Introduction

In today's technology-driven world, the significance of quality PCB services cannot be overstated. Printed circuit boards (PCBs) serve as the backbone of electronic devices, making their manufacturing and assembly pivotal for reliability and performance. As the demand for sophisticated electronic products grows, so does the need for efficient PCB manufacturing companies that can deliver high-quality solutions.

Importance of Quality PCB Services

Quality in PCB manufacturing is essential to ensure that electronic devices function reliably and efficiently. Poorly manufactured circuit boards can lead to malfunctions, increased costs due to repairs, and even safety hazards. Thus, partnering with reputable PCB manufacturing companies is crucial for businesses looking to maintain a competitive edge in the electronics market.

Overview of PCB Manufacturing Companies

The landscape of PCB manufacturing companies is diverse, with each offering unique capabilities in terms of design, fabrication, and assembly processes. These companies specialize in various types of PCBs—including single-sided, double-sided, and multilayer boards—catering to a wide range of industries from consumer electronics to automotive applications. Understanding the strengths and specialties of different manufacturers can help businesses choose the right partner for their specific needs.

The Role of Bensun Technology in PCB Solutions

Bensun Technology stands out among PCB assembly manufacturers by offering comprehensive solutions that encompass every stage from design validation to circuit card assembly. With a commitment to quality control and customer satisfaction, Bensun ensures that every product meets stringent industry standards while also embracing innovations in electronic manufacturing services. By choosing Bensun Technology for your PCB fabrication and assembly needs, you gain a trusted partner dedicated to delivering excellence.

Understanding PCB Design

The world of PCB design is both intricate and fascinating, playing a pivotal role in the success of any electronic device. As technology advances, understanding the nuances of PCB manufacturing and assembly becomes crucial for engineers and designers alike. This section will delve into the key principles of PCB design, explore effective tools available, and highlight the importance of design validation.

Key Principles of PCB Design

At its core, PCB design revolves around several key principles that ensure functionality and reliability. First off, signal integrity is paramount; ensuring that signals travel without interference can make or break your circuit board's performance. Additionally, thermal management must be considered to prevent overheating during operation—after all, nobody wants their device to fry due to poor heat dissipation!

Another principle is component placement; strategically positioning components can optimize space and improve manufacturability during circuit card assembly. Designers also need to consider manufacturability from the get-go—choosing designs that align with the capabilities of pcb manufacturing companies can save time and costs later on. Ultimately, following these principles will lead to successful printed circuit assembly and a robust final product.

Tools for Effective PCB Design

Software like Altium Designer or Eagle provides powerful features for schematic capture and layout creation that streamline the entire process—from conception through pcb fabrication and assembly. These tools often come equipped with libraries filled with components tailored specifically for different applications.

Moreover, simulation software allows designers to test their circuits virtually before committing them to physical production—this step is invaluable in avoiding costly mistakes down the line! Another great tool includes online collaboration platforms where teams can work together seamlessly on designs regardless of location; this fosters innovation while keeping everyone on the same page during development phases. With these tools at hand, designers are well-equipped to tackle complex projects efficiently.

Importance of Design Validation

Design validation is not just an optional step; it's a critical phase in ensuring that your final product meets all specifications required for successful operation. It involves rigorous testing procedures that assess various parameters such as electrical performance under different conditions—a necessity when considering pcb manufacturing processes! Without thorough validation checks in place, you risk encountering issues post-production which could lead to expensive recalls or redesigns.

Additionally, validating designs against industry standards ensures compliance with regulations set forth by governing bodies—a must-have when dealing with electronic manufacturing services across different markets globally! Involving multiple stakeholders during this phase helps gather diverse insights which can enhance overall quality assurance efforts too! So remember: investing time into design validation pays off significantly when it comes down to actual production efficiency.

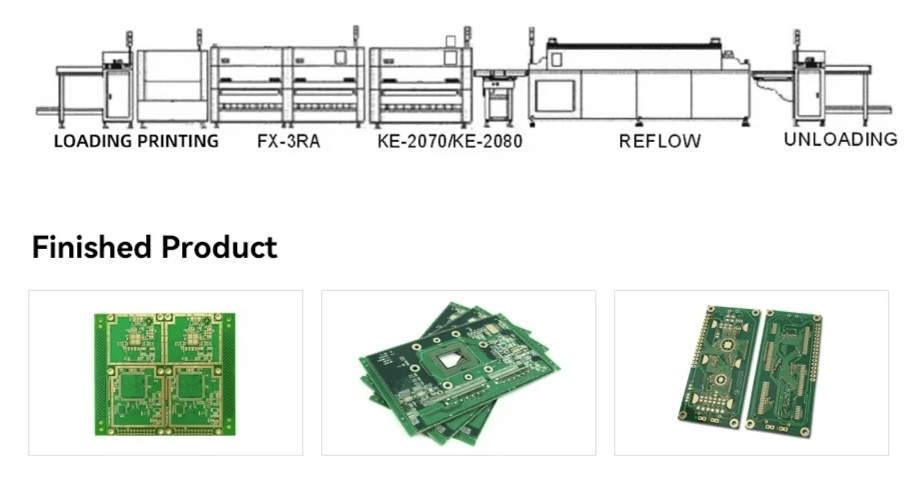

PCB Manufacturing Process Explained

The PCB manufacturing process is a complex yet fascinating journey that transforms a design concept into a functional circuit board. Understanding this process is essential for anyone involved in electronic manufacturing services, as it lays the groundwork for quality and efficiency in both PCB fabrication and assembly. Let’s delve into the steps involved, the types of PCBs available, and the materials that bring them to life.

Steps in PCB Fabrication

The journey of creating a printed circuit board begins with design files generated from sophisticated software tools. These files are then converted into photomasks, which guide the etching of copper layers on substrate materials during the fabrication process. After etching, additional processes like drilling holes for components and applying solder mask layers come into play, ensuring that each circuit card meets its intended specifications before moving on to assembly.

Once the initial fabrication is complete, manufacturers conduct rigorous testing to validate electrical integrity and ensure functionality. This step is crucial as it helps identify any potential issues before components are added during circuit card assembly. Finally, once all these steps are meticulously executed, we arrive at a fully fabricated PCB ready for its next phase—assembly.

Types of PCBs and Their Uses

PCB manufacturing companies offer a variety of PCBs tailored to different applications. Among these are single-sided PCBs, which are commonly used in simpler devices like calculators; double-sided PCBs that support more complex circuits; and multilayer PCBs designed for high-density applications such as smartphones or computers. Each type serves specific needs within various industries ranging from consumer electronics to automotive systems.

In addition to these standard types, flexible PCBs have gained popularity due to their ability to bend without damaging circuitry—ideal for wearables or compact devices where space is at a premium. Rigid-flex boards combine both rigid and flexible elements, allowing manufacturers greater versatility in design while maintaining structural integrity. These diverse options ensure that there's an ideal solution for every electronic application.

Common Materials Used in PCB Manufacturing

When it comes to materials used in PCB manufacturing and assembly, several key components play vital roles in performance and durability. The most common substrate material is FR-4—a glass-reinforced epoxy laminate known for its excellent insulation properties and mechanical strength under various conditions. Other materials might include polyimide for flexible circuits or aluminum substrates specifically designed for high-power applications.

Conductive layers typically consist of copper due to its superior conductivity properties; however, alternative materials may be employed depending on specific requirements or constraints within certain environments. Additionally, solder masks made from polymer-based substances protect against oxidation while ensuring reliable connections during circuit card assembly processes. The careful selection of these materials directly influences not only the functionality but also the longevity of the final product.

Circuit Card Assembly Techniques

Circuit card assembly is a critical phase in the life of any electronic device. It involves the meticulous process of placing and soldering components onto a printed circuit board (PCB) to create a functional electronic assembly. This stage is essential for ensuring that the final product meets quality standards and performs reliably, making it a focal point for many PCB manufacturing companies.

Overview of Circuit Board Assembly

Circuit board assembly encompasses various processes that transform bare PCBs into fully operational circuit cards. This includes component placement, soldering, and testing to ensure functionality. The assembly can be done manually or through automated systems, with each method offering different advantages depending on production volume and complexity.

As part of the broader PCB manufacturing and assembly landscape, circuit card assembly plays a vital role in determining the final product's reliability and performance. It’s not just about connecting components; it’s about ensuring that every connection is secure and capable of withstanding operational stresses. With advancements in technology, modern techniques have streamlined this process significantly while enhancing precision.

Differences Between Printed Circuit Assembly and Others

Printed circuit assembly (PCA) specifically refers to assembling components onto printed circuit boards, distinguishing it from other types of electronic manufacturing services such as surface mount technology (SMT) or through-hole technology (THT). While PCA focuses on integrating components directly onto PCBs, other methods may involve different substrates or less permanent connections.

One key difference lies in how components are attached; PCA often employs soldering techniques that provide strong electrical connections suitable for high-performance applications. In contrast, other methods might use adhesive bonding or mechanical fastening which can be less reliable under certain conditions. Understanding these distinctions helps businesses choose the right approach based on their specific needs within the PCB fabrication and assembly realm.

Benefits of Professional Circuit Card Assembly

Opting for professional circuit card assembly offers numerous advantages that can enhance product quality and reduce time-to-market for electronics manufacturers. Professional assemblers bring expertise in optimizing layout designs to minimize signal interference while maximizing space efficiency on PCBs—crucial factors in today’s compact electronic devices.

Moreover, partnering with experienced PCB assembly manufacturers ensures adherence to industry standards and regulatory compliance throughout the entire process—from sourcing materials to final testing phases. This level of professionalism not only elevates product reliability but also instills confidence among clients regarding quality assurance practices employed by PCB manufacturing companies.

In conclusion, investing in professional circuit card assembly can lead to superior product outcomes while allowing manufacturers to focus on innovation rather than getting bogged down by production complexities inherent in DIY approaches.

Choosing a PCB Assembly Manufacturer

Selecting the right PCB assembly manufacturer can be a daunting task, especially with the multitude of options available in the market today. Factors such as quality, cost, lead time, and customer support play pivotal roles in making an informed decision. As you navigate through various pcb manufacturing companies, understanding what sets each apart will help ensure that your circuit card assembly needs are met efficiently.

Factors to Consider When Selecting a Manufacturer

When evaluating potential pcb assembly manufacturers, start by considering their experience and reputation within the industry. Look for companies that specialize in printed circuit assembly and have a proven track record of delivering high-quality products on time. Additionally, assess their capabilities in terms of technology and equipment; advanced machinery can significantly enhance the efficiency of pcb fabrication and assembly processes.

Another key factor is communication; you want a partner who is responsive and open to collaboration throughout your project’s lifecycle. Ensure they offer comprehensive electronic manufacturing services that cover everything from design support to final assembly. Lastly, don’t forget to check customer reviews and testimonials—these insights can provide valuable information about the manufacturer’s reliability and service quality.

Bensun Technology’s Approach to Quality Control

Bensun Technology stands out among pcb manufacturing companies due to its rigorous approach to quality control at every stage of production. They implement strict testing protocols during both pcb fabrication and assembly processes to ensure that every circuit board meets industry standards before it leaves the facility. This commitment not only minimizes defects but also enhances overall product reliability.

Furthermore, Bensun employs advanced inspection technologies such as automated optical inspection (AOI) systems that catch potential issues early on in production. Their skilled team conducts regular audits and reviews to continuously improve processes based on feedback from clients and internal assessments alike. This proactive stance guarantees that customers receive top-notch printed circuit assemblies tailored precisely to their specifications.

Customer Testimonials on PCB Services

Customer testimonials speak volumes about a company’s ability to deliver quality services consistently, particularly when it comes to pcb manufacturing companies like Bensun Technology. Many clients rave about their seamless experience with Bensun—from initial design consultations through final delivery—highlighting how responsive their team is throughout each phase of circuit card assembly projects.

Satisfied customers often emphasize how Bensun's attention to detail has positively impacted their own operations, leading them to choose this manufacturer repeatedly for ongoing electronic manufacturing services needs. The positive feedback reflects not just product quality but also excellent customer service—a crucial component when selecting a reliable pcb assembly manufacturer for your projects.

Electronic Manufacturing Services and Trends

The landscape of electronic manufacturing services is evolving rapidly, driven by technological advancements and increasing market demands. As businesses seek to streamline production and enhance product quality, the need for reliable PCB manufacturing companies has surged. This growing demand underscores the importance of efficient circuit card assembly processes that can meet diverse industry requirements.

Growing Demand for Electronic Manufacturing Services

In recent years, the demand for electronic manufacturing services has skyrocketed, fueled by advancements in technology and a robust consumer electronics market. Companies are increasingly outsourcing their PCB fabrication and assembly needs to specialized manufacturers to focus on their core competencies. This trend not only optimizes production efficiency but also allows businesses to leverage the expertise of seasoned PCB assembly manufacturers who can deliver high-quality results at competitive prices.

As industries such as automotive, telecommunications, and medical devices expand their reliance on complex electronics, the need for sophisticated printed circuit assembly techniques has become paramount. The ability to produce reliable circuit boards quickly is crucial in meeting tight deadlines while ensuring compliance with stringent regulatory standards. Consequently, PCB manufacturing companies are continuously innovating their processes to stay ahead of this growing demand.

Innovations in PCB Fabrication and Assembly

Innovation is at the heart of modern PCB fabrication and assembly techniques, with new technologies emerging that revolutionize how circuit boards are produced. Advanced automation in manufacturing processes enhances precision while reducing lead times significantly—an essential factor in today's fast-paced market environment. Moreover, innovations such as 3D printing and additive manufacturing are reshaping traditional methods of producing PCBs by enabling more complex designs that were previously unattainable.

Another exciting development is the integration of smart technologies into circuit card assembly operations—think IoT-enabled machines that monitor performance metrics in real-time! These innovations ensure higher quality control standards while minimizing human error during production runs. As a result, manufacturers can produce highly intricate printed circuit assemblies that cater to specialized applications across various sectors.

Future Trends in PCB Manufacturing

Looking ahead, several trends are poised to shape the future of PCB manufacturing significantly. One key trend is sustainability; more pcb manufacturing companies are adopting eco-friendly practices by utilizing recyclable materials and reducing waste during production processes. This shift not only meets consumer demand for greener products but also helps companies comply with increasing environmental regulations.

Additionally, we anticipate a rise in flexible PCBs due to their versatility across different applications—from wearable technology to compact devices needing space-saving designs. The evolution toward miniaturization will drive innovation further within both pcb fabrication and assembly sectors as manufacturers strive to create thinner yet robust circuit boards without compromising performance or reliability.

Finally, as global supply chains recover from disruptions caused by recent events like pandemics or geopolitical tensions, we expect an increased focus on local sourcing strategies among businesses seeking stability in their electronic manufacturing services partnerships. By collaborating closely with reputable pcb assembly manufacturers domestically or regionally, companies can ensure quicker response times while maintaining high-quality standards.

Conclusion

In the ever-evolving world of electronics, insights into PCB manufacturing and assembly are crucial for staying ahead. From understanding the intricacies of PCB design to the importance of circuit card assembly techniques, we've covered the essential elements that make up the backbone of electronic devices. Partnering with reputable PCB manufacturing companies can significantly enhance product quality and reliability.

Summary of PCB Manufacturing Insights

Throughout our exploration, we delved into various aspects of PCB fabrication and assembly, highlighting its significance in modern electronics. We discussed key principles of effective PCB design, emphasizing how these foundational elements lead to successful printed circuit assembly processes. Additionally, we examined the diverse types of PCBs available and their applications across different industries, underscoring the versatility and necessity of quality circuit boards.

Importance of Partnering with Reputable Companies

Choosing a reliable PCB assembly manufacturer is vital for ensuring high standards in production and service delivery. Reputable companies often have established quality control measures that guarantee consistent results in circuit board manufacturing. By partnering with trusted names in electronic manufacturing services, businesses can mitigate risks associated with poor-quality components or assembly errors that may impact overall performance.

Why Choose Bensun Technology for PCB Solutions

Bensun Technology stands out among other pcb manufacturing companies due to its commitment to excellence in both pcb fabrication and assembly processes. Their approach emphasizes thorough quality checks at every stage—from design validation through to final inspection—ensuring top-notch products tailored to client needs. With numerous positive customer testimonials attesting to their reliability and innovation, choosing Bensun Technology means investing in superior solutions for all your circuit card assembly requirements.