Introduction

In today's tech-driven world, printed circuit board manufacturers play a pivotal role in the electronics industry. From smartphones to medical devices, the importance of finding the right PCB manufacturer cannot be overstated. Whether you're asking yourself, Which company makes PCBs? or pondering Who is the largest PCB manufacturer in the US?, it's essential to navigate this landscape with clarity and purpose.

Understanding the Importance of PCB Manufacturers

The choice of a PCB manufacturer can significantly impact product performance and reliability. With so many options available globally, including those who specialize in fast turn printed circuit boards, understanding their capabilities is crucial. Additionally, considering whether PCBs are manufactured in the US or overseas can affect lead times and quality assurance.

Key Factors for Selecting a Manufacturer

When selecting a PCB manufacturer, several key factors come into play—quality of materials used, manufacturing capabilities, and customer support are just a few examples. It's vital to compare quotes from various manufacturers to ensure you get not only competitive pricing but also superior service. This process helps answer questions like Where are most PCBs manufactured? while ensuring you choose a partner that aligns with your project needs.

Navigating the PCB Manufacturing Landscape

Navigating through different printed circuit board manufacturers requires diligence and foresight. Understanding each manufacturer's strengths can help you identify who best meets your requirements for both production timeframes and customization options. As you explore potential partnerships with PCB assembly manufacturers, keep an eye on their reputation within the industry to make an informed decision.

Quality of Materials

Assess the Raw Materials Used

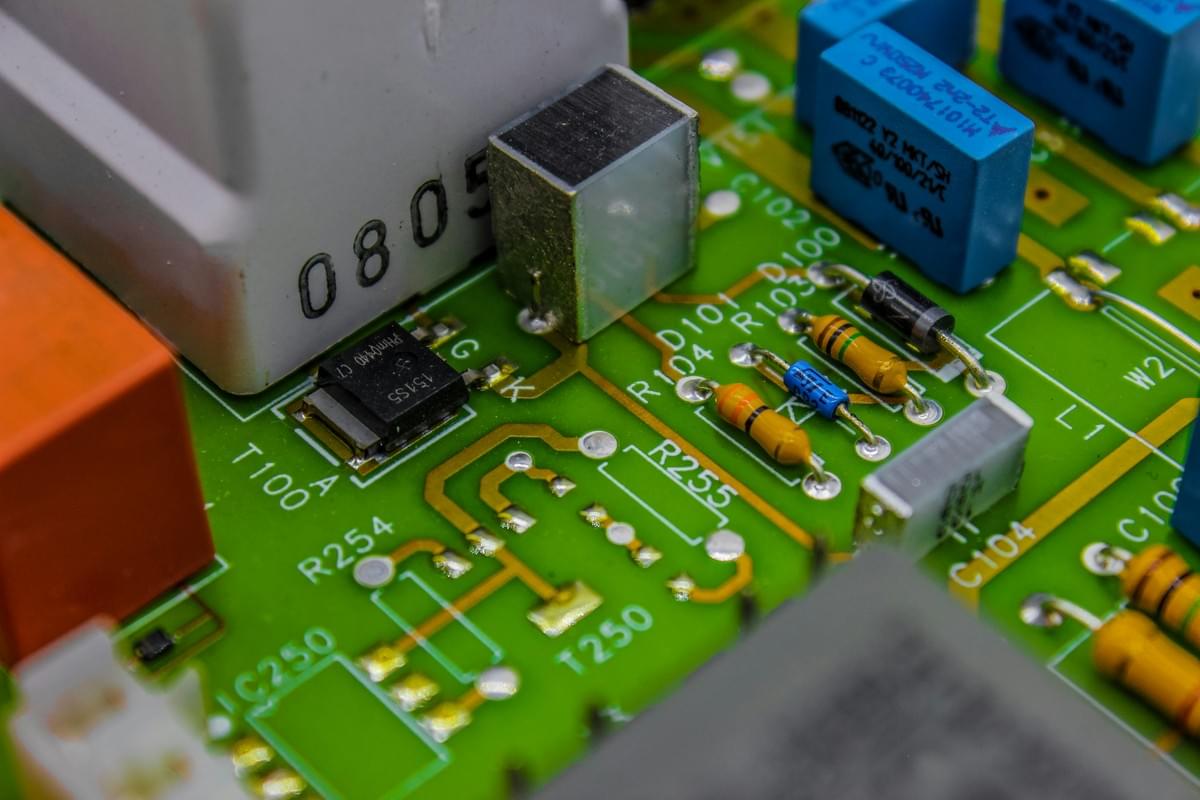

The first step in evaluating any PCB manufacturer is to assess the raw materials they use. High-quality copper, laminates, and substrates are essential for ensuring durability and performance in electronic applications. Many fast turn printed circuit board manufacturers take pride in sourcing top-notch materials, which can significantly impact your project's success.

Moreover, it's crucial to inquire about specific material grades and their suitability for your application. For instance, some projects may require high-frequency laminates or specialized coatings for environmental protection. By understanding what goes into your PCBs, you can make a more informed choice when selecting a PCB assembly manufacturer.

Importance of Certifications

Certifications are another critical factor when assessing the quality of materials used by PCB manufacturers. Industry standards like IPC-A-600 and ISO 9001 signify that a company adheres to stringent guidelines for quality control and manufacturing processes. Being aware of these certifications not only gives you confidence in their products but also answers questions like Are PCBs manufactured in the US? with assurance about compliance.

Furthermore, certifications can influence a manufacturer's reputation within the industry; many clients prefer working with certified companies due to their commitment to excellence. When comparing different printed circuit board manufacturers, checking for these credentials can help narrow down your options significantly. Ultimately, choosing a certified manufacturer ensures that you're investing in reliable products that meet industry standards.

Supplier Relationships and Impact

The relationships that PCB manufacturers have with their suppliers can significantly impact material quality and availability. Strong partnerships often lead to better pricing on raw materials and quicker access to new technologies—both essential factors when considering who is the largest PCB manufacturer in the US or any other region. If a manufacturer has established long-term relationships with reputable suppliers, it typically translates into higher-quality components for your PCBs.

Additionally, effective supplier management allows for flexibility during production runs; if issues arise with one material type or supply chain disruptions occur, having multiple reliable sources can mitigate delays in production timelines. Therefore, when evaluating potential partners among various printed circuit board manufacturers, consider not just their capabilities but also how well-connected they are within their supply chain networks.

Manufacturing Capabilities

Range of Services Offered

The range of services offered by PCB manufacturers can vary widely, from basic prototyping to full-scale production runs. Many companies specialize in PCB assembly manufacturing, providing a one-stop shop for both fabrication and assembly. Additionally, some fast turn printed circuit board manufacturers focus on quick turnaround times without sacrificing quality, making them ideal for urgent projects.

It's essential to consider whether a manufacturer provides additional services like design support or testing capabilities. These value-added services can streamline your project and reduce time-to-market significantly. When evaluating potential partners, ask about their complete service offerings to ensure they meet your project requirements.

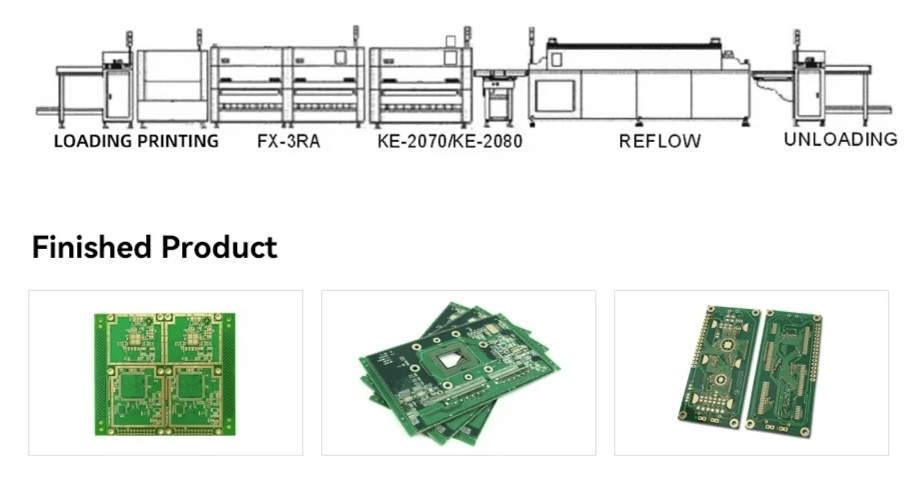

Technology and Equipment Used

The technology and equipment used by PCB manufacturers are key indicators of their production capabilities and quality standards. Advanced machinery allows for precise fabrication processes that yield high-quality PCBs with minimal defects. For instance, automated pick-and-place machines are often employed by leading PCB assembly manufacturers to enhance efficiency and accuracy during component placement.

Moreover, the use of cutting-edge technology such as laser drilling or high-frequency testing can set top-tier printed circuit board manufacturers apart from their competitors. Understanding what equipment is utilized gives you insight into the manufacturer's ability to handle complex designs or high-density interconnects (HDI). Therefore, it's wise to inquire about the specific technologies in use when considering which company makes PCBs that will meet your project's demands.

Customization Options Available

Customization is often a critical factor when selecting a PCB manufacturer because many projects require unique specifications tailored to individual needs. The best printed circuit board manufacturers offer various customization options ranging from size and shape variations to different layer counts and materials used in construction. This flexibility ensures that whether you're looking for standard designs or highly specialized configurations, there's a suitable solution available.

Additionally, some companies provide custom design services where skilled engineers collaborate with clients to create tailored solutions from scratch—ideal if you're venturing into uncharted territory with your product development. It's also important to check if they accommodate small batch sizes or prototypes since those requirements often arise in R&D phases of projects. Ultimately, understanding these customization options will help you choose a PCB manufacturer capable of bringing your vision to life.

Production Timeframes

Evaluating Lead Times

Lead times can vary widely among different PCB manufacturers, and it’s essential to evaluate these before making a commitment. Some companies specialize in rapid prototyping and offer expedited services for those urgent projects, while others may have longer production cycles due to the complexity of their processes or the materials used. When asking Which company makes PCBs? ensure that they provide clear information about their lead times so you can align them with your project requirements.

Importance of Timely Deliveries

Timely deliveries are not just a luxury; they are often critical for keeping your project on schedule. Delays from PCB assembly manufacturers can cascade through your entire workflow, leading to missed deadlines and budget overruns. If you're wondering who is the largest PCB manufacturer in the US, remember that even top-tier companies must uphold their delivery promises to maintain client satisfaction and trust.

Impact on Your Project Schedule

The impact of production timeframes on your project schedule cannot be overstated. If you’re working within tight deadlines, partnering with fast turn printed circuit board manufacturers becomes paramount; any delay could jeopardize product launches or client commitments. On the flip side, if you have more flexibility in your timeline, you might find value in exploring various options for quality and pricing among different PCB manufacturers.

Pricing and Cost Structures

Understanding Pricing Models

Printed circuit board manufacturers often utilize diverse pricing models that can include per-unit costs, bulk discounts, or flat-rate fees for specific services. It's essential to understand whether you're paying for just the PCB fabrication or if assembly and other services are included in the quoted price. Additionally, some manufacturers may offer tiered pricing based on volume, so knowing your project’s scale can help you negotiate better deals.

Comparing Quotes from Manufacturers

When evaluating who is the largest PCB manufacturer in the US or searching for fast turn printed circuit board manufacturers, it’s vital to compare quotes carefully. Don’t just look at the bottom line; delve into what each quote includes—like materials used and lead times—to ensure you're making an apples-to-apples comparison. This process will also help identify which manufacturers provide better value for money while meeting your specific needs.

Hidden Costs to Watch Out For

While comparing prices from PCB assembly manufacturers, be vigilant about hidden costs that could sneak up on you later in the project timeline. These costs can include setup fees, tooling charges, or additional fees for expedited shipping—especially important when working with fast turn printed circuit board manufacturers who promise quick turnaround times but might charge extra for it. Always ask potential PCB manufacturers about any possible hidden fees upfront to avoid budget overruns.

Customer Support and Communication

When it comes to printed circuit board manufacturers, effective communication can make or break your project. A responsive manufacturer ensures that you’re always in the loop, whether it’s about design changes or production updates. This level of communication not only fosters trust but also minimizes the chances of costly mistakes down the line.

Importance of Responsive Communication

In the fast-paced world of PCB manufacturing, having a manufacturer who prioritizes responsive communication is crucial. You might wonder, Which company makes PCBs? The answer lies not just in their capabilities but also in how quickly they address your inquiries and concerns. If you’re dealing with a manufacturer that takes days to respond, you may find yourself lagging behind competitors who rely on fast turn printed circuit board manufacturers.

Support During Production Process

Once you've selected a PCB manufacturer, ongoing support during the production process becomes vital. A good PCB assembly manufacturer will provide regular updates on your order status and be available to discuss any issues that arise. This hands-on approach can significantly impact your project timeline and quality; after all, timely interventions can prevent minor hiccups from escalating into major setbacks.

Post-Manufacturing Support

After your PCBs have been delivered, the relationship with your manufacturer shouldn't just end there; post-manufacturing support is equally important. Whether it's troubleshooting issues or managing returns, a reliable PCB manufacturer will stand by their product long after it leaves their facility. Inquiring about post-manufacturing services can help you gauge which company offers comprehensive support and whether they are truly one of the largest PCB manufacturers in the US.

Conclusion

In the ever-evolving world of technology, making an informed decision on PCB manufacturers is crucial for your project's success. The right choice can significantly impact not just the quality of your product but also the efficiency of your production process. By considering factors such as material quality, manufacturing capabilities, and customer support, you can navigate the competitive landscape of printed circuit board manufacturers with confidence.

Making an Informed Decision on PCB Manufacturers

When selecting a PCB manufacturer, it’s essential to do your homework. Start by asking questions like Which company makes PCBs? and “Who is the largest PCB manufacturer in the US?” This research will help you identify reliable partners who meet your specific needs and ensure that you're not just picking any random name from a list of fast turn printed circuit board manufacturers.

Quality should always be at the forefront of your decision-making process. Are PCBs manufactured in the US? If so, are those local manufacturers able to provide you with high-quality materials and certifications? Understanding these aspects will help you make a well-rounded choice that aligns with both your budget and project requirements.

Evaluating Long-Term Partnership Potential

Choosing a PCB manufacturer isn't just about immediate needs; it’s about building a relationship for future projects as well. A reliable PCB assembly manufacturer can become an invaluable partner as your business grows and evolves over time. Look for companies that demonstrate flexibility in their services; this will allow them to adapt to any changes in technology or design that may arise down the line.

Long-term partnerships also foster better communication and collaboration, which are vital components for successful project execution. When considering options among printed circuit board manufacturers, evaluate how they handle customer support during production processes and whether they offer post-manufacturing assistance. This ongoing relationship can save time and money while ensuring consistent quality across all projects.

Looking Ahead: Future Needs in PCB Manufacturing

As technology advances rapidly, so do the demands placed on PCB manufacturing processes. It’s important to consider where most PCBs are manufactured today—many companies are looking for innovative solutions that keep pace with industry trends while maintaining quality standards. Assessing potential manufacturers' ability to meet future needs is essential for staying competitive in this fast-paced market.

Keep an eye out for emerging technologies within the realm of printed circuit board manufacturing that could enhance performance or reduce costs over time. Engaging with forward-thinking companies will equip you with new opportunities as they arise, allowing you to remain agile in a constantly changing landscape. The right partnership today can set you up for success tomorrow—so choose wisely!