Introduction

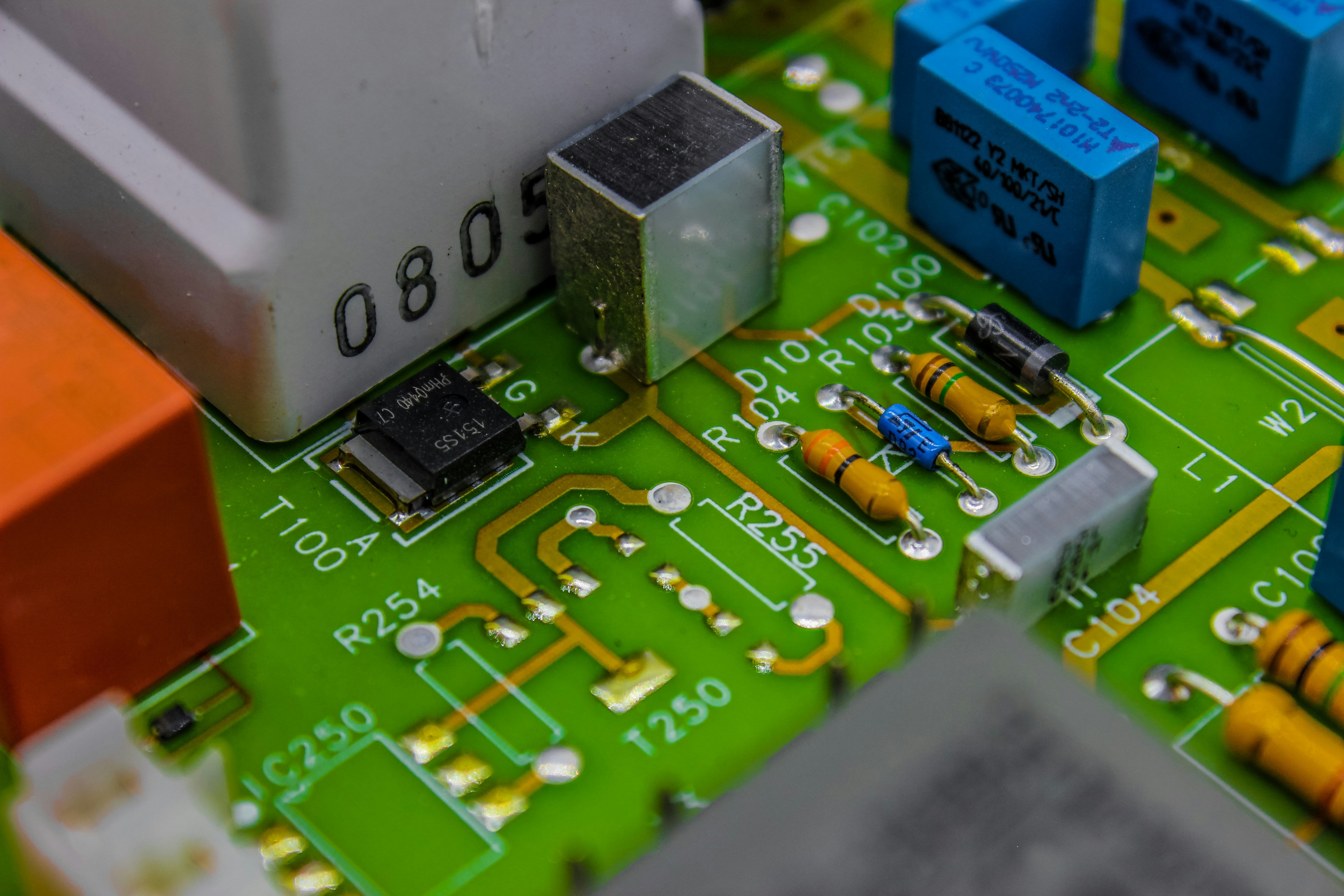

In the world of electronics, the reliability and longevity of a circuit board can make or break a project. This is where PCB coating comes into play, acting as a protective shield for your precious PCB boards. Understanding the importance of this coating is crucial not only for enhancing performance but also for ensuring that your printed circuit board withstands various environmental challenges.

Understanding the Importance of PCB Coating

PCB coating serves as an essential layer that protects circuit boards from moisture, dust, chemicals, and other potential hazards. Without proper protection, even the most meticulously designed PCB circuit board can suffer from corrosion or failure over time. Printed circuit board manufacturers recognize that investing in quality coatings can significantly extend the lifespan and functionality of their products.

Key Benefits of PCB Coating for Projects

Choosing to apply a suitable PCB coating brings a multitude of benefits to any project involving PCBA circuit boards. First and foremost, these coatings enhance longevity by providing a barrier against environmental stressors that could lead to premature failures. Additionally, they improve overall performance in harsh conditions—think extreme temperatures or exposure to humidity—making them indispensable in many applications.

Common Types of PCB Coatings

Conformal coatings offer versatility by adapting to various shapes and sizes while potting compounds provide maximum protection against physical damage and environmental factors. Each type has its unique advantages; hence understanding these differences is key when consulting with PC board manufacturers about which option best meets your specific needs.

What is PCB Coating?

PCB coating is an essential process in the electronics industry, specifically for protecting printed circuit boards (PCBs) from various environmental factors. By applying a protective layer to the circuit board, manufacturers can significantly enhance the longevity and reliability of their products. This coating serves not just as a barrier but also plays a crucial role in maintaining optimal performance under challenging conditions.

Definition and Purpose of PCB Coating

At its core, PCB coating refers to the application of a protective material over a printed circuit board to safeguard it against moisture, dust, chemicals, and other potential hazards. The primary purpose of this coating is to prevent corrosion and short circuits that could arise from environmental exposure. In essence, it's like giving your pcb circuit board a raincoat—keeping it safe while allowing it to function properly.

Differences Between Various Coating Types

There are several types of coatings available for PCBs, each with its unique properties and applications. Conformal coatings are thin layers that conform to the contours of the pcb board, providing effective protection without adding significant bulk. On the other hand, potting compounds offer maximum protection by encasing components in a solid mass—ideal for environments where extreme protection is necessary.

When comparing acrylic and silicone coatings, one finds that acrylics provide excellent moisture resistance but may not withstand high temperatures as well as silicones do. Each type has its pros and cons depending on specific project needs; thus understanding these differences is vital when selecting the right type for your pcba circuit board.

Role of PCB Coatings in Protection

The role of pcb coatings extends beyond mere aesthetics; they play a pivotal part in ensuring long-term reliability and performance of electronic devices. By acting as insulators against humidity and contaminants, these coatings help maintain signal integrity within the circuit board while minimizing failure rates over time. Additionally, they can reduce mechanical stress on components during thermal cycling or vibration—further enhancing overall durability.

In summary, choosing an appropriate pcb coating is essential for any project involving printed circuit boards. It not only protects sensitive components but also ensures that your investment remains viable in various operating conditions throughout its lifecycle.

The Benefits of Choosing PCB Coating

Enhanced Longevity of PCB Boards

One of the standout benefits of applying a robust PCB coating is the enhanced longevity it provides for your PCBA circuit board. Coatings act as a barrier against moisture, dust, and other contaminants that can lead to corrosion or damage over time. This means that printed circuit boards coated with high-quality materials are less likely to fail prematurely, allowing you to enjoy greater reliability from your electronics.

Moreover, when you consider the costs associated with replacing damaged or malfunctioning PC boards, it's clear that investing in durable PCB coating pays off in spades. With the right protection, your circuit boards can withstand wear and tear much better than their uncoated counterparts. Ultimately, this leads to fewer repairs and replacements down the road.

Improved Performance in Harsh Environments

For those operating in challenging environments—be it extreme temperatures, humidity, or exposure to chemicals—PCB coating offers essential protection for your electronic components. A well-coated PCB circuit board can maintain its performance even when subjected to adverse conditions that would typically compromise uncoated boards. This resilience is crucial for industries such as automotive, aerospace, and medical devices where reliability is non-negotiable.

Additionally, specific coatings are designed for unique challenges; some repel moisture while others resist chemical exposure or extreme heat. By selecting an appropriate type of coating tailored to your needs, you ensure that every aspect of your printed circuit board's functionality is safeguarded against potential threats. This improved performance translates into increased trustworthiness and efficiency in critical applications.

Cost-Effectiveness Over Time

While there may be an initial investment involved in applying high-quality PCB coatings from reputable printed circuit board manufacturers, this choice proves cost-effective over time. The durability provided by these coatings means fewer failures and lower maintenance costs associated with repairs or replacements of PCBA circuit boards due to environmental damage or component degradation.

Moreover, many manufacturers recognize the long-term savings associated with using protective coatings; hence they often recommend them as a standard practice during production processes for their PC boards. By opting for effective PCB coating solutions now, you're essentially saving money while ensuring optimal performance down the line—a win-win situation!

Types of PCB Coatings Available

When it comes to protecting your precious PCB boards, choosing the right type of coating is crucial. Each coating type offers distinct advantages tailored to various environments and applications. Understanding these options will help you make informed decisions that enhance the performance and longevity of your circuit board.

Conformal Coating: The Versatile Choice

Conformal coating is a popular choice among printed circuit board manufacturers due to its versatility and adaptability. This thin layer of protective material conforms to the contours of the PCB circuit board, providing a reliable shield against moisture, dust, and other environmental contaminants. With options like acrylic, silicone, and polyurethane coatings available, you can select a formulation that best fits your specific application needs.

One key advantage of conformal coatings is their ease of application; they can be sprayed, brushed, or dipped onto the PCB printed circuit board. This flexibility makes them suitable for various production processes used by PCBA circuit board manufacturers. Additionally, conformal coatings are often transparent or tinted, allowing for visual inspection of components while still offering robust protection.

Potting Compounds: Maximum Protection

If you're seeking maximum protection for your PCB boards in extreme conditions, potting compounds are hard to beat. These thick materials encapsulate entire assemblies within a solid mass that guards against moisture, chemicals, and mechanical stress. Potting compounds provide an unparalleled level of durability that is ideal for applications where reliability is non-negotiable.

The primary downside? While potting compounds offer superior protection compared to traditional pcb coating methods like conformal coatings, they can complicate repairs or modifications since they completely encase components on the pc board. However, if your priority is safeguarding sensitive electronics from harsh environments—think automotive or aerospace—potting compounds are worth considering as a robust solution.

Acrylic and Silicone Coatings Comparison

Acrylic and silicone coatings are two popular options in the realm of pcb coating materials; each has its unique strengths suited for different scenarios. Acrylic coatings tend to dry quickly and provide good moisture resistance while maintaining excellent clarity on the pcb printed circuit board surface—ideal for applications where visibility matters! Conversely, silicone coatings excel in high-temperature environments due to their flexibility and ability to withstand thermal cycling without cracking.

When comparing these two types of coatings from pcba circuit board manufacturers’ perspectives, consider factors such as operating temperature ranges and potential exposure to chemicals or solvents in your specific use case. While both acrylics and silicones offer excellent protective qualities for electronic components on a printed circuit board layout, understanding their differences will help you choose wisely based on project requirements.

Factors to Consider for PCB Coating

When it comes to selecting the right PCB coating for your project, several factors come into play that can significantly impact the performance and longevity of your circuit board. Understanding these considerations is crucial for ensuring that your printed circuit board meets the demands of its intended environment and application. Let's dive deeper into what you need to keep in mind when choosing a PCB coating.

Environment and Application Needs

The first step in selecting an appropriate PCB coating is assessing the environment where the PCB circuit board will operate. For instance, if your application involves exposure to moisture, dust, or extreme temperatures, a robust protective coating is essential to safeguard the integrity of your PCBA circuit board. Different coatings offer varying levels of resistance against environmental factors; therefore, understanding these needs will help you choose a suitable solution that enhances the durability of your printed circuit board.

Moreover, specific applications may require specialized coatings tailored to unique challenges. For example, automotive and aerospace applications often demand coatings that withstand vibrations and chemicals while maintaining electrical performance. By carefully considering environmental conditions and application requirements, you can ensure that your PCB coating contributes positively to the overall reliability of your circuit board.

Compatibility with Components

Another critical factor in selecting a PCB coating is ensuring compatibility with all components on the printed circuit board. Not all coatings are created equal; some may interact negatively with certain materials or components used in your design. Therefore, it's imperative to evaluate how different types of coatings will affect sensitive elements like connectors or integrated circuits on your PCBA circuit board.

Incompatibility can lead not only to physical damage but also degradation of electronic performance over time. It’s wise to consult data sheets from both component manufacturers and those who produce PCB coatings before making a decision on which product best suits your needs. By prioritizing compatibility with components during selection, you can avoid potential pitfalls down the line and enhance the overall performance of your pcb printed circuit board.

Consult Results from PCB Board Manufacturers

Finally, consulting results from reputable printed circuit board manufacturers can provide invaluable insights into which type of pcb coating would be most effective for your specific project needs. Many manufacturers conduct rigorous testing on various coatings under different conditions; their findings can guide you toward making an informed decision that aligns with industry standards and best practices.

Additionally, leveraging feedback from these manufacturers allows you to tap into their expertise regarding successful projects similar to yours—what worked well and what didn’t? This collaborative approach not only enhances trust but also increases confidence in choosing a suitable pcb coating for optimal results in durability and functionality. Ultimately, engaging with experts ensures you're making choices based on proven success rather than guesswork.

Leading the Charge: Bensun Technology

In the ever-evolving world of electronics, Bensun Technology stands out as a beacon of innovation in PCB coating solutions. With a deep understanding of the challenges faced by printed circuit board manufacturers, Bensun has developed cutting-edge techniques that enhance the durability and performance of PCB boards. Their commitment to research and development ensures that clients receive products that not only meet but exceed industry standards.

Innovative Solutions in PCB Coating

Bensun Technology takes pride in offering innovative solutions for PCB coating that cater to diverse needs across various industries. Their advanced formulations are designed to protect circuit boards from moisture, dust, and other environmental factors, ensuring longevity and reliability. By leveraging state-of-the-art application methods, they guarantee uniform coverage on every PCB circuit board, enhancing performance even in the most challenging conditions.

Commitment to Quality in PCBA Manufacturing

Quality is at the heart of Bensun's operations as they strive to deliver exceptional results in PCBA manufacturing. The company employs rigorous testing protocols to ensure every PCB printed circuit board meets stringent quality benchmarks before reaching customers. This dedication not only reinforces their reputation among pc board manufacturers but also builds trust with clients who rely on high-performance electronic components.

Flexible Services Tailored to Your Needs

Understanding that each project is unique, Bensun Technology offers flexible services tailored specifically to meet individual customer requirements. Whether you need standard coatings or specialized formulations for specific applications, their team works closely with you to develop tailored solutions for your pcba circuit board projects. This personalized approach not only enhances satisfaction but also fosters long-term partnerships with clients seeking reliable and efficient PCB coating options.

Conclusion

In the fast-paced world of electronics, the importance of PCB coating cannot be overstated. These coatings serve as a protective shield for circuit boards, ensuring their longevity and performance in various environments. As projects become more complex, understanding the role of PCB coatings becomes essential for success.

Why PCB Coating is Essential for Projects

PCB coating is crucial for safeguarding printed circuit boards against moisture, dust, and other contaminants that can lead to failures. Without proper protection, even the most advanced PCB circuit board designs can suffer from degradation over time. By investing in high-quality pcb coating solutions, project managers can enhance reliability and extend the lifespan of their pcba circuit board assemblies.

Making the Right Choice in Coatings

Selecting the appropriate type of pcb coating involves understanding your specific needs and environmental conditions. Different coatings offer varying levels of protection and compatibility with components used by printed circuit board manufacturers. Evaluating factors such as thermal resistance and chemical exposure will help you make an informed choice that aligns with your project requirements.

Future of PCB Coating Technologies

The future of pcb coating technologies looks promising, with advancements aimed at improving efficiency and effectiveness. Innovations are continuously emerging to enhance durability while minimizing environmental impact—an important consideration for modern pc board manufacturers. As these technologies evolve, they will further solidify the role of pcb coatings as indispensable components in high-performance electronic devices.