Introduction

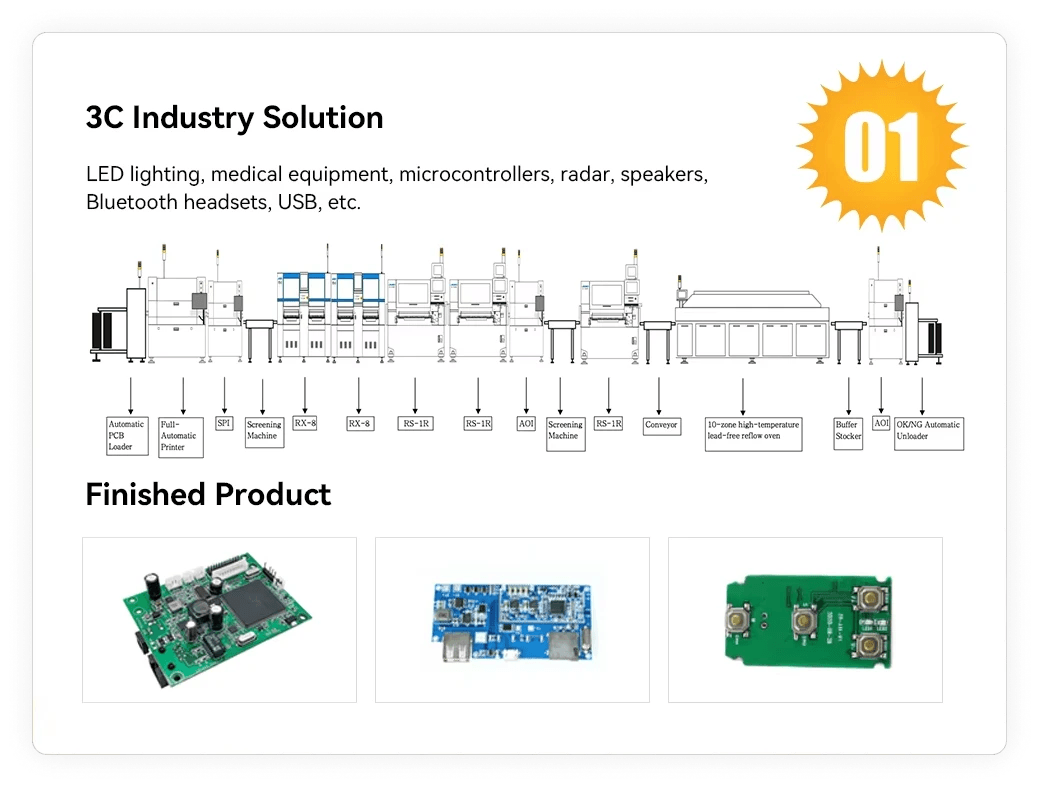

In the world of electronics manufacturing, efficiency and precision are paramount. Enter the SMT feeder, a critical component in the surface-mount technology (SMT) assembly process that ensures components are delivered accurately to the printed circuit board (PCB). Understanding what a SMT feeder is, along with its various types and sizes, can significantly impact production line effectiveness.

What is a SMT feeder?

A SMT feeder is a device used in automated assembly lines to supply surface-mount devices (SMDs) to pick-and-place machines during PCB assembly. Essentially, it acts as a bridge between the storage of electronic components and their placement on circuit boards. The efficiency of an SMT feeder directly influences the overall speed and accuracy of the manufacturing process.

Understanding SMT feeder types

When exploring what are the three types of SMT feeders, one typically encounters tape and reel feeders, tray feeders, and bulk feeders. Each type serves a unique purpose based on component size, shape, and packaging requirements. By understanding these SMT feeder types, manufacturers can choose solutions that best fit their specific production needs.

The importance of SMT feeder size

The size of an SMT feeder plays a crucial role in optimizing production efficiency and minimizing downtime during assembly operations. A correctly sized feeder not only accommodates various component dimensions but also enhances workflow by reducing changeover times between different parts. Therefore, selecting the right SMT feeder size is essential for maintaining productivity while ensuring high placement accuracy in PCB assembly.

What Does SMT Stand For?

Surface-Mount Technology, or SMT, is a cornerstone of modern electronics manufacturing. It refers to a method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact and efficient designs. Understanding what SMT stands for is crucial for anyone involved in the assembly process, especially when considering the role of an SMT feeder.

Definition and significance

So, what does SMT stand for? At its core, Surface-Mount Technology revolutionized how we assemble electronic devices by enabling smaller and lighter designs without sacrificing functionality. The significance of this technology cannot be overstated; it has paved the way for advancements in everything from smartphones to medical devices, making them more reliable and cost-effective.

The importance of an SMT feeder in this context is immense. These feeders play a vital role in ensuring that components are delivered accurately and efficiently to the PCB assembly line, which is crucial for maintaining high production speeds and quality standards.

History of surface-mount technology

The history of surface-mount technology dates back to the 1960s when engineers began exploring ways to reduce component size and improve circuit density. Initially met with skepticism due to concerns about reliability and performance, SMT gained traction through innovations that demonstrated its effectiveness in various applications. By the 1980s, it became widely adopted as manufacturers recognized its potential for increasing production efficiency while minimizing space on PCBs.

As we delve into what types of SMT exist today—namely tape-and-reel feeders, tray feeders, and bulk feeders—it’s essential to appreciate how far we've come since those early days. The evolution from through-hole technology to surface-mount has not only changed manufacturing practices but also influenced design philosophies across industries.

Evolution in electronics manufacturing

The evolution in electronics manufacturing driven by SMT has been nothing short of extraordinary. With advancements such as automated pick-and-place machines working hand-in-hand with sophisticated SMT feeder types, manufacturers can now achieve higher throughput than ever before. This shift towards automation has led to significant gains in productivity while reducing labor costs associated with manual assembly processes.

Additionally, understanding the function of a feeder within this landscape helps clarify its critical role: delivering components swiftly and accurately ensures seamless integration into high-speed production lines. As we explore different aspects like SMT feeder size next, it's clear that selecting appropriate feeders is essential for optimizing both efficiency and product quality on any assembly line.

Exploring SMT Feeder Types

Overview of tape and reel feeders

Tape and reel feeders are among the most commonly used SMT feeder types in modern electronics manufacturing. These feeders present components in a continuous strip, making it easy for machines to pick and place them accurately onto PCBs. The design allows for high-speed operation, which is crucial for meeting the demands of mass production while ensuring that each component is securely held in place until needed.

The versatility of tape and reel feeders makes them suitable for various component sizes and shapes, allowing manufacturers to adapt quickly to changing production needs. Additionally, they minimize the risk of damage during transport as components are protected within the tape's pockets. This feature not only boosts efficiency but also contributes to maintaining high-quality standards throughout the assembly process.

Benefits of tray feeders

Tray feeders offer a distinct advantage when dealing with larger or more delicate components that may not be suited for tape and reel systems. These SMT feeder types utilize trays or bins where components are laid out neatly, allowing for easy access during assembly operations. The design helps prevent damage from excessive handling or jostling that might occur with other feeding methods.

One significant benefit of tray feeders is their ability to accommodate odd-shaped or oversized parts that require special handling during placement on PCBs. This flexibility can lead to improved accuracy in component placement, ultimately enhancing product quality. Furthermore, tray feeders can be easily integrated into existing production lines without requiring extensive modifications.

Advantages of bulk feeders

Bulk feeders represent another innovative option among SMT feeder types, particularly suited for high-volume production runs where speed is essential. These systems dispense components directly from a bulk container into the pick-and-place machine without individual packaging constraints like those found in tape or tray systems. This method significantly reduces setup time and enhances throughput by allowing machines to work continuously with minimal interruptions.

The primary advantage of bulk feeders lies in their cost-effectiveness; they eliminate packaging waste while streamlining logistics associated with managing multiple component formats. Additionally, bulk feeding reduces the chances of mechanical jams since there are fewer moving parts involved compared to other feeder types like trays or reels. This results in increased uptime on production lines—an essential factor when considering overall efficiency.

The Function of a SMT Feeder

SMT feeders play a pivotal role in the world of PCB assembly, acting as the unsung heroes that ensure components are delivered accurately and efficiently to the assembly line. But what is a SMT feeder, you ask? Essentially, it's a device designed to hold and dispense surface-mount technology (SMT) components during the manufacturing process. Understanding the function of a feeder is crucial for anyone looking to enhance their production capabilities.

Role in PCB assembly

In the intricate dance of PCB assembly, SMT feeders serve as essential facilitators that streamline operations. By providing precise and reliable access to various components, they ensure that each part is placed correctly on the printed circuit board (PCB). Without these feeders, achieving high-volume production would be akin to trying to assemble a jigsaw puzzle without knowing what pieces you have—chaotic at best!

Efficiency and productivity gains

When it comes to efficiency and productivity gains in electronics manufacturing, SMT feeders are game changers. By automating the delivery of components directly to pick-and-place machines, they significantly reduce downtime and enhance throughput on production lines. In fact, companies leveraging advanced SMT feeder types often see marked improvements in their overall output—it's like upgrading from a bicycle to a sports car!

Importance of accuracy in placement

Accuracy in placement is vital for ensuring quality in electronic assemblies; after all, even one misaligned component can lead to costly defects or product failures down the line. This is where understanding what does SMT stand for becomes essential: it emphasizes precision engineering at every stage of production. With well-designed SMT feeders tailored for specific applications, manufacturers can achieve remarkable accuracy levels—making them indispensable tools in modern electronics manufacturing.

Choosing the Right SMT Feeder Size

When it comes to selecting the right SMT feeder size, several factors come into play that can significantly influence your choice. Understanding these factors is crucial for optimizing your production line and ensuring that your PCB assembly process runs smoothly. The right SMT feeder size not only affects efficiency but also plays a vital role in maintaining accuracy during component placement.

Factors influencing feeder size

Several elements can dictate the appropriate SMT feeder size for your operation. First, the type of components being used is essential; larger components may require wider feeders, while smaller ones can fit into narrower options. Additionally, production volume plays a critical role; high-volume productions benefit from larger feeders that hold more parts, reducing changeover times and enhancing productivity.

Another consideration is the layout of your production line. The physical space available for feeders can limit your choices; therefore, understanding the dimensions of your machinery and workstation is key to making an informed decision. Lastly, compatibility with existing equipment cannot be overlooked; ensuring that the selected SMT feeder integrates seamlessly with current systems will save time and minimize disruptions.

Impact on production line efficiency

The size of an SMT feeder directly impacts overall production line efficiency in various ways. A well-chosen feeder allows for quicker changeovers between different components, which translates to less downtime and a smoother workflow. Conversely, using an incorrectly sized SMT feeder may lead to bottlenecks in the assembly process, ultimately delaying product delivery timelines.

Moreover, larger feeders tend to accommodate more components at once—this means fewer refills and interruptions during operation. Consequently, this enhances continuous flow on the production line while also minimizing labor costs associated with frequent handling of materials. In essence, selecting the right SMT feeder size fosters an environment where productivity thrives.

Tips for optimizing feeder selection

Optimizing your SMT feeder selection involves a few strategic steps that can make all the difference in your manufacturing process. Start by conducting a thorough analysis of component types and sizes you frequently use; this data will help you determine what sizes are necessary for maintaining efficiency without sacrificing accuracy in placement—a critical function of any SMT feeder.

Next, consider investing in flexible feeders that can adapt to various component sizes as needed; this versatility allows you to adjust easily as project demands change over time without requiring significant additional investment in new equipment or training staff on multiple systems. Lastly, consult with manufacturers like Bensun Technology who specialize in providing tailored solutions based on industry standards—this partnership could yield insights into future trends or innovations relevant to your operations.

In conclusion, choosing the right SMT feeder size is no small task—it requires careful consideration of multiple factors including component types and production volume while keeping an eye on overall efficiency gains within your assembly line processes.

Leading SMT Feeder Manufacturers

When diving into the world of SMT feeders, it’s essential to recognize the key players who shape this industry. Among them, Bensun Technology stands out for its innovative approaches and commitment to quality. Understanding what these manufacturers offer can help businesses choose the right SMT feeder for their production needs.

Innovations from Bensun Technology

Bensun Technology has been at the forefront of SMT feeder innovation, consistently pushing the envelope in design and functionality. Their latest models feature advanced automation capabilities that enhance the efficiency of PCB assembly, a crucial function of a feeder. Additionally, Bensun's focus on user-friendly interfaces allows operators to easily manage different SMT feeder types without extensive training.

One notable innovation is their adaptive feeding system, which adjusts automatically based on component size and type—an impressive feat that optimizes production line efficiency. With an emphasis on precision placement, Bensun’s feeders ensure components are accurately positioned during assembly, significantly reducing errors. This level of sophistication makes them a prime choice for companies looking to streamline their manufacturing processes while maintaining high standards.

Comparison of Top Brands

When comparing top brands in the SMT feeder market, it becomes clear that each offers unique advantages tailored to various manufacturing needs. While Bensun Technology excels in automation and adaptability, other brands may focus more on cost-effectiveness or specialized feeders for niche applications in electronics manufacturing. For instance, some brands emphasize bulk feeders that cater specifically to high-volume operations.

Understanding what is a SMT feeder in this context helps manufacturers make informed choices based on their specific requirements—be it speed, accuracy, or flexibility across different product lines. Additionally, examining customer reviews and case studies can provide insights into how well these brands perform under real-world conditions. Ultimately, choosing between these top brands involves weighing factors like reliability and support against performance features.

Industry Standards and Certifications

In an industry where precision matters immensely—especially when discussing what does SMT stand for—adhering to established industry standards is paramount for any leading manufacturer of SMT feeders. Certifications from organizations such as IPC (Institute for Printed Circuits) ensure that products meet stringent quality and safety guidelines essential for modern electronics manufacturing processes.

These certifications not only bolster consumer confidence but also guarantee that manufacturers are using best practices in production methods—a critical factor when considering various SMT feeder types available today. Moreover, compliance with international standards fosters greater collaboration between manufacturers globally as they strive towards common goals in quality assurance and innovation within surface-mount technology.

Conclusion

In summary, SMT feeders play a pivotal role in the world of electronics manufacturing, ensuring that components are delivered accurately and efficiently during PCB assembly. Understanding what a SMT feeder is and its various types—tape and reel, tray, and bulk—can help manufacturers optimize their production lines. The size of an SMT feeder significantly impacts overall efficiency, making it crucial to choose the right one for your specific needs.

Key takeaways on SMT feeders

What is a SMT feeder? It's not just a fancy gadget; it's essential for modern electronic assembly processes. The three types of SMT feeders—tape and reel, tray, and bulk—each have unique advantages tailored to specific production scenarios. Remember that the function of a feeder goes beyond mere delivery; it enhances accuracy and productivity on the assembly line.

Future trends in SMT technology

Looking ahead, the future of SMT technology promises exciting advancements driven by automation and artificial intelligence. As manufacturers seek to improve efficiency further, innovations in smart feeders that can adapt to various component sizes will become more prevalent. Additionally, sustainability will likely shape future designs as companies strive for eco-friendly solutions in their manufacturing processes.

Why partner with Bensun Technology

When considering your options for SMT feeders, partnering with Bensun Technology stands out as a smart choice. Known for their innovative designs and commitment to quality, they offer cutting-edge solutions tailored to meet diverse industry needs. By choosing Bensun Technology as your partner, you're not just investing in equipment; you're investing in enhanced productivity and reliability on your production line.