Introduction

In the fast-paced world of electronic device manufacturing, understanding SMT placement equipment is crucial for achieving efficiency and quality. This specialized machinery plays a pivotal role in the circuit card assembly process, ensuring that electronic components are accurately placed on PCB assembly boards. Without the right tools, even the most sophisticated designs can falter, leading to costly delays and subpar products.

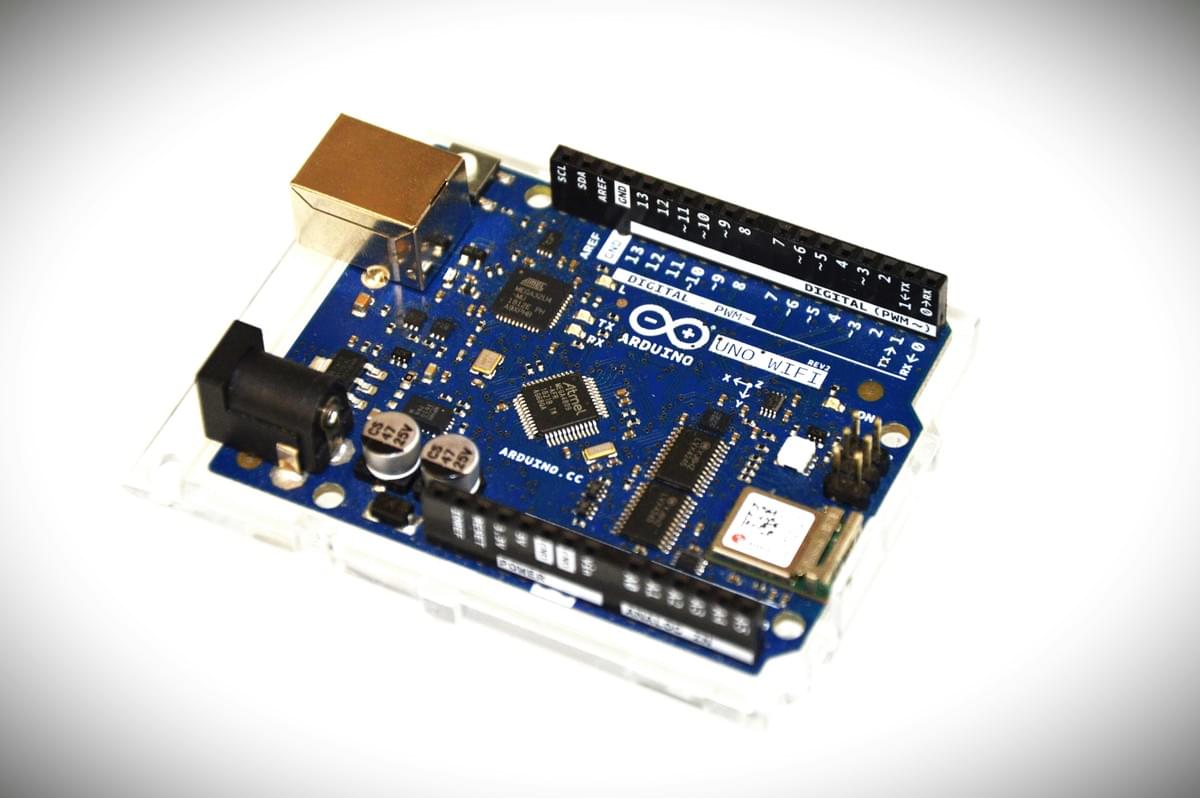

Understanding SMT Placement Equipment

SMT placement equipment encompasses a range of machines designed for surface mount device (SMD) assembly, including pick and place machines, solder paste printers, and reflow ovens. These devices work in harmony to streamline the printed circuit assembly process by accurately positioning tiny electronic components onto circuit boards. Mastering this technology is essential for manufacturers who aim to meet modern demands for speed and precision.

Why Proper Equipment Matters

Investing in high-quality SMT placement equipment can significantly impact production outcomes, influencing everything from yield rates to overall product reliability. Properly functioning machines ensure that each component is placed with precision, minimizing defects that could lead to failures in electronic devices. The right equipment not only enhances efficiency but also reduces long-term costs associated with rework and warranty claims.

Overview of Circuit Card Assembly

Circuit card assembly involves multiple steps that transform bare PCB assembly boards into fully functional electronic devices ready for market deployment. From applying solder paste to placing surface mount devices and finally curing them in reflow ovens, each stage relies on specialized SMT placement equipment for optimal results. Understanding this intricate process helps manufacturers make informed decisions about their production capabilities and future investments.

Types of SMT Placement Equipment

In the world of circuit card assembly, selecting the right SMT placement equipment is crucial for ensuring efficiency and quality in printed circuit assembly (PCA). Each type of equipment plays a distinct role in the manufacturing process, from applying solder paste to placing electronic components and ultimately reflowing them into place. Understanding these essential machines will help you make informed decisions that align with your production needs.

Pick and Place Machines

Pick and place machines are the backbone of any SMT placement operation, designed specifically for accurately positioning surface mount devices (SMDs) onto a PCB assembly board. These machines utilize advanced robotics to pick up electronic components from a feeder system and precisely place them on the circuit board according to a predetermined layout. With their ability to handle various component sizes and types, pick and place machines significantly enhance production speed while minimizing errors.

Modern pick and place machines come equipped with features such as vision systems for real-time verification of component placement, which is vital for maintaining high-quality standards in electronic device manufacturing. The integration of software allows these machines to quickly adapt to different circuit board designs, making them versatile tools in any PCB assembly facility. Ultimately, investing in a reliable pick and place machine can lead to improved throughput, reduced labor costs, and enhanced overall efficiency.

Solder Paste Printers

Solder paste printers are another critical piece of SMT placement equipment that ensures the successful application of solder paste onto circuit boards before components are placed. These printers utilize stencils or templates that allow precise deposits of solder paste on designated pads where electronic components will be attached later on. The accuracy of solder paste application directly impacts the quality and reliability of the finished product.

With advancements in technology, modern solder paste printers offer features like automatic alignment systems that ensure perfect registration between the stencil and PCB layout, reducing misalignment issues significantly. Additionally, some models incorporate closed-loop feedback mechanisms that monitor thickness consistency during printing—a game-changer for high-volume production runs where precision is paramount. By optimizing this initial step in printed circuit assembly, manufacturers can enhance yield rates and minimize rework costs.

Reflow Ovens

Once components have been placed on the PCB using pick and place machines, they must undergo reflow soldering to create strong electrical connections between surface mount devices (SMDs) and their respective pads on the circuit board. Reflow ovens heat up gradually following a specific temperature profile that melts solder paste while avoiding damage to sensitive electronic components. This step is essential for ensuring durability in finished electronic devices.

Reflow ovens vary widely in design—from simple convection models to sophisticated infrared or vapor phase systems—each offering unique advantages depending on production requirements. Features like programmable profiles allow manufacturers to customize heating cycles based on different types of solder materials or component sensitivities; thus ensuring optimal results every time they process a PCB assembly board. Investing wisely in an efficient reflow oven can drastically reduce defects while improving overall product quality.

Key Features to Consider

When diving into the world of SMT placement equipment, understanding key features is crucial for optimizing circuit card assembly processes. The right equipment can significantly enhance the efficiency and quality of printed circuit assembly (PCA). Let’s explore what to look for when choosing your SMT placement machinery.

Speed and Capacity

Speed and capacity are paramount when evaluating SMT placement equipment for your production line. High-speed machines can handle a greater volume of electronic components, reducing cycle times and increasing throughput on your PCB assembly board. If you're ramping up production or dealing with complex circuit boards, investing in faster machines could mean the difference between meeting deadlines and falling behind.

Moreover, capacity isn't just about speed; it's also about how many components can be placed simultaneously. Machines with higher capacity allow for more efficient handling of surface mount devices (SMDs), which is essential in today’s fast-paced electronic device manufacturing landscape. Ultimately, balancing speed with capacity ensures that you maintain quality while scaling your operations effectively.

Precision and Accuracy

Precision and accuracy are non-negotiable features in any SMT placement equipment designed for printed circuit assembly. The slightest misalignment can lead to costly errors or even total failure of an electronic device, making it imperative that machines offer high levels of precision during component placement on the PCB assembly board. Look for technologies like vision systems that enhance alignment accuracy, ensuring each surface mount device is positioned perfectly.

Furthermore, the ability to handle a wide range of component sizes without sacrificing precision is essential as well. As you navigate through various projects involving different electronic components, maintaining consistent accuracy across all placements will help uphold product integrity and reliability in your final assemblies. Remember: in the world of electronics, a millimeter off could mean disaster!

Compatibility with Electronic Components

Compatibility with various electronic components is another critical feature to consider when selecting SMT placement equipment. Not all machines can handle every type of SMD or PCB layout; therefore, ensuring that your chosen equipment aligns with your specific needs is vital for effective circuit card assembly. This includes checking if the machine supports different package types like QFN, BGA, or chip resistors.

Additionally, consider how easily the machine integrates into existing workflows within your manufacturing setup. A versatile machine that accommodates multiple types of electronic components without requiring extensive modifications will save time and costs down the line while also enhancing productivity during printed circuit assembly processes. In essence, ensuring compatibility means fewer headaches as you scale up production efforts.

Top Brands in SMT Placement Equipment

When it comes to SMT placement equipment, the market is filled with brands that promise efficiency and precision in circuit card assembly. Each brand brings its unique strengths to the table, catering to various needs in printed circuit assembly and electronic devices. Let's dive into three of the top players in this field: Bensun Technology, Yamaha Motor Co., and ASM Assembly Systems.

Bensun Technology

Bensun Technology has carved out a niche for itself by focusing on high-performance SMT placement equipment that excels in speed and accuracy. Their machines are designed with advanced features that ensure precise placement of surface mount devices (SMDs) on PCB assembly boards, making them ideal for complex electronic components. With a commitment to quality and innovation, Bensun is a go-to brand for manufacturers looking to enhance their production capabilities.

What sets Bensun apart is their user-friendly interface combined with robust technology that minimizes setup time while maximizing output. This makes their equipment suitable for both small-scale operations and large manufacturing plants aiming for high-volume production runs. As the demand for intricate circuit board designs grows, Bensun continues to adapt its offerings to meet evolving industry standards.

Yamaha Motor Co.

Yamaha Motor Co. is not just known for motorcycles; they also lead the charge in SMT placement equipment with a reputation built on reliability and performance. Their machines are engineered to handle various types of electronic components efficiently, ensuring optimal results during circuit card assembly processes. With Yamaha’s extensive experience in automation technology, they have developed systems that integrate seamlessly into existing production lines.

What makes Yamaha stand out is their commitment to continuous improvement and innovation in PCB assembly solutions. They offer customizable options that allow manufacturers to tailor machines according to specific needs, whether it's speed or complexity of design. This adaptability has made Yamaha a favorite among companies striving for excellence in electronic device manufacturing.

ASM Assembly Systems

ASM Assembly Systems is another heavyweight contender when it comes to SMT placement equipment, renowned globally for its cutting-edge technology and innovative designs. They provide comprehensive solutions tailored specifically for printed circuit assembly needs, ensuring high precision even when dealing with the smallest surface mount devices (SMDs). Their machinery not only boosts productivity but also enhances quality control throughout the entire manufacturing process.

A key feature of ASM's offerings is their intelligent software integration which helps streamline operations from setup through maintenance phases—making life easier for engineers on the floor! Moreover, ASM's focus on sustainability aligns well with modern manufacturing practices aimed at reducing waste while maximizing efficiency in electronic component handling. This combination of performance and environmental responsibility positions ASM as a leader in advancing PCB assembly technologies.

Evaluating Your Production Needs

When it comes to selecting the right SMT placement equipment for your production line, a thorough evaluation of your specific needs is essential. Understanding the intricacies of circuit card assembly, including the types of electronic components you plan to use, can significantly influence your decision-making process. By taking a closer look at these factors, you can ensure that your chosen equipment aligns perfectly with your production goals.

Assessing Circuit Board Complexity

The complexity of the circuit board plays a pivotal role in determining the type of SMT placement equipment you'll need. For instance, if you're working with intricate designs featuring multiple surface mount devices (SMDs) and varied component sizes, you'll require more advanced machinery capable of handling such precision. Assessing this complexity not only helps in choosing the right equipment but also ensures seamless operation during printed circuit assembly (PCA).

Moreover, understanding how different electronic components interact on a circuit board can guide you in selecting features that enhance performance and reliability. If your design includes high-density layouts or specialized components, investing in sophisticated SMT placement machines with advanced capabilities will pay off in efficiency and quality. Ultimately, recognizing the complexity upfront allows for better planning and resource allocation.

Understanding Volume Requirements

Volume requirements are another critical factor when evaluating SMT placement equipment for your operations. Whether you're producing small batches or mass quantities of PCB assembly boards will dictate not just speed but also machine specifications and capabilities. High-volume production demands machines that can deliver consistent output while maintaining accuracy across various runs.

Additionally, consider how fluctuations in demand may affect volume requirements over time; having flexible solutions can save costs and improve responsiveness to market changes. Investing in scalable SMT placement equipment ensures you won't be left scrambling when orders increase unexpectedly or when introducing new product lines into your manufacturing process. A clear understanding here will help align resources effectively with market needs.

Considering Future Scalability

Future scalability is crucial when selecting SMT placement equipment because technology and market demands are ever-evolving landscapes. As you grow and adapt to new trends within electronic devices manufacturing, having machinery that can expand its capabilities without requiring extensive overhauls is invaluable. Opting for modular systems allows integration of new technologies as they emerge while keeping existing workflows intact.

Moreover, consider how future advancements in electronic components may influence design changes on circuit boards down the line; compatibility with upcoming standards ensures long-term viability for your investment in PCB assembly machinery. This foresight not only protects against obsolescence but also positions you favorably against competitors who may struggle to keep pace with industry innovations.

In summary, evaluating production needs through assessing circuit board complexity, understanding volume requirements, and considering future scalability creates a solid foundation for selecting optimal SMT placement equipment tailored to your business's unique demands.

Cost Considerations

When investing in SMT placement equipment, understanding the cost dynamics is crucial for any manufacturer involved in circuit card assembly. The initial outlay for high-quality machines can be significant, but it’s essential to balance this with the long-term savings they may provide. Efficient SMT equipment can drastically reduce production time and waste, ultimately leading to a more profitable operation.

Initial Investment vs. Long-Term Savings

The initial investment in SMT placement equipment often raises eyebrows, especially for startups or small manufacturers venturing into printed circuit assembly. However, the right equipment can lead to substantial long-term savings through increased efficiency and reduced labor costs. By automating processes that were once manual, companies can not only speed up production but also minimize errors associated with human handling of electronic components.

Additionally, investing in advanced technology means that your circuit board production will be more adaptable to future trends and demands in electronic devices. This adaptability ensures that you won’t have to frequently replace outdated machinery as market needs evolve. In essence, while the upfront cost of quality SMT placement equipment may seem daunting, the potential return on investment through enhanced productivity is undeniable.

Maintenance and Operating Costs

Every piece of machinery requires maintenance, and SMT placement equipment is no exception if you want it to perform at its best during circuit card assembly operations. Regular maintenance ensures that these machines continue to operate efficiently, preventing costly downtime that could disrupt your PCB assembly timeline. Moreover, understanding the operating costs—such as energy consumption and spare parts—is vital for budgeting effectively over time.

Choosing reliable brands known for their durability can help mitigate unexpected repair costs down the line; after all, nobody wants their surface mount device (SMD) placements interrupted by malfunctioning gear! Additionally, consider how user-friendly the machine is: intuitive controls can reduce training time and operational errors among staff members engaged in electronic component handling. Ultimately, factoring these elements into your overall cost considerations will lead to a more informed purchasing decision.

Financing Options for PCB Assembly

Navigating financing options for acquiring SMT placement equipment doesn’t have to be a headache; there are several avenues available tailored specifically for PCB assembly needs. Many manufacturers offer leasing options which allow businesses to use high-end machines without bearing the full brunt of upfront costs immediately—perfect for those looking to manage cash flow while still upgrading their operations!

Additionally, some financial institutions specialize in lending solutions designed specifically for manufacturing sectors like electronics; they understand your unique requirements better than traditional banks might. Exploring grants or government programs aimed at boosting technological advancement within industries could also yield financial support opportunities you hadn’t considered before.

In conclusion, being strategic about your financial decisions surrounding SMT placement equipment will not only ease immediate budgetary concerns but also position your business favorably against competitors in an ever-evolving market landscape.

Conclusion

In the fast-paced world of electronic device manufacturing, understanding SMT placement equipment is essential for any business aiming to thrive. The right tools can significantly impact the efficiency and quality of circuit card assembly, ensuring that your printed circuit assembly meets industry standards. As you navigate through options, a well-informed decision will pave the way for successful production and innovation.

Making an Informed Decision

When selecting SMT placement equipment, it's crucial to weigh your specific needs against the features available in different machines. Consider factors like speed, precision, and compatibility with various electronic components to ensure your chosen equipment aligns with your production goals. Ultimately, making an informed decision can enhance your operational efficiency and reduce errors in assembling circuit boards.

Importance of After-Sales Support

After-sales support is a vital aspect that shouldn't be overlooked when investing in SMT placement equipment. Reliable service ensures that any issues with your machinery are addressed promptly, minimizing downtime during critical production phases of PCB assembly boards. Strong after-sales support also fosters a long-term relationship with manufacturers, providing access to upgrades and additional resources as technology evolves.

Staying Ahead in Electronic Device Manufacturing

To remain competitive in electronic device manufacturing, staying updated on advancements in SMT placement equipment is essential. Embracing new technologies not only improves the quality of surface mount devices but also enhances overall productivity in circuit card assembly processes. By continuously adapting and investing wisely in cutting-edge solutions, businesses can secure their position at the forefront of the industry.