Introduction

In the world of electronics manufacturing, reflow soldering stands as a pivotal technique that ensures the reliable assembly of printed circuit boards (PCBs). This process involves heating SMT solder paste to create strong connections between components and the PCB, necessitating a keen understanding of both the fundamentals and equipment involved. With the right reflow soldering machine, manufacturers can achieve consistent quality and efficiency in their PCB soldering operations.

Understanding Reflow Soldering Fundamentals

Reflow soldering is a method where solder paste is applied to a PCB, followed by placing surface-mount components before they are subjected to heat. The heat causes the solder paste to melt and flow, creating electrical connections once it cools down. Familiarity with SMT (Surface Mount Technology) and how SMT solder paste behaves during this process is essential for achieving optimal results in any reflow machine.

Importance of the Right Equipment

Choosing an appropriate reflow soldering machine is crucial for ensuring high-quality results in PCB assembly. The right equipment not only affects the reliability of joints but also impacts production speed and overall efficiency. Investing in a quality SMT reflow machine can minimize defects, reduce waste, and enhance productivity across manufacturing operations.

Overview of the Reflow Process

The reflow process consists of several critical steps that begin with preparing the PCB for effective soldering. Once prepared, specific heating profiles are employed within the reflow oven to ensure that all components reach optimal temperatures without causing damage or defects. Finally, proper cooling techniques are essential to solidify connections effectively while preventing issues such as warping or thermal shock.

The Basics of Reflow Soldering

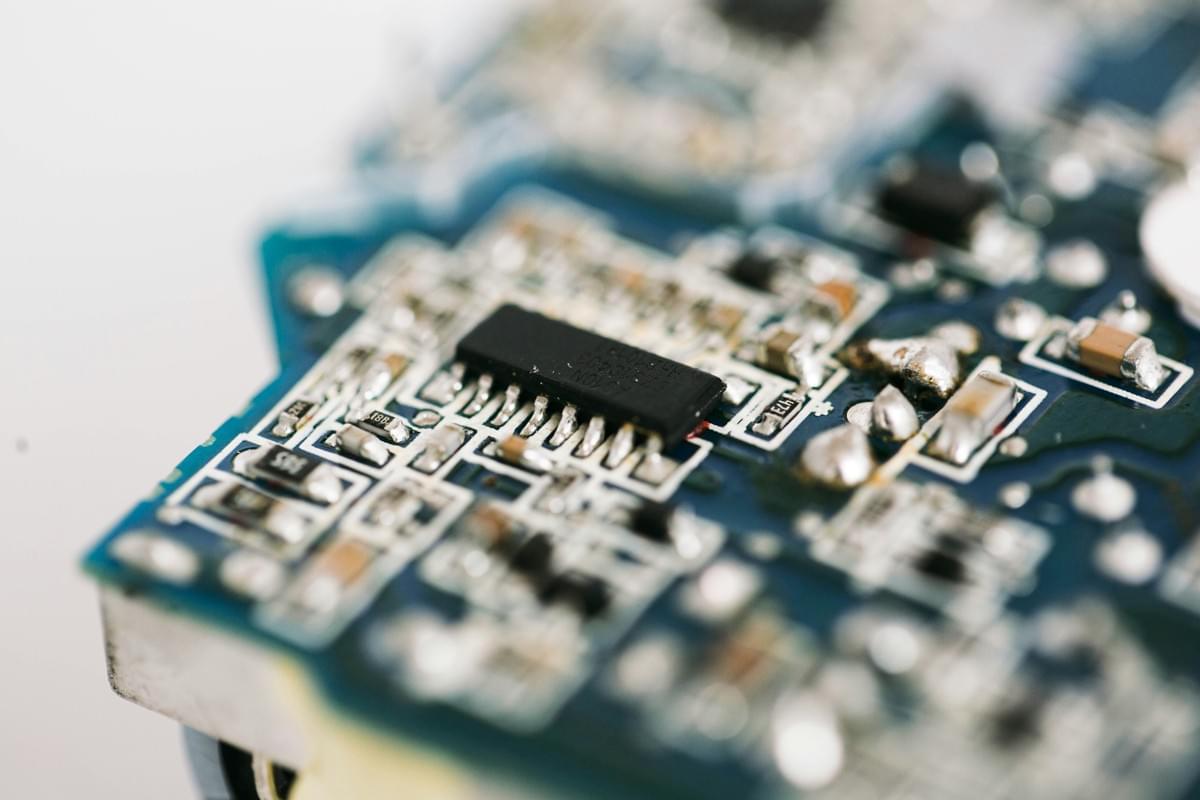

Reflow soldering is a crucial process in modern electronics manufacturing, particularly for surface mount technology (SMT). It involves melting solder paste to create reliable electrical connections between components and the printed circuit board (PCB). Understanding the fundamentals of reflow soldering is essential for anyone involved in PCB assembly, as it directly impacts the quality and reliability of electronic devices.

What is Reflow Soldering?

Reflow soldering is a technique used to attach electronic components to PCBs by heating solder paste until it melts and forms a solid joint. This method is particularly favored in SMT applications due to its efficiency and ability to handle small components with precision. Essentially, the process starts with applying SMT solder paste onto the PCB, placing components on top, and then using a reflow machine to heat everything up until the solder flows perfectly.

The beauty of reflow soldering lies in its ability to create strong bonds while minimizing thermal stress on sensitive components. By carefully controlling temperature profiles during heating and cooling phases, manufacturers can achieve optimal results without damaging delicate parts. Thus, mastering reflow soldering techniques is vital for any successful SMT operation.

How SMT Solder Paste Works

SMT solder paste plays a pivotal role in the reflow process by acting as both an adhesive and conductor for electrical connections. Composed of tiny metal particles suspended in a flux medium, this paste ensures that when heated during reflow soldering, it melts smoothly and adheres well to both the PCB pads and component leads. The right formulation of SMT solder paste not only facilitates excellent wetting but also provides sufficient viscosity to hold components securely before the actual heating occurs.

When applying SMT solder paste onto PCBs, precision is key; too much or too little can lead to defects like bridging or insufficient connections. Once placed under a reflow machine's controlled environment, the heat causes the flux within the paste to activate first—cleaning surfaces before melting begins—ensuring optimal bonding conditions are met. This seamless interaction between SMT solder paste and heat makes it an indispensable part of effective PCB soldering.

Role of the Reflow Soldering Machine

The reflow soldering machine acts as the heart of any effective SMT assembly line by providing precise control over temperature profiles needed for successful connections. These machines come equipped with advanced features that allow operators to customize heating cycles based on specific requirements for different types of PCBs or components being used. As such, selecting an appropriate reflow machine can significantly enhance production efficiency while ensuring high-quality results.

A typical reflow machine operates through several zones: preheat, soak, reflow, and cooling stages—all critical for achieving optimal results during PCB soldering processes. The preheat phase gradually raises temperatures to prepare both the board and components for melting; soaking ensures even heat distribution; while peak temperatures during reflow are carefully monitored so that all joints form correctly without overheating sensitive parts. Finally, controlled cooling helps solidify joints quickly enough to prevent issues like tombstoning or warping.

In summary, understanding how each component interacts within this intricate dance—from SMT solder paste application through various stages in a capable reflow machine—is essential knowledge for anyone involved in high-quality electronics manufacturing.

Types of Reflow Soldering Machines

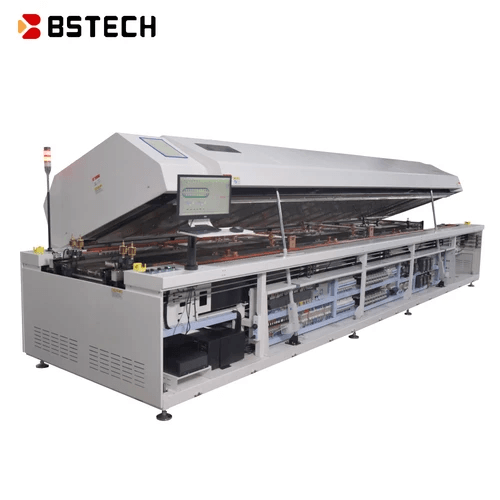

Overview of SMT Reflow Machines

SMT reflow machines are essential tools in modern electronics manufacturing, particularly for surface mount technology (SMT) applications. These machines utilize a combination of heat and time to melt solder paste, allowing components to securely attach to printed circuit boards (PCBs). The right reflow soldering machine not only ensures a reliable bond but also minimizes defects that can arise during the soldering process.

In essence, an SMT reflow machine is designed to create an optimal environment for melting the SMT solder paste applied on PCBs. The machine's design focuses on maintaining precise temperature control throughout the heating cycle, which is vital for achieving consistent results. With advancements in technology, these machines have become increasingly sophisticated, featuring programmable profiles that cater to different types of materials and components.

Comparing Reflow Oven Types

When comparing different types of reflow ovens, you'll encounter several options: convection ovens, infrared ovens, and vapor phase ovens. Convection ovens use heated air circulation to evenly distribute heat across the PCB surface; this method is popular due to its effectiveness at producing high-quality results with minimal thermal shock. On the other hand, infrared ovens utilize radiant heat sources that directly warm up specific areas of the board—ideal for quick heating but may require more careful management.

Vapor phase ovens present a unique alternative by using boiling fluids as a heat source; they maintain consistent temperatures without risking overheating sensitive components. Each type has its pros and cons depending on factors like production volume and component sensitivity. Ultimately, selecting the right type involves weighing factors such as thermal performance versus cost-effectiveness while ensuring compatibility with your chosen SMT solder paste.

Key Features to Look For

When investing in a reflow soldering machine or oven, several key features should be on your checklist to ensure you make an informed decision. First off is temperature profiling capability; this allows you to set specific heating curves tailored for different PCB designs and materials—crucial for achieving optimal results with various types of SMT components and solder pastes used in production.

Another important feature is user-friendly software that enables easy programming and monitoring throughout the reflow process—this can save significant time during setup while reducing errors during operation. Additionally, consider features such as energy efficiency ratings and maintenance accessibility; these aspects can greatly influence long-term operational costs associated with running your smt soldering machine effectively.

The Reflow Process Explained

The reflow process is a critical phase in PCB soldering that ensures reliable connections between components and the printed circuit board. This section will delve into the essential steps involved, from preparing the PCB for soldering to understanding the heating profile and cooling phases. Each step plays a vital role in achieving optimal results with your SMT soldering machine.

Preparing the PCB for Soldering

Before diving into reflow soldering, proper preparation of the PCB is essential to ensure a smooth process. Start by cleaning the surface of the PCB to remove any dust, oils, or contaminants that could interfere with solder adhesion. Once clean, apply SMT solder paste accurately onto each pad using a stencil; this paste serves as both an adhesive and conductor during reflow.

It's crucial to inspect your SMT solder paste application for consistency and accuracy because uneven distribution can lead to defects during reflow. Proper alignment of components on the board also plays a significant role; misalignment can result in insufficient connections or even component damage during heating. With everything prepped correctly, you're now ready to load your PCB into the reflow machine for an efficient soldering process.

The Heating Profile: an Essential Guide

The heating profile is arguably one of the most important aspects of successful reflow soldering. This profile dictates how quickly and uniformly heat is applied to both the PCB and components throughout different stages: preheat, soak, reflow, and cooling. Each stage has specific temperature requirements that must be adhered to in order for SMT solder paste to melt properly without damaging sensitive components.

During preheating, gradual temperature increases help eliminate moisture from both the board and components while preparing them for melting temperatures ahead. The soak phase allows for uniform heat distribution before reaching peak temperatures where solder melts—this step ensures all joints are adequately heated before solidifying again during cooling. A well-designed heating profile not only enhances reliability but also minimizes defects like tombstoning or cold joints.

Cooling and Its Importance in Reflow

Cooling might seem like an afterthought in the reflow process, but it’s just as crucial as heating when it comes to ensuring high-quality PCB soldering results. After reaching peak temperatures where SMT solder paste has melted into liquid form around component leads, controlled cooling helps solidify those connections evenly without introducing stress fractures or thermal shock risks.

Rapid cooling can lead to brittle joints while slow cooling may cause issues like poor mechanical strength or insufficient electrical conductivity—finding that perfect balance is key! Additionally, some advanced SMT reflow machines allow you to customize cooling rates based on specific project needs or component types which can significantly enhance overall performance.

Common Issues in Reflow Soldering

Reflow soldering can be a complex process, and even seasoned professionals may encounter issues that can affect the quality of PCB soldering. Identifying defects early in the reflow process is crucial to ensure that your SMT solder paste performs as intended. Understanding these common problems helps in troubleshooting effectively and maintaining high standards in production.

Identifying Defects in PCB Soldering

When it comes to PCB soldering, there are several defects that can arise during the reflow process, such as cold joints, bridging, and insufficient wetting. Cold joints occur when the solder does not melt properly, leading to weak connections that can fail over time. Bridging happens when excess solder creates unintended connections between pads, while insufficient wetting indicates poor adhesion of the SMT solder paste to the pad or component.

Visual inspection is often the first line of defense for identifying these issues; however, automated optical inspection (AOI) systems are becoming increasingly popular for their ability to detect defects more reliably and quickly. Additionally, monitoring temperature profiles throughout the reflow process can help pinpoint where things may have gone awry, allowing for adjustments to be made on-the-fly with your reflow machine. Being proactive about defect identification will save time and resources down the line.

Solutions for Common Problems

Addressing common problems in reflow soldering often requires a multifaceted approach involving equipment adjustments and procedural changes. For instance, if cold joints are prevalent, it might be time to revisit your heating profile on your SMT reflow machine; ensuring optimal temperatures at each stage is essential for proper melting of the SMT solder paste. Similarly, if bridging is an issue, consider reducing the amount of paste applied or adjusting nozzle heights during dispensing.

Another effective solution is regular maintenance of your reflow machine; worn-out components can lead to uneven heating or inadequate cooling stages which exacerbate existing problems. Implementing best practices such as using high-quality materials and ensuring cleanliness during setup will also contribute significantly to reducing defects in PCB soldering processes. By being vigilant about potential pitfalls and employing targeted solutions, you can enhance overall production quality.

The Impact of Equipment Quality

The quality of your equipment plays a pivotal role in mitigating issues related to reflow soldering. A high-quality reflow soldering machine ensures consistent heating profiles and precise temperature control throughout each cycle—factors that directly influence the performance of SMT solder paste on PCBs. Investing in reliable machinery not only reduces defect rates but also improves throughput by minimizing downtime due to equipment failures.

Moreover, using inferior machines may lead you down a rabbit hole of ongoing repairs and adjustments that could have been avoided altogether with better equipment choices upfront. When selecting an SMT reflow machine or any related machinery for PCB assembly processes, consider factors like brand reputation, customer reviews, and service support availability—these elements often indicate long-term reliability and operational efficiency. In short: don’t skimp on quality if you want smooth sailing through your reflow processes!

Best Practices for Successful Reflow Soldering

When it comes to achieving flawless results in reflow soldering, following best practices is crucial. A well-executed process not only enhances the quality of PCB soldering but also minimizes defects and rework. Here are some key strategies to ensure your SMT soldering machine operates at its best.

Tips for Using SMT Soldering Machines

Using a reflow soldering machine effectively requires a solid understanding of its operation and settings. Start by calibrating the machine according to the specifications of the SMT solder paste you’re using; different pastes may require unique temperature profiles for optimal performance. Additionally, always monitor the heating profile during operation to avoid common pitfalls like overheating or cold joints, which can lead to costly repairs.

Another tip is to ensure that your PCB is clean and free of contaminants before starting the reflow process. Any residue can interfere with adhesion and lead to defects in your PCB soldering results. Lastly, don’t forget about proper placement—ensure components are aligned correctly on the board prior to running them through the SMT reflow machine; this small step can save you from significant headaches later on.

Maintenance for Longevity and Efficiency

To keep your reflow machine humming along smoothly, regular maintenance is non-negotiable. Schedule routine inspections and cleaning sessions; neglecting this can lead to build-up that affects performance over time. Pay special attention to areas where SMT solder paste might accumulate, as these can cause blockages or uneven heating if not addressed.

Additionally, check all sensors and heating elements regularly for signs of wear or malfunction; replacing these components proactively will help maintain efficiency in your PCB soldering operations. Remember that a well-maintained SMT soldering machine will ultimately save you time and money by reducing downtime caused by equipment failures.

Choosing the Right Partner: Bensun Technology

Selecting a reliable partner like Bensun Technology can significantly enhance your experience with reflow soldering machines. Not only do they offer high-quality equipment tailored for various needs, but their expertise in SMT technology ensures you receive comprehensive support throughout your production journey. From initial setup guidance to ongoing maintenance tips, having Bensun by your side means you're never alone in navigating challenges.

Moreover, their commitment to innovation means you'll always have access to cutting-edge solutions designed specifically for modern manufacturing demands—keeping you ahead of competitors who may still be using outdated methods or equipment. With their support, you’ll be able to optimize every aspect of your reflow process while ensuring quality results that stand out in today’s market.

Conclusion

In the world of electronics manufacturing, mastering reflow soldering techniques is crucial for achieving high-quality PCB assemblies. By understanding the intricacies of the reflow process and utilizing the right equipment, manufacturers can ensure optimal performance and reliability in their products. As we look ahead, it’s clear that advancements in technology will continue to shape the landscape of reflow soldering.

Key Takeaways on Reflow Techniques

Reflow soldering is a sophisticated process that involves several critical steps, from preparing the PCB to cooling after soldering. The use of SMT solder paste is essential for creating strong connections between components and circuit boards, while an efficient reflow machine ensures consistent heating profiles for optimal results. Remember, quality matters; investing in a top-notch reflow soldering machine can significantly reduce defects and improve overall production efficiency.

Future Trends in Reflow Soldering

The future of reflow soldering looks promising with innovations like advanced thermal profiling technologies and automated systems gaining traction. These advancements aim to enhance precision in temperature control, ensuring better melting of SMT solder paste and minimizing defects during PCB soldering. Additionally, as manufacturers strive for sustainability, eco-friendly materials and processes are likely to become more prevalent in the realm of SMT reflow machines.

Choosing the Right Equipment for Success

Selecting the right equipment is paramount for successful reflow soldering operations. When evaluating options like an SMT soldering machine or a dedicated reflow oven, consider key features such as temperature accuracy, size compatibility with your PCBs, and ease of use. Partnering with reliable suppliers like Bensun Technology can provide valuable insights into selecting a high-performing reflow machine tailored to your specific needs.