Introduction

The Surface Mount Technology (SMT) industry in China has rapidly evolved into a powerhouse, playing a crucial role in the global electronics manufacturing landscape. With the increasing demand for compact and efficient electronic devices, the significance of chip mounter machines—commonly known as pick and place machines—has soared. These sophisticated machines are pivotal in ensuring precision and speed during the assembly process, making them indispensable in modern manufacturing.

Overview of SMT Industry in China

China's SMT industry is characterized by its robust growth and technological advancements, positioning itself as a leader in electronics production. The country boasts numerous china chip mounter machine factories that cater to both domestic and international markets, reflecting its commitment to innovation and quality. With an emphasis on research and development, these factories are continuously improving their machine SMT capabilities to meet evolving industry demands.

Importance of Chip Mounter Machines

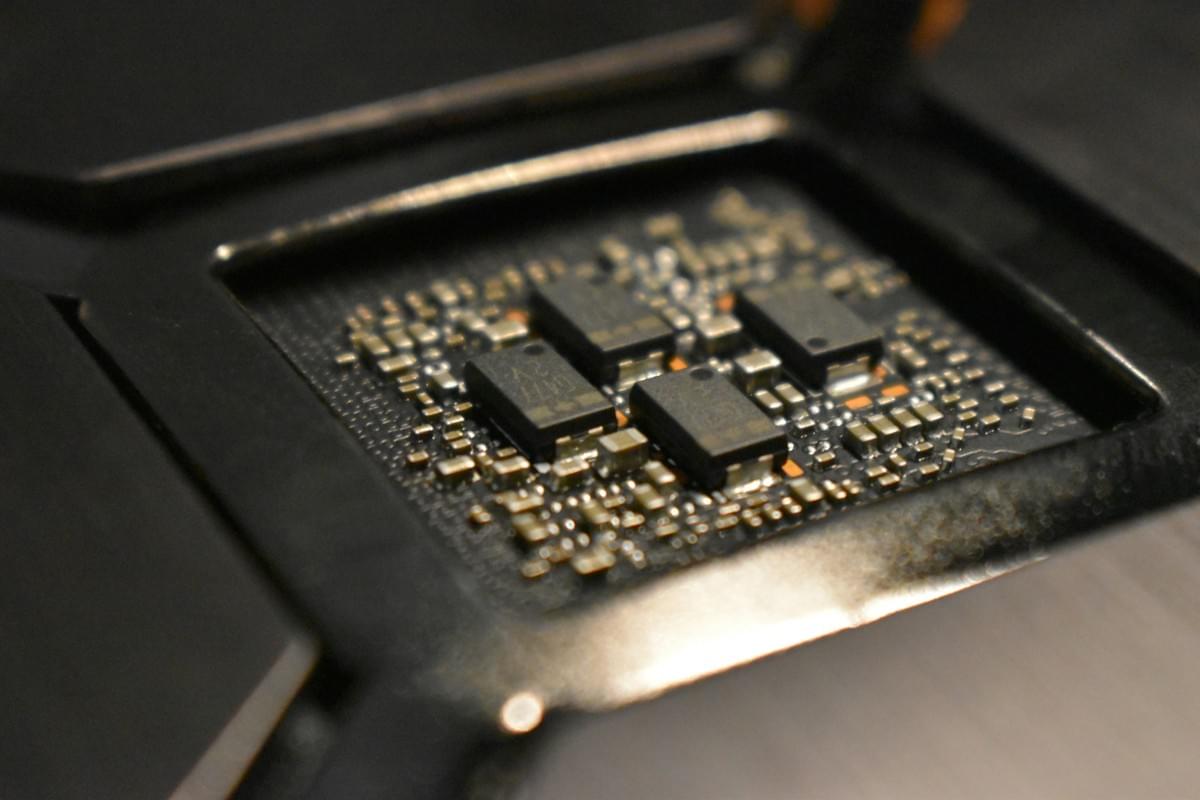

Chip mounter machines are at the heart of SMT processes, enabling manufacturers to efficiently place components onto printed circuit boards (PCBs). The accuracy of these pick & place machines directly impacts product quality and production speed, making them vital for competitive advantage. As the electronics sector continues to expand, investing in advanced SMT machines becomes essential for businesses aiming to enhance productivity and maintain high standards.

Top Manufacturers in China

In China's bustling market for SMT machinery, several manufacturers stand out due to their innovative technologies and reliable products. Companies like JUKI, Yamaha Motor Co., and Hanwha Techwin have established themselves as leaders by offering state-of-the-art chip mounter solutions tailored for various applications. These top manufacturers not only provide high-quality pick and place options but also demonstrate a commitment to customer service that is crucial for long-term partnerships.

Understanding SMT and Its Applications

The world of Surface Mount Technology (SMT) is a fascinating realm where tiny components meet precision machinery. At the heart of this technology are machines that play a critical role in modern electronics manufacturing—specifically, the pick and place machines. These devices are essential for assembling printed circuit boards (PCBs) efficiently and accurately, making them indispensable in any china chip mounter machine factory.

What Is SMT Technology

Surface Mount Technology (SMT) refers to the method of mounting electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, which requires drilling holes into the board, SMT allows for a more compact design with greater component density. This innovative approach not only enhances performance but also streamlines production processes, making it a favored choice among manufacturers seeking to optimize their operations.

Key Benefits of SMT Machines

SMT machines bring a plethora of advantages to electronics manufacturing that cannot be overlooked. First and foremost, they significantly reduce assembly time due to their high-speed capabilities—allowing for rapid machine pick and place operations that keep production lines moving smoothly. Additionally, these machines contribute to better reliability and performance by ensuring precise placement of components, which leads to fewer defects and rework.

Moreover, SMT machines are designed with flexibility in mind; they can handle various component sizes and types without extensive reconfiguration. This adaptability makes them ideal for factories looking to diversify their product offerings while maintaining efficiency in their production lines. In short, investing in quality smt machines can yield substantial returns through improved productivity and reduced operational costs.

Industries Utilizing SMT

The applications of SMT technology span across numerous industries due to its versatility and efficiency. The consumer electronics sector is perhaps the most prominent user; smartphones, tablets, and laptops all rely heavily on advanced pick & place systems for assembly efficiency. Beyond consumer goods, automotive manufacturers increasingly adopt SMT processes to produce reliable electronic control units (ECUs) that enhance vehicle safety features.

Medical device companies also benefit from this technology as precision is paramount in creating life-saving equipment such as monitors or diagnostic devices where even minor errors can have significant consequences. Furthermore, telecommunications firms utilize SMT methods in developing sophisticated network equipment that demands high performance under varying conditions—a true testament to the adaptability offered by machine smt solutions.

Leading China Chip Mounter Machine Factories

When it comes to the SMT industry in China, several chip mounter machine factories stand out for their innovation and quality. Among these, Bensun Technology has carved a niche as a prominent player in the market. Known for its advanced pick and place machines, Bensun represents the cutting edge of what machine SMT technology can achieve.

Bensun Technology Overview

Bensun Technology is a leading china chip mounter machine factory that specializes in producing high-quality pick and place machines. Their commitment to precision engineering ensures that their SMT machines deliver exceptional performance, catering to various industries from electronics to automotive manufacturing. With a diverse range of machine pick and place solutions, Bensun has positioned itself as a go-to supplier for businesses looking to enhance their production capabilities.

One of the standout features of Bensun's offerings is their focus on flexibility and efficiency in design. They provide specialized pick & place options that accommodate different component sizes and types, making them suitable for complex assembly tasks. This adaptability not only improves productivity but also helps clients optimize their manufacturing processes with advanced machine SMT technologies.

Moreover, Bensun Technology emphasizes quality assurance through rigorous testing and certification processes. By adhering to international standards, they ensure that each pick and place machine meets stringent performance criteria before it reaches customers' hands. This dedication to quality positions Bensun as a trusted partner for businesses seeking reliable chip mounter machines within China's competitive landscape.

Types of Pick and Place Machines

In the world of SMT, pick and place machines are the unsung heroes that drive efficiency and precision in electronic assembly. These machines come in various types, each designed to meet specific production needs. Understanding the different options available is crucial for any manufacturer looking to invest in a reliable machine from a china chip mounter machine factory.

High-Speed Pick and Place Options

High-speed pick and place machines are designed for maximum throughput, making them essential for high-volume production lines. These machines utilize advanced robotics and sophisticated algorithms to quickly position components with incredible accuracy, reducing cycle times significantly. For manufacturers aiming to ramp up their output without sacrificing quality, investing in a high-speed pick & place solution from a reputable china chip mounter machine factory is often the way to go.

The technology behind these machines allows them to handle an array of components—from tiny 0201 chips to larger connectors—ensuring versatility alongside speed. Many high-speed models also feature real-time monitoring systems that track performance metrics, helping manufacturers optimize their operations further. With such capabilities, it's no wonder that these machines are favored by industries requiring rapid turnaround times.

Flexible Pick and Place Solutions

Flexibility is key in today's fast-paced manufacturing environment, which is why flexible pick and place solutions have gained immense popularity among SMT manufacturers. These machines can easily adapt to different production requirements without needing extensive reconfiguration or downtime—ideal for companies that deal with varying product lines or smaller batch sizes. A well-designed flexible pick & place machine can save time and resources while maintaining high-quality standards.

These solutions often incorporate interchangeable tooling systems that allow operators to switch between component types seamlessly. This adaptability means that manufacturers can respond quickly to changing market demands or customer preferences without being hampered by rigid machinery setups. When sourcing from a china chip mounter machine factory, it's vital to consider how flexibility can enhance your overall production efficiency.

Specialized Machines for Unique Tasks

While many SMT applications can be handled by standard pick and place machines, some tasks require specialized solutions tailored for unique challenges. Specialized pick & place machines are engineered for specific functions such as handling unusual component shapes or sizes, placing components on uneven surfaces, or even working within confined spaces on complex circuit boards. Investing in such machinery can significantly enhance productivity where standard smt machines may fall short.

These specialized options often incorporate advanced features like vision systems that ensure precise placement even under challenging conditions—think multi-layered boards or intricate designs where accuracy is paramount. Choosing a specialized machine from a trusted china chip mounter machine factory ensures you have the right tools at your disposal for niche applications without compromising on quality or performance standards.

In summary, whether you’re opting for high-speed models, flexible solutions, or specialized equipment tailored for specific tasks, understanding the landscape of pick and place machinery is essential for maximizing your SMT capabilities.

Factors to Consider When Choosing Suppliers

When selecting a supplier for your SMT machines, especially from a china chip mounter machine factory, several crucial factors come into play. The right choice can significantly impact your production efficiency and overall operational success. Here, we delve into some key considerations that should guide your decision-making process.

Quality Assurance and Certifications

Quality assurance is paramount when investing in pick and place machines for your operations. A reputable china chip mounter machine factory should possess relevant certifications that validate their manufacturing processes and product quality. Look for standards such as ISO 9001 or IPC certifications, which indicate a commitment to excellence in producing reliable SMT machines.

In addition to certifications, it’s essential to assess the quality control measures in place at the factory. This includes understanding their testing protocols for each machine pick and place unit before it reaches you. Ensuring that you partner with a supplier who prioritizes quality will save you time and resources in the long run.

Price vs. Value Analysis

While cost is always a consideration when purchasing SMT machines, it’s vital to weigh price against value rather than simply opting for the lowest bid. A cheap pick & place solution may initially seem appealing but could lead to higher maintenance costs or inferior performance down the line. Therefore, analyze what features are included with each machine pick and place option to ensure you're getting adequate value for your investment.

Consider not only the upfront costs but also potential long-term savings through efficiency gains or reduced downtime provided by high-quality equipment from a trusted china chip mounter machine factory. Investing in superior SMT machines can yield better return on investment (ROI) over time compared to cheaper alternatives that may require frequent repairs or replacements.

Customer Support and Service

The level of customer support offered by suppliers can significantly influence your experience with their SMT machines after purchase. A reliable china chip mounter machine factory will provide ongoing support, including training on how to effectively operate their pick and place machinery as well as troubleshooting assistance when issues arise.

Assessing customer service ratings and reviews can give you insight into how responsive and helpful a supplier is post-sale; this factor should not be overlooked! An excellent support system can mean the difference between smooth operations and costly delays due to equipment malfunctions or misunderstandings about machine functionalities.

Innovations in SMT Machinery

The world of Surface Mount Technology (SMT) is rapidly evolving, driven by the need for increased efficiency and precision in manufacturing. In China, chip mounter machine factories are at the forefront of these innovations, introducing advanced technologies that enhance the capabilities of pick and place machines. As industries continue to demand faster production cycles and higher quality outputs, the evolution of SMT machines becomes paramount.

Emerging Technologies in SMT Machines

Emerging technologies in SMT machines are transforming how manufacturers approach assembly processes. For instance, artificial intelligence (AI) is being integrated into pick and place machines to optimize placement accuracy and speed, reducing errors during production. Additionally, advancements in vision systems allow for real-time adjustments based on component variations, further enhancing the performance of machine pick and place operations.

Another exciting trend is the development of modular designs for SMT machines that allow for easy upgrades and customization. This flexibility enables manufacturers to adapt their equipment as technology advances without needing a complete overhaul. As a result, factories can maintain competitiveness while minimizing downtime—a crucial factor in today's fast-paced market.

Sustainability Trends in Production

Sustainability is becoming a central theme in manufacturing practices worldwide, including within chip mounter machine factories across China. Many companies are focusing on energy-efficient designs for their SMT machines to reduce overall energy consumption during production processes. Innovations such as smart sensors help monitor energy usage in real-time, allowing for better resource management.

Moreover, there's a growing emphasis on using eco-friendly materials for machine construction and packaging solutions that minimize waste generation during transportation and installation. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers who prioritize sustainability when choosing products from suppliers.

Furthermore, recycling initiatives within factories are gaining traction as manufacturers look to repurpose components from older machines into new ones—extending their lifecycle while reducing environmental impact. By embracing these sustainability trends, companies can enhance their brand image while contributing positively to global ecological efforts.

Future of Chip Mounter Machines

The future of chip mounter machines looks promising with continuous advancements paving the way for smarter manufacturing solutions. In upcoming years, we can expect an increase in automation within SMT machinery that leverages robotics alongside traditional pick & place methods—leading to heightened operational efficiency. This will enable manufacturers not only to meet rising demands but also improve labor conditions by reducing manual handling tasks.

Additionally, connectivity through IoT (Internet of Things) technology will play a vital role in shaping the landscape of machine SMT operations moving forward. Real-time data analytics will empower manufacturers with insights into performance metrics and predictive maintenance needs—ultimately decreasing downtime associated with unexpected failures or repairs.

As industries evolve towards Industry 4.0 standards emphasizing digital transformation and smart manufacturing techniques; chip mounter machine factories must remain agile—adapting swiftly while implementing cutting-edge technologies that cater specifically to market demands today and tomorrow.

Conclusion

In the rapidly evolving landscape of electronics manufacturing, the choice of an SMT machine supplier is pivotal for businesses aiming to stay competitive. Selecting a reliable china chip mounter machine factory can significantly influence production efficiency and product quality. By prioritizing suppliers with proven track records, certifications, and customer support, companies can ensure they invest in the right pick and place machines for their needs.

Choosing the Right SMT Machine Supplier

When it comes to choosing an SMT machine supplier, several factors must be taken into account. Firstly, a reputable china chip mounter machine factory should offer a variety of options that cater to different production scales and complexities. Additionally, evaluating their quality assurance processes and after-sales service can provide insights into their commitment to customer satisfaction.

Moreover, consider the long-term relationship you wish to establish with your supplier. A good partnership with a reliable pick and place machine manufacturer can lead to better support during equipment upgrades or troubleshooting issues down the line. Ultimately, selecting the right supplier is about more than just price—it's about value and reliability.

Evaluating Machine Pick and Place Options

Not all pick & place machines are created equal; hence, evaluating your options thoroughly is crucial before making a decision. High-speed models may be ideal for mass production environments where speed is paramount, while flexible pick and place solutions might suit businesses that require versatility in handling various component sizes. Understanding your unique manufacturing requirements will help you choose an appropriate machine SMT that aligns with your operational goals.

Additionally, consider how user-friendly each option is; intuitive interfaces can drastically reduce training time for operators while minimizing errors during assembly processes. It's also worth exploring how easily these machines integrate with existing production lines—seamless integration can save both time and money in the long run.

The Future of SMT in China

The future of SMT in China looks promising as technological advancements continue to reshape manufacturing capabilities across industries. With innovations emerging from leading china chip mounter machine factories focusing on automation and artificial intelligence, we can expect even greater efficiency from next-generation pick & place machines. This evolution not only enhances productivity but also paves the way for sustainable practices within electronic manufacturing.

Furthermore, as global demand for electronics continues to rise, so too does China's influence in this sector—positioning itself as a leader in advanced SMT machinery development worldwide. Companies that embrace these changes will likely find themselves at the forefront of innovation while maintaining competitiveness on both local and international stages.