Introduction

In the ever-evolving landscape of manufacturing, understanding the intricacies of pick and place feeders is vital. These components play a crucial role in ensuring efficiency and precision in surface mount technology (SMT) processes. As we delve deeper into the world of SMT feeder types, we will uncover how these devices enhance productivity and streamline operations.

Understanding Pick and Place Feeders

Pick and place feeders are essential tools that facilitate the automated assembly of electronic components onto printed circuit boards (PCBs). By accurately positioning components for placement by a pick and place machine, these feeders significantly reduce manual labor and increase production speed. The diversity among SMT feeder types allows manufacturers to select options tailored to their specific operational needs, enhancing overall efficiency.

The Role of SMT in Modern Manufacturing

Surface Mount Technology (SMT) has revolutionized modern manufacturing by enabling smaller, more efficient electronic devices. This technology relies heavily on precise component placement, making pick and place machines indispensable in the assembly process. With advancements in SMT techniques, manufacturers can achieve higher production rates while maintaining exceptional quality standards.

Key Factors in Choosing a Feeder

Selecting the right feeder involves considering several key factors that impact operational efficiency. First, understanding what is a SMT feeder helps identify its functionality within your production line; this includes evaluating its size compatibility with existing equipment. Additionally, assessing factors such as cost-effectiveness—like what is the price of JUKI pick and place machines—can help determine which feeder best meets your manufacturing goals.

What is a Pick and Place Machine?

Pick and place machines are the unsung heroes of surface mount technology (SMT) processes, revolutionizing how components are assembled onto printed circuit boards (PCBs). These machines utilize advanced robotics to precisely pick up electronic components from feeders and place them accurately on the PCB. This automation not only boosts production speed but also enhances accuracy, making it a staple in modern manufacturing.

Overview of Pick and Place Technology

At its core, pick and place technology involves sophisticated mechanisms that allow machines to identify, grasp, and position components with remarkable precision. The heart of this technology lies in its ability to integrate seamlessly with various SMT feeder types, ensuring that each component is delivered at the right moment for optimal efficiency. With advancements in vision systems and motion control, today's pick and place machines can handle an array of component sizes—making them versatile tools in any assembly line.

Importance in SMT Processes

The significance of pick and place machines in SMT processes cannot be overstated; they are integral to achieving high throughput while maintaining quality standards. By automating the placement process, manufacturers can reduce human error associated with manual assembly methods. Furthermore, these machines work harmoniously with different SMT feeder sizes to accommodate varying production demands, allowing for flexible manufacturing solutions.

Applications in Various Industries

Pick and place machines find applications across a multitude of industries—from consumer electronics to automotive manufacturing—demonstrating their versatility beyond just one sector. In consumer electronics, they ensure the rapid assembly of smartphones and tablets; while in automotive sectors, they contribute to complex circuit assemblies essential for modern vehicles' functionality. This widespread utility underscores why understanding what is a pick and place machine is crucial for businesses looking to optimize their production lines.

What is a SMT Feeder?

In the world of Surface Mount Technology (SMT), a feeder plays a pivotal role in ensuring that components are accurately placed on printed circuit boards (PCBs). Essentially, an SMT feeder is a device that supplies these components to pick and place machines, which are critical for automated assembly processes. Understanding what a pick and place feeder is, and how it functions, can significantly enhance production efficiency.

Definition and Functionality

A SMT feeder is defined as a mechanical device designed to deliver surface mount components to a pick and place machine precisely when needed. It works by holding various types of components—such as resistors, capacitors, and integrated circuits—within its compartments until they are ready for placement on the PCB. The functionality of an SMT feeder is crucial; it ensures that the right component is delivered at the right time, minimizing downtime and maximizing productivity.

When considering what is a pick and place machine?, it's essential to recognize that these machines rely heavily on feeders to maintain their speed and accuracy during assembly. The seamless operation between feeders and pick-and-place machines forms the backbone of efficient SMT processes. Thus, understanding the definition of an SMT feeder provides valuable insight into its integral role in modern manufacturing.

Different SMT Feeder Types Explained

There are several types of SMT feeders available on the market today, each designed for specific applications or component types. Common SMT feeder types include tape feeders, tray feeders, tube feeders, and bulk feeders—each catering to different component shapes and sizes. For instance, tape feeders are widely used for standard surface mount components due to their ease of use and efficiency in loading.

Understanding these various SMT feeder types can help manufacturers choose the best option based on their production needs. For example, while rotary feeders may offer higher capacity for certain parts, linear feed systems can provide quicker changeovers between different component sizes—a crucial factor when evaluating overall productivity. Knowing which type suits your production line best can significantly impact your output quality.

How Feeders Integrate with Pick and Place Machines

The integration between pick-and-place machines and SMT feeders is vital for achieving optimal performance in PCB assembly lines. When discussing how these systems work together, it becomes clear that synchronization between them impacts speed significantly; if one lags behind or fails to deliver components promptly, it can create bottlenecks in production flow.

Moreover, understanding what is a pick-and-place machine? helps clarify why accurate feeding mechanisms are necessary: they ensure that each component arrives at precisely the right moment during the assembly process without any delay or misalignment issues. This seamless interaction not only enhances efficiency but also reduces errors associated with manual handling.

In summary, knowing how SMT feeder size affects compatibility with equipment helps manufacturers make informed decisions about their machinery investments—especially when considering factors like space constraints within manufacturing facilities or evaluating what is the price of JUKI pick-and-place machines? Ultimately investing in quality feed systems will pay off through improved operational efficiency.

Evaluating SMT Feeder Size

When it comes to selecting the right pick and place feeder, size is a critical factor that can significantly impact production efficiency. A well-chosen SMT feeder size ensures that components are handled effectively, minimizing downtime and maximizing throughput. Understanding the nuances of SMT feeder sizes is essential for any manufacturing facility aiming to optimize its processes.

Importance of Size in Production

The size of an SMT feeder plays a pivotal role in production efficiency, as it directly affects how components are supplied to the pick and place machine. If the pick and place feeder is too small, it may require frequent reloading, leading to interruptions in the assembly line. Conversely, an oversized feeder might take up unnecessary space and complicate logistics within the factory floor.

Moreover, different SMT feeder types can accommodate varying component sizes; thus, selecting an appropriate size ensures compatibility with your specific production needs. This balance between capacity and functionality is crucial for maintaining a smooth workflow in high-paced environments. Ultimately, understanding what is a pick and place machine will help you appreciate how vital proper sizing of feeders can be for overall productivity.

Compatibility with Equipment

Ensuring compatibility between your chosen SMT feeder size and existing equipment is paramount for seamless operation. Not all pick and place machines can accommodate every type or size of SMT feeder; thus, understanding these specifications upfront will save time and resources down the line. When evaluating what is a SMT feeder?, consider both its dimensions and how they align with your machinery.

For instance, some feeders are designed specifically for compact assembly lines while others cater to larger operations requiring extensive component handling capabilities. It’s essential to check manufacturer guidelines regarding compatible sizes before making any purchase decisions related to JUKI pick and place machines or other brands available in the market. This foresight helps avoid costly modifications or disruptions during production runs.

Space Considerations in Manufacturing Facilities

Space constraints are another vital aspect when evaluating SMT feeder sizes within manufacturing facilities. An efficient layout not only enhances workflow but also ensures safety standards are met—cramped spaces can lead to accidents or inefficiencies during operation. Therefore, it's important to assess how much room you have available before committing to any particular pick and place feeder configuration.

In larger facilities, there may be more flexibility regarding SMT feeder types; however, smaller operations must be particularly strategic about their choices to maximize productivity without compromising space utilization. Additionally, think about future growth: choosing a slightly larger pick and place feeder now might save you from needing upgrades later on as production demands increase over time! Remember that every square foot counts when optimizing your facility's layout for maximum efficiency.

Comparing SMT Feeder Types

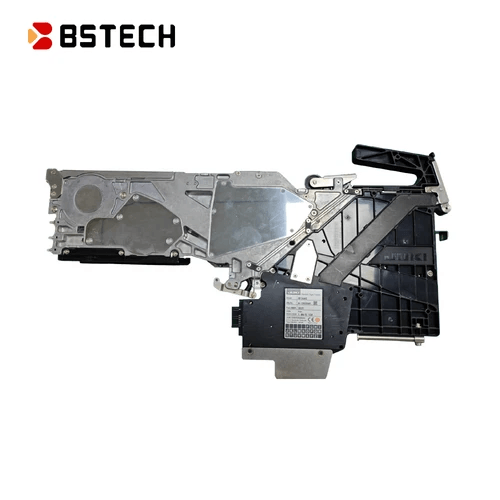

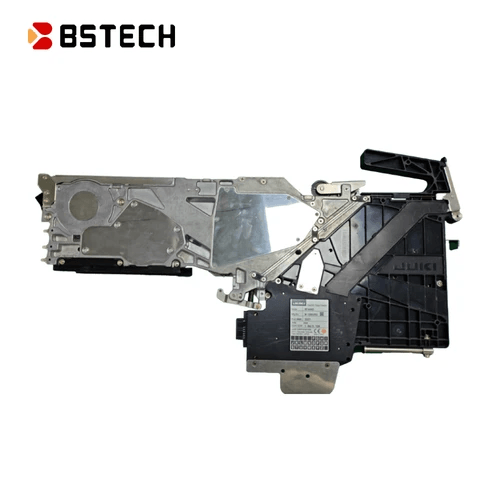

When it comes to selecting the right pick and place feeder, understanding the differences between SMT feeder types is crucial. Two of the most common designs are linear and rotary feeders, each offering unique advantages depending on production needs. This section will delve into these two types, highlight their benefits, and provide real-world examples from Bensun Technology Co., Ltd.

Linear vs. Rotary Feeders

Linear feeders operate by moving components in a straight line to the pick and place machine, which can streamline the feeding process for certain applications. They are typically easier to maintain and can handle larger components efficiently, making them ideal for high-volume production setups. On the other hand, rotary feeders utilize a circular motion to deliver components, allowing for more compact designs that save space in manufacturing facilities where SMT feeder size is a concern.

Both linear and rotary feeders have their merits; linear feeders excel in simplicity and ease of use while rotary feeders offer versatility in handling various component sizes. The choice between these SMT feeder types often depends on specific production requirements such as speed, component size variability, and available space within the facility. Understanding what is a pick and place machine helps clarify how these feeders integrate into overall operations.

Advantages of Different Designs

The advantages of linear feeders lie primarily in their straightforward design and reliability; they can accommodate larger parts without complicated adjustments or settings. This makes them particularly appealing for manufacturers focusing on high throughput with minimal downtime—essentially maximizing efficiency when considering what is a SMT feeder? Conversely, rotary feeders shine in environments where space is at a premium or where there’s a need for rapid changeovers between different component types.

In addition to physical design advantages, each type also offers distinct operational benefits that influence overall production efficiency. For instance, while linear feeders may require less frequent maintenance due to fewer moving parts, rotary feeders can be programmed for flexibility in handling diverse component shapes and sizes—showcasing their adaptability across various industries looking at what is the price of JUKI pick and place machine? Ultimately, selecting between these designs boils down to balancing efficiency with operational needs.

Case Studies from Bensun Technology Co., Ltd.

Bensun Technology Co., Ltd., known for its innovative solutions in automated assembly lines, provides compelling case studies illustrating the effectiveness of different SMT feeder types in action. In one scenario involving high-speed electronics manufacturing using linear pick and place feeders, Bensun achieved significant reductions in cycle times while maintaining precision placement—a clear demonstration of how choosing the right pick and place feeder impacts productivity directly.

Another case study highlighted Bensun's use of rotary feeders for assembling smaller consumer electronics components where space constraints were paramount. By integrating these compact systems into their workflow, they managed not only to optimize floor space but also enhance flexibility when switching between product lines—an essential factor when evaluating what is a SMT feeder? These real-life examples underscore how understanding both linear and rotary designs can lead to tailored solutions that meet specific manufacturing demands effectively.

What is the Price of JUKI Pick and Place Machines?

When considering the price of JUKI pick and place machines, it's essential to understand that various factors come into play. The cost can vary significantly based on features, capabilities, and the specific model chosen. Additionally, market demand and technological advancements also influence pricing trends in the industry.

Factors Influencing Pricing

Several key factors contribute to the pricing of JUKI pick and place machines. First, the complexity of the machine plays a crucial role; advanced models with greater precision and speed typically command higher prices. Second, options like automated SMT feeder types or additional tooling can increase overall costs, as these features enhance production efficiency but require investment.

Another factor is market competition; as new models are released or technology evolves, prices may fluctuate accordingly. Furthermore, regional differences in manufacturing costs can affect pricing as well—machines sold in areas with higher operational costs may be priced differently than those in more competitive markets. Understanding these factors helps manufacturers make informed decisions when evaluating what is a pick and place machine that best suits their needs.

Value vs. Cost in Production Efficiency

When analyzing what is the price of JUKI pick and place machines, it’s important to weigh value against cost regarding production efficiency. While initial investments can seem steep for high-end models equipped with advanced SMT feeder types, they often lead to significant long-term savings through increased throughput and reduced labor costs. This balance between upfront expenditure and ongoing operational efficiency determines whether a machine represents a smart investment for your manufacturing line.

Moreover, understanding how different SMT feeder sizes impact overall production can help justify spending on more capable equipment. For instance, larger feeders might allow for longer runs without interruptions for reloading components—translating to higher productivity levels over time. Thus, manufacturers must evaluate not just purchase price but also potential gains from enhanced performance when considering their budget.

Return on Investment Analysis

Conducting a return on investment (ROI) analysis is vital when contemplating what is the price of JUKI pick and place machines within your operation's context. An effective ROI assessment takes into account both tangible benefits—such as increased output—and intangible advantages like improved product quality due to precise placement offered by modern pick and place feeders. By calculating expected gains against initial costs over time, companies can better gauge if their investment aligns with strategic goals.

In addition to direct financial returns from enhanced operational efficiencies provided by various SMT feeder types, consider potential savings from reduced waste or defects that improve overall profitability over time. The analysis should also factor in future scalability; investing in versatile machines today might save money later if expansion or adaptation becomes necessary due to evolving production needs or market demands for new products.

Ultimately, understanding these elements equips manufacturers with insights needed to navigate pricing while ensuring they select equipment that delivers both immediate benefits and long-term value—a crucial aspect when determining what is a SMT feeder suited for their processes.

Conclusion

In the ever-evolving landscape of manufacturing, the choice of a pick and place feeder is crucial for optimizing production efficiency. As we've explored, understanding what a pick and place machine is and how it operates can significantly influence your decision-making process. Selecting the right SMT feeder types tailored to your specific needs can enhance not only productivity but also product quality.

Choosing the Right Pick and Place Feeder

When it comes to choosing a pick and place feeder, several factors come into play. First, you need to consider what is a SMT feeder? This knowledge will help you evaluate different SMT feeder sizes and their compatibility with your existing machinery. Ultimately, the right pick and place feeder will streamline your operations while ensuring that you maintain high standards of quality.

Importance of Industry Expertise

Navigating through various SMT feeder types requires industry expertise that can make all the difference in your production line's success. Understanding nuances such as what is a pick and place machine? or what is a SMT feeder? allows you to make informed decisions that align with your operational goals. With seasoned professionals guiding you through this intricate landscape, you'll be better positioned to leverage technology for maximum returns.

The Future of SMT Technology in Manufacturing

The future of SMT technology in manufacturing looks incredibly promising, driven by advancements in automation and smart technologies. As manufacturers continue to seek efficient solutions like JUKI pick and place machines at competitive prices, innovation will remain at the forefront of industry growth. By embracing new trends while understanding what is the price of JUKI pick and place machines today, companies can stay ahead in an increasingly competitive market.