Introduction

In the fast-paced world of electronics, understanding PCB assembly and manufacturing is crucial for creating reliable devices. Printed Circuit Boards (PCBs) serve as the backbone of modern technology, enabling everything from smartphones to medical devices to function efficiently. As we dive into the intricacies of these processes, it becomes clear that both PCB manufacturing and assembly play vital roles in ensuring high-quality end products.

Understanding PCB Manufacturing

PCB manufacturing involves a series of intricate steps that transform raw materials into functional circuit boards. It starts with designing the layout, followed by etching copper onto a substrate and applying various layers to create a multi-layered board. The quality of this manufacturing process directly impacts the performance and reliability of the final product, making it essential for manufacturers to adhere to stringent standards.

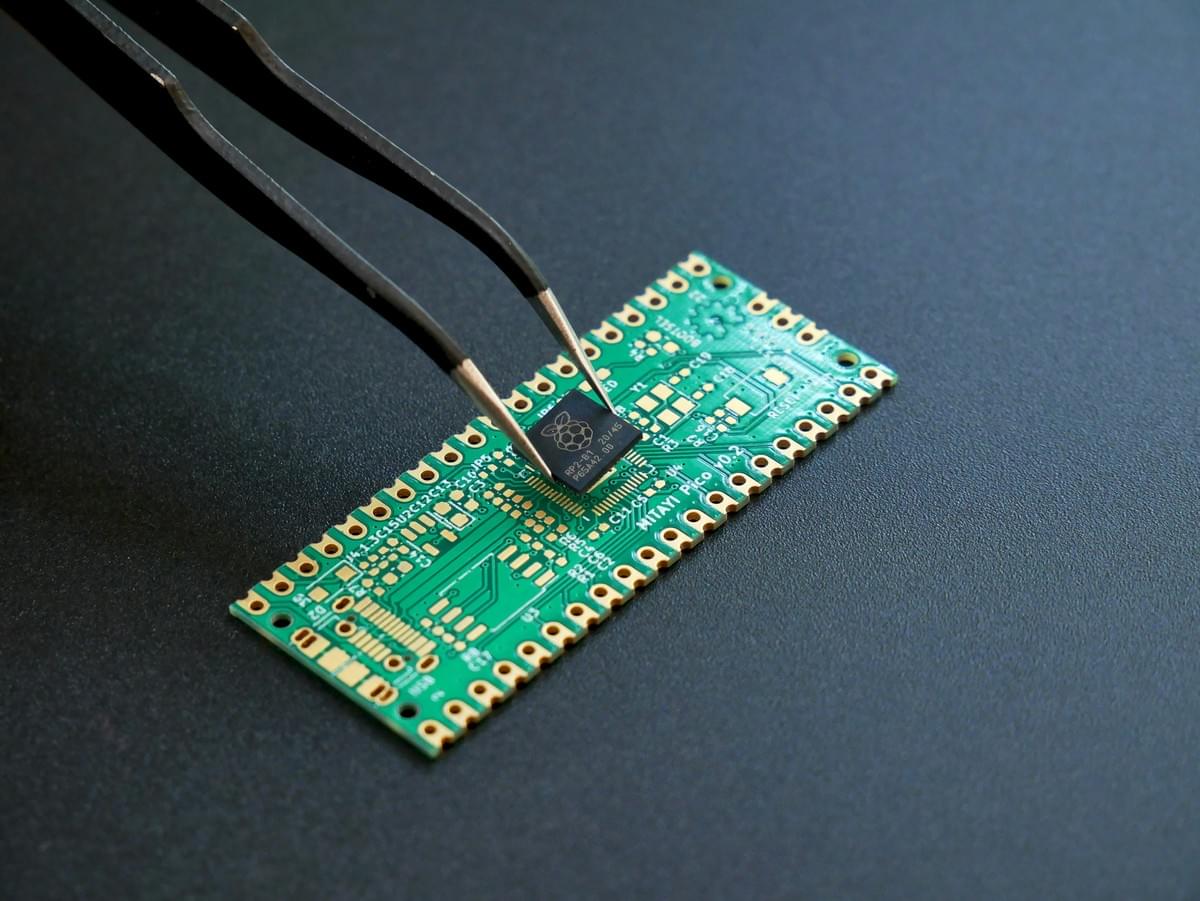

Exploring PCB Assembly

Once PCBs are manufactured, they undergo the PCB assembly process where electronic components are mounted onto the boards. This phase includes soldering components like resistors, capacitors, and integrated circuits onto the board's surface or within its layers. The efficiency of this PCB assembly line can significantly influence production timelines and cost-effectiveness while ensuring that all necessary PCB assembly components are correctly placed for optimal functionality.

Importance of Both Processes

The synergy between PCB manufacturing and assembly is paramount; without one, the other cannot thrive. Effective collaboration between these two processes ensures that products not only meet design specifications but also maintain high standards of quality throughout their lifecycle. Ultimately, selecting a reputable PCB assembly manufacturer can make all the difference in achieving superior performance in electronic devices.

What is PCB Manufacture?

PCB manufacturing is the foundational process that sets the stage for creating the printed circuit boards (PCBs) essential for modern electronics. It involves transforming raw materials into a functional board that can house various electronic components and facilitate their connections. Understanding this process is crucial, as it directly impacts the efficiency and reliability of the subsequent PCB assembly process.

The Basics of PCB Manufacture

At its core, PCB manufacture involves designing a layout that dictates where each component will be placed on the board. This design is then translated into physical layers using materials like fiberglass and copper, which are bonded together to create a multi-layered circuit board. The result is a sturdy platform ready for the intricate dance of soldering components during the PCB assembly process.

In essence, PCB manufacturing encompasses several critical steps, including etching circuits, drilling holes for component leads, and applying protective coatings to ensure durability. Each step must be executed with precision to avoid defects that could lead to failures in electronic devices down the line. Thus, a solid understanding of both theory and practice in PCB manufacturing ensures high-quality outcomes.

Key Steps in PCB Manufacturing

The journey of PCB manufacturing begins with designing schematics using specialized software followed by producing photomasks based on these designs. Next comes etching—where unwanted copper is removed from laminated sheets to form circuits—and drilling precise holes necessary for component placement. Finally, surface finishes are applied to enhance solderability and protect against corrosion before moving on to testing.

These key steps highlight how interconnected each phase of manufacturing is; any misstep can lead to issues during the later stages of assembly or even result in malfunctioning products altogether. Each layer built up during this process must adhere strictly to quality standards since they form the backbone upon which all subsequent operations depend—especially when considering how crucial these boards are within an entire assembly line.

Equipment Used in PCB Manufacture

In order to execute these intricate processes effectively, manufacturers rely on an array of specialized equipment designed specifically for PCB manufacture tasks. This includes photoplotters for creating high-resolution images used in etching processes and laser drills capable of making precise holes without damaging surrounding materials. Additionally, automated optical inspection (AOI) systems play a vital role by checking each board’s integrity before it progresses further along its journey toward becoming part of an electronic device.

Moreover, advancements in technology have led manufacturers towards adopting more sophisticated machinery such as computer numerical control (CNC) machines that enhance accuracy while reducing production time significantly compared with manual methods from years past. As technology continues evolving at breakneck speed so too does equipment used within this field; staying ahead means investing wisely into tools that streamline operations while ensuring top-notch quality throughout every step—from manufacture through final assembly by trusted PCB assembly manufacturers.

What is PCB Assembly?

PCB assembly is a critical phase in the electronics manufacturing process, where various components are mounted onto a printed circuit board (PCB) to create functional electronic devices. This process transforms bare PCBs into fully operational units that can be integrated into larger systems. Understanding the nuances of the PCB assembly process is essential for manufacturers aiming to produce high-quality electronic products.

The PCB Assembly Process Explained

The PCB assembly process involves several key steps that ensure components are accurately placed and soldered onto the board. It typically begins with surface mount technology (SMT), where components are placed on the surface of the PCB using automated pick-and-place machines. After placement, soldering techniques—either reflow or wave soldering—are employed to create secure electrical connections, completing the initial stage of assembly before moving on to testing and inspection.

Each step in the PCB assembly process is designed to maximize efficiency and minimize errors, making it crucial for manufacturers to adhere strictly to best practices. Quality control measures are implemented throughout this phase, ensuring that any defects are caught early before they escalate into larger issues down the line. Ultimately, a well-executed PCB assembly process leads to reliable products that meet industry standards and customer expectations.

Key PCB Assembly Components

Understanding key PCB assembly components is vital for anyone involved in electronics manufacturing. These components include resistors, capacitors, integrated circuits (ICs), connectors, and other essential parts that contribute to circuit functionality. Each component plays a specific role within an electronic device; for example, resistors control current flow while capacitors store energy.

In addition to these fundamental parts, there are also passive and active components that serve different functions within a circuit design. The right combination of these elements ensures optimal performance of the final product assembled on the PCB assembly line. Familiarity with these components not only aids in design but also assists manufacturers in selecting appropriate suppliers and managing inventory effectively.

The Role of PCB Assembly Manufacturers

PCB assembly manufacturers play an indispensable role in bringing electronic designs from concept to reality through efficient production processes and expertise in handling various types of assemblies. They provide services ranging from prototype development to high-volume production runs tailored specifically for different industries such as automotive, aerospace, consumer electronics, and medical devices.

These manufacturers often invest heavily in advanced technologies and skilled labor forces capable of executing complex designs while adhering strictly to quality standards throughout each stage of production on their dedicated PCB assembly lines. By collaborating closely with clients during design reviews and offering valuable insights based on industry experience, they help ensure that products not only function as intended but also meet market demands swiftly.

Comparing PCB Manufacture and Assembly

When diving into the world of electronics, understanding the distinction between PCB manufacturing and PCB assembly is crucial. While both processes are essential to creating functional electronic devices, they serve different purposes in the production pipeline. PCB manufacturing focuses on creating the printed circuit boards themselves, while PCB assembly involves placing components onto those boards to create a finished product.

Key Differences in Processes

The key differences between PCB manufacture and assembly lie primarily in their objectives and methodologies. PCB manufacturing encompasses the design and fabrication of the circuit board, including layering materials, etching circuits, and drilling holes for component placement. In contrast, the PCB assembly process involves taking these fabricated boards and populating them with various electronic components such as resistors, capacitors, and integrated circuits using specialized techniques on a dedicated PCB assembly line.

Another notable difference is in equipment usage; while manufacturing often employs large-scale machinery for etching and layering processes, assembly relies on precision tools like pick-and-place machines for accurate component placement. Additionally, the timelines differ: manufacturing can take longer due to material processing requirements, whereas assembly tends to be faster once components are ready. Understanding these distinctions helps clarify how each phase contributes uniquely to the overall production of electronic devices.

How They Work Together

PCB manufacture and assembly are two sides of the same coin—each dependent on the other for successful product completion. The quality of a finished electronic device hinges on both well-manufactured PCBs and meticulous assembly processes that ensure all components fit perfectly onto those boards. Collaboration between manufacturers and assemblers ensures that any design specifications or adjustments needed during production can be swiftly addressed.

Moreover, effective communication between PCB manufacturers and assembly manufacturers can lead to improved efficiency throughout both processes. For instance, if a manufacturer identifies an issue during fabrication that could affect component placement later on in the PCB assembly process, they can proactively collaborate with assemblers to find solutions before it becomes a larger problem down the line. This synergy not only streamlines operations but also enhances overall product reliability.

Impact on Product Quality

The impact of both PCB manufacture and assembly on product quality cannot be overstated; together they form a critical foundation for reliable electronics. High-quality manufacturing translates into durable PCBs that withstand environmental stressors while maintaining performance integrity over time. Conversely, precise execution during the PCB assembly process ensures that each component functions harmoniously within its designated role.

Moreover, rigorous quality control measures implemented at both stages help catch potential defects early—whether that's an improperly etched circuit or poorly aligned components during soldering on a PCB assembly line—ultimately safeguarding against costly recalls or failures post-production. As technology evolves with advanced inspection methods like automated optical inspection (AOI), manufacturers are better equipped than ever to uphold high standards throughout both manufacture and assembly phases.

Equipment in PCB Assembly

The equipment used in the PCB assembly process is crucial for ensuring that electronic components are accurately placed and soldered onto printed circuit boards. A well-equipped PCB assembly line can dramatically enhance efficiency, reduce errors, and ultimately contribute to the overall quality of the final product. Understanding the essential tools and advanced technologies involved in PCB assembly can empower manufacturers to optimize their processes.

Essential Tools for PCB Assembly

In any successful PCB assembly process, several essential tools play a pivotal role. Soldering irons and reflow ovens are at the forefront, facilitating precise connections between components and circuit boards. Additionally, pick-and-place machines automate the placement of PCB assembly components with incredible speed and accuracy, minimizing human error and increasing productivity on the assembly line.

Other indispensable tools include inspection equipment such as AOI (Automated Optical Inspection) systems that ensure every component is correctly positioned before soldering occurs. This level of scrutiny helps catch potential issues early in the manufacturing process, leading to higher-quality outcomes. By utilizing these essential tools effectively, a PCB assembly manufacturer can streamline operations while maintaining high standards of excellence.

Advanced Technologies in PCB Assembly

As technology evolves, so does the landscape of PCB assembly processes. Advanced technologies like 3D printing are making waves by allowing rapid prototyping of complex geometries that traditional methods struggle with. Furthermore, robotics have become integral to modern PCB assembly lines; they enhance precision while reducing labor costs associated with manual handling.

Another exciting development is smart manufacturing technology that employs IoT (Internet of Things) devices for real-time monitoring and data analysis throughout the production cycle. This ensures optimal performance by identifying bottlenecks or inefficiencies instantly so adjustments can be made on-the-fly. With these advanced technologies integrated into their processes, manufacturers can achieve unprecedented levels of efficiency and product quality in their PCB assembly operations.

Introduction to Bensun Technology Solutions

Bensun Technology Solutions stands out as a leader in providing innovative solutions for both PCB manufacturing and assembly needs. With a commitment to quality control and cutting-edge technology integration, Bensun ensures that every stage of the PCB assembly process meets rigorous industry standards. Their state-of-the-art facilities are equipped with all essential tools along with advanced machinery designed specifically for efficient production.

What sets Bensun apart is their expertise in customizing solutions tailored to each client's specific requirements—be it low-volume runs or high-mix production environments on their versatile PCB assembly line. Their focus on continuous improvement allows them to stay ahead of industry trends while delivering exceptional service as a reliable PCB assembly manufacturer you can trust.

The Importance of Quality Control

In the world of PCB assembly and manufacturing, quality control is not just a box to check; it’s the cornerstone of successful production. High-quality PCBs are essential for ensuring that electronic devices function reliably and efficiently. Without robust quality control measures, manufacturers risk producing flawed products that could lead to costly recalls or damage to their reputation.

Ensuring Quality in PCB Manufacture

Quality assurance begins right at the PCB manufacturing stage, where precision is paramount. Each step in the PCB assembly process must adhere to strict standards, from material selection to etching and layering techniques. Manufacturers often employ advanced testing methods like Automated Optical Inspection (AOI) and X-ray inspection to catch defects early and ensure that all components meet specifications.

Quality Assurance in PCB Assembly

Once the PCBs are manufactured, the focus shifts to quality assurance during the PCB assembly process. This phase involves soldering components onto the board with meticulous attention to detail, as any misalignment can lead to malfunctioning devices. A reputable PCB assembly manufacturer will implement rigorous testing protocols throughout this stage, including functional testing and thermal cycling tests, ensuring that each assembled unit performs as intended.

Best Practices for Quality Control

To maintain high standards in both manufacturing and assembly processes, companies should adopt best practices for quality control at every level. Regular audits of both the PCB assembly line and manufacturing facilities can help identify areas for improvement before they become significant issues. Additionally, investing in training for staff on quality standards related to PCB assembly components will foster a culture of excellence that permeates every aspect of production.

Conclusion

In the ever-evolving landscape of electronics, understanding the synergy between PCB assembly and manufacturing is crucial. These two processes, while distinct, work hand-in-hand to bring cutting-edge technology to life. A seamless integration of the PCB assembly process and manufacturing techniques not only enhances efficiency but also elevates product quality, ensuring that your electronic devices perform at their best.

The Synergy Between Manufacture and Assembly

The relationship between PCB manufacture and assembly is akin to a well-rehearsed duet; each component plays its part in harmony. The PCB assembly components must be meticulously crafted during the manufacturing phase to ensure they fit perfectly during assembly. When both processes are aligned, it results in a streamlined production line that minimizes errors and maximizes output—truly a win-win for manufacturers.

Choosing the Right PCB Assembly Manufacturer

Selecting a reputable PCB assembly manufacturer can make or break your project’s success. Look for companies that demonstrate expertise in both PCB manufacturing and the entire PCB assembly process, as this indicates a comprehensive understanding of how each stage affects overall quality. Additionally, consider their track record with various industries; a manufacturer experienced with diverse applications will likely provide innovative solutions tailored to your needs.

Future Trends in PCB Manufacturing and Assembly

As technology continues to advance at breakneck speed, future trends in PCB manufacturing and assembly are set to reshape the industry landscape. Expect innovations like automation in the PCB assembly line, which will streamline processes further while reducing costs and human error. Moreover, advancements in materials used for both manufacture and assembly will enhance performance capabilities—ensuring that electronics can keep up with our ever-growing demand for efficiency.