Introduction

In the rapidly evolving world of electronics, the quality of printed circuit assembly (PCA) is paramount. As devices become more complex and integral to daily life, the demand for high-quality circuit boards has surged. Consequently, partnering with reputable PCB assembly companies is essential to ensure reliability and performance.

Importance of Quality in PCB Assembly

Quality in PCB manufacturing and assembly directly impacts the functionality and longevity of electronic devices. High-quality PCBs can withstand various environmental conditions, reducing failure rates and enhancing overall product reliability. Therefore, investing in top-notch printed board assembly processes not only safeguards your products but also builds trust with customers.

Key Benefits of Choosing a Manufacturer

Choosing a reliable manufacturer for your PCB fabrication and assembly needs offers numerous advantages. Firstly, established pcb manufacturing assembly companies often utilize advanced technologies that enhance precision during production. Secondly, they provide comprehensive support throughout the process—ensuring that your project meets deadlines without compromising on quality.

Overview of PCB Assembly Industry

The PCB assembly industry has seen significant growth due to the increasing demand for electronic components across various sectors such as automotive, healthcare, and telecommunications. This growth has led to a diverse landscape filled with numerous pcb assembly companies specializing in different aspects of production—from design to fabrication and final assembly. Understanding this landscape is crucial for businesses looking to navigate their options effectively while seeking high-quality solutions tailored to their specific needs.

Understanding PCB Assembly

Printed circuit board (PCB) assembly is a critical process in the electronics industry, where various electronic components are mounted onto a circuit board to create functional devices. The purpose of PCB assembly is to ensure that these components work harmoniously together, allowing for the efficient operation of electronic products. With the increasing demand for advanced technology, understanding the nuances of PCB manufacturing and assembly has never been more important.

Definition and Purpose

PCB assembly refers to the process of soldering electrical components onto a printed circuit board to form a complete electronic circuit. This involves both surface mount technology (SMT) and through-hole technology, depending on the design requirements of the circuit board. The primary purpose is to create reliable connections between components, which is essential for ensuring that electronic devices perform as intended.

Importance of High-Quality PCBs

High-quality PCBs are vital for the longevity and reliability of electronic devices; they can significantly impact performance and reduce failure rates in critical applications. Poorly manufactured printed board assemblies can lead to malfunctions, costly repairs, or even safety hazards in some industries. Therefore, choosing reputable pcb assembly companies that prioritize quality in their fabrication and assembly processes is crucial for any business looking to maintain its reputation and customer satisfaction.

Common Applications and Industries

PCBs are used across various industries including consumer electronics, automotive, telecommunications, medical devices, and aerospace. In consumer electronics, they serve as the backbone for smartphones, laptops, and home appliances—making reliable printed circuit assemblies essential for everyday use. Meanwhile, industries like automotive rely on high-performance pcbs for safety features such as anti-lock braking systems or airbag deployment mechanisms; thus highlighting how crucial quality assurance is in pcb manufacturing assembly.

Selecting the Right PCB Assembly Company

Choosing the right PCB assembly company is crucial for ensuring the success of your electronic projects. The quality of printed circuit assembly directly impacts the functionality and reliability of your final product. With a plethora of options available, understanding what to look for can help you make an informed decision that aligns with your specific needs.

Factors to Consider in a Manufacturer

When evaluating pcb assembly companies, several factors come into play that can make or break your project. First and foremost, consider their experience in pcb manufacturing and assembly; a company with a solid track record is more likely to deliver high-quality results. Additionally, assess their capability in handling various types of circuit board designs, as this flexibility can be essential depending on your project's complexity.

Quality control measures are another critical aspect to investigate; manufacturers should have robust processes in place to ensure defect-free printed board assembly. It's also wise to look at their customer service and support—after all, open communication can lead to smoother collaboration throughout the manufacturing process. Lastly, don't forget to evaluate pricing structures; while you want high-quality pcb fabrication and assembly, it’s essential that it fits within your budget.

Bensun Technology: A Leader in Quality

Bensun Technology stands out among pcb assembly companies due to its unwavering commitment to quality and innovation in the industry. With years of experience specializing in printed circuit assembly and comprehensive services encompassing pcb manufacturing and assembly, Bensun has established itself as a trusted partner for businesses seeking superior solutions. Their state-of-the-art facilities utilize cutting-edge technology that ensures precision during every phase of production.

What sets Bensun apart is not just their technical expertise but also their customer-centric approach; they work closely with clients from initial design through final delivery, ensuring each step meets rigorous standards for quality control. Furthermore, they offer tailored services that accommodate unique project requirements—whether it's small volume runs or large-scale production—making them an ideal choice for diverse applications across industries. Choosing Bensun Technology means investing in reliability and excellence for your next project.

Comparing Services Offered by Different Companies

As you navigate through various pcb assembly companies, it's vital to compare the range of services they provide carefully. Not all manufacturers specialize equally; some may focus solely on basic printed board assembly while others offer extensive customization options alongside advanced technologies like surface mount technology (SMT) or through-hole components integration within their pcb manufacturing and assembly processes. Understanding these differences will help you identify which company aligns best with your project needs.

Moreover, consider additional services such as prototyping capabilities or after-sales support when comparing different manufacturers; these elements can significantly influence both efficiency and long-term satisfaction with your chosen provider. Don't hesitate to request samples or case studies from potential partners—they can give you valuable insight into each company's work quality and turnaround times on actual projects involving circuit board fabrication and assembly.

In conclusion, selecting the right PCB assembly company involves careful consideration of various factors including experience, quality control measures, service offerings, and customer support—all crucial elements that contribute significantly to successful outcomes in electronic design projects.

The PCB Manufacturing Process

The journey from concept to a fully functional printed circuit board (PCB) is a fascinating one, filled with intricate steps and advanced technology. Understanding the PCB manufacturing process is crucial for anyone involved in electronics, whether you're an engineer or a hobbyist. This section will guide you through the essential phases of PCB manufacturing and assembly, highlighting the importance of quality at every stage.

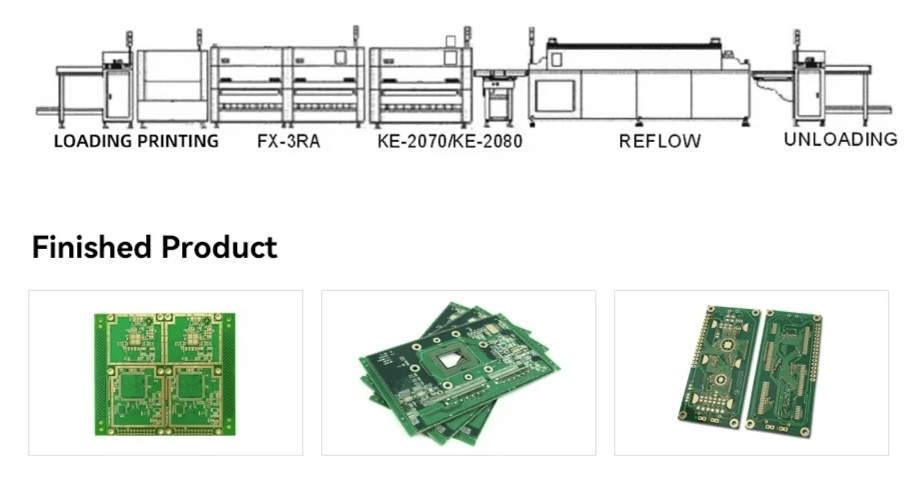

Step-by-Step Breakdown of PCB Manufacturing

The PCB manufacturing process begins with designing the circuit board layout using specialized software, ensuring that all components are placed accurately. Once the design is finalized, it moves to the fabrication stage where raw materials are transformed into printed circuit assemblies through techniques like etching and drilling. After fabrication, components are soldered onto the board in a meticulous assembly process, which can involve both automated machinery and skilled labor.

Next comes testing to ensure that each printed board assembly meets stringent quality standards before it’s sent out for distribution. Each step in this process plays a vital role in guaranteeing that the final product functions as intended in its application—be it consumer electronics or critical industrial equipment. By choosing reputable pcb assembly companies, businesses can ensure that their products are built on a solid foundation of quality and reliability.

Quality Control Measures in Place

Quality control is paramount throughout pcb manufacturing and assembly processes to prevent defects that could lead to costly failures later on. Manufacturers implement rigorous testing protocols at various stages—from initial design verification to final functional testing—ensuring every aspect meets industry standards. Techniques such as Automated Optical Inspection (AOI) and X-ray inspection allow for thorough examination of solder joints and component placements without damaging the circuit boards.

Moreover, many leading pcb assembly companies adhere to international standards like ISO 9001 or IPC-A-610, which provide frameworks for maintaining high-quality production practices. These measures not only enhance product reliability but also instill confidence among clients who understand that their printed circuit assemblies have undergone meticulous scrutiny before reaching them. In an industry where precision is key, robust quality control measures cannot be overlooked.

Role of Technology in PCB Production

Technology has revolutionized pcb fabrication and assembly by introducing advanced machinery and software tools designed to improve efficiency and accuracy. From Computer Numerical Control (CNC) machines used for precise drilling to sophisticated pick-and-place machines that automate component placement on pcbs, technological advancements streamline production while reducing human error. Additionally, simulation software allows designers to predict performance issues before physical prototypes are created.

Furthermore, innovations such as additive manufacturing (3D printing) are beginning to make waves in how circuit boards are produced—offering new possibilities for complex designs that were previously unattainable with traditional methods. As technology continues to evolve within the realm of printed circuit board assembly, manufacturers must stay ahead of trends to maintain competitiveness while ensuring high-quality outputs remain consistent across all products they produce.

Innovations in PCB Assembly

The world of PCB assembly is rapidly evolving, driven by technological advancements and changing market demands. As industries increasingly rely on printed circuit assembly for their electronic devices, manufacturers are embracing innovative practices to enhance efficiency and quality. This section explores the emerging trends in the industry, how technology is enhancing quality, and what the future holds for high-quality PCBs.

Emerging Trends in the Industry

One prominent trend in PCB manufacturing and assembly is the shift toward automation. Many pcb assembly companies are investing in automated systems to streamline production processes, reduce labor costs, and improve precision. Additionally, there's a growing emphasis on eco-friendly practices within printed board assembly, as manufacturers seek sustainable materials and waste reduction methods to meet environmental standards.

Another trend gaining traction is miniaturization. As electronic devices become smaller and more complex, there’s a demand for intricate circuit board designs that can accommodate advanced functionalities without sacrificing performance. This has led to innovations in pcb fabrication and assembly techniques that allow for tighter component placement while maintaining signal integrity.

Lastly, the rise of IoT (Internet of Things) has significantly impacted how pcbs are designed and assembled. With more devices becoming interconnected, manufacturers are focusing on developing high-density interconnect (HDI) boards that support advanced communication technologies. These trends highlight the industry's commitment to meeting modern demands while pushing the boundaries of what’s possible with printed circuit assemblies.

How Technology Enhances Quality

Technology plays a crucial role in enhancing the quality of PCB manufacturing assembly processes. Advanced software tools enable designers to simulate circuit behavior before physical production begins, ensuring potential issues are addressed early on. Moreover, real-time monitoring systems during production help identify defects instantly, allowing for immediate corrections that minimize waste.

Furthermore, innovations like 3D printing are transforming traditional pcb fabrication and assembly methods by allowing rapid prototyping of complex designs at a fraction of conventional costs. This not only speeds up development times but also enables companies to test various configurations quickly without committing extensive resources upfront. The integration of AI-driven analytics into manufacturing workflows also aids in predictive maintenance—reducing downtime by anticipating equipment failures before they occur.

Finally, improved materials technology contributes significantly to higher-quality pcbs by offering better thermal management properties and enhanced electrical performance capabilities. These advancements ensure that products not only meet but exceed industry standards while providing reliability even under demanding conditions.

The Future of High-Quality PCBs

Looking ahead, the future of high-quality PCBs promises exciting developments driven by continuous innovation within pcb assembly companies worldwide. One significant focus will be on integrating smart technologies into pcbs themselves—creating intelligent circuits capable of self-diagnosis or adaptive functionality based on environmental conditions or user interaction patterns.

Additionally, as 5G technology expands globally, there will be an increased demand for robust printed circuit assemblies capable of supporting higher frequencies without compromising performance or reliability. This shift will likely lead to new design paradigms focused on optimizing signal pathways while minimizing interference—a challenge that will require cutting-edge solutions from both manufacturers and designers alike.

Lastly, sustainability will remain at the forefront as consumers demand greener electronics solutions; thus driving further research into recyclable materials used in pcb manufacturing and assembly processes alongside energy-efficient production methods—ensuring that tomorrow's products not only perform well but also contribute positively towards our planet's health.

Advantages of High-Quality PCB Assembly

Reliability in Critical Applications

Reliability is paramount when it comes to circuit boards used in mission-critical applications such as medical devices, aerospace systems, and automotive electronics. High-quality PCB manufacturing and assembly processes ensure that each printed board assembly meets rigorous standards, minimizing the risk of failure under pressure. When you choose reputable PCB assembly companies, you’re not just selecting a service; you're opting for peace of mind knowing that your products will perform reliably even in the most demanding environments.

The durability provided by high-quality PCBs translates into fewer malfunctions and recalls, which can be disastrous for businesses relying on these technologies. This reliability leads to greater customer trust and satisfaction—essential factors that can enhance your brand reputation over time. In an industry where every second counts, having dependable circuit boards at your disposal makes all the difference.

Cost Savings Over Time

While opting for low-cost solutions might seem appealing initially, high-quality printed circuit fabrication and assembly often lead to significant cost savings down the line. Superior materials and precise manufacturing techniques reduce defects, leading to fewer replacements or repairs over time. This means less money spent on warranty claims or product recalls—savings that can be redirected towards innovation or expansion efforts.

Moreover, investing in quality from reputable PCB manufacturing companies often results in more efficient production cycles due to fewer errors during assembly. These efficiencies not only save money but also speed up time-to-market for new products, giving businesses a competitive edge in their respective industries. Ultimately, choosing high-quality PCB manufacturing assembly services pays off by enhancing both operational efficiency and profitability.

Enhancing Product Performance

High-quality PCB fabrication and assembly directly contribute to enhanced product performance across various applications—from consumer electronics to industrial machinery. Well-designed printed circuit assemblies ensure optimal electrical conductivity while minimizing signal loss or interference issues that could hinder functionality. This is particularly important as devices become more complex; every component must work seamlessly together for optimal performance.

Additionally, advanced technology used by leading pcb assembly companies helps ensure that components are placed with precision during the manufacturing process—resulting in improved overall device efficiency. The better your circuit board performs, the more likely it is to meet customer expectations for speed and reliability—both critical factors in today’s fast-paced market landscape. By prioritizing quality at every stage of production with trusted pcb manufacturing and assembly partners, you set yourself up for success.

Conclusion

In the fast-paced world of electronics, the significance of quality in PCB assembly cannot be overstated. High-quality printed circuit assembly ensures that your circuit boards function reliably and efficiently, which is crucial for both consumer and industrial applications. As we’ve explored throughout this guide, choosing the right PCB manufacturing and assembly partner is vital for your project's success.

Why Quality Matters in PCB Assembly

Quality matters in PCB assembly because it directly impacts the performance and longevity of electronic devices. A well-manufactured printed board assembly can withstand rigorous conditions, reducing the likelihood of failures that could lead to costly downtime or product recalls. Moreover, high-quality circuit board fabrication and assembly not only enhance reliability but also contribute to overall cost savings by minimizing repairs and replacements over time.

Choosing Bensun Technology for Your Needs

When it comes to selecting a manufacturer from the myriad of PCB assembly companies available, Bensun Technology stands out as a leader in quality and innovation. With a commitment to excellence in pcb manufacturing and assembly processes, they ensure that every printed circuit assembly meets stringent industry standards. Their advanced technology and skilled workforce are dedicated to providing tailored solutions that cater to your specific needs in pcb fabrication and assembly.

Next Steps for Your PCB Assembly Journey

As you embark on your PCB manufacturing journey, consider evaluating your project requirements carefully before making a decision on a manufacturer. Reach out to Bensun Technology for consultations or quotes; their team is ready to assist you with any questions regarding printed circuit assembly services or capabilities. Take action now—investing in high-quality pcb manufacturing assembly will pay off significantly as you strive for success in today’s competitive market.