Introduction

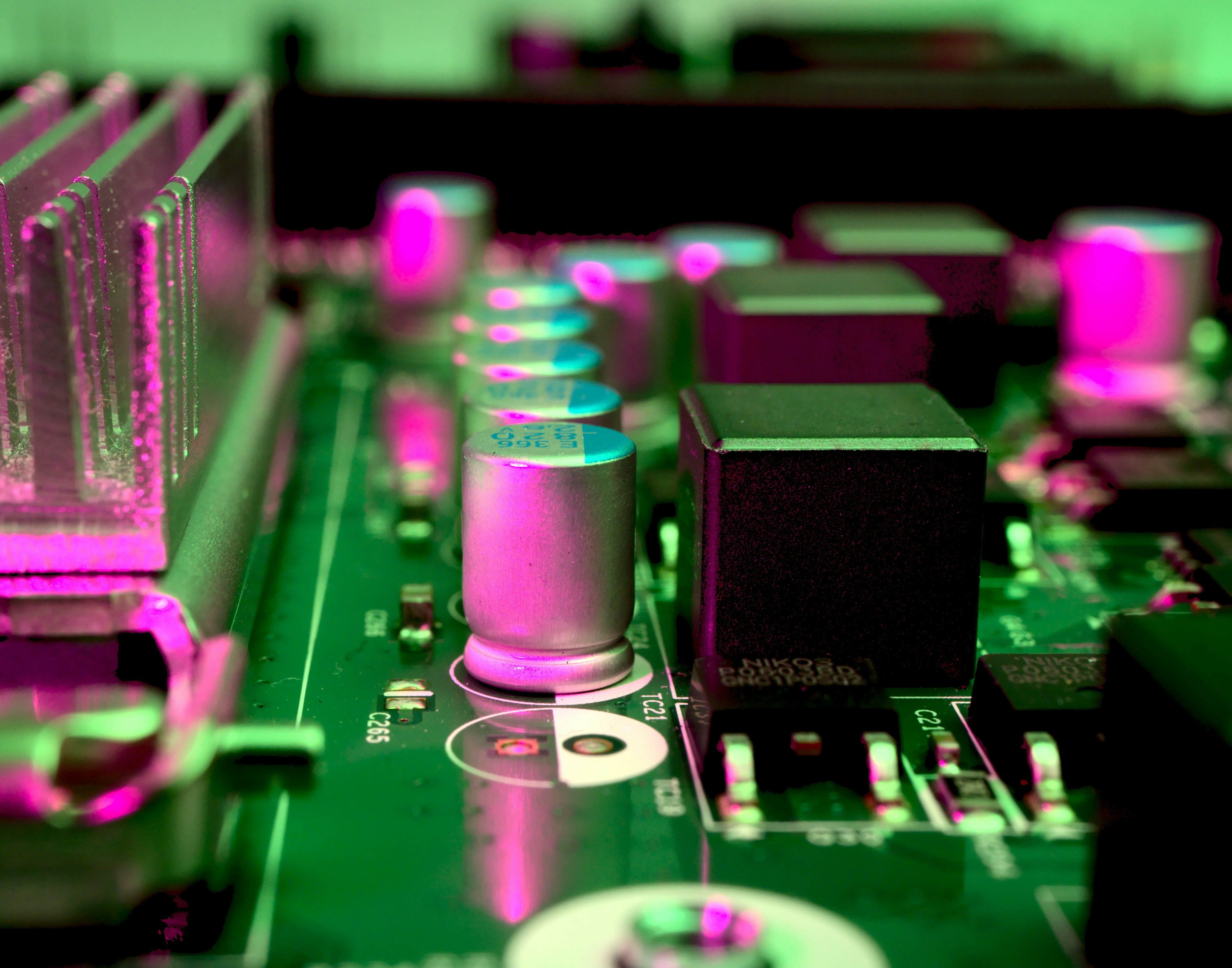

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). As we delve into the world of SMT assembly, it becomes clear that this method not only enhances efficiency but also significantly reduces the size and weight of electronic devices. Understanding what SMT assembly entails is essential for anyone involved in electronics manufacturing, as it plays a crucial role in modern technology.

Understanding Surface Mount Technology

At its core, surface mount technology involves mounting electronic components directly onto the surface of PCBs rather than inserting them through holes. This innovative approach allows for a higher density of components and more compact designs, making it a preferred choice in today's fast-paced electronics industry. To grasp what is SMT assembly fully, one must appreciate how it integrates various components seamlessly into everyday devices.

Importance of SMT in Electronics

The importance of SMT in electronics cannot be overstated; it has become the standard for assembling circuit boards across numerous applications. By facilitating smaller and lighter designs, SMT enables manufacturers to create more efficient products that cater to consumer demands for portability and performance. Furthermore, understanding what does SMT stand for helps clarify its significance: it's not just about mounting; it's about advancing technology.

Overview of SMT Assembly Techniques

The SMT assembly process encompasses several techniques that ensure precision and reliability when integrating components into PCBs. From solder paste application to component placement and reflow soldering, each step is critical in achieving optimal performance and durability of electronic devices. By exploring what is the SMT used for, we can see how these techniques contribute to various industries ranging from consumer electronics to automotive applications.

What is SMT Assembly?

Surface Mount Technology (SMT) assembly is a revolutionary method of assembling electronic components onto printed circuit boards (PCBs). This innovative technique allows for the placement of components directly onto the surface of the PCB, rather than inserting them through holes as in traditional methods. The result? A more compact design, improved performance, and increased efficiency in the manufacturing process.

Definition and Basics

So, what is SMT assembly exactly? At its core, SMT assembly refers to the process of mounting electronic components—like resistors, capacitors, and integrated circuits—onto PCBs using surface mount technology. This method has gained prominence due to its ability to accommodate smaller components and higher circuit densities compared to conventional through-hole techniques.

The basics of SMT assembly involve several steps: component placement on the PCB, solder paste application, reflow soldering, and inspection. Each step plays a crucial role in ensuring that electronic devices function correctly and efficiently. Understanding these fundamentals sets a solid foundation for grasping how SMT assembly has transformed modern electronics.

Historical Background

The evolution of SMT assembly can be traced back to the 1960s when manufacturers began seeking ways to miniaturize electronic components without sacrificing performance. Initially developed for military applications due to their ruggedness and reliability, surface mount technology quickly made its way into commercial products by the 1980s. The demand for smaller devices with enhanced capabilities fueled further advancements in this field.

By the late 1990s, what does SMT stand for? It stood for a standard that was synonymous with innovation in electronics manufacturing. Today’s gadgets—from smartphones to advanced medical equipment—are all products of this groundbreaking technology that shifted paradigms in how we think about circuitry.

Key Components of SMT

When discussing what is SMT used for, it's essential to highlight some key components involved in this process. First up are passive components like resistors and capacitors that help manage electrical flow within circuits. Next are active components such as microcontrollers and integrated circuits—these are often considered the brains behind any device.

Another vital element in the SMT assembly process is solder paste; it acts as both adhesive and conductor during component attachment on PCBs. Additionally, specialized machines known as SMT assembly machines streamline this entire operation by automating placement and soldering tasks with remarkable precision. Together, these elements form an intricate dance that makes modern electronics possible while showcasing why surface mount technology remains at the forefront of innovation today.

What Does SMT Stand For?

When diving into the world of electronics, you may have stumbled upon the acronym SMT. But what does it really mean? Understanding this term is crucial for anyone involved in the SMT assembly process, as it encapsulates a technology that has revolutionized how electronic components are mounted on circuit boards.

Breakdown of the Acronym

SMT stands for Surface Mount Technology. This term highlights a method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs), rather than being inserted through holes as in traditional methods. The efficiency and compactness of SMT assembly have led to its widespread adoption in modern electronics.

Terminology in Surface Mount Technology

In the realm of surface mount technology, several key terms frequently pop up. You'll encounter phrases like solder paste, which is essential for attaching components during the SMT assembly process, and pick-and-place, referring to machines that automate component placement on PCBs. Familiarity with these terms can significantly enhance your understanding and communication within the electronics field.

How SMT Differs from Through-Hole Technology

One major distinction between SMT and through-hole technology lies in their mounting techniques. While through-hole components are inserted into drilled holes on a PCB, SMT assembly relies on soldering components directly onto the board's surface, allowing for greater design flexibility and miniaturization. This fundamental difference not only impacts manufacturing processes but also influences performance characteristics such as electrical efficiency and thermal management.

What is SMT Used For?

Surface Mount Technology (SMT) is a pivotal aspect of modern electronics, enabling the miniaturization and enhanced performance of devices. So, what is SMT used for? The applications are vast and varied, ranging from consumer electronics to medical devices, automotive components, and beyond. This technology allows for more compact designs while maintaining high reliability and efficiency.

Applications in Modern Electronics

In today’s world, SMT assembly plays a crucial role in numerous applications across various sectors. From smartphones that fit comfortably in our pockets to sophisticated medical equipment that saves lives, SMT is everywhere. Additionally, it’s widely used in automotive electronics such as engine control units (ECUs), advanced driver-assistance systems (ADAS), and infotainment systems—essentially powering the tech that drives us forward.

Moreover, the versatility of SMT means it can be found in everyday household items like microwaves and washing machines as well as complex industrial machinery. As we delve deeper into what does the SMT stand for? It represents innovation and efficiency—a cornerstone of electronic manufacturing today.

Benefits Over Traditional Methods

What makes SMT assembly stand out when compared to traditional through-hole technology? Firstly, the ability to place components on both sides of a circuit board significantly increases component density without sacrificing performance. This leads to smaller PCB sizes while enhancing functionality—perfect for today's compact gadgets where space is at a premium.

Another benefit of Surface Mount Technology is improved electrical performance due to shorter interconnections between components. This reduced lead length minimizes parasitic capacitance and inductance—issues that can plague traditional methods. In summary, what is the SMT used for? It streamlines production processes while offering superior quality and reliability over older technologies.

Industries Benefiting from SMT

The industries benefiting from SMT are extensive; virtually every sector that relies on electronics has embraced this technology. Consumer electronics manufacturers leverage SMT assembly to produce everything from TVs to gaming consoles with remarkable speed and precision. Similarly, the medical industry utilizes surface mount technology for devices like pacemakers or diagnostic equipment where reliability is non-negotiable.

Furthermore, aerospace and defense sectors have also adopted this technology due to its robustness under extreme conditions—think satellites or military communications equipment where failure simply isn’t an option! In conclusion, understanding what does the SMT stand for opens up a world of possibilities across industries driven by innovation.

The SMT Assembly Process

The SMT assembly process is a crucial component in the world of electronics, where precision and efficiency are paramount. Understanding this process helps demystify how modern electronic devices are produced, showcasing the elegance of surface mount technology (SMT). From preparation to final inspection, each step plays a vital role in ensuring quality and functionality.

Step-by-Step Overview

So, what is SMT assembly? It begins with PCB design, where engineers lay out the circuit board with designated areas for components. Next comes solder paste application, where a stencil applies solder paste to the pads on the PCB—this is essential for holding components in place during assembly. Following that, placement machines or SMT assembly machines accurately position components onto the board before they undergo reflow soldering to create strong electrical connections. Finally, post-assembly inspection ensures everything is up to snuff before products head off to market.

Importance of Quality Control

Quality control in the SMT assembly process cannot be overstated; it’s like having a safety net that catches mistakes before they spiral out of control. With surface mount technology being so precise, even minor defects can lead to significant failures down the line—nobody wants their smartphone to short-circuit! Implementing rigorous quality checks at every stage—from solder paste application through reflow—ensures that what goes out into the world meets stringent industry standards.

Common Challenges in SMT Assembly

While the benefits of surface mount technology are clear, challenges exist within the SMT assembly process that manufacturers must navigate carefully. For instance, component misalignment can occur during placement if not monitored closely; this could lead to faulty connections or even complete device failure! Additionally, managing thermal profiles during reflow soldering requires expertise because too much heat can damage sensitive components while too little may not create adequate joints—it's all about striking that perfect balance.

SMT Assembly Machines

Types of Machines Explained

There are several types of SMT assembly machines that cater to various stages of the SMT assembly process. First up are pick-and-place machines, which are essential for positioning components accurately onto PCBs. Next, we have solder paste printers that apply solder paste onto pads before component placement—a key step in ensuring a reliable connection. Lastly, reflow ovens complete the process by melting the solder to create permanent joints between components and boards.

Each type of machine serves a specific function within the broader context of what is SMT assembly? Having a clear understanding of these machines helps manufacturers optimize their production lines and reduce errors during assembly. The right combination of these machines can significantly impact both quality and speed, making them indispensable in modern electronics manufacturing.

Leading Brands like Bensun Technology

When discussing leading brands in SMT assembly machinery, Bensun Technology stands out as a notable player in this field. Known for its innovative solutions and high-quality equipment, Bensun specializes in providing comprehensive SMT assembly systems that cater to diverse industrial needs. Their commitment to excellence ensures that manufacturers have access to cutting-edge technology designed specifically for Surface Mount Technology applications.

Bensun Technology has developed a reputation not just for reliability but also for customer service that supports clients throughout their production journey. By choosing reputable brands like Bensun, companies can be confident they’re investing in equipment that will enhance their overall efficiency while minimizing downtime during the SMT assembly process.

Choosing the Right Equipment

Selecting the right equipment is crucial when diving into what does SMT stand for? It’s essential to consider factors such as production volume, board complexity, and specific application requirements before making any purchases. For example, if your operation focuses on high-volume production runs with simple designs, investing in high-speed pick-and-place machines might be ideal.

Conversely, companies working with intricate designs or low-volume productions may benefit from modular systems that allow flexibility without compromising on quality or speed during the SMT assembly process. Ultimately, understanding your unique needs will guide you toward making informed choices about which equipment best suits your operations while maximizing productivity.

Tips for Successful SMT Assembly

Navigating the world of SMT assembly can feel like a maze, but with the right strategies, you can streamline your process. From design to execution, every step counts in ensuring that your surface mount technology projects are successful. Here are some essential tips to enhance your SMT assembly experience.

Best Practices in PCB Design

When it comes to PCB design for SMT assembly, simplicity is key. Aim for a layout that minimizes trace lengths and avoids sharp corners; this not only improves signal integrity but also makes the assembly process smoother. Additionally, consider using larger pads for components to ensure better solder joint reliability during the SMT assembly process.

It's also crucial to maintain proper spacing between components to facilitate easier handling and inspection after the SMT unit is assembled. By adhering to standardized design rules, you can reduce errors during manufacturing and improve overall efficiency in what is often a complex process. Remember, good design lays the foundation for successful surface mount technology implementation.

Importance of Solder Paste Selection

Solder paste selection plays a pivotal role in achieving high-quality solder joints during SMT assembly. The right type of solder paste can significantly influence how well components adhere to the board and how effectively they conduct electricity once soldered. Consider factors such as viscosity and melting point when choosing your solder paste; these will affect both application and performance.

Moreover, using fresh solder paste is essential for optimal results—expired or improperly stored paste can lead to defects that compromise your entire SMT assembly project. Always test different types of solder pastes on sample boards before committing them to production runs; this helps identify which works best for specific applications within surface mount technology.

Maintenance Tips for SMT Equipment

Maintaining your SMT assembly machine is vital for ensuring longevity and optimal performance throughout its lifecycle. Regular cleaning of nozzles and other critical components prevents buildup that could lead to misalignment or faulty placements during the assembly process. Schedule routine inspections based on usage frequency—this proactive approach minimizes unexpected breakdowns.

Additionally, keeping an eye on software updates ensures that your equipment stays current with industry standards and technological advancements relevant to surface mount technology practices. Don't forget about operator training; knowledgeable staff can spot maintenance issues early on while optimizing machine settings during production runs, ultimately enhancing productivity in your SMT unit operations.

Conclusion

In wrapping up our exploration of Surface Mount Technology (SMT) and its assembly techniques, it's clear that SMT is not just a trend; it's the backbone of modern electronics. As we embrace the future of SMT assembly, innovations continue to emerge, enhancing efficiency and precision in manufacturing processes. The importance of understanding what SMT is used for cannot be overstated, as it shapes the landscape of various industries.

Embracing Surface Mount Technology's Future

The future of surface mount technology looks promising, with advancements consistently pushing boundaries in both capabilities and applications. As we delve deeper into what is SMT assembly? we find that it evolves to meet the demands for smaller, faster, and more efficient electronic devices. The ongoing development in SMT assembly machines signifies a shift towards automation and smart manufacturing processes that will redefine efficiency standards.

Customized Solutions from Bensun Technology

When it comes to tailored solutions in SMT assembly processes, Bensun Technology stands out as a leader in the field. Their commitment to providing specialized SMT units ensures that businesses can optimize their production lines for maximum output and quality control. By leveraging cutting-edge technology and expertise, Bensun offers customized solutions that cater specifically to diverse industry needs while simplifying what does the SMT stand for?

Final Thoughts on SMT Assembly Techniques

As we've discussed throughout this guide, understanding what is the SMT used for? reveals its critical role across multiple sectors including telecommunications, automotive, and consumer electronics. The versatility of surface mount technology allows manufacturers to achieve high-density designs without compromising performance or reliability. Ultimately, staying informed about the latest trends in the SMT assembly process will empower businesses to innovate continuously while maintaining competitive advantages.