Introduction

In the fast-evolving world of electronics manufacturing, SMT chip mounters play a pivotal role in ensuring efficient production processes. These machines, often referred to as pick and place machines, are essential for assembling electronic components onto printed circuit boards (PCBs) with precision and speed. Understanding the nuances of SMT machines is crucial for manufacturers aiming to enhance their operational efficiency and product quality.

Understanding SMT Chip Mounters

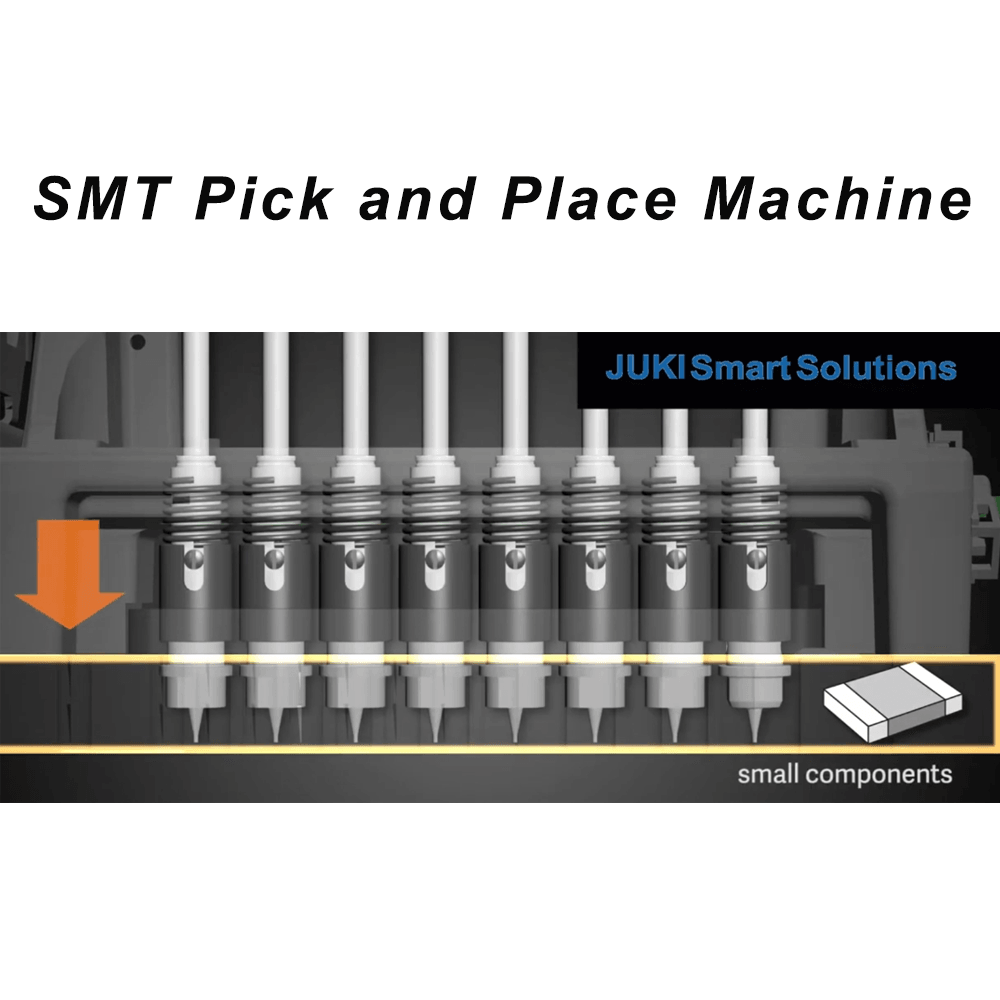

SMT chip mounters are sophisticated pieces of machinery designed to automate the placement of surface mount technology (SMT) components onto PCBs. They utilize advanced pick and place technology that enables them to handle various component sizes and types with remarkable accuracy. This versatility makes machine SMT an indispensable asset in modern electronics assembly lines, significantly reducing manual labor while increasing throughput.

The Importance of Quality in SMT Machines

Quality is paramount when it comes to selecting an SMT machine; any compromise can lead to defects that affect product performance and reliability. High-quality SMT equipment ensures precise placement, which directly impacts the overall functionality of electronic devices. Investing in reliable machines not only enhances production efficiency but also minimizes costly rework and warranty claims down the line.

Key Factors to Consider

When evaluating different SMT chip mounters, several key factors should be taken into account: precision, speed, flexibility, user interface, reliability, and maintenance requirements. Each factor plays a critical role in determining how well a machine can meet specific production needs while maintaining high-quality standards. By carefully assessing these elements, manufacturers can make informed decisions that align with their operational goals.

Precision Placement Technology

In the world of SMT (Surface Mount Technology), precision placement technology is the backbone of efficient production. A reliable SMT chip mounter ensures that components are accurately positioned on circuit boards, which directly influences the quality and performance of electronic devices. The importance of this technology cannot be overstated; it is what differentiates a high-performance pick and place machine from its less capable counterparts.

How Accuracy Affects Production

Accuracy in placement significantly affects production rates and product quality in line SMT operations. When a machine pick and place system misaligns components, it can lead to defects that require costly rework or even scrapping entire batches. Therefore, investing in high-precision SMT machines not only enhances yield but also minimizes downtime, making your production line more efficient.

The Role of Vision Systems

Vision systems play a crucial role in ensuring the accuracy of an SMT chip mounter's operations. These advanced optical systems allow machines to verify component placement in real-time, correcting any misalignments before soldering occurs. By integrating sophisticated vision technology into machine SMT processes, manufacturers can maintain higher standards of quality control while reducing human error.

Impact on Overall Efficiency

The integration of precision placement technology and vision systems significantly boosts overall efficiency in SMT equipment usage. Machines that excel at precise component placement can operate at higher speeds without compromising quality, leading to increased throughput on production lines. Ultimately, this combination not only enhances productivity metrics but also strengthens a company's competitive edge in the fast-paced electronics market.

Speed and Throughput

When it comes to SMT chip mounters, speed and throughput are paramount. In a fast-paced production environment, the ability of a pick and place machine to operate efficiently can make or break your output. Understanding how to assess machine performance is essential for optimizing the functionality of your SMT machines.

Assessing Machine Performance

To truly gauge the performance of your SMT equipment, you need to consider several factors, including speed ratings and placement accuracy. A high-speed machine pick and place unit will not only increase production rates but also maintain precision in component placement. Regular assessments will help identify any bottlenecks in the line SMT process, ensuring that your overall productivity remains on track.

Balancing Speed and Quality

While it may be tempting to prioritize speed above all else in your SMT machines, balancing speed with quality is crucial for long-term success. A pick and place machine that sacrifices accuracy for quicker throughput can lead to costly rework or defective products down the line. Striking this balance means investing in advanced technology that enhances both the speed of operation and the quality of output from your SMT equipment.

Productivity Metrics to Monitor

Monitoring productivity metrics is vital for understanding how well your smt chip mounter is performing within your production line. Key indicators like cycle time, first-pass yield, and overall equipment effectiveness (OEE) provide insights into areas needing improvement. By keeping an eye on these metrics, manufacturers can make informed decisions about their smt machines—ensuring they get the most out of their investment while maintaining high standards.

Flexibility and Adaptability

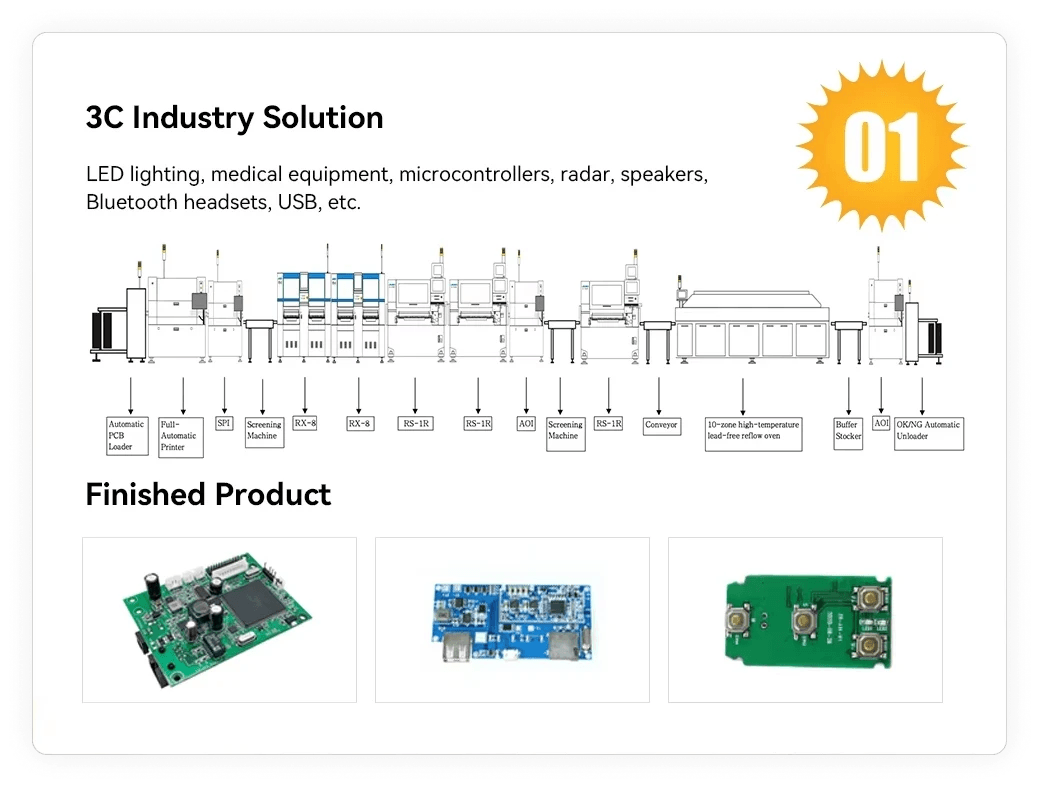

In the fast-paced world of electronics manufacturing, flexibility and adaptability in SMT machines are paramount. A versatile SMT chip mounter can handle a variety of projects, from small-scale prototypes to large production runs with ease. This adaptability not only saves time but also enhances the overall efficiency of the production line.

Customization Options for Different Projects

Customization is a key feature that sets modern SMT machines apart from their predecessors. Many pick and place machines now offer various customization options, allowing manufacturers to tailor their equipment according to specific project requirements. Whether it’s adjusting component sizes or accommodating different board layouts, having a customizable machine smt can significantly streamline production processes.

Moreover, the ability to easily switch between different configurations means that an SMT machine can adapt to evolving market demands without requiring extensive downtime or costly modifications. This level of flexibility ensures that manufacturers remain competitive in an ever-changing landscape while maximizing their investment in smt equipment. Ultimately, being able to customize your machine pick and place is crucial for meeting diverse customer needs efficiently.

Multi-functionality of SMT Equipment

The multi-functionality of modern SMT machines has revolutionized the electronics manufacturing industry. Today’s smt chip mounters are designed not just for placement but also for a range of tasks including inspection, soldering, and even testing—all within one integrated system. This consolidation reduces the need for multiple pieces of equipment on the line smt, saving both space and costs.

Additionally, having a single machine capable of performing various functions allows manufacturers to streamline their operations further by reducing workflow interruptions caused by switching between different devices. With advanced software integration, these machines can be programmed for various tasks seamlessly—making them indispensable tools in any assembly line setup. The versatility offered by multi-functional SMT equipment helps businesses maintain high quality while adapting quickly to new challenges.

Benefits of a Versatile SMT Chip Mounter

Investing in a versatile SMT chip mounter offers numerous benefits that go beyond mere convenience; it enhances overall productivity and operational efficiency as well. With capabilities spanning multiple applications—from surface-mount technology (SMT) assembly to complex circuit board designs—a single machine can cater to diverse manufacturing needs without sacrificing performance or quality.

Furthermore, this versatility enables businesses to pivot quickly when market demands shift or new technologies emerge—providing them with a competitive edge over those reliant on more specialized machinery. In addition, reduced training times mean operators can become proficient faster when working with adaptable smt machines equipped with user-friendly interfaces designed for ease-of-use across various functions.

Ultimately, embracing flexibility and adaptability through versatile pick and place machines positions manufacturers not just as participants but as leaders in an ever-evolving industry landscape.

User-Friendly Interfaces

In the fast-paced world of electronics manufacturing, having user-friendly interfaces in SMT machines can make all the difference. A well-designed interface not only enhances operator efficiency but also minimizes errors during operation. This is particularly crucial for pick and place machines, where precision is paramount.

Importance of Intuitive Controls

Intuitive controls are essential in any SMT chip mounter because they allow operators to navigate complex tasks with ease. When controls are straightforward and logically laid out, it reduces the cognitive load on users, leading to faster setup times and fewer mistakes. Moreover, an intuitive design can significantly improve overall productivity in line SMT operations by enabling quicker adjustments when needed.

Training and Learning Curves

The learning curve associated with operating a new SMT machine can be steep if the interface is complicated or non-intuitive. However, a user-friendly design can drastically shorten this learning period, allowing operators to become proficient much more quickly. This not only saves time but also reduces training costs for companies investing in new machine pick and place technology.

Enhancements in Software Design

Recent advancements in software design have revolutionized how SMT equipment operates, making them more accessible to users at all skill levels. Enhanced graphical interfaces provide real-time feedback and diagnostics that help operators monitor performance effortlessly. As a result, these improvements lead to greater reliability and efficiency within the entire production process of smt machines.

Reliability and Maintenance

In the world of SMT (Surface Mount Technology) chip mounters, reliability and maintenance play crucial roles in ensuring consistent production quality. A well-maintained pick and place machine can significantly reduce downtime, allowing for smoother operations on the line SMT. When selecting an SMT machine, considering long-term performance is essential to avoid costly disruptions.

Long-term Performance Considerations

When investing in an SMT chip mounter, it’s vital to think about long-term performance capabilities. These machines are often a significant financial investment, so you want one that will stand the test of time without frequent breakdowns. The durability of components within your machine pick and place setup directly impacts how efficiently your production line operates over the years.

A robust smt machine should be able to handle various production demands while maintaining accuracy and speed. If your equipment is prone to malfunctions, you’ll find yourself spending more time troubleshooting than producing quality products. Therefore, it’s wise to choose smt machines known for their reliability and proven track records in the industry.

Importance of Regular Maintenance

Regular maintenance is not just a suggestion; it's a necessity for any successful operation utilizing SMT equipment. Just like any other machinery, neglecting routine checks can lead to unexpected failures that halt production lines unexpectedly. By implementing a structured maintenance schedule for your pick and place machine, you ensure that every component functions optimally.

Moreover, regular upkeep helps identify potential issues before they escalate into significant problems that could compromise quality or efficiency on the line smt. This proactive approach saves both time and money by reducing emergency repairs and extending the life of your smt equipment. After all, an ounce of prevention is worth a pound of cure when it comes to maintaining productivity.

Choosing Durable SMT Machines

Choosing durable SMT machines requires thorough research into manufacturers known for their high-quality standards and reliable performance history. Look for features such as sturdy construction materials and components designed specifically for longevity in demanding environments—these factors contribute significantly to overall durability in pick and place machines.

Additionally, consider user reviews and testimonials from other businesses within your industry; real-world experiences often reveal insights about reliability that specifications may not fully capture. Investing in a durable machine smt not only enhances productivity but also provides peace of mind knowing you've made a sound choice for long-term success in your operations.

Conclusion

In the ever-evolving world of electronics manufacturing, selecting the right SMT chip mounter is crucial for maintaining a competitive edge. With various factors such as precision, speed, flexibility, and ease of use to consider, it’s essential to evaluate your specific needs carefully. A well-chosen machine can significantly impact your production efficiency and product quality.

Evaluating Your SMT Equipment Needs

When assessing your SMT equipment needs, consider the scale and complexity of your projects. The right pick and place machine should align with your production goals—whether you require high-speed throughput or precise placement for intricate designs. Additionally, think about the adaptability of the machine; a versatile SMT machine can handle diverse tasks without necessitating frequent upgrades.

It’s also wise to analyze how different models fit into your existing line SMT setup. You want an SMT chip mounter that integrates seamlessly with your current processes while offering room for growth as demand shifts. Ultimately, understanding these requirements will guide you toward making an informed investment in reliable smt equipment.

Why Choose Bensun Technology

Bensun Technology stands out in the crowded market of SMT machines due to its commitment to innovation and quality. Their machines are designed with cutting-edge technology that ensures precision placement and optimal speed—two critical factors for any successful pick and place machine operation. Moreover, Bensun's focus on user-friendly interfaces means that even those new to machine SMT operations can quickly adapt without a steep learning curve.

Another compelling reason to choose Bensun is their exceptional customer support and maintenance services tailored specifically for their equipment. This level of service not only enhances long-term performance but also builds trust between manufacturers and their machinery providers. By opting for Bensun Technology, you're not just purchasing a piece of machinery; you're investing in a partnership focused on achieving excellence in electronic assembly.

Future Trends in SMT Chip Mounters

As technology advances at breakneck speed, future trends in SMT chip mounters will likely revolve around increased automation and artificial intelligence integration within these systems. Expect smarter pick and place machines equipped with enhanced vision systems capable of real-time adjustments based on production variables—this could revolutionize efficiency levels across various industries!

Moreover, sustainability will play a vital role; manufacturers are increasingly focusing on eco-friendly practices by developing machines that minimize waste while maximizing productivity metrics—an essential consideration in today’s environmentally-conscious market landscape. Embracing these trends not only prepares businesses for future challenges but also positions them as leaders in the rapidly changing electronics manufacturing arena.