Introduction

In the fast-paced world of electronics manufacturing, SMT chip mounter technology stands at the forefront, revolutionizing how components are assembled onto printed circuit boards (PCBs). The shift towards Surface Mounters has not only enhanced production efficiency but also reduced costs, making it an essential aspect for businesses looking to stay competitive. As the demand for precision and speed increases, understanding the intricacies of SMT mounter machines becomes crucial for anyone in the industry.

Understanding SMT Chip Mounter Technology

SMT chip mounters are sophisticated machines designed to place surface mount technology (SMT) components onto PCBs with remarkable accuracy and speed. These machines have evolved significantly, incorporating advanced robotics and vision systems that enhance their functionality and reliability. By utilizing SMT feeders effectively, manufacturers can streamline their production processes, ensuring that each component is placed precisely where it needs to be.

The Rise of Online Manufacturing

The rise of online manufacturing has transformed traditional supply chains into agile networks capable of meeting rapid market demands. Companies can now access a variety of services including instant quotes and real-time tracking through online platforms specializing in SMT solutions. This shift not only democratizes access to high-quality equipment like JUKI SMT machines but also allows smaller players to compete on a global scale.

Key Industry Players in SMT

Within the realm of SMT technology, several key players have emerged as leaders in innovation and manufacturing capabilities. Companies such as Amd SMT have carved out a niche by offering specialized solutions tailored to diverse production needs while maintaining high standards of quality. Meanwhile, JUKI continues to set benchmarks with its cutting-edge machinery that integrates seamlessly with modern production environments, ensuring optimal performance across various applications.

What is an SMT Chip Mounter?

In the realm of electronics manufacturing, an SMT chip mounter stands as a pivotal player in the assembly process. This sophisticated equipment is designed to place surface mount technology (SMT) components onto printed circuit boards (PCBs) with precision and speed. As technology advances, the role of SMT mounters becomes increasingly crucial for manufacturers aiming to produce high-quality electronic devices efficiently.

Overview of SMT Technology

Surface Mount Technology (SMT) revolutionized how electronic components are assembled on PCBs, allowing for smaller and more efficient designs compared to traditional through-hole methods. The key advantage of SMT lies in its ability to accommodate a wide variety of components, from tiny resistors to complex integrated circuits, all while maximizing board space. With JUKI SMT machines leading the charge in this technology, manufacturers can achieve higher production rates and improved reliability in their electronics.

Benefits of SMT Chip Mounters

One cannot overlook the myriad benefits that come with using an SMT chip mounter in production lines. For starters, these machines significantly reduce assembly time by automating the placement of components—something that manual processes simply can't compete with! Additionally, Amd SMT offers innovative solutions that enhance accuracy and minimize errors during assembly, ensuring high-quality output every time.

Moreover, incorporating surface mounters into your production process can lead to cost savings over time due to reduced labor costs and increased throughput. As manufacturers strive for efficiency and competitiveness in a fast-paced market, investing in advanced SMT technology becomes not just beneficial but essential.

Key Components of an SMT Mounter Machine

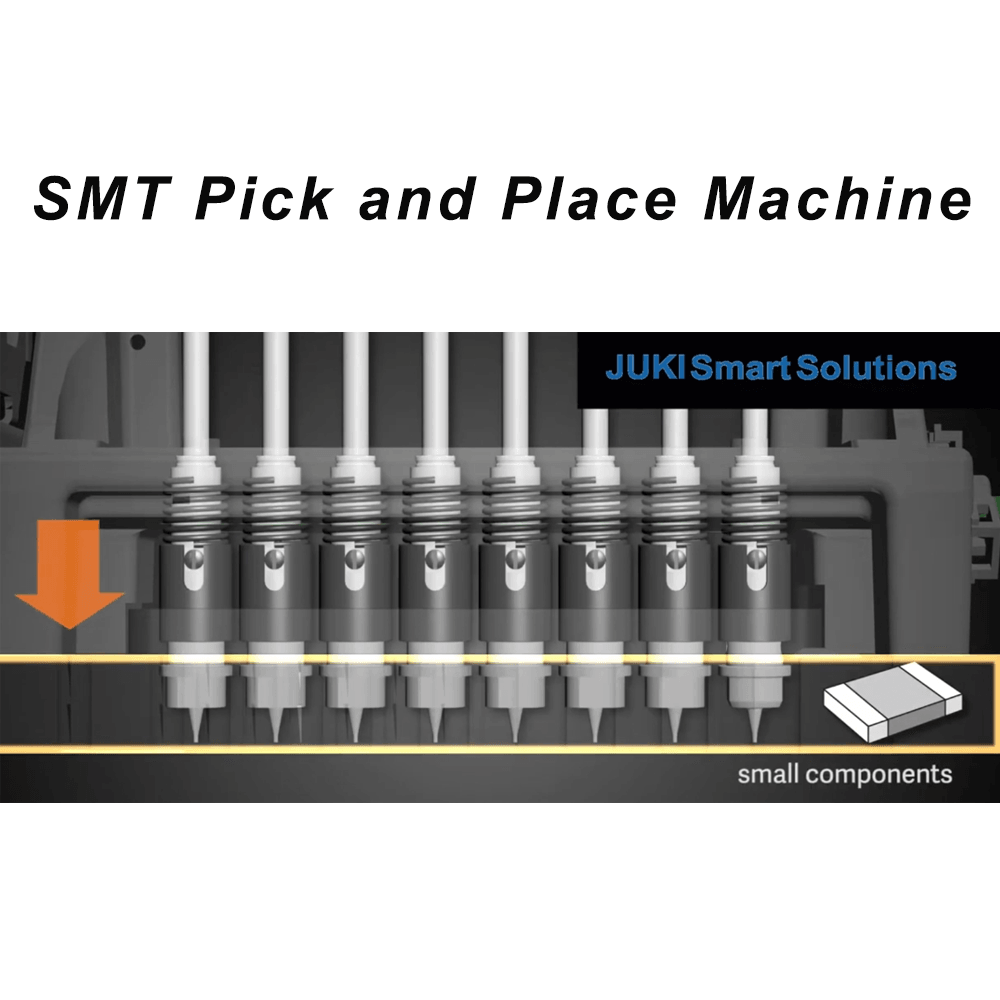

Understanding the key components of an SMT mounter machine is crucial for appreciating its functionality and effectiveness. At its core, these machines are equipped with precision placement heads that accurately position smt chips on PCBs using advanced vision systems for alignment checks. Furthermore, integrating various types of SMT feeders allows for seamless loading and handling of multiple component types without interrupting production flow.

Another vital element includes conveyor systems that facilitate smooth transport between different stages of assembly—ensuring that every PCB moves efficiently through the process without bottlenecks or delays. Collectively, these components work harmoniously within a JUKI SMT machine or any leading brand's offering to deliver outstanding performance tailored to modern manufacturing needs.

Leading SMT Mounter Machines

In the competitive landscape of electronics manufacturing, the choice of SMT mounter machines can significantly impact production efficiency and quality. Various manufacturers offer unique advantages, each with specialized features that cater to diverse production needs. By exploring leading SMT mounter machines, businesses can better understand how to optimize their operations.

JUKI SMT Machine Overview

The JUKI SMT machine is renowned for its precision and reliability in the world of surface mount technology. With advanced features such as high-speed placement and flexible configuration options, JUKI has positioned itself as a leader in the SMT chips mounter market. Their machines are designed to handle a wide range of components, making them ideal for both small-batch and high-volume production runs.

JUKI's commitment to innovation is evident in their continuous development of new technologies that enhance performance and reduce downtime. From intelligent software systems that streamline setup processes to robust hardware designed for longevity, JUKI's SMT mounters are built to withstand the rigors of modern manufacturing environments. Additionally, JUKI offers comprehensive support services to ensure customers get the most out of their investment in an SMT mounter machine.

With a reputation for quality and service excellence, JUKI remains a top choice among manufacturers looking for reliable SMT solutions. The integration of user-friendly interfaces with sophisticated automation features allows operators to maximize productivity while minimizing errors during assembly processes. This combination makes JUKI's offerings particularly attractive for companies aiming to stay ahead in an increasingly competitive market.

Competitive Edge of Amd SMT

Amd smt has carved out a niche by focusing on flexibility and customization within its line of surface mount technology solutions. Their innovative approach allows manufacturers to tailor their equipment according to specific production requirements without sacrificing speed or accuracy in placing components like resistors or capacitors on PCBs (Printed Circuit Boards). This adaptability is crucial as industries demand more varied product lines with shorter lead times.

One standout feature of Amd smt machines is their integrated software platform that optimizes workflow management across multiple stages of production. By utilizing real-time data analytics, users can monitor performance metrics and adjust processes dynamically, enhancing overall efficiency when using these advanced SMT feeders. This level of insight empowers businesses not only to meet but exceed industry standards while maintaining cost-effectiveness.

Moreover, Amd smt emphasizes customer collaboration throughout the entire lifecycle of their products—from initial consultation through installation and ongoing support—creating strong partnerships with clients seeking optimal solutions tailored specifically for them. Their dedication ensures that even as technology evolves rapidly within electronics manufacturing, customers remain equipped with cutting-edge tools designed for long-term success.

Exploring Bensun Technology’s Offerings

Bensun Technology has emerged as a formidable player in the realm of JUKI SMT chip mounters by focusing on value-driven solutions tailored for diverse manufacturing needs. Their product lineup includes several versatile models capable of handling various component sizes efficiently while maintaining high placement accuracy—essential traits desired by any manufacturer invested in surface mount technology today!

What sets Bensun apart is its commitment to integrating advanced automation features into its machines without compromising affordability—a crucial factor for many small-to-medium enterprises looking at investing in an effective smt chips mounter solution without breaking the bank! Furthermore, Bensun's emphasis on user-friendly design ensures operators can quickly adapt without extensive training sessions or steep learning curves associated with complex machinery setups often found elsewhere on the market.

Additionally, Bensun Technology continuously innovates its offerings by incorporating feedback from users directly into future designs—an approach that fosters lasting relationships between manufacturers and those who rely heavily upon efficient assembly processes powered by state-of-the-art equipment like theirs! As they expand globally while keeping sight firmly set on meeting client demands head-on through quality products backed up by stellar service teams ready at hand when needed most; it’s clear why Bensun remains relevant amidst fierce competition within this industry segment today!

The Role of SMT Feeders

In the world of surface mount technology, SMT feeders play a crucial role in the production process. These devices are responsible for supplying SMT chips to the mounter machine, ensuring that components are placed accurately and efficiently on printed circuit boards (PCBs). Without reliable SMT feeders, even the most advanced SMT mounter machines, like the JUKI SMT machine or Amd SMT, would struggle to maintain optimal production rates.

Importance of SMT Feeders in Production

SMT feeders are essential for streamlining operations in any manufacturing environment that utilizes surface mount technology. They provide a steady flow of components to the SMT chips mounter, which is vital for maintaining high throughput and minimizing downtime. By ensuring that components are consistently available for placement, these feeders help manufacturers meet tight deadlines and maintain quality control.

Moreover, efficient SMT feeders can significantly reduce labor costs by automating component handling and feeding processes. This automation not only enhances productivity but also minimizes human error during assembly—an important factor when dealing with intricate electronic designs. As a result, organizations can focus their resources on innovation rather than repetitive tasks.

Types of SMT Feeders

There are several types of SMT feeders available in the market today, each designed to cater to specific production needs. The most common types include tape feeders, tray feeders, and tube feeders—each offering unique advantages depending on the type of components being used with your SMT chips mounter. Tape feeders are particularly popular due to their ability to handle a wide range of component sizes while maintaining precise placement accuracy.

Tray and tube feeders tend to be ideal for larger or more delicate components that require careful handling during assembly. Additionally, some advanced feeder systems incorporate smart technologies that allow them to communicate with the JUKI SMT machine or other models seamlessly—optimizing inventory management and reducing setup time between different production runs. Ultimately, choosing the right type of feeder is essential for maximizing efficiency in your manufacturing process.

Innovations in SMT Feeder Technology

The landscape of feeder technology is evolving rapidly as manufacturers seek ways to enhance efficiency and reduce costs further. Recent innovations include automated vision systems integrated into feeder designs that allow real-time monitoring and adjustment during operation—ensuring accurate component delivery without manual intervention. This technological leap not only increases precision but also reduces waste associated with incorrect placements.

Additionally, advancements in materials used for feeder construction have led to lighter yet more durable designs capable of operating at higher speeds without compromising reliability. Companies like Amd SMT have been at the forefront of these developments by incorporating smart features into their products that adaptively manage inventory levels based on real-time data from connected systems such as their own surface mounters or JUKI machines.

As we move forward into an increasingly automated future within electronics manufacturing, it's clear that innovations in SMT feeder technology will continue playing a pivotal role in shaping efficient production processes across various industries.

Online Manufacturing Trends

The landscape of manufacturing has undergone a seismic shift with the rise of online SMT services, changing how companies approach production. As businesses increasingly seek efficiency and flexibility, the demand for SMT chip mounters has surged. This transition is not just about convenience; it's a strategic move to enhance competitiveness in a rapidly evolving market.

The Shift to Online SMT Services

Online SMT services have revolutionized how manufacturers source and assemble their products. With just a few clicks, companies can now access advanced SMT mounter machines like the JUKI SMT machine or Amd SMT solutions without needing extensive physical infrastructure. This shift allows businesses to scale operations quickly, leveraging cloud-based platforms that streamline the entire manufacturing process from design to delivery.

The adoption of online platforms for sourcing surface mounters has also democratized access to high-quality manufacturing capabilities. Small and medium enterprises can now compete on an equal footing with larger corporations by utilizing sophisticated technology that was once only available to industry giants. As more manufacturers embrace this digital transformation, the traditional barriers associated with production are steadily eroding.

Advantages of Online SMT Solutions

One of the most significant advantages of online SMT solutions is cost-effectiveness. By eliminating overhead costs associated with maintaining physical facilities and staffing, businesses can allocate resources more efficiently towards innovation and product development. Additionally, online platforms often provide flexible pricing models that cater to various project sizes, making it easier for companies to manage their budgets while accessing top-notch SMT feeders and equipment.

Another key benefit is speed; online manufacturing services significantly reduce lead times from design submission to final assembly. By utilizing state-of-the-art equipment like JUKI SMT machines and advanced software systems, manufacturers can achieve rapid prototyping and faster turnaround times on orders—an essential factor in today’s fast-paced market environment. Moreover, these services often include comprehensive technical support that helps clients navigate any challenges they may encounter during production.

Case Studies of Successful Online Manufacturers

Several case studies highlight how successful online manufacturers have harnessed the power of digital solutions in their operations. For instance, Company X leveraged an Amd SMT solution to streamline its electronics assembly process, dramatically reducing production time while maintaining high quality standards through automated inspections using innovative surface mounter technology. Their success story demonstrates how integrating advanced technologies into online platforms can yield substantial efficiency gains.

Another compelling example is Company Y's use of a JUKI SMT machine in conjunction with tailored online services that allowed them to adapt quickly to changing market demands without sacrificing quality or increasing costs significantly. This agility enabled them not only to meet customer expectations but also exceed them by delivering products ahead of schedule—a feat made possible through effective collaboration between their teams and an experienced online manufacturer specializing in SMT feeders.

These case studies illustrate that embracing online manufacturing trends is not merely a passing fad; it’s becoming essential for staying competitive in today’s dynamic business landscape.

Choosing the Right SMT Solution

In the rapidly evolving world of electronics manufacturing, selecting the right SMT solution can be a game-changer for your production line. With various options available, from traditional SMT mounters to advanced online services, it’s essential to consider several factors that can significantly influence your operations. This section will guide you through the critical components of choosing an SMT chips mounter that aligns with your specific needs.

Factors to Consider for Your Production

When deciding on an SMT mounter machine, there are multiple factors to keep in mind. First and foremost is the production volume; high-volume manufacturers may benefit more from robust machines like JUKI SMT machines that offer speed and efficiency. Additionally, consider the types of components you’ll be working with—different surface mounters have varying capabilities when it comes to handling diverse SMT feeders and chip sizes.

Another crucial factor is flexibility; a good SMT chips mounter should easily adapt to changes in product design or production runs without requiring extensive reconfiguration. Look for machines that provide quick changeovers and are compatible with various feeder systems, such as those offered by Amd SMT or Bensun Technology. Finally, assess your budget—not just for purchase but also for maintenance and potential upgrades down the line.

Comparing Different SMT Options

With numerous options available in the market, comparing different SMT solutions can feel overwhelming at first glance. Start by evaluating leading models like JUKI's offerings against competitors like Amd SMT; both brands are known for their reliability but cater to slightly different needs within the industry. Consider aspects such as speed, precision, ease of use, and software support when weighing these options.

Next up is looking at feeder compatibility—an essential element that often gets overlooked! The best surface mounters will seamlessly integrate with a variety of feeders to ensure efficient component placement during production runs. Don't forget about scalability either; as your business grows, so should your equipment's capabilities.

The Importance of Technical Support

While choosing an advanced machine is crucial, having reliable technical support can make all the difference when things go awry during production cycles. When investing in an SMT chips mounter from brands like JUKI or Amd SMT, ensure they come with excellent customer service and support options tailored specifically for their machines. After all, even top-of-the-line equipment may face hiccups now and then!

Having access to knowledgeable technicians who understand not just how to operate but also how to troubleshoot issues related to specific models adds tremendous value over time—saving you both money and downtime! Moreover, look into online resources or forums where other users share their experiences; this community knowledge can be invaluable when navigating challenges associated with surface mount technology.

Conclusion

The world of SMT technology is rapidly evolving, and as we look to the future, it's clear that innovations in SMT chip mounters will play a pivotal role in the industry. From smarter algorithms for placement accuracy to enhanced connectivity features that allow for real-time monitoring, the next generation of SMT mounter machines promises to push production efficiency to new heights. Companies like JUKI and Amd SMT are already exploring these advancements, setting the stage for a transformative era in electronics manufacturing.

Future Innovations in SMT Technology

Future innovations in SMT technology will likely focus on increasing automation and precision within the manufacturing process. For instance, developments in AI-driven systems could enable SMT feeders to adapt dynamically based on production demands, enhancing throughput without sacrificing quality. Furthermore, improvements in machine learning algorithms may allow surface mounters to predict maintenance needs before breakdowns occur, ensuring uninterrupted operations.

The Impact of Online Manufacturing on Industry

The rise of online manufacturing has revolutionized how businesses approach their production needs, particularly concerning SMT chips mounters and related technologies. By leveraging online platforms, manufacturers can easily access a variety of services and solutions tailored specifically for their projects without geographical constraints. This shift not only streamlines procurement but also fosters collaboration among industry players like JUKI and Amd SMT, ultimately driving innovation forward.

Harnessing the Power of SMT for Efficiency

Harnessing the power of advanced SMT technologies is essential for businesses looking to maximize efficiency within their operations. By investing in high-quality SMT mounter machines equipped with cutting-edge features such as smart feeders and real-time analytics, companies can significantly reduce waste while improving output quality. As manufacturers continue to embrace these technologies and adapt to online solutions, they position themselves at the forefront of an increasingly competitive landscape.