Introduction

In the world of electronics, quality solder is not just a luxury—it's a necessity. The best solder for circuit boards can mean the difference between a reliable product and one that fails at the worst possible moment. Whether you're working with lead solder or exploring modern lead-free options, understanding the nuances of solder and flux is crucial for achieving strong, lasting connections.

What Makes Quality Solder Important

Quality solder ensures that electrical connections are solid and durable, which is essential for any circuit board's performance. Poor-quality solder can lead to weak joints, increased resistance, and ultimately device failure, making it imperative to choose wisely among available options. Additionally, understanding how solder flux interacts with different types of solder can enhance your overall soldering experience.

Understanding Solder and Flux Basics

Solder is an alloy that melts to create a bond between electronic components on a circuit board, while flux serves as a cleaning agent that prepares surfaces for this bond. Together, they play an integral role in surface mount soldering as well as PCB to PCB soldering techniques. Familiarizing yourself with various types of solders—including lead-based and lead-free alternatives—will empower you to make informed decisions when selecting materials for your projects.

Top Trends in Circuit Board Soldering

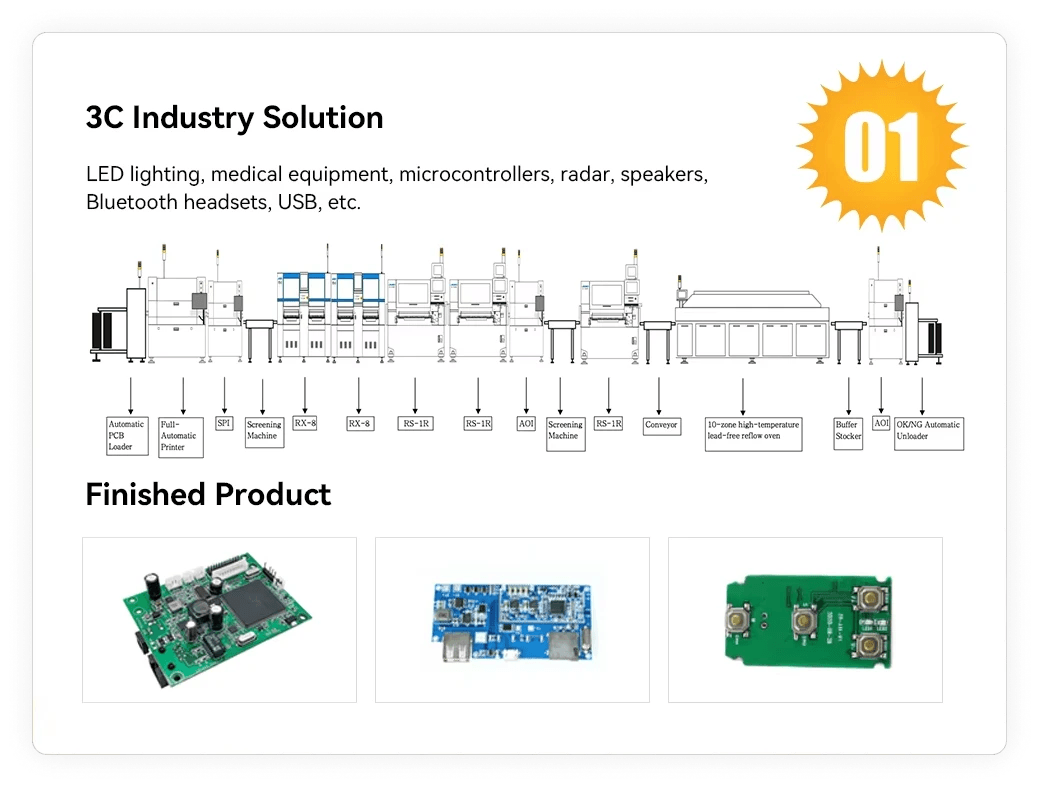

As technology evolves, so do the practices surrounding circuit board assembly and repair. One notable trend is the growing preference for lead-free solders due to environmental regulations and health concerns associated with lead exposure. Additionally, advancements in circuit board soldering tools are making it easier than ever to achieve precision in both surface mount and traditional through-hole applications.

The Best Solder Types for Circuit Boards

Lead Solder: Pros and Cons

Lead solder has been a staple in electronics for decades, known for its excellent thermal conductivity and ease of use. One of its primary advantages is that it melts at a lower temperature than many alternatives, making it suitable for delicate components during surface mount soldering. However, despite its favorable properties, lead solder poses health risks due to lead exposure, leading to increased regulations and a push towards safer alternatives.

The cons don’t stop there; many manufacturers are now moving away from lead-based solders in favor of more environmentally friendly options. While some enthusiasts still swear by lead solder for its reliability, others argue that the long-term benefits of adopting safer materials outweigh the short-term gains. In conclusion, understanding both sides helps you make an informed decision on whether to use lead solder or explore other avenues.

The Rise of Lead-Free Options

In recent years, there has been a significant shift towards lead-free options in circuit board manufacturing due to regulatory pressures and environmental concerns. These solders typically contain tin combined with other metals like silver or copper to enhance performance while eliminating harmful substances like lead. Although they may require higher temperatures during PCB to PCB soldering processes, advancements in technology have made these solders increasingly effective.

The best solder for circuit boards today often includes these innovative formulations that provide strong mechanical bonds without compromising safety standards. Moreover, as manufacturers continue refining these materials, their reliability matches or even surpasses traditional lead-based solders in many applications. Embracing these changes not only aligns with regulatory requirements but also promotes sustainability within the electronics industry.

Solder Flux: Enhancing Your Joints

Solder flux plays an essential role in ensuring strong connections during any type of circuit board assembly—be it surface mount or through-hole techniques. By cleaning metal surfaces and preventing oxidation during heating processes, flux allows for better adhesion between the solder and components on your PCB. This results in improved electrical conductivity and longevity of your joints.

There are various types of flux available today—rosin-based being one of the most common—each catering to different applications and preferences among hobbyists and professionals alike. When used appropriately alongside quality solders (both lead-based and lead-free), solder flux can dramatically enhance joint integrity while reducing defects associated with poor connections. Ultimately, investing time into understanding how to effectively use both solder and flux will elevate your overall circuit board soldering game.

Surface Mount Soldering Essentials

Surface mount soldering (SMT) has revolutionized the way we assemble circuit boards, allowing for smaller, more efficient designs. To achieve optimal results in SMT, it's crucial to equip yourself with the right tools and techniques. Whether you're a hobbyist or a professional, understanding the essentials of surface mount soldering will enhance your PCB projects significantly.

Tools for Surface Mount Soldering

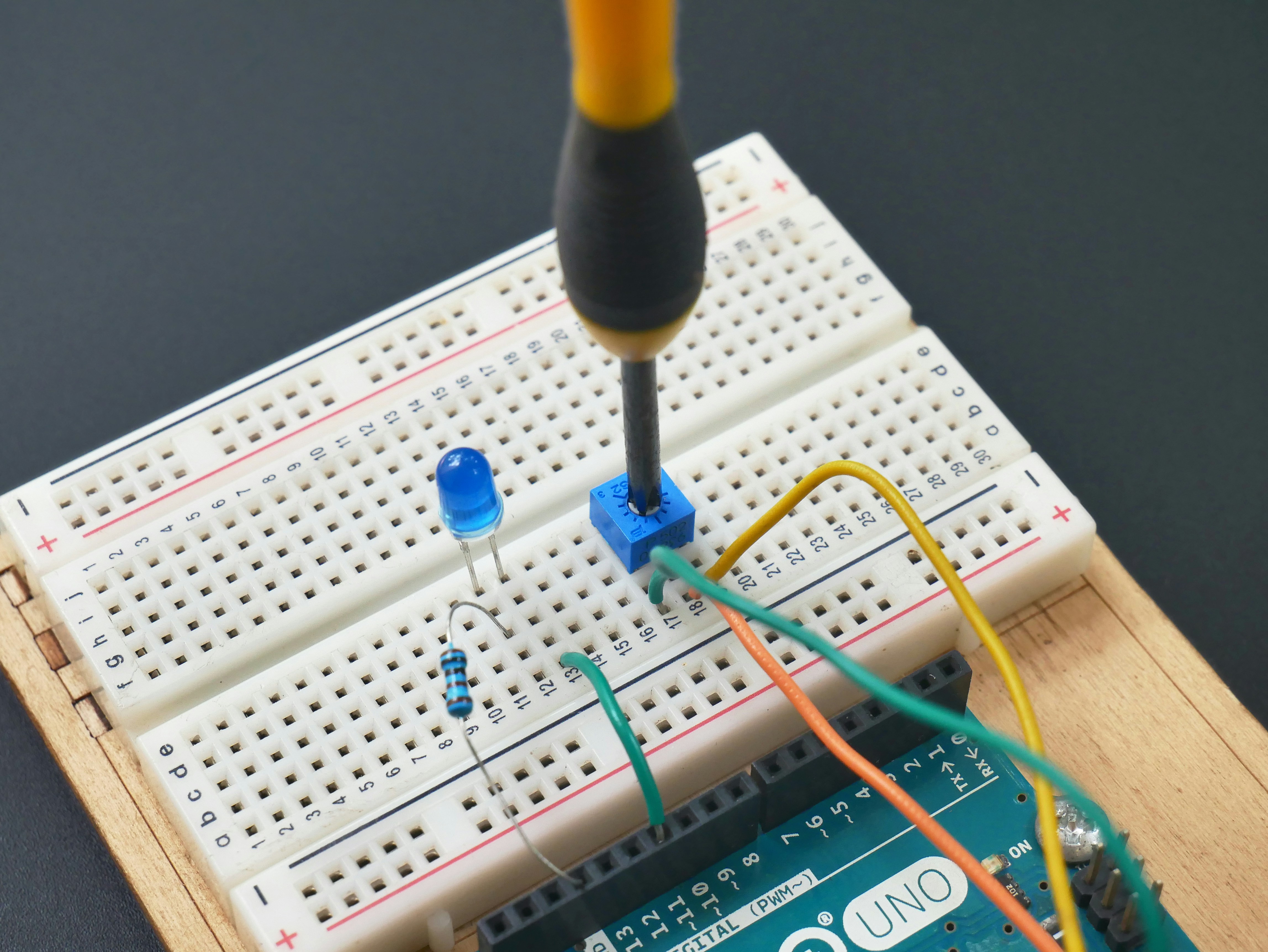

Essential tools include precision tweezers for handling tiny components, a hot air rework station for desoldering and soldering without damage, and a microscope or magnifying lamp to ensure accuracy during assembly. Additionally, investing in quality solder flux is vital as it improves adhesion and conductivity while minimizing oxidation during the process.

For those serious about their SMT projects, consider adding a good quality soldering iron with adjustable temperature settings to your toolkit. This allows you to select the best solder for circuit boards based on your specific needs—be it lead-free or traditional lead solder. Remember that every tool plays its part; neglect one and you might end up with unsightly cold joints or worse!

Techniques for Successful SMT

Start by ensuring that both your PCB and components are clean; any residue can interfere with effective bonding between the solder and flux used in your joints. Next, apply an appropriate amount of flux before placing components on the board; this helps facilitate smooth flow when heat is applied.

Once everything is positioned correctly, use either a fine-tipped iron or hot air tool to carefully heat each joint until you see that shiny finish indicating good wetting of the best solder for circuit boards being used. Patience is key; rushing through this step can lead to mistakes like bridging connections between pads—something every SMT enthusiast dreads! Finally, always double-check your work under magnification before moving on; prevention is better than correction!

Choosing the Right Solder for SMT

Selecting the best solder for circuit boards designed for surface mount applications requires careful consideration of various factors including composition and melting point. Lead-free solders have gained popularity due to environmental regulations but often require higher temperatures compared to traditional lead solder options—something worth noting if you're working with heat-sensitive components!

Additionally, consider using low-temperature solders specifically formulated for delicate applications where overheating could be detrimental—this ensures that even sensitive parts remain intact during assembly processes like pcb to pcb soldering tasks. Don’t forget about compatibility with your chosen flux; using them together effectively can greatly enhance joint reliability over time.

In conclusion, understanding these essential aspects of surface mount soldering will empower you in creating reliable electronic assemblies that stand up against time and usage demands.

PCB to PCB Soldering Techniques

The Importance of Compatibility

Compatibility in soldering materials is paramount for achieving optimal results in circuit board soldering. Using the best solder for circuit boards means selecting options that work harmoniously with various substrates and finishes, such as ENIG or HASL. If you mix incompatible materials, you risk encountering issues like poor adhesion or oxidation, which can lead to joint failure over time.

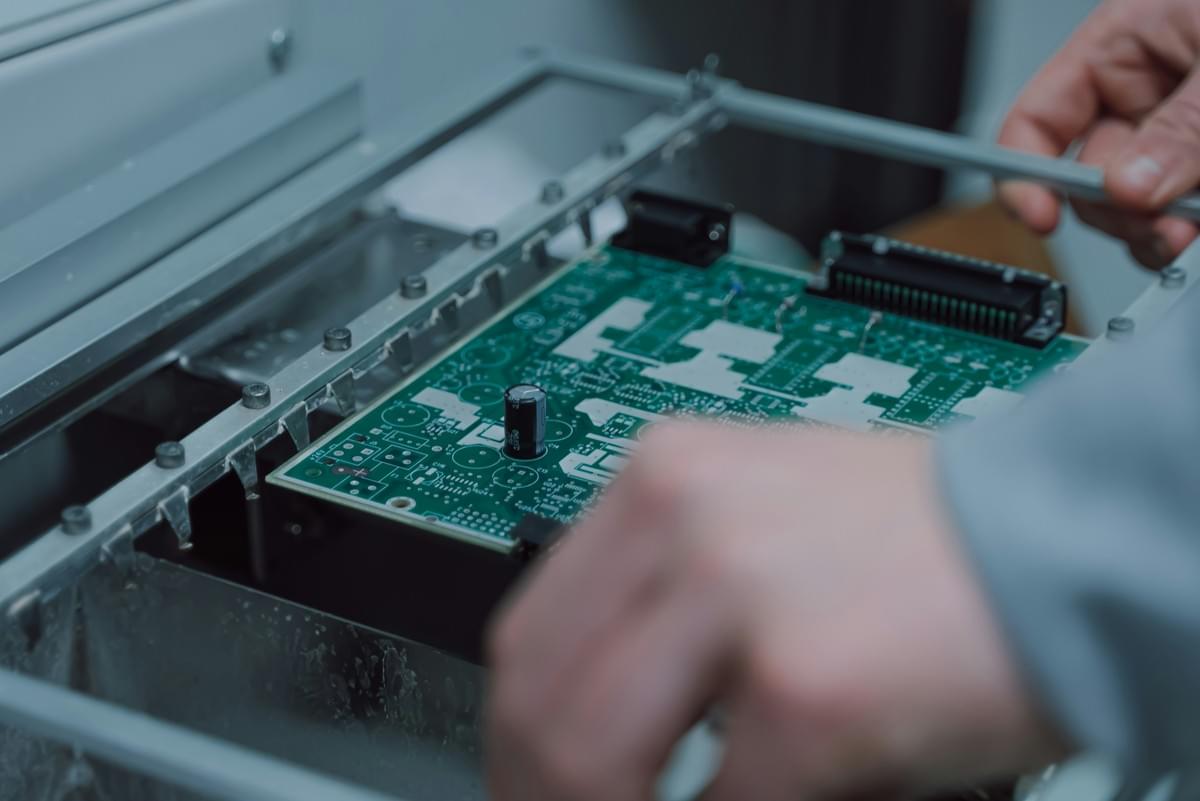

Preparing Your Boards for Soldering

Preparation is key when it comes to successful PCB to PCB soldering. Start by cleaning the surfaces thoroughly; any dust or grease can hinder the effectiveness of your solder and flux application. Once clean, ensure that both boards are properly aligned before applying heat; this will help maintain precision during the process and result in stronger connections.

Tools Needed for PCB Connections

Having the right tools at your disposal makes all the difference in executing effective PCB connections. Essential circuit board soldering tools include high-quality soldering irons, precise nozzles for surface mount soldering, and effective solder flux for enhancing joint quality. Investing in these tools not only streamlines your workflow but also ensures that you're using the best practices when tackling complex circuitry.

Soldering Tools You Can’t Live Without

When it comes to circuit board soldering, having the right tools can make all the difference between a flawless connection and a frustrating mess. The best solder for circuit boards is only as effective as the tools you use to apply it. Investing in quality soldering tools not only enhances your efficiency but also ensures that your solder and flux work harmoniously to create strong, reliable joints.

Recommended Circuit Board Soldering Tools

To achieve optimal results in circuit board soldering, you’ll need a solid toolkit. Essential tools include a high-quality soldering iron with adjustable temperature settings, which allows for versatility when working with various types of solder, including lead solder and lead-free options. Additionally, a good pair of tweezers is invaluable for handling small components during surface mount soldering (SMT), while wire cutters help tidy up excess leads after PCB to PCB soldering.

Don’t overlook the importance of a reliable desoldering pump or wick; mistakes happen even to the best of us! These handy gadgets allow you to correct errors without damaging your circuit boards. Lastly, investing in proper safety gear—like anti-static wrist straps—will protect both you and your sensitive electronic components from static discharge.

Understanding Soldering Stations

A well-equipped soldering station can elevate your circuit board soldering game significantly. Unlike standalone irons, these stations offer features such as temperature control and built-in stands that keep everything organized while you work on your projects. A good station will also often come with interchangeable tips suited for different tasks—essential when switching between lead-free solders or tackling intricate surface mount connections.

With advanced models offering digital displays for precise temperature readings, you'll have better control over your process, ensuring that you're using the best solder for circuit boards effectively without risking damage from overheating. Plus, many modern stations are designed with ergonomic considerations in mind, making long hours of PCB to PCB soldering much more comfortable.

Importance of Quality Tips and Nozzles

Quality tips and nozzles are crucial components that can dramatically affect your success with any type of circuit board project. Using high-grade tips ensures efficient heat transfer and longevity; after all, nobody wants their tip wearing out mid-project! Whether you're working on delicate SMT tasks or robust lead solder applications, having the right tip shape can make precision work easier by allowing better access to tight spaces on complex PCBs.

Nozzles play an equally important role when using hot air rework stations for surface mount applications; they help direct airflow precisely where it's needed most while minimizing collateral damage to adjacent components. Remember: investing in quality tips and nozzles means fewer headaches down the road—and who doesn’t want smoother sailing when tackling their next big project?

Partnering with Experts: Bensun Technology

When it comes to circuit board soldering, having a reliable partner can make all the difference. Bensun Technology stands out as a leader in providing comprehensive solutions tailored to meet your unique circuit board needs. Whether you're looking for the best solder for circuit boards or need assistance with solder flux, Bensun has you covered.

Comprehensive Solutions for Circuit Board Needs

Bensun Technology offers an impressive range of services and products designed specifically for the electronics industry. From sourcing high-quality lead solder to providing advanced surface mount soldering tools, they ensure that every aspect of your project is addressed. Their expertise in solder and flux applications means you can trust them to deliver optimal results every time.

In addition to offering various types of solder, including lead-free options, Bensun also provides guidance on selecting the right materials for your specific projects. This is crucial because using the wrong type of solder can lead to weak joints and unreliable connections, which is something no one wants in their PCB to PCB soldering tasks. With Bensun's comprehensive solutions, you'll have access to everything needed for successful circuit board assembly.

How Bensun Enhances Soldering Processes

Bensun Technology employs innovative techniques that enhance traditional soldering processes while ensuring quality and efficiency are maintained at all times. By utilizing state-of-the-art technology and equipment, they streamline operations that often bog down other manufacturers. This not only reduces production time but also improves the durability of your electronic assemblies.

Their approach includes training sessions on best practices in surface mount soldering and proper application techniques for different types of solder flux. This educational component empowers clients by ensuring they understand how to achieve optimal results with their chosen materials and tools. As a result, customers can expect not only high-quality products but also top-notch support throughout their projects.

Custom Services for Your Soldering Projects

One of the standout features of partnering with Bensun Technology is their ability to offer custom services tailored specifically to your project's requirements. Whether you need specialized formulations of lead-free solders or unique flux compositions that enhance adhesion, they have the flexibility to accommodate diverse needs effectively. Their team will work closely with you from start to finish, ensuring that every detail aligns perfectly with your expectations.

Furthermore, if you're venturing into complex PCB connections or require assistance with specific circuit board soldering tools, they provide expert consultation services as well. This personalized approach helps eliminate guesswork from the equation while maximizing efficiency during production runs—saving you both time and resources in the long run! With Bensun’s custom solutions at your disposal, you'll be well-equipped for any challenge that comes your way in electronic manufacturing.

Conclusion

In the world of circuit board soldering, understanding the nuances of solder and flux can significantly impact the quality and durability of your connections. From lead solder options to innovative lead-free alternatives, each choice comes with its own set of pros and cons that must be carefully considered. Ultimately, mastering these elements will help you achieve reliable joints that stand the test of time.

Key Takeaways on Solder and Flux

Solder flux plays a vital role in enhancing joint quality by preventing oxidation and ensuring better adhesion during the soldering process. By understanding how these components work together, you can make informed decisions that elevate your circuit board projects.

Finding the Right Tools for You

Equipping yourself with the right circuit board soldering tools is essential for achieving optimal results in your projects. Whether you’re diving into surface mount soldering or tackling PCB to PCB soldering tasks, having quality tools at your disposal will make all the difference in efficiency and effectiveness. Don’t underestimate the importance of investing in a good soldering station along with high-quality tips and nozzles designed for specific applications.

Future of Circuit Board Soldering Practices

As technology continues to evolve, so too will practices around circuit board soldering. The shift toward more environmentally friendly options like lead-free solders is just one example of how industry standards are changing to meet modern demands. Staying ahead of trends will not only enhance your skills but also ensure that you remain competitive in an ever-advancing field.