Introduction

In the world of electronics, understanding how circuit boards are made is fundamental to grasping the intricacies of modern technology. Circuit boards serve as the backbone for countless devices, from smartphones to sophisticated medical equipment, enabling them to function efficiently and reliably. The journey of a circuit board begins with meticulous design and planning, transitioning through various stages until it becomes a fully operational printed circuit assembly.

Understanding the Circuit Board Journey

The journey of a circuit board is both fascinating and complex, involving several critical phases that transform raw materials into functional electronic components. Initially, engineers and designers collaborate to create detailed schematics that outline how each component will connect within the board. This process not only determines the layout but also sets the stage for successful circuit card assembly that meets specific performance requirements.

Key Components of Circuit Board Manufacturing

Circuit board manufacturing encompasses various essential components, including substrates, conductive materials, and electronic components that come together during printed circuit board assembly. Each element plays a crucial role in ensuring that the final product can withstand operational demands while maintaining quality standards. Understanding these key components helps demystify how circuit boards are made and highlights their significance in PCB assembly.

Importance of Quality in PCB Assembly

Quality in PCB assembly cannot be overstated; it directly impacts device reliability and performance in real-world applications. High-quality materials and precise manufacturing processes ensure that electronic components function as intended without failure over time. As industries increasingly rely on advanced technology, prioritizing quality in every step of printed circuit assembly becomes essential for achieving optimal results.

The Design Phase

The design phase is where the magic begins in the journey of how circuit boards are made. It transforms abstract ideas into tangible blueprints that guide the entire manufacturing process. This phase sets the foundation for successful printed circuit assembly, ensuring that every detail is meticulously planned out.

How Schematics Turn into Blueprints

Schematics serve as the initial roadmap for circuit board assembly, illustrating how electronic components will be connected and function together. Engineers take these diagrams and convert them into detailed blueprints, specifying layout, dimensions, and component placements essential for printed circuit board assembly. This transformation is crucial; it ensures that when the time comes for pcb board assembly, everything fits together like a well-oiled machine.

The Role of CAD Software in Designing

Computer-Aided Design (CAD) software plays a pivotal role in modern circuit card assembly by allowing engineers to create precise designs with ease. With advanced features like 3D visualization and simulation capabilities, CAD tools help streamline the design process while minimizing errors before physical production begins. As a result, using CAD software enhances efficiency in creating complex layouts for printed circuit assemblies.

Collaboration with Engineers and Designers

Collaboration among engineers and designers is vital during this design phase to ensure all perspectives are considered when developing a new PCB layout. By working closely together, they can address potential challenges early on, ensuring that electronic components are optimally placed within the constraints of size and functionality during pcb assembly. This teamwork not only improves the overall quality of circuit board assembly but also fosters innovation as ideas flow freely between disciplines.

Materials Used in Circuit Boards

In the realm of circuit board assembly, the choice of materials is crucial to ensuring optimal performance and reliability. Each component plays a distinct role in how are circuit boards made, influencing not just functionality but also durability and cost-effectiveness. Understanding the types of materials used can help demystify the printed circuit assembly process.

Types of Substrates and Their Properties

Substrates are the backbone of any printed circuit board assembly, providing structural support for electronic components while facilitating electrical connections. Common substrate materials include FR-4, a fiberglass-reinforced epoxy laminate known for its excellent electrical insulation properties and thermal stability. Other options like polyimide or ceramic substrates cater to specialized applications requiring higher temperatures or flexibility, showcasing how diverse substrates can enhance circuit card assembly.

When considering how are circuit boards made, it's essential to recognize that each substrate type offers unique characteristics that affect performance and manufacturing processes. For instance, FR-4 is widely used due to its affordability and versatility, while polyimide substrates are favored in aerospace applications where weight and heat resistance are critical factors. Ultimately, selecting the right substrate is fundamental to achieving high-quality PCB board assembly.

Sourcing Electronic Components for Assembly

Sourcing electronic components for printed circuit board assembly involves navigating a complex landscape filled with numerous suppliers and manufacturers. The goal is to find reliable sources that offer high-quality components at competitive prices without compromising on performance or safety standards. This step is vital because even minor discrepancies in component quality can lead to significant issues during circuit card assembly.

As you delve into how are circuit boards made, consider that sourcing involves evaluating potential suppliers based on their reputation, product range, and compliance with industry standards such as RoHS (Restriction of Hazardous Substances). Building strong relationships with suppliers can lead to better pricing agreements and more consistent supply chains—critical elements in maintaining smooth PCB assembly operations. Furthermore, understanding market trends can aid manufacturers in anticipating changes in component availability or pricing fluctuations.

The Importance of Quality Materials

The importance of quality materials cannot be overstated when it comes to PCB board assembly; they directly impact both performance and longevity of electronic devices. High-quality substrates ensure better signal integrity and thermal management while premium electronic components contribute significantly to overall reliability during operation. In an age where consumers expect flawless performance from their devices, manufacturers must prioritize quality at every stage—from material selection through final testing.

Moreover, using inferior materials may save costs initially but could lead to catastrophic failures down the line—think about what’s at stake! Manufacturers should always ask themselves: Is this worth risking our reputation? By investing in top-notch materials for printed circuit board assembly processes today, companies lay a solid foundation for future success while ensuring customer satisfaction remains high.

The Manufacturing Process

The manufacturing process of circuit boards is a meticulous journey that transforms raw materials into functional electronic devices. Understanding how circuit boards are made requires an appreciation for the intricate steps involved in printed circuit board assembly. From initial design to final testing, each phase plays a crucial role in ensuring the quality and reliability of the finished product.

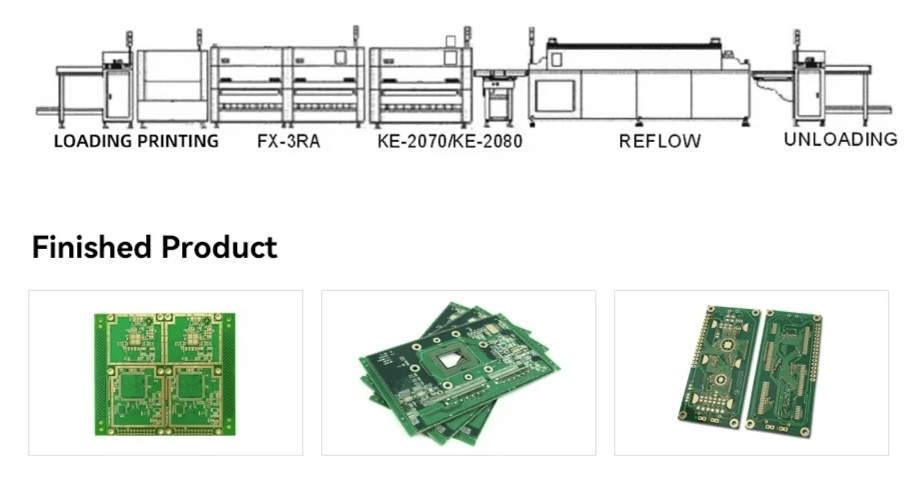

Steps in Printed Circuit Board Assembly

The first step in printed circuit board assembly is creating the bare PCB, which involves applying copper to a substrate and etching away excess material to form the desired circuitry. Once the PCB is prepared, it’s time for solder paste application, where tiny dots of solder paste are strategically placed on pads where electronic components will be mounted. Next comes component placement, where various electronic components are accurately positioned onto the PCB before they’re permanently attached through soldering processes like reflow or wave soldering.

After soldering, it's essential to inspect the assembly for any defects or misalignments as part of quality control measures. The final steps include functional testing to ensure that all components work correctly together within their intended applications. Through these stages, manufacturers can confidently say they’ve mastered printed circuit board assembly and can produce high-quality products that meet industry standards.

Techniques in Circuit Card Assembly

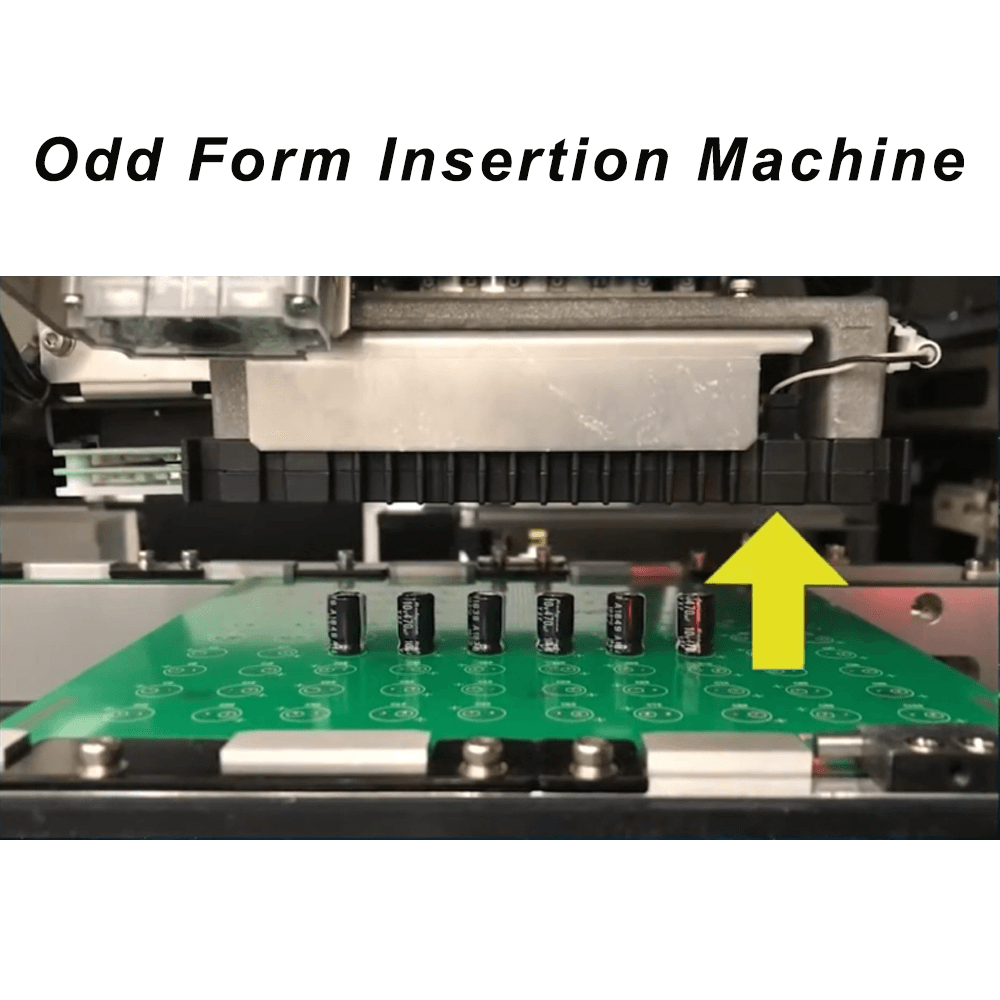

Circuit card assembly employs various techniques tailored to different types of electronic components and PCB designs. One popular method is surface mount technology (SMT), which allows for smaller components to be mounted directly onto the surface of PCBs, optimizing space and enhancing performance. Another technique is through-hole technology (THT), where leads from components pass through holes drilled into the PCB; this method provides strong mechanical connections but often takes up more space.

Additionally, manufacturers may use hybrid techniques that combine both SMT and THT for versatile designs capable of meeting diverse requirements in modern electronics. Each technique has its pros and cons; thus, selecting an appropriate method depends largely on factors such as component size, electrical performance needs, and production volume goals during circuit card assembly processes. Ultimately, mastering these techniques ensures efficient production while maintaining high standards in quality.

Key Considerations for PCB Board Assembly

When diving into pcb board assembly, several key considerations must be taken into account to guarantee success in manufacturing high-quality products. First off is material selection; using premium substrates and reliable electronic components significantly impacts both performance and longevity of the final product—after all, nobody wants a faulty device! Additionally, precision during placement and soldering processes cannot be overstated; even minor misalignments can lead to catastrophic failures down the line.

Another vital consideration is adhering to industry standards throughout manufacturing practices; compliance ensures not only safety but also compatibility with other devices within a given ecosystem—think about how your smartphone interacts with various peripherals! Finally, thorough testing after assembly helps catch any potential issues early on before products reach consumers' hands—a proactive approach that saves time and resources later on during troubleshooting phases post-production.

Quality Control and Testing

Ensuring the reliability of circuit boards is a crucial aspect of the manufacturing process. Quality control methods are employed at various stages of printed circuit board assembly to catch potential issues before they escalate. From initial design reviews to final product testing, these methods help guarantee that each PCB board assembly meets stringent industry standards.

Methods for Ensuring PCB Reliability

To understand how are circuit boards made reliably, manufacturers implement several quality assurance techniques throughout the production process. One commonly used method is Automated Optical Inspection (AOI), which examines the solder joints and component placements on the circuit card assembly for any discrepancies. Additionally, X-ray inspection can be utilized to verify hidden solder connections, ensuring that electronic components are securely attached and function as intended.

Another effective approach is implementing a rigorous testing protocol that includes both in-process inspections and final product evaluations. This includes functional tests that simulate real-world conditions to confirm that the printed circuit assembly performs correctly under various scenarios. By identifying potential failures early on, manufacturers can reduce costs associated with rework and enhance overall product reliability.

The Role of Visual Inspection Systems

Visual inspection systems play an integral role in maintaining high-quality standards during PCB assembly processes. These systems utilize advanced imaging technology to provide detailed views of assembled circuit boards, allowing operators to detect defects such as misaligned components or insufficient solder coverage quickly. As part of how are circuit boards made efficiently, visual inspections ensure that any issues are addressed before they lead to costly failures in electronic devices.

In addition to automated systems, skilled technicians often conduct manual inspections as a supplementary measure to catch any problems that machines might miss. This human touch adds an extra layer of scrutiny in the printed circuit board assembly process, making sure everything aligns perfectly with design specifications. Ultimately, visual inspection systems contribute significantly to achieving high-quality outcomes in both small-scale prototypes and large production runs.

Importance of Functional Testing

After completing the PCB board assembly process, functional testing emerges as a non-negotiable step in ensuring performance reliability. This type of testing evaluates whether all electronic components operate correctly within their intended environment by simulating real-life usage scenarios. It’s essential for identifying issues such as signal integrity problems or power distribution failures before products reach customers.

Functional tests not only validate design accuracy but also enhance customer satisfaction by ensuring products meet performance expectations right out of the box. By incorporating thorough functional testing into their workflows, manufacturers can confidently assure clients about how are circuit boards made with reliability at their core—boosting trust and reducing returns due to faulty assemblies!

In conclusion, quality control and testing serve as foundational pillars in PCB manufacturing processes like printed circuit assembly and circuit card assembly alike—ensuring every component functions harmoniously together while meeting strict industry standards.

Innovations in Circuit Board Technology

The world of circuit boards is constantly evolving, driven by technological advancements and the ever-growing demand for more efficient electronic devices. As we explore the innovations in circuit board technology, it becomes clear that understanding how are circuit boards made is crucial for staying ahead in this competitive landscape. From novel materials to sophisticated manufacturing techniques, the future of printed circuit assembly is bright.

Emerging Trends in Circuit Board Manufacturing

One of the most exciting emerging trends in circuit board manufacturing is the shift towards flexible and wearable electronics. These innovative designs require unique approaches to printed circuit board assembly that accommodate bending and folding without compromising functionality. Additionally, advancements in miniaturization allow for smaller electronic components to be integrated into these flexible circuits, making them ideal for modern applications such as smartwatches and health monitoring devices.

Another trend gaining traction is the use of environmentally friendly materials in PCB production. Manufacturers are increasingly prioritizing sustainable practices by sourcing recyclable substrates and reducing hazardous waste during the circuit card assembly process. This not only appeals to eco-conscious consumers but also adheres to stricter regulations regarding electronic waste management.

Lastly, automation plays a pivotal role in revolutionizing how are circuit boards made today. Automated processes enhance precision during PCB assembly while significantly reducing production time and costs. By implementing robotics and AI-driven technologies, manufacturers can improve efficiency while maintaining high-quality standards essential for reliable electronic components.

The Future of PCB Assembly with Bensun Technology

Bensun Technology stands at the forefront of innovation within the realm of PCB assembly, continuously pushing boundaries with their cutting-edge solutions. Their commitment to research and development ensures they remain leaders in creating advanced manufacturing techniques that streamline printed circuit board assembly processes. By leveraging state-of-the-art machinery and software tools, Bensun enhances productivity while delivering exceptional quality across all their products.

Moreover, Bensun's focus on integrating IoT (Internet of Things) capabilities into their PCBs opens up new avenues for smart technology applications across various industries. This integration allows for real-time data collection and monitoring directly from electronic components embedded within devices—transforming traditional products into intelligent systems that adapt to user needs seamlessly.

As they look toward future collaborations with clients, Bensun emphasizes customization based on specific requirements—a crucial aspect when considering how are circuit boards made today. Their agile approach enables them to adapt quickly to market demands while ensuring that every aspect of PCB board assembly aligns perfectly with customer expectations.

Adapting to Customer Needs in Production

In an age where consumer preferences shift rapidly, adapting production methods becomes vital for success within the PCB industry. Manufacturers must prioritize flexibility during printed circuit board assembly processes so they can accommodate varying order sizes or unique design specifications without sacrificing quality or efficiency—this adaptability is key when answering how are circuit boards made effectively today.

Customer feedback has become increasingly important; listening closely helps manufacturers refine their offerings based on real-world experiences from end-users utilizing these essential electronic components daily. By fostering open communication channels between designers and clients throughout each step—from initial design through final production—companies can ensure optimal results tailored specifically around user needs.

Finally, investing in training programs focused on new technologies ensures teams remain proficient amid ongoing developments within this fast-paced industry landscape surrounding PCB assembly practices overall! Continuous learning cultivates an environment where innovation thrives—ultimately leading towards better products designed explicitly around what customers want most!

Conclusion

In the world of electronics, the quality of circuit board assembly can make or break a product's performance. How are circuit boards made? It all starts with meticulous design, followed by careful material selection and a rigorous manufacturing process. When each step is executed flawlessly, the end result is a reliable printed circuit board assembly that meets both industry standards and customer expectations.

The Impact of Quality on Performance

Quality is not just a buzzword in PCB assembly; it’s the backbone of performance. A well-executed circuit card assembly ensures that electronic components function seamlessly together, leading to optimal device operation. Conversely, poor quality can lead to failures and malfunctions, emphasizing why investing in high-quality printed circuit board assembly is crucial for success.

The Significance of PCB Assembly Expertise

The intricacies involved in how are circuit boards made necessitate a high level of expertise in PCB assembly. Skilled professionals understand the nuances of circuit card assembly techniques and know how to source high-quality electronic components effectively. Their knowledge not only enhances reliability but also fosters innovation, paving the way for advancements in printed circuit assembly.

Looking Ahead in Circuit Board Manufacturing

The future of PCB manufacturing holds exciting possibilities as technology continues to evolve and adapt to customer needs. Innovations will drive more efficient methods for producing high-quality pcb board assembly while maintaining cost-effectiveness and speed. As we look ahead, embracing these changes will be key to staying competitive in an ever-evolving market.