Introduction

In the fast-paced world of electronics manufacturing, challenges in SMT pick and place processes can significantly impact the efficiency and quality of PCB assembly. Understanding these challenges is crucial for optimizing circuit card assembly operations, as even minor misalignments or handling errors can lead to costly rework and delays. By addressing common issues in machine pick and place operations, manufacturers can enhance productivity and ensure that their PCB and assembly processes run smoothly.

Understanding SMT Pick and Place Challenges

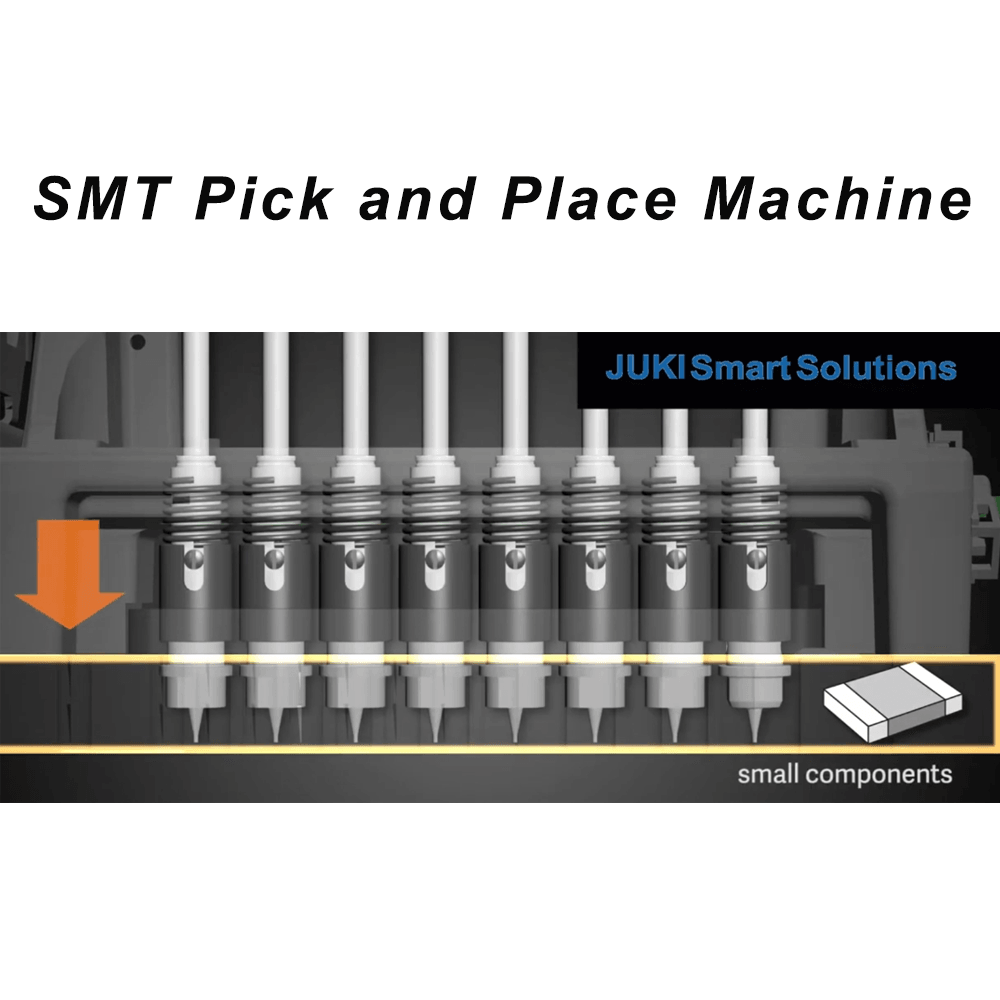

SMT pick and place machines are essential tools in the modern electronics manufacturing landscape, but they come with their own set of challenges. From component misalignment to improper handling techniques, each issue can derail an otherwise efficient circuit card assembly line. Recognizing these challenges is the first step toward implementing effective solutions that enhance both speed and accuracy in PCB assembly.

Importance of Efficient PCB Assembly

Efficient PCB assembly is not just a goal; it’s a necessity for staying competitive in today’s market. A smooth machine pick and place operation minimizes downtime while maximizing throughput, ensuring that products reach customers faster without sacrificing quality. As technology advances, companies that prioritize efficient circuit card assembly will be better positioned to adapt to evolving demands.

Overview of Solutions for Common Issues

To tackle the myriad issues associated with SMT pick and place processes, manufacturers must adopt a proactive approach that includes both technological solutions and best practices. From implementing advanced software integration to investing in regular equipment maintenance, there are numerous strategies available to enhance the reliability of PCB assembly operations. By understanding common pitfalls and actively seeking solutions, businesses can significantly improve their overall production efficiency.

Component Misalignment

Component misalignment is a common challenge faced in SMT pick and place processes. This issue can lead to significant setbacks in circuit card assembly, affecting the overall quality and reliability of PCB assembly. Understanding the causes and solutions for misalignment is crucial for optimizing the performance of pick & place machines.

Causes of Misalignment in SMT Pick and Place

Several factors contribute to component misalignment during the SMT pick and place process. One major cause is improper calibration of the pick & place machine, which can result in inaccurate placement of components on the PCB. Additionally, environmental factors such as static electricity or dust can interfere with component handling, further exacerbating alignment issues.

Another contributing factor is variations in component sizes and shapes; even slight discrepancies can throw off the precision required for effective circuit card assembly. Moreover, human error during setup or operation can also lead to misalignments that compromise the efficiency of PCB assembly processes. Understanding these causes helps manufacturers implement better practices to minimize their impact.

Impact on Circuit Card Assembly

The impact of component misalignment on circuit card assembly cannot be overstated. Misaligned components can lead to poor electrical connections, which may result in malfunctioning devices or complete failures post-assembly. This not only affects product quality but also increases production costs due to rework or scrap materials.

Furthermore, persistent alignment issues may disrupt workflow on the production line, causing delays that ripple through manufacturing schedules. Ultimately, these inefficiencies can tarnish a company’s reputation for quality and reliability within a competitive market where precision is paramount for success in PCB assembly endeavors. Addressing these impacts requires proactive measures from manufacturers to ensure consistency.

Solutions for Accurate Placement

To combat component misalignment effectively, manufacturers must adopt several best practices focused on enhancing accuracy during SMT pick and place operations. Firstly, regular calibration and maintenance of pick & place machines are essential to ensure they operate at peak performance levels consistently. Investing in high-quality equipment designed specifically for precise placement will also yield better results.

Implementing advanced vision systems within SMT machines can significantly improve alignment accuracy by providing real-time feedback during the placement process; this technology enables adjustments before components are permanently affixed to PCBs during assembly. Training operators thoroughly on handling techniques minimizes human error while promoting adherence to best practices throughout PCB assembly workflows.

By employing these solutions strategically, manufacturers can enhance their circuit card assembly processes while ensuring that their smt pick and place operations yield high-quality results consistently.

Improper Component Handling

In the world of PCB assembly, improper component handling can lead to a cascade of issues that disrupt the entire production process. When components are mishandled during the SMT pick and place operation, it can result in misalignment, damage, or even complete failure of circuit card assembly. These errors not only compromise the quality of the final product but also increase costs and extend lead times, making effective handling strategies crucial for any successful operation.

Risks of Handling Errors in PCB Assembly

Handling errors in PCB assembly can manifest in various ways, each carrying its own set of risks. For instance, if components are dropped or improperly oriented during machine pick and place processes, it can lead to significant defects that require rework or scrapping entirely. Moreover, such mishaps may cause delays in production schedules and harm customer relationships due to missed delivery deadlines.

Additionally, improper handling could result in electrostatic discharge (ESD) damage to sensitive components. This risk is particularly pronounced when using a pick & place machine that is not equipped with adequate ESD protection measures. Ultimately, these handling errors not only affect individual units but can have a ripple effect on overall productivity and profitability.

Best Practices for Picking and Placing

To mitigate risks associated with improper component handling during PCB assembly, implementing best practices is key. First and foremost, operators should be trained thoroughly on the specifics of their smt machine's operation—understanding how to load components correctly into the pick & place machine can prevent many common issues from arising. Regular training updates help keep everyone informed about new techniques or technologies that enhance efficiency.

Another vital practice involves maintaining a clean workspace free from contaminants that could interfere with component integrity during assembly. Using proper tools like tweezers for manual placement tasks ensures precision while minimizing physical contact with sensitive parts. Furthermore, organizing components systematically aids operators in quickly locating what they need without unnecessary fumbling.

Lastly, automated systems should be regularly calibrated to ensure accurate placement by the pick and place machine; this reduces human error significantly while enhancing overall output quality during circuit card assembly operations.

Tools to Improve Handling Efficiency

Investing in specialized tools designed for improving handling efficiency can dramatically enhance operations within PCB assembly environments. For instance, using vacuum-based pick-up systems allows for secure lifting of delicate components without risk of damage—a feature essential when working with small or fragile parts commonly found in modern electronic devices.

Moreover, integrating advanced vision systems into smt machines enhances accuracy by providing real-time feedback regarding component alignment before placement occurs—this helps catch potential errors before they escalate into larger problems down the line. Another beneficial tool is an automated storage system which simplifies inventory management by ensuring that all components are easily accessible when needed while reducing search times during production runs.

Lastly, employing software solutions designed specifically for managing workflows within PCB assembly lines streamlines communication between different stages—from design through manufacturing—ultimately optimizing overall efficiency across all facets involved with smt pick and place operations.

Software Integration Issues

In the fast-paced world of SMT pick and place technology, software integration can often feel like navigating a maze. The complexities of various software systems used in circuit card assembly can lead to inefficiencies that hinder productivity. Understanding these challenges is crucial for optimizing PCB assembly processes and ensuring smooth operations.

Challenges with SMT Machine Software

One of the primary challenges with SMT machine software is compatibility between different systems, which can create bottlenecks in production lines. When integrating a new pick and place machine into an existing setup, discrepancies in communication protocols or data formats may arise, leading to errors in component placement. Furthermore, outdated software can limit the capabilities of modern machines, making it difficult to leverage advancements in technology for efficient PCB assembly.

Importance of Seamless Integration

Seamless integration of software systems is vital for maximizing the efficiency and effectiveness of your pick & place machine operations. When all components—hardware and software—work harmoniously together, it significantly reduces the likelihood of errors during circuit card assembly processes. Moreover, this synergy allows teams to respond swiftly to production demands and adapt to changes without disrupting workflow.

Solutions for Software Compatibility

To tackle software integration issues effectively, investing in compatible systems is essential for any successful PCB assembly operation. Consider utilizing universal interface solutions that bridge gaps between different machines and their respective software environments; this approach can minimize compatibility headaches significantly. Additionally, regular updates and maintenance on both hardware and software fronts will ensure that your machine pick and place remains at peak performance while adapting seamlessly to any new technologies introduced into your production line.

Equipment Maintenance and Downtime

In the realm of SMT pick and place, equipment maintenance is crucial for ensuring optimal performance and minimizing downtime. Regular upkeep not only prolongs the lifespan of machines but also enhances the quality of circuit card assembly. Understanding common causes of equipment failure can help operators proactively address issues before they escalate.

Common Causes of Equipment Failure

The primary culprits behind equipment failure in SMT machines often include wear and tear on mechanical components, improper calibration, and inadequate cleaning practices. Over time, parts such as nozzles in pick & place machines can become clogged or damaged, leading to inaccurate placements during PCB assembly. Additionally, software glitches can disrupt machine functionality, resulting in costly delays in production.

Impact on Production Line Efficiency

When a machine pick and place malfunctions, the ripple effect can be felt throughout the entire production line. Delays caused by equipment failures not only slow down circuit card assembly but can also lead to increased labor costs as workers wait for repairs or replacements. Ultimately, unplanned downtime negatively impacts overall efficiency, reducing output and potentially harming customer satisfaction due to missed deadlines.

Preventative Maintenance Tips for SMT Machines

To ensure smooth operation of your SMT pick and place systems, implementing a robust preventative maintenance schedule is key. Regularly inspect critical components like nozzles and belts for wear; this will help catch problems before they escalate into major failures during PCB assembly processes. Additionally, keeping software updated ensures that your pick & place machine operates seamlessly with other systems on the production floor.

Quality Control Failures

Quality control is the backbone of any successful SMT pick and place operation, ensuring that every component is correctly positioned and soldered on the circuit card assembly. In PCB assembly, even minor defects can lead to significant failures down the line, affecting product reliability and customer satisfaction. Therefore, maintaining high standards of quality throughout the assembly process is crucial for minimizing rework and maximizing efficiency.

Importance of Quality in Pick and Place

In the world of circuit card assembly, quality is not just a goal; it’s a necessity. The precision required in SMT pick and place operations directly impacts the overall functionality of electronic devices. A single misaligned component can disrupt signal integrity or cause short circuits, ultimately leading to product recalls or warranty claims that can be costly for manufacturers.

Common Quality Issues in PCB Assembly

Several common quality issues plague PCB assembly processes, particularly those involving machine pick and place operations. These include misalignment during placement, insufficient solder joints, and even contamination from dust or oils on components or boards. Such problems can stem from inadequate training of operators using pick & place machines or poor maintenance practices that affect machine performance.

Implementing Effective Quality Control Measures

To combat these quality issues effectively, manufacturers must implement robust quality control measures throughout their SMT processes. Regular inspections should be conducted at various stages of PCB assembly to catch defects early before they escalate into larger problems. Utilizing advanced software solutions for real-time monitoring can also enhance the integration between hardware and processes in smt machines, ensuring that any deviations from expected performance are swiftly addressed.

Conclusion

In summary, the world of SMT pick and place technology is both intricate and vital to the success of modern circuit card assembly. By understanding the challenges associated with PCB assembly, including component misalignment, improper handling, software integration issues, equipment maintenance, and quality control failures, manufacturers can significantly enhance their production processes. Embracing these insights not only leads to improved efficiency but also ensures that the final products meet high-quality standards.

Key Takeaways on SMT Pick and Place

The key takeaways from our exploration of SMT pick and place revolve around recognizing common pitfalls in circuit card assembly and implementing effective solutions. Accurate component placement is paramount; even a slight misalignment can have cascading effects on PCB assembly quality. Additionally, proper handling techniques and routine equipment maintenance are essential for maximizing the performance of pick & place machines.

Preparing for Future Challenges in PCB Assembly

As technology advances at a rapid pace, preparing for future challenges in PCB assembly becomes increasingly important. This includes staying updated on new developments in pick and place machine capabilities as well as embracing software innovations that streamline integration processes. By proactively addressing potential issues now, manufacturers can ensure they remain competitive in an ever-evolving industry landscape.

Benefits of Partnering with Bensun Technology

Partnering with Bensun Technology offers numerous advantages for businesses looking to enhance their SMT pick and place operations. With expertise in optimizing machine pick and place performance, Bensun provides tailored solutions that address specific challenges faced during PCB assembly. Collaborating with such a knowledgeable partner not only boosts efficiency but also fosters innovation within your production line.