Introduction

A solder reflow station is an essential tool for anyone serious about surface mount technology (SMT) assembly. Understanding what these stations offer can significantly impact the quality of your work and the longevity of your projects.

Understanding Solder Reflow Stations

A solder reflow station is designed to heat solder paste on printed circuit boards (PCBs) so that it melts and bonds components effectively. These stations use a combination of temperature control and airflow to ensure even heating, which is crucial for creating reliable connections in electronic devices. With tools like Weller soldering tools, users can achieve precise results that enhance overall performance.

Key Features to Look For

When selecting a solder reflow station, several key features should be considered to ensure optimal performance. Temperature control and range are vital; you want a station that allows you to set and maintain specific temperatures for different types of soldering jobs. Additionally, user-friendly interfaces make operating the weller station soldering much more manageable, allowing both beginners and experienced technicians to work efficiently.

Benefits of High-Quality Stations

Investing in a high-quality solder reflow station pays off in multiple ways—reliability being at the forefront. Quality stations minimize defects during the soldering process, leading to fewer repairs down the line and increased productivity overall. Moreover, using reputable brands like Weller ensures that you're equipped with durable tools soldering professionals trust for their intricate tasks.

What is a Solder Reflow Station?

A solder reflow station is an essential tool in the world of electronics, particularly for surface mount technology (SMT) applications. This station utilizes controlled heat to melt solder paste, allowing components to bond securely to circuit boards. By providing precise temperature management and airflow, a solder reflow station ensures that every joint is reliable and durable.

Definition and Functionality

At its core, a solder reflow station functions by heating up solder paste to its melting point, enabling the attachment of electronic components onto PCBs (printed circuit boards). The process typically involves multiple temperature zones: preheating, soaking, reflowing, and cooling. This meticulous approach helps prevent thermal shock to sensitive components while achieving optimal solder joint quality.

Common Applications for SMT

Solder reflow stations are widely used in various industries where SMT is prevalent, including consumer electronics, automotive systems, and medical devices. They are indispensable for assembling complex circuit boards that require precision and reliability. Whether you’re working on a small batch of prototypes or large-scale production runs, having the right tools for soldering can significantly enhance efficiency and quality.

Why Choose Weller Soldering Tools

When it comes to selecting a reliable soldering solution, Weller soldering tools stand out in the market for their performance and durability. Known for their innovative designs and user-friendly features, Weller stations offer exceptional temperature control necessary for high-quality results in your projects. With an extensive range of accessories tailored specifically for their equipment, using a Weller station soldering setup ensures you're equipped with top-notch tools that meet both professional standards and personal preferences.

Essential Features of a Solder Reflow Station

When it comes to selecting a solder reflow station, understanding its essential features can make all the difference in your soldering experience. High-quality stations are designed with specific functionalities that enhance performance and ensure reliability. Let's delve into the crucial aspects you should consider to make an informed choice.

Temperature Control and Range

One of the most vital features of any solder reflow station is its temperature control and range. A precise temperature setting allows for accurate melting of solder, which is essential for achieving strong, reliable connections in surface mount technology (SMT). With Weller soldering tools, you can expect advanced temperature regulation that accommodates various types of soldering tasks, ensuring optimal performance every time.

Moreover, having a broad temperature range means you can work with different materials without worrying about damaging components or creating weak joints. This flexibility makes Weller's station soldering tools particularly appealing to both hobbyists and professionals alike. In summary, effective temperature control not only enhances your results but also prolongs the life of your components.

Size and Capacity Considerations

Size and capacity are also critical factors when selecting a solder reflow station that fits your workspace needs. Depending on the scale of your projects—whether small batch prototyping or larger production runs—you'll want to choose a station that can handle your specific requirements efficiently. Compact models may be ideal for limited spaces, while larger units often provide more robust capabilities for extensive operations.

Additionally, consider the number of PCBs you typically work with at one time; this will guide you in selecting a station with adequate capacity to meet those demands without compromising quality or speed. Weller soldering stations are known for their versatility in size options, allowing users to find just the right fit for their unique situations. Ultimately, choosing the right size ensures better workflow and productivity during your projects.

User-Friendly Interface and Operation

A user-friendly interface is another essential feature that sets apart high-quality solder reflow stations from mediocre ones. The ease of use directly impacts how effectively you'll be able to operate the equipment under various conditions—especially when you're racing against deadlines! Look for well-designed controls that allow quick adjustments without fumbling around or getting distracted from your task at hand.

Weller's user-friendly design philosophy shines through in their weller station soldering tools; intuitive controls simplify operation so you can focus on what really matters: achieving perfect joints every time! Additionally, clear display screens showing real-time data help keep track of temperatures and settings at all times—no more guesswork involved! Investing in tools with thoughtful designs not only enhances productivity but also makes learning easier for newcomers.

Comparing Popular Solder Reflow Stations

When diving into the world of solder reflow stations, it’s essential to know what’s hot and what’s not. With a plethora of options available, understanding the top models can help you make an informed decision. Let’s explore some standout contenders in the market that deserve your attention.

Top Models on the Market

Among the elite solder reflow stations, you’ll find brands like Weller, Hakko, and JBC leading the charge. The Weller WHA900 is particularly renowned for its exceptional temperature control and reliability, making it a favorite among professionals. Meanwhile, Hakko's FR-301 boasts quick heat-up times and user-friendly features that cater to both novices and seasoned users alike.

JBC's Advanced Rework Station is another noteworthy mention; it combines precision with a wide range of compatible tools soldering enthusiasts crave. Each of these soldering stations has unique strengths that cater to different needs within the SMT (Surface Mount Technology) community. So whether you're a hobbyist or running a production line, there’s likely a model tailored just for you.

Pros and Cons of Each Brand

Weller soldering tools are celebrated for their durability and performance; however, they can come with a higher price tag than some competitors. The Weller station soldering lineup offers excellent support for various applications but may require additional investment in accessories to maximize its potential. On the flip side, Hakko provides great value with affordable options but might lack some advanced features found in pricier models.

JBC stands out with its innovative technology and ergonomic design but can be intimidating due to its complexity for beginners in tools soldering. Each brand has its quirks; therefore, weighing these pros and cons will help you choose wisely based on your specific requirements while ensuring you get good value from your investment.

Specific Use Cases for Each Station

For those engaged in high-volume production runs or intricate PCB work, the Weller WHA900 excels due to its precise temperature settings—perfect for avoiding thermal damage during assembly processes. If you're frequently working on delicate components or need rapid rework capabilities, Hakko's FR-301 is ideal; it heats up quickly while offering excellent control over airflow and heat distribution.

On the other hand, JBC's Advanced Rework Station shines when dealing with complex assemblies requiring meticulous attention to detail—its advanced features allow for fine-tuning that ensures optimal results every time you use it. Understanding these specific use cases will empower you to select the right solder reflow station that aligns perfectly with your projects’ demands.

Tools Soldering: Beyond the Station

When it comes to tools soldering, a solder reflow station is just the beginning of a successful setup. To achieve optimal results, you’ll need to invest in several accessories that enhance your soldering experience. These necessary accessories not only aid in precision but also ensure safety and efficiency during your projects.

Necessary Accessories for Success

A well-equipped workstation goes beyond just having a reliable solder reflow station; it requires essential tools soldering accessories too. Items like anti-static mats, tweezers, and flux pens can significantly improve your workflow and protect sensitive components from damage. Additionally, consider investing in quality solder wire and desoldering pumps to manage any mishaps effectively.

Another critical accessory is a good quality fume extractor to keep the air clean while you work—after all, nobody wants to inhale those fumes! A proper magnifying glass or microscope can also make a world of difference when dealing with tiny SMT components. With these accessories at your disposal, you'll be well on your way to mastering the art of station soldering.

Importance of Quality Soldering Tools

Investing in high-quality soldering tools is paramount for anyone serious about their craft. Cheap tools may seem tempting due to their low cost but can lead to poor results and frustration down the line—nobody wants that! Quality tools not only provide better performance but also last longer, making them more economical over time.

Weller soldering tools are renowned for their reliability and precision, making them a favorite among professionals and hobbyists alike. Using top-notch equipment ensures that every joint you make is solid and dependable—essential for any electronics project involving a solder reflow station. Remember, good tools lead to great results; don’t skimp on what matters!

Best Practices with Weller Soldering Station

To get the most out of your Weller soldering station, adhering to best practices is key. Start by ensuring that your work area is tidy and organized; clutter can lead to mistakes or accidents during delicate tasks like SMT assembly or repairs using a solder reflow station. Always preheat components when necessary; this helps avoid thermal shock which could damage sensitive parts.

Maintaining your Weller station involves regular cleaning of tips and nozzles—this keeps everything working efficiently without unwanted residue build-up affecting performance. Additionally, familiarize yourself with temperature settings; different materials require specific temperatures for optimal adhesion without damaging components or boards during the process of station soldering.

By following these best practices with Weller’s robust lineup of products, you’ll not only enhance your skills but also ensure longevity for both your equipment and projects.

Maintenance Tips for Longevity

Keeping your solder reflow station in tip-top shape is not just a good idea; it’s essential for the longevity and performance of your tools soldering. A well-maintained station means fewer headaches during projects and better results overall. Let’s dive into some best practices to ensure your Weller soldering tools serve you well for years to come.

Regular Cleaning and Care

Cleaning your solder reflow station should be part of your routine, much like brushing your teeth—necessary and beneficial! Dust, flux residue, and other debris can accumulate over time, affecting both performance and safety. Use appropriate cleaning solutions that are safe for electronics, along with soft cloths or brushes to keep the surfaces pristine.

Don’t forget to check the nozzles and heating elements regularly; they can become clogged or dirty, which may impact heat distribution. For Weller soldering stations specifically, refer to the manufacturer’s guidelines on cleaning products that are compatible with their materials. Keeping everything clean will not only prolong the life of your station but also enhance its efficiency during use.

Troubleshooting Common Issues

Even the best tools soldering can run into hiccups from time to time; knowing how to troubleshoot common issues can save you valuable time and frustration. If you notice inconsistent heating or temperature fluctuations in your solder reflow station, check if there are any loose connections or if the calibration needs adjustment. Sometimes a simple reset or recalibration can resolve these pesky problems.

Another common issue is inadequate airflow or suction in hot air stations; ensure that filters are clean and unobstructed for optimal performance. If you encounter persistent problems despite troubleshooting efforts, consult Weller's customer support or user manuals for guidance tailored specifically to their range of products. Remember, identifying issues early on can prevent more significant repairs down the line!

When to Upgrade Your Station

If you're frequently finding that your current setup can't handle larger jobs or lacks features necessary for evolving technology demands, it might be time to consider an upgrade. High-quality models often come equipped with advanced features like programmable profiles that make them worth the investment.

Another indicator is when maintenance becomes more frequent than usual; if you're constantly fixing issues rather than working on projects, a new Weller soldering station could save you both effort and money in the long run. Additionally, if you've expanded into new applications requiring different temperature ranges or capabilities that your current model can't provide, upgrading ensures you're equipped for success!

Conclusion

In the fast-paced world of electronics manufacturing, choosing the right solder reflow station can make all the difference between a successful project and a frustrating failure. With so many options available, it's crucial to identify what features align best with your specific needs. Whether you’re a hobbyist or a seasoned professional, understanding your requirements will guide you toward a station that enhances your soldering experience.

Making the Right Choice for Your Needs

When selecting a solder reflow station, consider factors such as temperature control, size, and user interface. These elements are not just technical specifications; they directly affect how efficiently you can work with your tools soldering projects. By prioritizing these features, you'll ensure that your weller soldering tools deliver optimal performance tailored to your unique requirements.

Investing in Quality for Better Results

Investing in high-quality equipment ensures reliability and longevity while also improving the quality of your work. A sturdy and efficient station not only saves time but also reduces the risk of costly mistakes—so why settle for anything less?

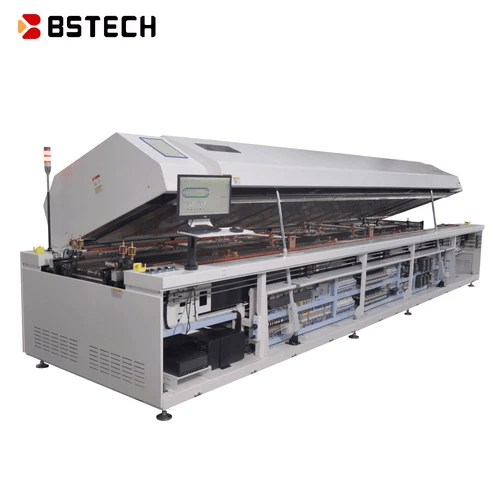

Exploring Options from Bensun Technology

Bensun Technology offers an impressive range of options for those seeking top-notch solder reflow stations that cater to various needs and budgets. Their commitment to quality ensures that every product meets rigorous standards, making them a reliable choice for both amateurs and professionals alike. Explore their offerings today to find the perfect weller station soldering solution tailored just for you!