Introduction

In the ever-evolving world of electronics, the chip mounter machine stands out as a critical player in PCB assembly. These machines are designed to efficiently place components onto printed circuit boards (PCBs), ensuring precision and speed that manual methods simply can’t match. Understanding how these machines work, along with their key components, is essential for anyone involved in electronics manufacturing.

Understanding the Chip Mounter Machine

A chip mounter machine is a sophisticated piece of equipment that automates the placement of electronic components onto PCBs. Its primary purpose is to enhance production efficiency while maintaining high levels of accuracy in component placement. By utilizing advanced technology, these machines streamline the assembly process and significantly reduce human error.

Key Components of PCB Assembly

The PCB assembly process relies on several critical machine parts working together seamlessly, including the soldering machine and pick and place machine. The soldering machine ensures secure connections between components and boards, while the pick place machine accurately positions each component before soldering occurs. Together, these elements form a cohesive system that enhances overall productivity in electronics manufacturing.

Advantages of High Accuracy Machines

High accuracy machines offer numerous advantages that can transform PCB assembly practices dramatically. With precise placement capabilities, they not only improve product quality but also minimize waste by reducing misplacements and rework costs associated with manual handling. Furthermore, investing in a reliable machine SMT enhances production speed, allowing manufacturers to meet increasing market demands without compromising on quality.

What is a Chip Mounter Machine?

The chip mounter machine is a pivotal player in the world of PCB assembly, revolutionizing how electronic components are placed on printed circuit boards. This sophisticated device streamlines the manufacturing process, ensuring high precision and efficiency. By automating the placement of components, it significantly reduces human error and enhances production speed.

Definition and Purpose

A chip mounter machine, often referred to as a pick place machine, is designed to accurately position surface mount devices (SMDs) onto PCBs during assembly. Its primary purpose is to facilitate the rapid and precise placement of components, which is crucial for modern electronics manufacturing. With advancements in technology, these machines have evolved to deliver exceptional accuracy and reliability in high-volume production settings.

How It Works in PCB Assembly

The operation of a chip mounter machine involves several key steps that integrate seamlessly into PCB assembly processes. Initially, the machine picks up components from reels or trays using its advanced pick and place mechanism. Once secured, the component is precisely placed onto the designated spot on the PCB before transitioning to a soldering machine for secure attachment—this entire sequence exemplifies how automation enhances efficiency.

Types of Chip Mounter Machines

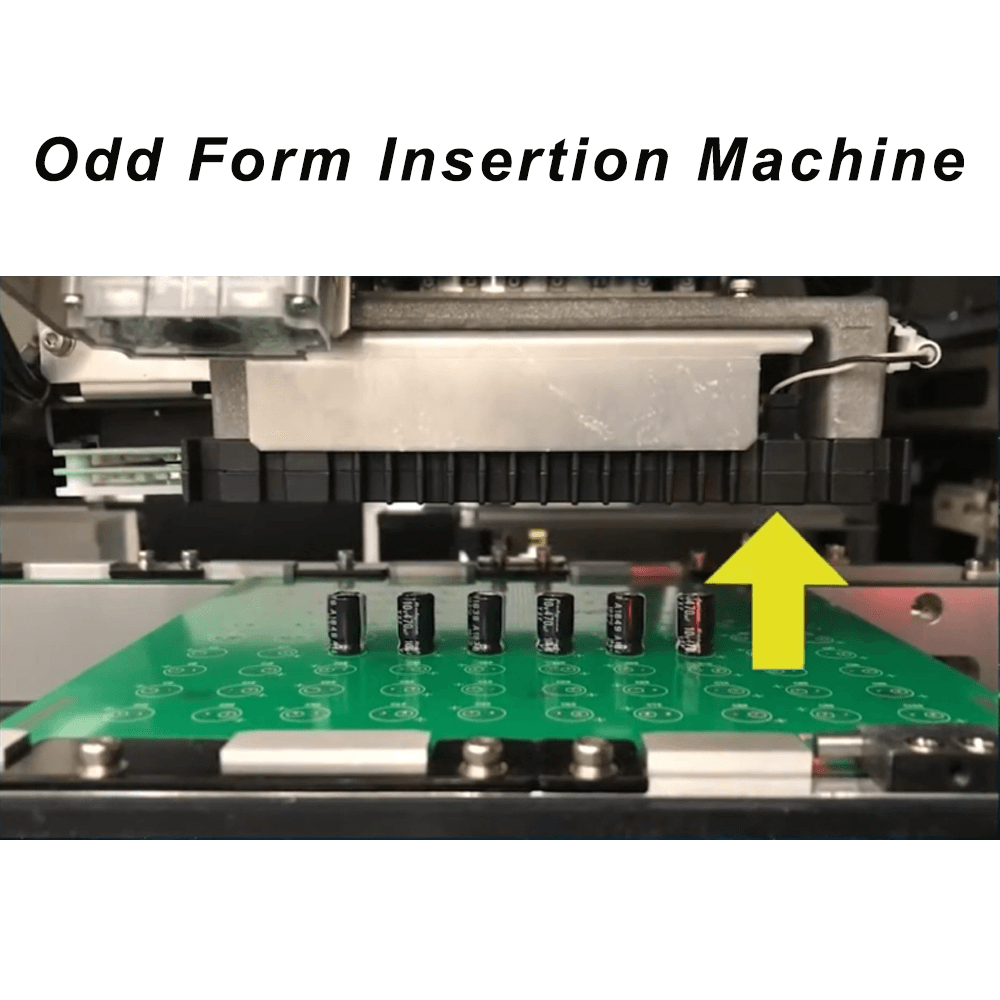

There are various types of chip mounter machines available on the market today, each tailored for different production needs and scales. From compact models designed for small-scale operations to large industrial machines capable of handling high volumes, manufacturers can choose based on their specific requirements. Additionally, some machines offer flexibility with interchangeable parts that allow users to adapt quickly to changing demands in their production lines.

Components that Make Up the Machine

When it comes to the inner workings of a chip mounter machine, understanding its components is crucial for anyone involved in PCB assembly. Each part plays a specific role, contributing to the overall efficiency and performance of the machine. Let’s delve into the essential machine parts, the pivotal role of soldering machines, and why pick and place machines are indispensable in this process.

Essential Machine Parts

A chip mounter machine consists of several essential components that work harmoniously to ensure precise placement and soldering of electronic components onto PCBs. Key machine parts include feeders, which supply components; vision systems that provide real-time feedback for accurate placement; and conveyors that transport PCBs through different stages of assembly. These elements collectively enhance the functionality of SMT machines, allowing them to operate with high speed and precision.

Understanding these essential parts helps in troubleshooting potential issues during production runs. For instance, if there’s a misalignment or failure in component pickup, it might be traced back to feeder malfunctions or vision system inaccuracies. Hence, maintaining these machine parts is vital for ensuring optimal performance in any pick place machine setup.

Role of the Soldering Machine

The soldering machine is another key player within a chip mounter system that cannot be overlooked. After components are accurately placed on the PCB by the pick and place machine, they need to be securely attached using soldering techniques. This process can involve wave soldering or reflow soldering methods depending on whether through-hole or surface mount technology (SMT) is being utilized.

Incorporating advanced soldering machines allows for consistent quality control during PCB assembly processes. The precision with which these machines operate directly impacts both durability and reliability of electronic devices post-manufacturing. Thus, investing in high-quality soldering machinery enhances overall production efficiency while minimizing defects—an absolute win-win for manufacturers!

Importance of the Pick and Place Machine

The pick and place machine is arguably one of the most critical components within any SMT setup due to its direct influence on placement accuracy and speed during PCB assembly operations. It automates component handling by picking up various electronic elements from feeders before placing them onto designated spots on PCBs with remarkable precision—hence its name! This automation not only boosts productivity but also reduces human error significantly when compared to manual assembly methods.

Moreover, modern advancements in pick place machines have introduced features like dual-lane operation capabilities which allow simultaneous processing of multiple boards—maximizing throughput without compromising quality standards! As technology evolves further towards smart manufacturing solutions, integrating sophisticated software into these machines will likely enhance their adaptability across diverse production needs even more effectively than before.

The Technology Behind High Accuracy

In the world of PCB assembly, precision is everything, and that’s where the technology behind high accuracy shines. At the heart of this technology lies Surface Mount Technology (SMT), which has revolutionized how components are placed on printed circuit boards. By utilizing chip mounter machines equipped with advanced machine parts, manufacturers can achieve remarkable accuracy and efficiency in their production processes.

Understanding SMT Technology

SMT technology refers to the method of mounting electronic components directly onto the surface of a PCB rather than through holes. This technique allows for a more compact design and higher component density, making it essential for modern electronics. Chip mounter machines are specifically designed to handle SMT components with precision, employing sophisticated algorithms to ensure that every component is placed accurately.

The integration of SMT into manufacturing processes has led to significant advancements in speed and quality control. With machine pick and place systems, manufacturers can automate assembly lines while maintaining high standards of accuracy. This not only reduces production time but also minimizes human error, making SMT an invaluable aspect of contemporary PCB assembly.

How Accurate Placement Impacts Quality

Accurate placement is crucial in ensuring the reliability and performance of electronic devices. When components are positioned incorrectly on a PCB due to imprecise operations from a pick place machine, it can lead to circuit failures or reduced functionality. High-quality chip mounter machines excel in achieving precise placements that adhere to strict tolerances, thereby enhancing overall product quality.

Moreover, accurate placement directly impacts soldering processes performed by soldering machines attached to these systems. If components are misaligned during soldering, it can result in cold joints or bridging between leads—issues that compromise device integrity. Therefore, investing in advanced machine SMT solutions ensures that each step from placement to soldering is executed flawlessly.

Innovations in Machine SMT Design

The landscape of machine SMT design is constantly evolving with innovations aimed at improving efficiency and accuracy further. Recent advancements include real-time monitoring systems within chip mounter machines that utilize AI algorithms for predictive maintenance and performance optimization. These features help manufacturers stay ahead by reducing downtime caused by equipment failures.

Additionally, modern pick and place machines now incorporate vision systems that enhance component recognition capabilities while ensuring precise alignment during assembly processes. Such innovations not only boost productivity but also guarantee consistent quality across large production runs—an essential factor for competitive businesses today. As companies like Bensun Technology continue pushing boundaries in machine design, the future looks bright for high-accuracy PCB assembly.

Choosing the Right Machine for Your Needs

When it comes to selecting the right chip mounter machine, several factors come into play that can significantly affect your PCB assembly process. Understanding these factors will help you make an informed decision that meets your production requirements while ensuring high-quality output. From the size of components to production volume, each consideration plays a crucial role in determining the best fit for your needs.

Factors to Consider for Selection

One of the primary factors to consider when choosing a chip mounter machine is the type and size of components you'll be working with. Different machine parts are designed to handle specific component types, which means compatibility is key to successful assembly. Additionally, consider the speed and efficiency of the soldering machine and pick and place machine; faster machines can significantly reduce production time but may come at a higher cost.

Another important factor is the level of automation you require in your production line. Machines with advanced features like automatic setup and real-time monitoring can enhance productivity but may also necessitate more training for your staff. Lastly, think about maintenance and support services; investing in a reliable smt machine from a reputable provider ensures you have access to necessary repairs and upgrades over time.

Importance of Flexibility in Production

Flexibility is paramount in today’s fast-paced manufacturing environment where demand can fluctuate rapidly. A chip mounter machine that offers adaptable configurations allows you to switch between different product lines without extensive downtime or retooling costs. This capability not only enhances your responsiveness but also maximizes utilization across various projects.

Moreover, having a versatile pick place machine enables you to accommodate different sizes and types of components seamlessly, which is essential if you're catering to diverse client needs or evolving market trends. A flexible manufacturing setup helps ensure that you're not just reacting to current demands but also positioning yourself strategically for future opportunities in PCB assembly.

Bensun Technology Solutions for Chip Mounters

Bensun Technology stands out as a leading provider of innovative solutions tailored specifically for chip mounter machines. Their range includes advanced smt machines equipped with state-of-the-art features designed for high accuracy and efficiency in PCB assembly processes. With options that cater to various production scales, Bensun's technology ensures you're well-equipped regardless of whether you're running small batches or high-volume productions.

Additionally, their commitment to customer support means you'll receive guidance throughout the selection process and beyond—helping you integrate new equipment into your existing workflow smoothly. Investing in Bensun’s pick place machines not only enhances operational flexibility but also positions your business at the forefront of modern manufacturing practices.

The Future of PCB Assembly Machinery

The landscape of PCB assembly machinery is rapidly evolving, driven by advancements in technology and changing market demands. In particular, the chip mounter machine is becoming increasingly sophisticated, integrating automation and robotics to enhance efficiency. As manufacturers strive for higher productivity and lower costs, the future will likely see a surge in the use of these high-tech machines.

Trends in Automation and Robotics

Automation is no longer just a buzzword; it’s a reality reshaping the manufacturing industry. The integration of robotics into machine parts allows for faster and more precise operation, making chip mounter machines an essential asset in any assembly line. With pick place machines becoming more prevalent, manufacturers can enjoy reduced labor costs while maintaining high-quality standards.

Moreover, automation minimizes human error during the assembly process, particularly when it comes to placing components accurately on PCBs. This trend not only enhances efficiency but also opens doors for smaller companies to compete with larger players by adopting affordable automated solutions. As we move forward, expect to see an increase in fully automated systems that incorporate advanced AI algorithms to streamline operations even further.

Smart Manufacturing with Machine Pick and Place

Smart manufacturing is revolutionizing how we approach production processes, especially with machine pick and place technology at the forefront. These systems utilize real-time data analytics to optimize operations within PCB assembly lines effectively. By monitoring each step—from component placement to soldering—smart machines can make instantaneous adjustments that improve overall performance.

The evolution of machine SMT (Surface Mount Technology) has also paved the way for enhanced flexibility in production runs. Manufacturers can easily switch between different products without significant downtime or reconfiguration thanks to intelligent software embedded within these machines. This adaptability not only maximizes output but also caters to custom orders that are increasingly demanded by consumers today.

The Shift Towards Eco-Friendly Machines

Sustainability is no longer just a trend; it's becoming a crucial factor in machinery design and operation across industries—including PCB assembly machinery. Many manufacturers are now focusing on creating eco-friendly chip mounter machines that reduce waste and energy consumption without sacrificing performance or quality. Innovations such as energy-efficient soldering machines contribute significantly to this green initiative.

Additionally, eco-friendly practices extend beyond just machine parts; they encompass entire production processes from start to finish. Companies are adopting practices like recycling materials used during PCB assembly while ensuring their pick place machines operate at optimal efficiency with minimal environmental impact. As we look ahead, expect this shift towards sustainability to be a driving force behind new developments in SMT technology.

Conclusion

In the ever-evolving landscape of PCB assembly, the role of advanced machines, particularly chip mounter machines, cannot be overstated. These sophisticated devices streamline production processes, enhance precision, and significantly boost overall efficiency. By integrating high-quality machine parts like soldering machines and pick and place machines, manufacturers can achieve remarkable throughput while maintaining stringent quality standards.

Enhancing Efficiency with Advanced Machines

The introduction of modern chip mounter machines has revolutionized the way electronic components are assembled onto PCBs. These machines utilize cutting-edge technology to ensure that every component is placed accurately and quickly, reducing waste and optimizing production time. With features such as automatic adjustments and real-time monitoring, machine pick and place systems are designed to enhance operational efficiency while minimizing human error.

Importance of Quality Control in PCB Assembly

Quality control is paramount in PCB assembly; even a minor misalignment can lead to significant failures in electronic devices. The integration of advanced SMT machine technology ensures that every component is placed with high precision, which directly impacts the reliability of the final product. By utilizing a combination of soldering machines and pick place machines within their processes, manufacturers can maintain rigorous quality standards throughout production.

Partnering with Bensun Technology for Success

Choosing the right partner for your chip mounter machine needs is essential for staying competitive in today's market. Bensun Technology offers innovative solutions that cater to various production requirements while ensuring flexibility and scalability in operations. Their expertise in machine SMT design not only guarantees top-notch performance but also positions your business for long-term success in PCB assembly.