Introduction

In the ever-evolving world of electronics, the significance of SMT LED chip mounting cannot be overstated. This process plays a crucial role in ensuring that circuit boards function optimally, delivering reliable performance in various applications. With the right SMT machine, manufacturers can achieve high precision and efficiency, setting the stage for successful SMT production.

Understanding SMT LED Chip Mounting

SMT LED chip mounting is a specialized technique used to place LED chips onto circuit boards with remarkable accuracy. Utilizing advanced technology, an SMT placement machine ensures that each component is positioned correctly, minimizing errors and maximizing functionality. In today’s fast-paced manufacturing environment, understanding this process is essential for anyone involved in PCB SMT operations.

Importance of Precision in SMT Production

Precision is the backbone of effective SMT production; even the slightest misalignment can compromise a circuit board's performance. An accurate smt mounting machine guarantees that every component is placed where it should be, which directly impacts product reliability and longevity. Therefore, investing in high-quality equipment and maintaining proper calibration practices are vital for achieving optimal precision.

Efficiency in LED SMT Machine Operations

Efficiency in LED SMT machine operations not only boosts productivity but also reduces operational costs significantly. By streamlining processes through automation and advanced technologies, manufacturers can enhance their output without sacrificing quality or precision. Ultimately, efficient smt led chip mounters are key players in driving innovation within the electronics industry.

The Role of SMT LED Chip Mounters

In the world of electronics, SMT LED chip mounters play a pivotal role in ensuring that circuit boards are assembled with precision and efficiency. These machines are specifically designed to place LED chips onto printed circuit boards (PCBs) accurately, which is crucial for the performance of various electronic devices. By utilizing advanced technology and automation, SMT placement machines enhance the overall quality and speed of SMT production.

What is an SMT LED Chip Mounter?

An SMT LED chip mounter is a specialized machine that automates the process of placing surface-mount technology (SMT) components, particularly LEDs, onto circuit boards. Unlike traditional methods that rely heavily on manual labor, these machines use sophisticated algorithms and high-speed cameras to ensure precise placement of each component. This automation not only speeds up production but also significantly reduces the risk of human error during the assembly process.

Key Features and Benefits

One of the standout features of an SMT mounting machine is its ability to handle various sizes and types of LEDs without compromising accuracy. These machines often come equipped with advanced vision systems that allow for real-time monitoring and adjustment during operation, enhancing both precision and efficiency in PCB SMT processes. The benefits extend beyond just speed; manufacturers experience reduced waste due to fewer misplacements, leading to cost savings in materials and labor.

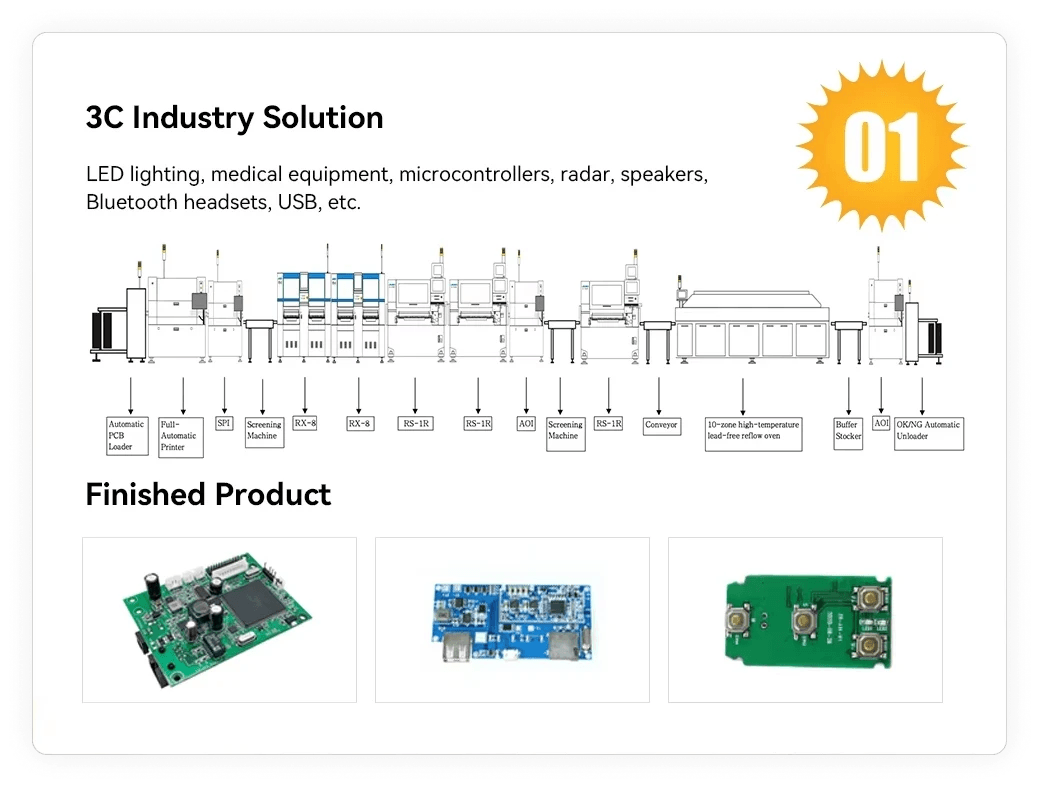

Applications in Various Industries

SMT LED chip mounters find applications across a multitude of industries including automotive, consumer electronics, telecommunications, and medical devices. In automotive manufacturing, for example, these machines ensure that critical lighting components are placed accurately for safety features such as headlights or dashboard indicators. Similarly, in consumer electronics like smartphones or televisions, precise placement by an LED SMT machine contributes to enhanced performance and reliability in everyday devices used by millions worldwide.

Precision Engineering in SMT Machines

In the realm of SMT production, precision engineering is not just a luxury; it's a necessity. The effectiveness of an SMT LED chip mounter relies heavily on high-precision placement techniques that ensure components are positioned accurately on the circuit board. This level of precision directly affects the performance and reliability of the final product, making it crucial for manufacturers to invest in top-notch SMT machines.

High-Precision Placement Techniques

High-precision placement techniques are at the heart of any successful SMT placement machine. These methods utilize advanced algorithms and sophisticated vision systems to identify and place components with pinpoint accuracy on circuit boards. By minimizing misalignment during assembly, manufacturers can enhance yield rates and reduce costly rework, ultimately leading to more efficient PCB SMT processes.

Moreover, modern LED SMT machines have incorporated technologies such as laser alignment and multi-axis movement, which further refine placement accuracy. These innovations allow for rapid adjustments during production runs, accommodating various component sizes and types without compromising precision. As a result, companies can achieve higher throughput while maintaining the integrity of their products.

Importance of Calibration

Calibration is a fundamental aspect that ensures the optimal performance of any SMT mounting machine. Regular calibration checks help maintain alignment accuracy over time, which is essential for achieving consistent results in PCB SMT applications. Without proper calibration, even the most advanced smt led chip mounter could falter in delivering precise placements.

The process involves fine-tuning various parameters such as speed, pressure, and angle settings to match specific component requirements. Neglecting this critical step can lead to increased defects and lower overall efficiency in production lines—something no manufacturer wants on their ledger! Investing time in regular calibration ultimately pays off by safeguarding product quality and reducing waste.

The Impact of Precision on Final Products

The impact of precision engineering on final products cannot be overstated—especially when it comes to high-performance electronics utilizing smt led chip mounters. When components are placed accurately on circuit boards, it enhances electrical connectivity and functionality while minimizing issues like short circuits or signal degradation. This attention to detail translates into reliable products that meet customer expectations consistently.

Furthermore, precise placements contribute significantly to longevity and durability in electronic devices; after all, who wants gadgets that fail prematurely? As industries evolve toward more compact designs with higher functionality demands, maintaining precision becomes even more critical for competitive advantage within the market landscape. Ultimately, investing in high-quality smt machines equipped with advanced precision engineering capabilities is not just smart—it's essential for success.

Efficiency in PCB SMT Placement

In the fast-paced world of electronics manufacturing, efficiency is paramount, especially when it comes to PCB SMT placement. A well-optimized process not only reduces production time but also enhances the overall quality of circuit board assemblies. By implementing streamlined strategies, manufacturers can ensure that their SMT production lines remain competitive and responsive to market demands.

Streamlining the SMT Production Process

Streamlining the SMT production process involves a careful analysis of each step in circuit board assembly. From initial design to final testing, every phase must be optimized for maximum throughput and minimal waste. Utilizing advanced SMT machines, such as high-speed SMT LED chip mounters, allows manufacturers to achieve precise placements while maintaining an efficient workflow.

Moreover, integrating real-time monitoring systems can help identify bottlenecks in the production line before they become significant issues. This proactive approach ensures that any necessary adjustments can be made quickly, keeping the entire operation running smoothly. Ultimately, a streamlined process not only boosts productivity but also enhances product reliability and customer satisfaction.

The Role of Automation in Efficiency

Automation plays a crucial role in enhancing efficiency within PCB SMT placement operations. Modern LED SMT machines are equipped with sophisticated automation features that significantly reduce manual intervention and human error during assembly processes. By employing automated SMT placement machines, manufacturers can achieve consistent quality while dramatically increasing output rates.

Additionally, automation facilitates faster changeovers between different circuit board designs or configurations without compromising precision or accuracy. This flexibility is essential for meeting varying customer demands and adapting to new technologies quickly. As a result, businesses utilizing automated solutions often find themselves at a competitive advantage in the ever-evolving electronics landscape.

Case Studies: Success Stories in Efficiency

Several companies have successfully implemented innovative strategies to enhance efficiency through their PCB SMT processes using advanced smt mounting machines. For instance, one leading manufacturer reported a 30% increase in output after upgrading their traditional setup with high-performance LED smt machines capable of handling complex circuit boards with ease.

Another case study highlighted how a mid-sized electronics firm adopted an integrated automation system that reduced labor costs by 25%. By streamlining their workflow and investing in state-of-the-art smt production technology, they were able to deliver products faster while maintaining high standards of quality control throughout their operations.

These success stories illustrate how embracing efficiency through smart investments in technology can lead to substantial gains—both financially and operationally—for companies navigating today’s competitive marketplace.

Choosing the Right SMT Mounting Machine

Selecting the right SMT mounting machine is crucial for achieving optimal performance in your SMT production line. With various options available, understanding the specific requirements of your projects can help you choose a machine that enhances efficiency and precision. Factors such as speed, accuracy, and compatibility with different circuit board designs should be carefully evaluated.

Factors to Consider When Selecting a Machine

When selecting an SMT LED chip mounter, several factors come into play. First, consider the size and type of circuit boards you will be working with; this influences the machine’s placement capabilities and flexibility in handling various PCB SMT configurations. Additionally, assess the speed and accuracy of placement—machines that boast high precision can significantly impact the quality of your final products.

Another important factor is automation features; an advanced smt placement machine equipped with automation can streamline operations and reduce labor costs. Furthermore, evaluate maintenance requirements and support services offered by manufacturers to ensure long-term reliability of your investment in an LED SMT machine. Lastly, budget constraints are always a consideration; finding a balance between cost and functionality is essential for maximizing ROI.

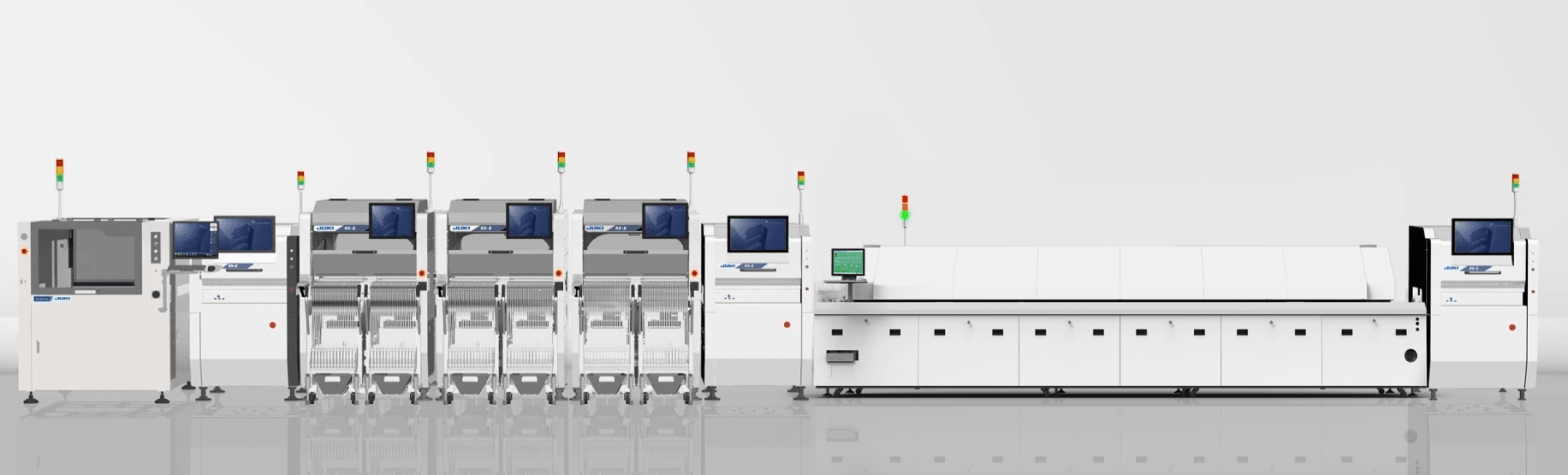

Comparing JUKI and Other Leading Brands

JUKI has established itself as a frontrunner in the realm of SMT machines, renowned for their reliability and advanced technology in PCB SMT applications. Their smt mounting machines are particularly praised for high-speed operation combined with exceptional precision—ideal for complex circuit board designs requiring meticulous attention to detail. However, other brands like Panasonic and Yamaha also offer competitive options worth considering.

When comparing these brands, look at specific features such as ease of use, software integration capabilities, and customer support services—these elements can greatly affect operational efficiency during smt production processes. Moreover, reviewing user feedback on performance in real-world applications helps provide insights into how different machines stack up against one another over time. Ultimately, selecting an appropriate brand involves weighing these factors against your unique production needs.

Recommendations from Bensun Technology Co., Ltd.

Bensun Technology Co., Ltd. offers tailored recommendations to help you navigate the selection process for an effective SMT LED chip mounter that aligns with your business goals. They emphasize choosing machines that not only meet current demands but also have scalability potential for future growth within PCB SMT applications—a smart move in today’s fast-paced market landscape!

Additionally, Bensun provides comprehensive after-sales support to ensure smooth operations post-purchase; this includes training on best practices for using their smt placement machines effectively while minimizing downtime during production cycles. With their expertise guiding you through this decision-making process, investing in a suitable LED SMT machine becomes less daunting while ensuring high-quality outputs tailored to industry standards.

Future Trends in SMT LED Technology

The landscape of SMT LED technology is rapidly evolving, driven by innovations that enhance efficiency and performance. As manufacturers strive to keep pace with increasing demands for high-quality circuit boards, the integration of advanced technologies into SMT production processes becomes essential. This section explores the latest advancements shaping the future of SMT LED chip mounters and their impact on various industries.

Innovations Shaping the SMT Industry

Innovations in smt machines are transforming how we approach PCB SMT processes, with a focus on speed and accuracy. Enhanced algorithms for placement accuracy are being developed, allowing smt placement machines to achieve unprecedented precision in positioning LED chips on circuit boards. Additionally, new materials and techniques are emerging that improve soldering quality and reliability, further elevating the capabilities of modern smt mounting machines.

Moreover, automation is taking center stage in these innovations, reducing human error while increasing throughput in SMT production lines. The introduction of AI-driven systems enables real-time monitoring and adjustments during production cycles, ensuring optimal performance from every smt led chip mounter. As these technologies continue to evolve, manufacturers can expect significant improvements in both efficiency and product quality.

The Impact of Industry 4.0 on SMT Production

Industry 4.0 is reshaping the manufacturing landscape by integrating smart technologies into traditional processes, including those involving smt led machines. This revolution promotes interconnectedness between devices through IoT (Internet of Things), enabling seamless communication across all stages of PCB SMT operations. Consequently, manufacturers can track production metrics more effectively while optimizing resource allocation.

With predictive maintenance becoming commonplace due to data analytics capabilities provided by Industry 4.0 solutions, downtime is minimized significantly for smt mounting machines. These insights allow companies to anticipate equipment failures before they occur—ensuring smooth operations throughout the entire smt production process. Ultimately, this shift enhances overall productivity and reduces costs associated with unplanned interruptions.

Sustainability and Efficiency in SMT Manufacturing

Sustainability has become a critical focus within the SMT industry as environmental concerns gain prominence worldwide; manufacturers are now seeking eco-friendly alternatives without compromising efficiency or quality in their processes involving led smt machines. By utilizing energy-efficient components and optimizing material usage during PCB assembly operations, companies can significantly reduce waste generated from their manufacturing activities.

Furthermore, advancements in recycling technologies enable greater recovery rates for electronic components discarded during production or after product lifecycle completion—paving the way for more sustainable practices within circuit board manufacturing sectors utilizing smt technology extensively. Embracing these sustainable approaches not only benefits our planet but also enhances brand reputation among increasingly eco-conscious consumers demanding responsible practices from businesses today.

In conclusion, staying abreast of future trends such as innovations shaping the industry landscape will be crucial for those invested heavily within this domain—from selecting an appropriate smt led chip mounter to understanding how automation impacts overall productivity levels across various applications alike!

Conclusion

In the rapidly evolving world of electronics, ensuring quality with SMT LED chip mounters is paramount. These machines are not just tools; they are integral to the production of reliable circuit boards that power our modern devices. By utilizing advanced technology in SMT production, manufacturers can achieve superior results that stand the test of time.

Ensuring Quality with SMT LED Chip Mounters

Quality assurance begins at the very first step of PCB SMT processes, where an SMT LED chip mounter plays a crucial role. These machines guarantee precise placement of components on circuit boards, minimizing the risk of defects and maximizing performance. With rigorous calibration and testing protocols in place, manufacturers can trust that their final products will meet stringent quality standards.

The Balance Between Precision and Efficiency

Finding the sweet spot between precision and efficiency is essential for any successful SMT machine operation. While it’s vital to achieve high accuracy in component placement with an SMT placement machine, it’s equally important to maintain a swift production pace to meet market demands. This balance allows companies to produce high-quality circuit boards while optimizing resource utilization and reducing overall costs.

Exploring Flexible Solutions with Bensun Technology

When it comes to investing in an SMT mounting machine, flexibility is key—especially for businesses looking to adapt to changing market conditions. Bensun Technology offers a range of innovative solutions tailored for various applications within LED SMT machines, ensuring that customers can find the perfect fit for their needs. As industry trends shift towards more customizable and efficient manufacturing processes, partnering with a forward-thinking company like Bensun could be your ticket to staying ahead of the competition.