Introduction

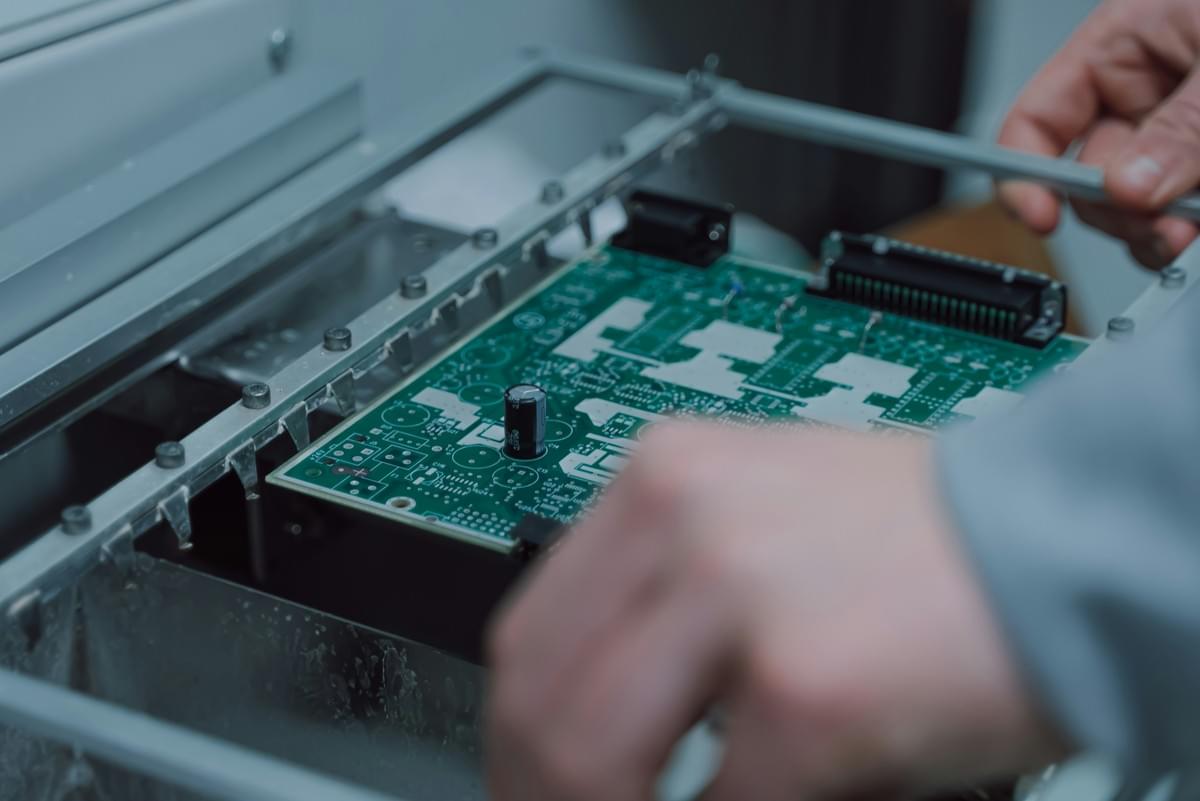

In the fast-paced world of electronics, understanding the nuances of PCB manufacturing is crucial for success. BSTECH stands out as a leading printed circuit board assembly manufacturer, offering unparalleled expertise in both PCB fabrication and assembly. Our commitment to quality ensures that your electronic products not only meet industry standards but also perform reliably in various applications.

Discover BSTECH's PCB Expertise

At BSTECH, we pride ourselves on our extensive knowledge and experience in printed circuit assembly and PCB manufacturing and assembly processes. Our team of experts is dedicated to providing tailored solutions that meet the unique needs of our clients across multiple industries. From rapid prototyping to full-scale production, we are your go-to partner for all things related to circuit card assembly.

The Importance of Quality PCB Manufacturing

Quality in PCB manufacturing is non-negotiable; it directly impacts the performance and longevity of electronic devices. As a reputable pcb assembly manufacturer, we understand that even minor defects can lead to significant failures down the line. That's why we focus on stringent quality control measures throughout our pcb manufacturing assembly processes, ensuring that every product meets or exceeds expectations.

Overview of PCB Fabrication Services

Our comprehensive range of PCB fabrication services caters to diverse requirements, from small prototypes to large production runs. We utilize advanced techniques and high-quality materials to ensure optimal performance in every printed circuit board we produce. By choosing BSTECH for your pcb fabrication and assembly needs, you are partnering with a company committed to excellence at every step of the process.

What is PCB Fabrication?

PCB fabrication is the intricate process of creating printed circuit boards (PCBs), which serve as the backbone for electronic devices. This process involves several stages, from design to production, ensuring that each board meets specific electrical and mechanical requirements. Understanding PCB fabrication not only highlights its complexity but also emphasizes its critical role in electronic manufacturing services.

Understanding the Process of PCB Manufacturing

The journey of PCB manufacturing begins with a well-crafted design, often created using sophisticated software tools that allow engineers to layout the circuit paths. Once finalized, this design is transferred onto a substrate material through various methods such as etching or printing. The result is a precise arrangement of conductive pathways that will eventually form the electronic connections needed for printed circuit assembly.

Following this initial step, additional layers may be added depending on the complexity of the circuit card assembly required for specific applications. Each layer undergoes rigorous testing to ensure functionality and reliability before moving on to assembly processes where components are soldered onto the board. The entire process is a delicate balance between art and science, with each stage influencing the overall quality and performance of the final product.

Key Materials Used in PCB Fabrication

Materials play an essential role in PCB fabrication, impacting not just durability but also performance characteristics such as conductivity and thermal management. Commonly used substrates include FR-4, a fiberglass-reinforced epoxy laminate known for its excellent electrical insulation properties and mechanical strength. Other materials like polyimide are employed for flexible PCBs, while copper serves as the primary conductor due to its high conductivity.

In addition to these core materials, solder masks and silkscreen inks are applied during fabrication to protect circuits and provide identification markings respectively. The choice of materials can significantly affect factors like signal integrity and heat dissipation in printed circuit board assembly manufacturer workflows. By selecting appropriate materials tailored for specific applications, manufacturers can enhance both reliability and efficiency in their products.

How PCB Fabrication Influences Electronic Performance

The quality of PCB fabrication directly influences electronic performance across various parameters such as signal integrity, thermal management, and overall durability. Poorly fabricated boards can lead to issues like signal loss or overheating—problems that can compromise device functionality or even cause failures in critical applications like automotive or medical devices. Therefore, meticulous attention during both manufacturing processes ensures optimal performance levels are achieved.

Moreover, advancements in technology have allowed manufacturers to explore innovative techniques within PCB manufacturing assembly processes that enhance performance metrics further still—think high-frequency capabilities or improved miniaturization techniques! These innovations enable electronics companies to push boundaries while meeting ever-increasing consumer demands for compact yet powerful devices. Ultimately, understanding how these elements intertwine helps businesses make informed decisions when selecting their printed circuit board assembly manufacturer.

BSTECH's PCB Prototype Capabilities

Prototyping is a critical phase in the development of electronic products, and BSTECH excels in providing top-notch PCB prototype capabilities. With a focus on rapid prototyping services, we ensure that your designs transition smoothly from concept to reality. Our expertise as a printed circuit board assembly manufacturer allows us to deliver high-quality prototypes that meet the rigorous demands of modern electronics.

Rapid Prototyping Services Explained

Rapid prototyping services at BSTECH streamline the entire process of printed circuit fabrication and assembly. We utilize advanced techniques and technologies to create prototypes quickly, allowing engineers to test and iterate their designs without unnecessary delays. This agility not only accelerates product development but also enhances collaboration between design teams and manufacturers.

Our capabilities include various methods tailored for different project requirements, ensuring flexibility regardless of complexity or scale. Whether you need a simple circuit card assembly or intricate multi-layer boards, our skilled team is equipped to handle it all efficiently. By prioritizing speed while maintaining quality, we set ourselves apart as a leading PCB manufacturing assembly provider.

Benefits of Quick Turnaround in Prototyping

The benefits of quick turnaround in prototyping cannot be overstated; it significantly reduces time-to-market for new products. In today's fast-paced tech landscape, being able to produce prototypes rapidly can give companies a competitive edge over others who may still be stuck in lengthy traditional processes. BSTECH’s commitment to efficiency means clients can expect timely delivery without compromising on quality.

Fast prototyping also fosters innovation by allowing teams to experiment with multiple iterations based on real-world feedback quickly. This iterative approach ensures that any issues are identified early in the development cycle, ultimately saving costs associated with extensive revisions later on. As a trusted partner for electronic manufacturing services, we understand that speed is crucial for our clients’ success.

Real-World Applications of Prototypes

Prototypes play an essential role across various industries where electronic devices are prevalent; from consumer electronics and automotive applications to medical devices and semiconductors, effective prototyping is vital for success. At BSTECH, our expertise enables us to cater specifically to these sectors by providing tailored solutions that meet unique challenges faced during product development stages.

For instance, in the automotive industry, quick-turn prototypes allow manufacturers to refine features such as advanced driver-assistance systems (ADAS) before mass production begins. Similarly, medical device developers rely on precise printed circuit assemblies during testing phases—ensuring safety and compliance with strict regulations before reaching consumers' hands. By partnering with us as your PCB assembly manufacturer, you gain access to innovative solutions designed for real-world applications across diverse markets.

PCB Assembly: A Comprehensive Overview

PCB assembly is a critical step in the electronics manufacturing process, transforming bare printed circuit boards into fully functional electronic devices. This stage involves placing and soldering electronic components onto the PCB, ensuring connectivity and functionality. As a leading printed circuit board assembly manufacturer, BSTECH understands the intricate balance between precision and efficiency required in this phase.

Exploring PCB Assembly Methods

There are several methods used in PCB assembly, each tailored to meet specific production needs and component types. Surface Mount Technology (SMT) is one of the most prevalent methods, allowing for high-density component placement on both sides of a PCB. Through-Hole Technology (THT) is another method that provides robust connections for larger components, often used in applications requiring higher durability.

In addition to these traditional techniques, hybrid methods combine both SMT and THT for optimal performance across various applications. The choice of assembly method can significantly affect the overall quality and reliability of the final product, making it crucial for any printed circuit assembly to utilize appropriate techniques based on design requirements. Ultimately, understanding these methods helps businesses select a suitable PCB assembly manufacturer that aligns with their project needs.

Differences between Circuit Card Assembly and PCB Assembly

While circuit card assembly and PCB assembly are often used interchangeably, they encompass distinct processes within electronic manufacturing services. Circuit card assembly typically refers to the entire process of assembling components onto a circuit board that may include additional elements such as connectors or heat sinks—essentially creating an entire functional unit ready for integration into larger systems.

On the other hand, PCB assembly focuses specifically on placing components onto printed circuit boards without necessarily including all supplementary parts needed for complete functionality. Understanding this difference is vital when engaging with a pcb manufacturing and assembly service provider because it determines project scope and expectations regarding timelines and costs.

Quality Assurance in PCB Assembly

Quality assurance is paramount in ensuring reliable performance in any pcb fabrication and assembly process. Rigorous testing procedures are implemented throughout production to identify defects early on—this includes visual inspections as well as automated optical inspection (AOI) systems that verify component placement accuracy before soldering occurs.

Furthermore, adherence to industry standards such as IPC-A-610 ensures that all assemblies meet stringent quality requirements expected by clients across various sectors including automotive or medical devices where reliability is non-negotiable. By prioritizing quality assurance practices within their operations, BSTECH stands out among competitors as a trusted partner for those seeking top-tier electronic manufacturing services.

The Role of Bensun Technology in PCB Production

Bensun Technology Co., Ltd. has been a game changer in the realm of PCB production since its inception in 2009. Specializing in SMT (Surface Mount Technology) and MI (Mixed Technology) production equipment, Bensun is a key player for any printed circuit board assembly manufacturer looking to enhance their operations. With a diverse range of products, including JUKI pick and place machines and reflow ovens, they cater to various industries such as consumer electronics, automotive, and medical devices.

Innovative SMT Equipment from Bensun

The innovative SMT equipment from Bensun is designed to streamline the printed circuit assembly process, ensuring high-quality outputs with maximum efficiency. Their machinery not only enhances speed but also improves accuracy during the pcb manufacturing and assembly process. This commitment to innovation makes them an invaluable partner for any business seeking reliable electronic manufacturing services.

Bensun's equipment allows for precise placement of components on PCBs, which is crucial for achieving optimal performance in electronic devices. By utilizing advanced technology in their machines, they ensure that every circuit card assembly meets strict quality standards while minimizing waste during production. This focus on efficiency translates into cost savings for clients who need rapid prototyping or large-scale production runs.

Enhancing PCB Manufacturing with JUKI Machines

JUKI machines are at the forefront of enhancing PCB manufacturing processes across various sectors. Known for their reliability and precision, these machines play a pivotal role in the printed circuit board assembly manufacturer ecosystem by optimizing workflows and reducing lead times significantly. By integrating JUKI technology into their operations, companies can achieve higher throughput without compromising quality.

Moreover, JUKI’s advanced features allow manufacturers to handle complex designs with ease—ideal for today’s intricate electronic devices that demand meticulous attention to detail during pcb fabrication and assembly stages. This capability ensures that businesses remain competitive while meeting the evolving demands of the market efficiently.

How Bensun Supports Diverse Industries

Bensun Technology understands that different industries have unique requirements when it comes to printed circuit board manufacturing assembly processes; hence they offer tailored solutions that meet these specific needs effectively. From consumer electronics to medical devices, their equipment is versatile enough to adapt to various applications while maintaining top-notch performance standards throughout each phase of production.

By providing flexible solutions—including equipment sales, rentals, and contract manufacturing—Bensun empowers clients across multiple sectors to optimize their operations without heavy upfront investments on machinery. This adaptability not only supports businesses looking for quick turnarounds but also fosters long-term partnerships built on trust and reliability within the electronic manufacturing services landscape.

In summary, Bensun Technology stands out as an essential ally in PCB production through its innovative SMT equipment and strategic partnerships with leading machine manufacturers like JUKI. Their commitment to supporting diverse industries ensures that every client receives tailored solutions designed specifically for their needs while adhering strictly to industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer can make or break your electronic projects. With a multitude of options available, it’s crucial to evaluate potential partners based on their capabilities and experience in printed circuit fabrication and assembly. A reliable manufacturer should not only meet your technical specifications but also align with your business values and deadlines.

Factors to Consider in PCB Manufacturing Assembly

When searching for a printed circuit board assembly manufacturer, consider factors such as production capacity, technology used, and turnaround times. The ideal partner should have advanced equipment that supports efficient pcb manufacturing and assembly processes, ensuring high-quality output without unnecessary delays. Additionally, look for a company that offers flexibility in their electronic manufacturing services to accommodate various project sizes and complexities.

Another critical factor is communication; a transparent dialogue between you and the pcb assembly manufacturer can prevent misunderstandings and ensure smoother project execution. Evaluate their customer support structure—do they provide assistance during design phases? Are they responsive to inquiries? Strong communication can significantly enhance your overall experience with the manufacturer.

Lastly, consider the manufacturer's reputation within the industry. Look for reviews or testimonials from other clients who have utilized their printed circuit assembly services. A company with a proven track record is more likely to deliver consistent quality in both pcb fabrication and assembly.

The Importance of Certifications and Standards

Certifications play a pivotal role in determining the credibility of a pcb manufacturing assembly service provider. Industry standards such as ISO 9001 ensure that manufacturers adhere to consistent quality management practices throughout their processes. When selecting an electronic manufacturing services partner, verify that they hold relevant certifications—this not only indicates reliability but also enhances trust in their capabilities.

Moreover, compliance with safety standards is vital for ensuring that products are safe for end-users while meeting regulatory requirements across different markets. A certified printed circuit board assembly manufacturer will have established protocols for quality assurance that help mitigate risks associated with defective products or non-compliance issues.

In addition to general certifications, specialized standards like IPC-A-610 focus on requirements for soldered electrical assemblies—essential when evaluating potential partners for circuit card assembly projects. By prioritizing manufacturers who meet these rigorous standards, you can safeguard your investment while enhancing product performance.

Why BSTECH Stands Out Among Competitors

BSTECH distinguishes itself as a premier pcb assembly manufacturer through its commitment to innovation and quality assurance at every stage of production. With state-of-the-art facilities equipped with cutting-edge technology, BSTECH excels in both pcb fabrication and assembly processes—ensuring precision from prototype development through mass production runs.

Additionally, BSTECH's dedication to customer satisfaction sets it apart from competitors; they offer tailored solutions designed around specific client needs within various industries such as automotive electronics or medical devices. Their extensive experience enables them to tackle complex projects while maintaining quick turnaround times—a crucial factor when time-to-market is essential for success.

Finally, partnering with BSTECH means gaining access to expert guidance throughout your project lifecycle—from initial design consultations through final testing phases of printed circuit assemblies. This level of support ensures that you are not just another order number; instead, you become part of a collaborative journey towards achieving excellence in electronic manufacturing services.

Conclusion

In the rapidly evolving landscape of electronics, the importance of quality PCB manufacturing cannot be overstated. With advancements in technology and increasing demand for precision, the future of PCB fabrication and assembly looks promising. As a leading printed circuit board assembly manufacturer, BSTECH is poised to adapt and thrive in this dynamic environment.

The Future of PCB Manufacturing Trends

The future of PCB manufacturing trends is leaning towards miniaturization and increased functionality within smaller form factors. Innovations such as flexible PCBs and higher layer counts are becoming standard as industries push for more compact designs without compromising performance. Furthermore, the integration of smart technologies into printed circuit assembly processes will enhance efficiency and accuracy, setting new benchmarks for electronic manufacturing services.

Maximizing Efficiency with Quality PCB Assembly

Maximizing efficiency in PCB manufacturing assembly hinges on adopting advanced techniques and high-quality materials that ensure durability and reliability. By focusing on precision during circuit card assembly, manufacturers can reduce defects and improve overall product quality, which translates to less waste and lower costs. Partnering with a reputable pcb assembly manufacturer like BSTECH guarantees that you receive not only top-notch products but also streamlined processes that enhance your production capabilities.

Partnering with BSTECH for Your PCB Needs

Choosing to partner with BSTECH means gaining access to comprehensive electronic manufacturing services tailored to meet your specific requirements. Our expertise in both pcb fabrication and assembly ensures that your projects are handled with utmost care from prototyping through to full-scale production. With our commitment to innovation and quality, we stand out among competitors as the go-to choice for all your printed circuit board needs.