but also minimizes human error during assembly.

Furthermore, the compact nature of SMD technology enables more efficient use of space on printed circuit boards (PCBs), allowing manufacturers to fit more components into smaller areas without compromising performance. This density can lead to savings on materials and shipping costs as well since smaller boards are generally lighter and easier to transport. In contrast, larger PCB layouts required for through-hole components may incur additional expenses related to material usage and logistics.

Case Studies of Cost-effective Solutions

Several companies have successfully transitioned from through-hole technologies to using Types of SMD LED in their products with impressive results in terms of cost-effectiveness. For instance, a leading automotive manufacturer found that switching from traditional lighting solutions to Surface Mount LEDs not only reduced their production time but also cut their energy consumption by 30%. This shift resulted in significant savings over several years while enhancing product reliability.

Another example comes from consumer electronics where a company redesigned its product line utilizing Surface Mount LED technology instead of bulky through-hole designs. The new design allowed them to produce slimmer devices without sacrificing functionality or performance while reducing overall production costs by nearly 20%. These case studies illustrate how adopting surface mount devices can lead not only to immediate financial benefits but also pave the way for innovation and improved product offerings.

Design Considerations for LED Selection

When it comes to selecting the right LED for your project, design considerations play a crucial role, especially when dealing with Surface Mount LEDs. The layout of your PCB can significantly impact the performance and efficiency of Surface Mount LED installations. Understanding how to effectively incorporate these devices into your designs will allow you to maximize their potential while minimizing issues.

PCB Layout Impact with Surface Mount LED

The arrangement of components on a Surface Mount LED PCB is vital for ensuring optimal performance. A well-planned layout can enhance heat dissipation and improve electrical connectivity, which are essential for the longevity of surface mount device LEDs. Additionally, proper spacing between SMD LEDs and other components helps prevent interference and ensures that each light source shines at its best.

When designing a PCB for Surface Mount LEDs, it's important to consider the footprint of each type of SMD LED you plan to use. Different types of SMD LEDs come in various sizes and shapes; therefore, understanding their dimensions will help you avoid overcrowding the board. Moreover, using simulation tools during the design phase can help visualize how different layouts affect overall performance.

Lastly, take into account any additional features such as vias or thermal pads that may be necessary when integrating these devices into your PCB design. These elements can further enhance heat management and signal integrity, ensuring that your surface mount device LEDs operate efficiently without overheating or failing prematurely.

Space and Size Constraints

One major advantage of using Surface Mount LEDs is their compact size, which allows for greater flexibility in design compared to traditional through-hole options. However, this compactness also brings challenges related to space constraints on PCBs. Designers must carefully assess available real estate on their boards while considering other components' placements.

The small footprint of surface mount device LEDs means they can fit into tight spaces where larger components cannot go, making them ideal for portable electronics or densely packed devices. However, cramming too many components onto a single board can lead to issues such as reduced airflow and increased heat buildup around SMDs—factors that could negatively impact performance over time. Therefore, striking a balance between maximizing space usage and maintaining adequate thermal management is essential.

Additionally, designers should consider future scalability when planning their layouts; leaving room for expansion might save headaches later if new features or enhancements are desired down the road! Planning ahead ensures that even with limited space now, there’s potential growth without compromising functionality or aesthetics.

Integration with Other Components

Integrating Surface Mount LEDs with other electronic components requires careful consideration to ensure compatibility and functionality throughout the circuit design process. The electrical characteristics of SMDs may differ from those of through-hole counterparts; thus understanding voltage requirements is key to avoiding mismatches during integration efforts. This knowledge helps prevent short circuits or component damage resulting from improper connections.

Moreover, attention must be paid not just to electrical compatibility but also mechanical aspects when placing surface mount device LEDs alongside capacitors or resistors on a PCB layout—ensuring there’s enough clearance between parts reduces risks associated with soldering defects during assembly processes! Proper integration also involves considering how light emitted by an SMD interacts with surrounding materials; choosing appropriate lenses or diffusers enhances visibility while maintaining aesthetic appeal.

Lastly, don’t overlook communication protocols if integrating smart features like dimming capabilities or color-changing options within your designs! Ensuring seamless interaction among all elements leads ultimately towards creating high-quality products that function reliably under diverse conditions—making every detail count!

Conclusion

In wrapping up our exploration of LED types, it’s clear that both through-hole and surface mount technologies have unique advantages and applications. The choice between these types often hinges on specific project requirements, such as space constraints and assembly processes. Understanding the characteristics of each can lead to more informed decisions when designing electronic circuits.

Key Takeaways on LED Types

Through-hole LEDs are typically easier to handle during assembly and provide robust durability, making them ideal for prototyping or applications requiring frequent replacements. On the other hand, surface mount devices (SMD) offer a sleek design and are favored in modern electronics for their compact size and efficiency. Ultimately, recognizing the various types of SMD LED can streamline your design process and enhance product performance.

Making Informed Choices for Your Needs

When deciding between through-hole and Surface Mount LED options, consider factors like PCB layout impact, space availability, and integration with other components. The versatility of Surface Mount LED technology allows for innovative designs but requires careful planning to maximize efficiency. Evaluating your project’s specific needs will help you select the best type of LED that balances performance with practicality.

How Bensun Technology Can Help You

Bensun Technology stands out in providing tailored solutions for both through-hole and Surface Mount LEDs, ensuring you find exactly what you need for your project. With extensive expertise in manufacturing various types of SMD LED products, they can guide you toward optimal choices that fit your design specifications perfectly. By partnering with Bensun Technology, you gain access to cutting-edge innovations in LED solutions that can elevate your electronic designs.