Introduction

In the fast-paced world of electronics manufacturing, chip mounter machines play a crucial role in ensuring efficiency and precision. These sophisticated machines, often referred to as pick and place machines, are essential for placing components onto printed circuit boards (PCBs) with high accuracy. As industries increasingly rely on machine SMT (Surface Mount Technology), understanding the landscape of chip mounter machine suppliers becomes vital for manufacturers seeking to enhance their production capabilities.

Overview of Chip Mounter Machines

Chip mounter machines are at the heart of modern electronics production, automating the assembly process for various components on PCBs. These machines utilize advanced technology to perform intricate tasks that were once done manually, significantly improving speed and reliability in manufacturing. With various types available, each designed for specific applications, choosing the right machine pick and place is essential for optimizing production workflows.

Importance of Reliable Suppliers

When it comes to selecting a chip mounter machine supplier, reliability is paramount. A dependable supplier not only provides high-quality equipment but also offers essential after-sales support that can make or break a manufacturing operation. In an industry where downtime can lead to significant losses, partnering with trusted suppliers ensures that your pick & place operations run smoothly and efficiently.

Key Market Players in China

China has emerged as a powerhouse in the electronics manufacturing sector, with numerous key players dominating the market for chip mounter machines. Leading companies like Bensun Technology Co., Ltd., Hanwha Precision Machinery, and Yamaha Motor Co., Ltd., have established themselves as frontrunners by providing innovative solutions tailored to meet diverse industry needs. By understanding these key market players and their offerings, manufacturers can make informed decisions when selecting a PCB machine that aligns with their operational requirements.

Understanding Chip Mounter Machines

In the world of electronics manufacturing, chip mounter machines play a crucial role in assembling components onto printed circuit boards (PCBs). These machines, often referred to as pick and place machines, are essential for automating the placement of various electronic components with precision and speed. Understanding their functionality and types is vital for anyone looking to invest in a reliable chip mounter machine supplier.

Definition and Functionality

A chip mounter machine is designed to automate the process of placing surface mount technology (SMT) components onto PCBs. Utilizing advanced robotics and vision systems, these machines can accurately position tiny components on circuit boards, ensuring high precision and minimizing errors. The functionality of a machine pick and place goes beyond mere placement; it also involves inspecting components for quality control, making them indispensable in modern manufacturing.

Types of Chip Mounter Machines

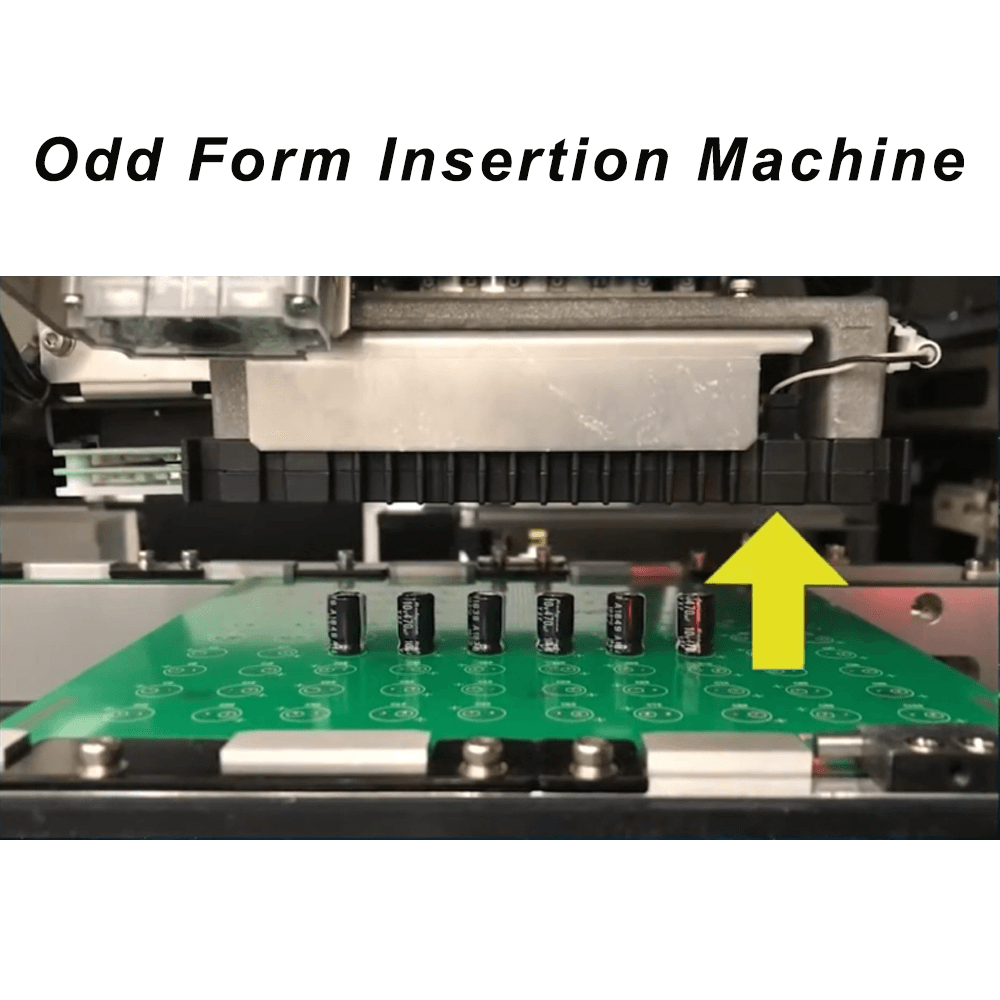

There are several types of chip mounter machines available on the market today, each tailored for specific applications within electronics manufacturing. For instance, high-speed pick & place machines are optimized for mass production environments where speed is paramount, while flexible SMT machines cater to smaller batches with varying component sizes. Additionally, some PCB machines are equipped with advanced features such as multi-functionality that allows them to handle both surface mount devices (SMDs) and through-hole components seamlessly.

Applications in Various Industries

Chip mounter machines find applications across a diverse range of industries due to their versatility and efficiency. In consumer electronics, they are used extensively for assembling smartphones, tablets, and other gadgets where compact circuitry is crucial. Beyond electronics manufacturing, these machines also play significant roles in automotive industries—where reliability is key—and medical device production—where precision can be a matter of life or death.

Leading Chip Mounter Machine Suppliers in China

When it comes to chip mounter machines, selecting a reliable supplier is crucial for the efficiency of your production line. In China, several key players have established themselves as leaders in the market, providing innovative solutions that cater to a variety of industries. This section will delve into three prominent chip mounter machine suppliers: Bensun Technology Co., Ltd., Hanwha Precision Machinery, and Yamaha Motor Co., Ltd.

Bensun Technology Co., Ltd.

Bensun Technology Co., Ltd. has made its mark as a notable chip mounter machine supplier in the competitive landscape of SMT (Surface Mount Technology). Known for their high-quality pick and place machines, Bensun focuses on delivering precision and reliability that manufacturers can depend on. Their product range includes advanced PCB machines designed to optimize assembly processes across various sectors.

The company prides itself on its innovative technology and commitment to customer satisfaction, ensuring that each machine pick and place solution meets industry standards. With a strong emphasis on research and development, Bensun continually updates its offerings to incorporate the latest advancements in pick & place technology. This dedication not only enhances productivity but also positions them as an influential player among other machine SMT suppliers.

Furthermore, Bensun's after-sales support is commendable; they offer comprehensive training programs for operators and maintenance staff alike. This ensures that clients can maximize their investment in chip mounter machines while minimizing downtime during operation. Overall, choosing Bensun means opting for quality equipment backed by excellent service.

Hanwha Precision Machinery

Hanwha Precision Machinery stands out as another leading chip mounter machine supplier known for its cutting-edge technology and robust machinery performance. Their range of SMT machines includes some of the most sophisticated pick and place systems available today, catering to diverse manufacturing needs from small-scale operations to large factories. With a focus on automation and efficiency, Hanwha’s products help streamline production processes significantly.

One of their flagship offerings is the advanced pick & place system designed with user-friendly interfaces that simplify operation without sacrificing functionality or precision. The integration of AI-driven features allows these machines to adapt quickly to changing production demands while maintaining high-speed assembly capabilities—an essential factor in today’s fast-paced manufacturing environment. As such, companies looking for reliable PCB machines often turn to Hanwha for their innovative solutions.

In addition to offering top-tier equipment, Hanwha provides extensive after-sales support including maintenance services tailored specifically for their SMT machinery users. Their commitment extends beyond just selling machines; they aim to create long-term partnerships with clients by ensuring optimal performance over time through ongoing assistance and upgrades when necessary.

Yamaha Motor Co., Ltd.

Yamaha Motor Co., Ltd., widely recognized beyond just motorcycles, has also carved out a significant niche within the world of chip mounter machine suppliers with its exceptional line-up of SMT equipment. Their focus on creating versatile pick and place solutions makes them an attractive option for manufacturers seeking flexibility in production lines without compromising speed or accuracy with their PCB machines. Yamaha's reputation stems from decades of engineering excellence combined with innovation-driven design principles.

What sets Yamaha apart is their ability to integrate advanced technologies such as vision systems into their machinery—enhancing inspection capabilities during assembly processes while ensuring precise placement every time using state-of-the-art machine pick and place features. This level of sophistication not only boosts productivity but also reduces waste by minimizing errors during manufacturing runs—a critical component in maintaining profitability within competitive markets.

Moreover, Yamaha provides comprehensive training programs alongside robust customer support services aimed at optimizing user experience with their products over time—making them more than just another vendor but rather a partner invested in mutual success within the electronics manufacturing landscape.

Factors to Consider When Choosing a Supplier

When it comes to selecting a chip mounter machine supplier, several critical factors come into play. The right choice can significantly influence your production efficiency, product quality, and overall profitability. Understanding these factors will help you make an informed decision that aligns with your operational needs.

Quality of Equipment

The quality of equipment is paramount when evaluating a chip mounter machine supplier. High-quality pick and place machines are designed for precision and reliability, ensuring that components are placed accurately on PCBs every time. Investing in a top-notch SMT machine can lead to fewer errors, reduced waste, and ultimately higher productivity in your manufacturing process.

Moreover, the durability of the equipment should not be overlooked; robust machines tend to have longer lifespans and require less frequent maintenance. A reliable chip mounter machine supplier will offer detailed specifications and performance metrics for their machines, allowing you to compare options effectively. When examining various suppliers, prioritize those who provide comprehensive warranties and guarantees on their products.

After-Sales Support

After-sales support is another vital aspect to consider when choosing a chip mounter machine supplier. The complexity of SMT machines means that occasional technical issues may arise; having reliable support can save you time and money in troubleshooting these problems. A good supplier should offer prompt customer service, access to spare parts, and maintenance services tailored to your specific needs.

Additionally, training resources are essential for ensuring that your team can operate the pick & place machinery efficiently from day one. Suppliers who provide thorough training programs demonstrate their commitment to customer satisfaction and long-term partnerships. Remember that strong after-sales support can be the difference between seamless operations or frustrating downtime.

Price and Financing Options

While price shouldn't be the sole deciding factor when selecting a chip mounter machine supplier, it certainly plays a crucial role in your decision-making process. It's important to find a balance between cost-effectiveness and quality; opting for the cheapest option may lead to compromises that could affect production outcomes negatively over time. Evaluate what each supplier offers concerning features versus price—sometimes paying slightly more upfront can save money down the line through improved efficiency.

Financing options also deserve consideration; many suppliers provide flexible payment plans or leasing arrangements which can ease cash flow concerns for smaller businesses or startups venturing into PCB assembly for the first time. Be sure to inquire about any hidden fees or additional costs associated with financing options as well—transparency is key! Ultimately, making an informed choice based on these financial factors will set you up for success in your manufacturing endeavors.

Innovations in Chip Mounter Technology

The world of chip mounter machines is evolving at a rapid pace, driven by technological advancements and the increasing demand for precision in manufacturing. As industries lean more towards automation, innovations in pick and place machines are becoming essential for maintaining competitiveness. The integration of smart technologies into SMT machines is reshaping how manufacturers approach production efficiency.

Latest Trends and Developments

Recent trends highlight the rise of machine learning and artificial intelligence within chip mounter technology. These advancements allow for smarter machine pick and place operations, enhancing accuracy while reducing human intervention. Additionally, the development of compact PCB machines is enabling manufacturers to save space without compromising on performance, making them a popular choice among various industries.

Another noteworthy trend is the shift towards modular designs in SMT machines, allowing users to customize their setups according to specific production needs. This flexibility not only improves efficiency but also reduces downtime during equipment changeovers. Moreover, advancements in vision systems have made it possible for pick & place operations to achieve unprecedented levels of precision, ensuring that every component is accurately placed on the PCB.

Impact of Technology on Productivity

The impact of these innovations on productivity cannot be overstated; modern chip mounter machines are designed to significantly enhance throughput while minimizing errors. With faster processing speeds and improved accuracy from advanced machine pick and place systems, manufacturers can meet tight deadlines without sacrificing quality. This boost in productivity translates directly into increased profitability for businesses that invest in cutting-edge SMT technology.

Furthermore, automation features integrated into these machines reduce labor costs by minimizing manual intervention during assembly processes. As a result, companies can allocate resources more effectively across their operations while maintaining high standards of quality control with less effort required from human operators. The cumulative effect is a streamlined production line that not only meets current demands but also adapts quickly to future challenges.

Future Prospects for Chip Mounter Machines

Looking ahead, the future prospects for chip mounter machines are bright as they continue to evolve alongside emerging technologies like IoT and Industry 4.0 initiatives. The potential for interconnected SMT machinery means real-time data analytics will become commonplace, allowing manufacturers to monitor performance metrics instantly and make informed decisions on-the-fly regarding their production processes.

Moreover, sustainability will likely play a significant role in shaping the next generation of chip mounter technology; eco-friendly materials and energy-efficient designs will become increasingly important as industries strive to reduce their environmental footprints. As innovation continues at this pace within the realm of pick & place technology, we can expect even greater advancements that push boundaries further than ever before—making it an exciting time for both suppliers and manufacturers alike.

The Role of Chip Mounter Machines in Global Supply Chains

In today's fast-paced manufacturing environment, chip mounter machines play a pivotal role in enhancing efficiency and productivity across various industries. These machines, often referred to as pick and place machines, are essential for automating the assembly process of printed circuit boards (PCBs). By streamlining operations, a reliable chip mounter machine supplier can significantly reduce production times and improve overall output quality.

Importance in Manufacturing Efficiency

The efficiency of manufacturing processes relies heavily on the capabilities of SMT machines, particularly chip mounter machines. These devices enable rapid placement of components onto PCBs with high precision, minimizing human error and maximizing throughput. As a result, manufacturers can meet increasing demand without compromising on quality or speed, making them indispensable in global supply chains.

Moreover, the integration of advanced technology into these machines has further enhanced their efficiency. Features like vision systems for component alignment and real-time data analytics allow for smarter decision-making during production. This evolution not only boosts productivity but also helps companies stay competitive in an ever-evolving marketplace.

Integration with Other Production Equipment

To fully capitalize on the benefits offered by chip mounter machines, seamless integration with other production equipment is crucial. For instance, coupling a pick & place machine with reflow ovens or soldering stations creates a cohesive workflow that optimizes the entire assembly line process. This integration ensures that each stage complements the others while reducing bottlenecks that can hinder productivity.

Additionally, modern SMT machinery often comes equipped with software solutions that facilitate communication between different devices on the production floor. Such interoperability allows manufacturers to automate workflows more effectively and respond swiftly to changes in demand or design specifications. Hence, choosing a versatile chip mounter machine supplier who understands these dynamics is vital for success.

Case Studies of Successful Implementations

Several companies have successfully implemented advanced chip mounter technology to revolutionize their manufacturing processes. For example, one leading electronics manufacturer integrated state-of-the-art PCB machines into its assembly lines and saw a dramatic reduction in cycle times—by up to 30%. This shift not only improved their output but also enhanced product reliability due to reduced handling errors.

Another case involved a mid-sized firm that adopted an innovative pick and place system from a reputable supplier specializing in SMT machinery. By streamlining their operations through this machine's capabilities, they managed to increase their production capacity without expanding their workforce significantly—demonstrating how effective automation can lead to remarkable gains.

These examples underscore how critical it is for companies to partner with reliable chip mounter machine suppliers who offer both cutting-edge technology and robust support systems tailored to specific needs within global supply chains.

Conclusion

In the ever-evolving landscape of electronics manufacturing, selecting the right chip mounter machine supplier is crucial. With an array of options available, businesses must consider factors such as technology, reliability, and support services. By evaluating leading suppliers in China, manufacturers can optimize their production processes and enhance overall efficiency.

Evaluating the Best Chip Mounter Machine Suppliers

When assessing chip mounter machine suppliers, it’s essential to look beyond just price tags. The quality of equipment plays a pivotal role in determining the longevity and performance of a pick and place machine. Companies like Bensun Technology Co., Ltd., Hanwha Precision Machinery, and Yamaha Motor Co., Ltd. stand out not only for their innovative offerings but also for their commitment to after-sales support—a critical aspect that can make or break your production line.

The Impact of Quality on Production Outcomes

Quality in machinery directly correlates with production outcomes; a reliable SMT machine ensures that every component is placed accurately on the PCB machine. This precision minimizes errors and reduces waste, ultimately leading to higher profitability for manufacturers. Investing in a top-notch pick & place system from reputable suppliers enhances productivity while ensuring that your products meet rigorous industry standards.

Future Trends in Chip Mounter Technology

The future of chip mounter technology looks promising with advancements in automation and artificial intelligence transforming traditional practices into smart manufacturing solutions. As machines become more integrated with IoT capabilities, expect significant improvements in efficiency through real-time data analytics from your pick and place machines. Staying ahead means embracing these trends—after all, who wouldn't want a cutting-edge machine SMT that elevates their production game?