Introduction

In today's fast-paced technological landscape, the demand for efficient and reliable PCB assembly has surged. This increase is largely attributed to the rise of on-demand manufacturing, which allows companies to respond quickly to market needs while minimizing waste. As a leading PCB assembly manufacturer, Bensun Technology stands at the forefront of this evolution, providing innovative solutions that cater to diverse client requirements.

Understanding PCB Assembly On-Demand

PCB assembly on-demand refers to the process of producing printed circuit boards (PCBs) in response to immediate market demands rather than relying on pre-manufactured stocks. This approach not only enhances customization options but also allows for rapid adjustments based on consumer feedback. For businesses looking for flexibility, partnering with a skilled PCB manufacturer in China can ensure that they receive high-quality products tailored specifically to their needs.

The Rise of Flexible Manufacturing

The flexibility offered by modern manufacturing techniques has transformed the way businesses operate, particularly in industries reliant on electronic components. With traditional manufacturing often leading to excess inventory and wasted resources, flexible manufacturing presents an attractive alternative by aligning production closely with actual demand. Consequently, many companies are turning towards reputable PCB manufacturers who specialize in responsive and adaptable production methods.

Bensun Technology's Role in PCB Solutions

Bensun Technology is not just another name among PCB manufacturers; it represents innovation and commitment in the realm of PCB assembly solutions. With a focus on quality assurance and customer satisfaction, Bensun has established itself as a trusted partner for businesses seeking efficient PCBA factory services. By leveraging cutting-edge technology and industry expertise, Bensun continues to lead the charge toward more sustainable and effective PCB assembly practices.

What is PCB Assembly?

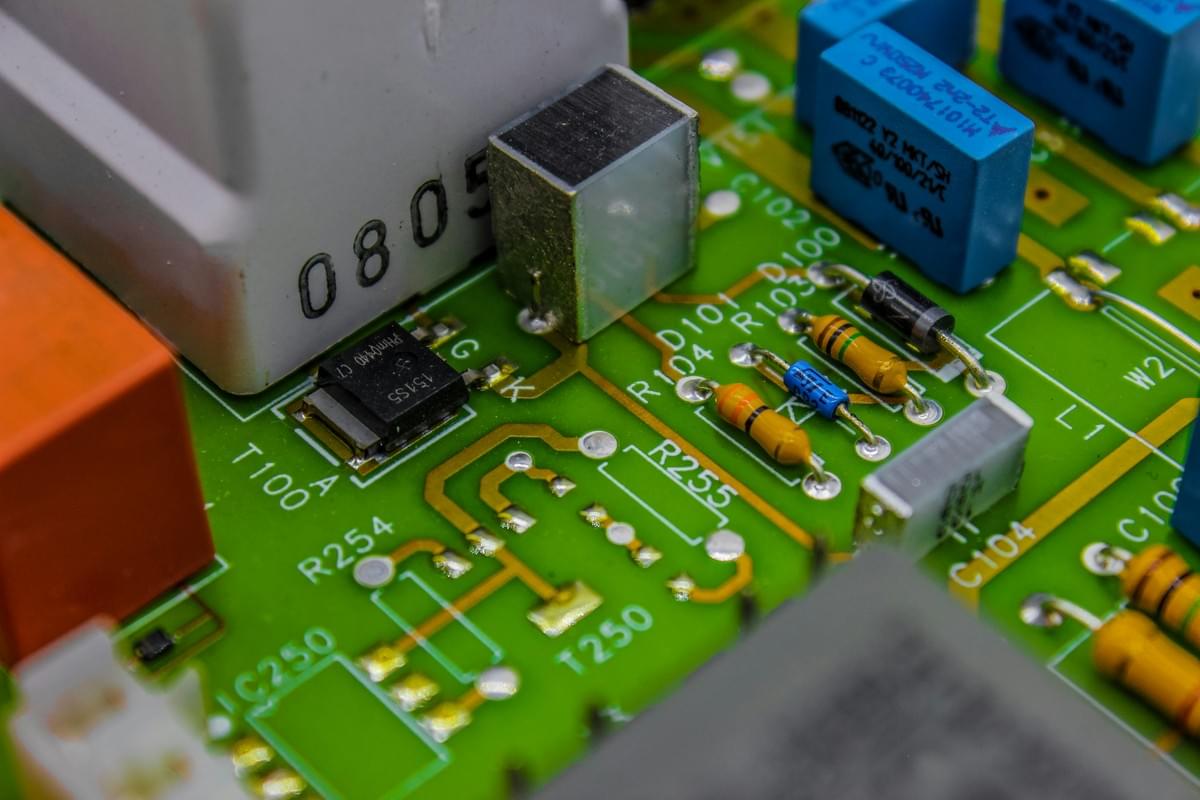

PCB assembly is the process of connecting electronic components to a printed circuit board (PCB) to create a functional electronic device. This procedure involves several steps, including component placement, soldering, and testing, which are crucial for ensuring that the final product meets performance standards. Understanding these processes is vital for anyone looking to partner with a PCB assembly manufacturer or seeking PCB assembly services.

Defining PCB Assembly Processes

The PCB assembly process can be broken down into various stages, starting with designing the layout of the circuit board and selecting the appropriate components. Once the design is finalized, components are placed onto the board either manually or through automated machines, depending on the scale of production. After placement, soldering techniques—such as reflow or wave soldering—are employed to secure components firmly in place, ensuring that they function correctly in their intended applications.

Importance of Quality in Assembly

Quality in PCB assembly cannot be overstated; it directly impacts the reliability and longevity of electronic devices. A reputable PCB manufacturer understands that subpar quality can lead to product failures and costly recalls, which can tarnish a company's reputation. Therefore, stringent quality control measures must be implemented throughout every stage of assembly—from sourcing high-grade materials to conducting rigorous testing before shipment—to ensure that only top-notch products reach consumers.

Overview of PCB Assembly Techniques

There are several techniques used in PCB assembly today, each with its unique advantages and applications. Surface Mount Technology (SMT) has become increasingly popular due to its ability to accommodate smaller components and higher-density layouts—a necessity for modern electronics. Additionally, through-hole technology remains relevant for specific applications requiring robust connections; thus, many PCB manufacturers employ a combination of both methods to optimize performance and efficiency while catering to diverse client needs.

The Benefits of On-Demand Manufacturing

In the fast-paced world of electronics, on-demand manufacturing has emerged as a game-changer, especially for PCB assembly. This approach allows companies to respond quickly to market demands while ensuring high-quality output. With a strong focus on customization and flexibility, on-demand manufacturing is revolutionizing the way PCB manufacturers operate.

Customization and Flexibility

One of the standout benefits of on-demand manufacturing is its inherent ability to provide customization and flexibility in PCB assembly. Unlike traditional methods that often rely on large production runs, an agile PCB manufacturer can adapt quickly to specific client requirements, allowing for tailored solutions that meet unique project needs. This level of personalization not only enhances customer satisfaction but also fosters innovation in product design.

When working with a PCB assembly manufacturer that offers on-demand services, clients can experiment with various designs without the fear of excessive costs or waste. The ability to modify specifications or materials mid-production means that companies can stay ahead in competitive markets by rapidly iterating their products based on real-time feedback. Ultimately, this flexibility empowers businesses to create more effective and relevant electronic solutions.

Reducing Waste and Inventory Costs

On-demand manufacturing plays a crucial role in minimizing waste and reducing inventory costs for businesses involved in PCB assembly China and beyond. By producing only what is necessary at any given time, manufacturers can significantly decrease excess stockpiling that often leads to financial losses. This lean approach not only conserves resources but also aligns with modern sustainability goals.

Furthermore, partnering with a reliable PCB manufacturer in China allows companies to streamline their supply chains effectively. With less inventory sitting idle, organizations can allocate funds more efficiently toward research and development or new project initiatives rather than tying up capital in unsold goods. As such, embracing an on-demand model leads to smarter financial management while promoting environmentally friendly practices.

Speeding Up Time to Market

On-demand manufacturing accelerates the PCB assembly process by minimizing lead times associated with traditional production methods. By working closely with an experienced PCBA factory that prioritizes rapid turnaround times, businesses can launch their products faster than ever before.

This agility not only satisfies consumer demand but also enables companies to capitalize on emerging trends before competitors do. With swift access to quality PCBs from a reputable PCB manufacturer in China, organizations can pivot quickly based on market shifts or technological advancements without missing a beat. In essence, faster time-to-market translates into increased revenue potential and enhanced brand reputation.

Choosing the Right PCB Manufacturer

When it comes to selecting a PCB assembly manufacturer, the stakes are high. Your choice can significantly impact the quality, cost, and time efficiency of your project. With so many options available, especially in PCB assembly China, it's crucial to evaluate potential manufacturers thoroughly.

Evaluating PCB Manufacturer Capabilities

Before you partner with a PCB manufacturer, assess their capabilities to ensure they align with your project requirements. Look for manufacturers that specialize in various PCB assembly techniques and have experience with different technologies. A reliable PCB assembly manufacturer should also provide comprehensive services—from prototyping to full-scale production—allowing you to streamline your processes.

Additionally, consider their production capacity and lead times. A capable PCB manufacturer can handle both small-batch orders and large-scale productions without compromising quality or timelines. By understanding these aspects, you can make an informed decision that meets your specific needs.

Importance of Certifications and Quality Standards

Certifications are not just fancy badges; they represent a manufacturer's commitment to quality standards in the industry. When choosing a PCB manufacturer in China or elsewhere, prioritize those with certifications like ISO 9001 or IPC-A-610 compliance. These certifications indicate adherence to rigorous quality control processes that can significantly reduce defects in your final product.

Moreover, a certified PCBA factory is more likely to invest in advanced technologies and skilled personnel who understand best practices in PCB assembly. This investment translates into better reliability and performance for your assembled PCBs—essential factors for any successful product launch.

Comparing PCB Manufacturers in China

China is known as a global hub for electronics manufacturing, but not all manufacturers are created equal. When comparing PCB manufacturers in China, look beyond price tags; consider factors such as reputation, customer reviews, and service offerings as well. Engaging with other businesses that have worked with specific manufacturers can provide valuable insights into their reliability and performance.

Also, keep an eye on turnaround times and communication practices during the selection process; effective communication is vital for smooth collaboration throughout the project lifecycle. By conducting thorough comparisons among potential partners, you'll find a suitable match that elevates your project's success while ensuring high-quality standards are met.

Bensun Technology: Innovating PCBA Services

Bensun Technology stands at the forefront of PCB assembly innovation, providing top-notch services tailored to diverse industry needs. As a leading PCB manufacturer in China, Bensun specializes in delivering high-quality printed circuit board assembly (PCBA) solutions that cater to both small and large-scale production runs. Their commitment to excellence and flexibility makes them a go-to choice for businesses seeking reliable PCB assembly.

Overview of Bensun Technology's Offerings

At Bensun Technology, the offerings encompass a wide range of services designed to streamline the PCB assembly process. From prototyping to full-scale manufacturing, they cover all aspects of PCB assembly with precision and care. As a prominent PCB manufacturer, their capabilities include surface mount technology (SMT), through-hole technology (THT), and mixed technology assemblies that ensure every client’s specific requirements are met.

Additionally, Bensun prides itself on utilizing state-of-the-art equipment and advanced techniques in its PCBA factory. This commitment ensures that each product not only meets but often exceeds industry standards for quality and performance. With an eye on innovation, Bensun continuously updates its processes to incorporate the latest technologies available in the market.

How Bensun Adapts to Client Needs

One of the standout features of Bensun Technology is its adaptability in meeting client needs throughout the PCB assembly process. They understand that each project comes with unique challenges and requirements; therefore, they prioritize communication with clients from initial consultation through production completion. This collaborative approach allows them to tailor their services effectively, ensuring that customers receive exactly what they envisioned.

Moreover, being a flexible PCB manufacturer in China means they can quickly respond to changes in order volumes or specifications without compromising quality or timelines. Whether clients need rapid prototyping or large batch runs, Bensun has established processes that allow for seamless adjustments while maintaining efficiency. This level of adaptability is crucial for companies looking to stay competitive in fast-paced markets.

Success Stories from Bensun's PCBA Factory

Bensun Technology has garnered numerous success stories that highlight their prowess as a leading PCB assembly manufacturer. For instance, one notable project involved collaborating with a tech startup aiming to launch an innovative IoT device within tight deadlines. Thanks to Bensun’s agile manufacturing capabilities and dedication to quality control, the startup successfully brought their product to market ahead of schedule—an achievement celebrated by both parties.

Another success story features an established automotive company seeking high-reliability PCBs for critical safety systems. By leveraging its expertise as a trusted PCB manufacturer in China, Bensun delivered robust solutions that not only met stringent industry standards but also enhanced overall product safety and performance metrics significantly.

These examples illustrate how partnering with an experienced PCBA factory like Bensun can lead businesses toward achieving their goals efficiently while ensuring top-tier quality throughout every step of the process.

Trends in PCB Assembly

The landscape of PCB assembly is evolving rapidly, driven by technological advancements and changing market demands. As the industry adapts to these trends, both established players and new entrants are finding innovative ways to enhance their offerings. In this section, we will explore emerging technologies, the shift towards eco-friendly solutions, and what the future holds for PCB assembly.

Emerging Technologies in PCB Manufacturing

Emerging technologies are redefining how a PCB assembly manufacturer approaches production processes. Automation and artificial intelligence are becoming integral to enhancing efficiency and precision in manufacturing lines. Moreover, advanced materials such as flexible substrates and high-frequency laminates are allowing PCB manufacturers to push the boundaries of design capabilities.

In addition to automation, 3D printing is making waves in the prototyping phase of PCB assembly. This technology enables rapid iteration of designs without the lengthy lead times associated with traditional methods, thus allowing a quicker turnaround for clients seeking prototypes from a reliable PCB manufacturer in China. As these technologies continue to mature, we can expect even more significant transformations within PCBA factories worldwide.

Finally, IoT (Internet of Things) integration is revolutionizing supply chain management for PCB assembly processes. By utilizing real-time data analytics and connectivity between machines, manufacturers can optimize production schedules while minimizing downtime—an essential factor for any competitive PCB assembly China operation aiming for excellence.

The Shift Towards Eco-Friendly Solutions

The push towards sustainability is becoming increasingly prominent within the realm of PCB manufacturing. Consumers are demanding greener products that not only meet performance standards but also adhere to environmental regulations—this trend has prompted many PCB manufacturers to adopt eco-friendly practices proactively. From using recyclable materials to implementing energy-efficient processes, companies are striving to reduce their carbon footprint while maintaining high-quality standards.

Moreover, eco-conscious design practices have emerged as vital components of modern PCBA factories' operations. Manufacturers are now focusing on minimizing waste during production by adopting lean manufacturing principles that emphasize resource efficiency throughout every stage of the process. This shift not only benefits the environment but also results in cost savings that can be passed on to customers seeking budget-friendly solutions from a reputable PCB assembly manufacturer.

Looking ahead, we can expect regulations around electronic waste disposal and recycling initiatives to become even stricter globally—placing additional pressure on manufacturers across all regions including those operating as a leading PCB manufacturer in China. Companies that proactively embrace these changes will likely gain a competitive edge as they align their operations with consumer expectations for sustainable practices.

Future of PCB Assembly: What to Expect

As we gaze into the crystal ball regarding the future of PCB assembly, several key trends emerge that promise exciting developments ahead. First off, an increased focus on customization will continue shaping how PCBA factories operate; clients will seek tailored solutions designed specifically for their unique needs rather than one-size-fits-all products from generic suppliers.

Furthermore, advancements in AI-driven analytics will allow manufacturers greater insight into operational efficiencies—enabling them not just to react quickly but anticipate issues before they arise effectively! This proactive approach ensures higher quality control standards across all stages—from initial design through final testing—ultimately benefiting customers who rely heavily upon dependable service from their chosen partners like top-tier pcb assembly manufacturers.

Lastly—and perhaps most importantly—the ongoing globalization trend means more opportunities for collaboration between international players within this field! As businesses seek out partnerships with reputable firms like those found among leading pcb manufacturers in China or beyond; innovation thrives through shared knowledge exchange which fuels further growth prospects moving forward!

Conclusion

In the fast-paced world of electronics, understanding PCB assembly is crucial for businesses looking to innovate and stay competitive. The rise of on-demand manufacturing has transformed how companies approach their production needs, allowing for greater flexibility and customization. Partnering with a reliable PCB manufacturer can streamline the assembly process and enhance product quality.

Key Takeaways on PCB Assembly

PCB assembly is more than just connecting components; it’s about ensuring quality and efficiency throughout the manufacturing process. With various techniques available, from surface mount technology to through-hole assembly, choosing the right method can significantly impact the final product's performance. Moreover, a reputable PCB manufacturer in China can provide not only cost-effective solutions but also adhere to stringent quality standards that are essential in today’s market.

Why Partner with Expert Manufacturers

Working with an expert PCB assembly manufacturer offers numerous advantages that go beyond simple production capabilities. These manufacturers bring experience, advanced technology, and industry certifications that guarantee high-quality outputs while minimizing risks associated with errors or delays. By collaborating with a proven PCB manufacturer, businesses can leverage specialized knowledge to optimize their designs and accelerate their time to market.

The Future of On-Demand PCB Solutions

Looking ahead, the future of on-demand PCB solutions appears bright as emerging technologies continue to shape the landscape of electronic manufacturing. Innovations such as automation in PCBA factories and eco-friendly materials are paving the way for sustainable practices without compromising quality or performance. As demand for customization grows, partnering with forward-thinking PCB manufacturers will be vital for companies aiming to thrive in this evolving industry.