Introduction

In the rapidly evolving world of electronics, understanding SMT PCB board assembly is crucial for anyone involved in the design and manufacturing of electronic devices. Surface Mount Technology (SMT) has revolutionized the way printed circuit assemblies (PCAs) are created, allowing for greater efficiency and miniaturization of circuit boards. The intricacies of PCB manufacturing and assembly processes play a pivotal role in ensuring that these essential components meet the high standards required for modern applications.

Understanding SMT PCB Board Assembly

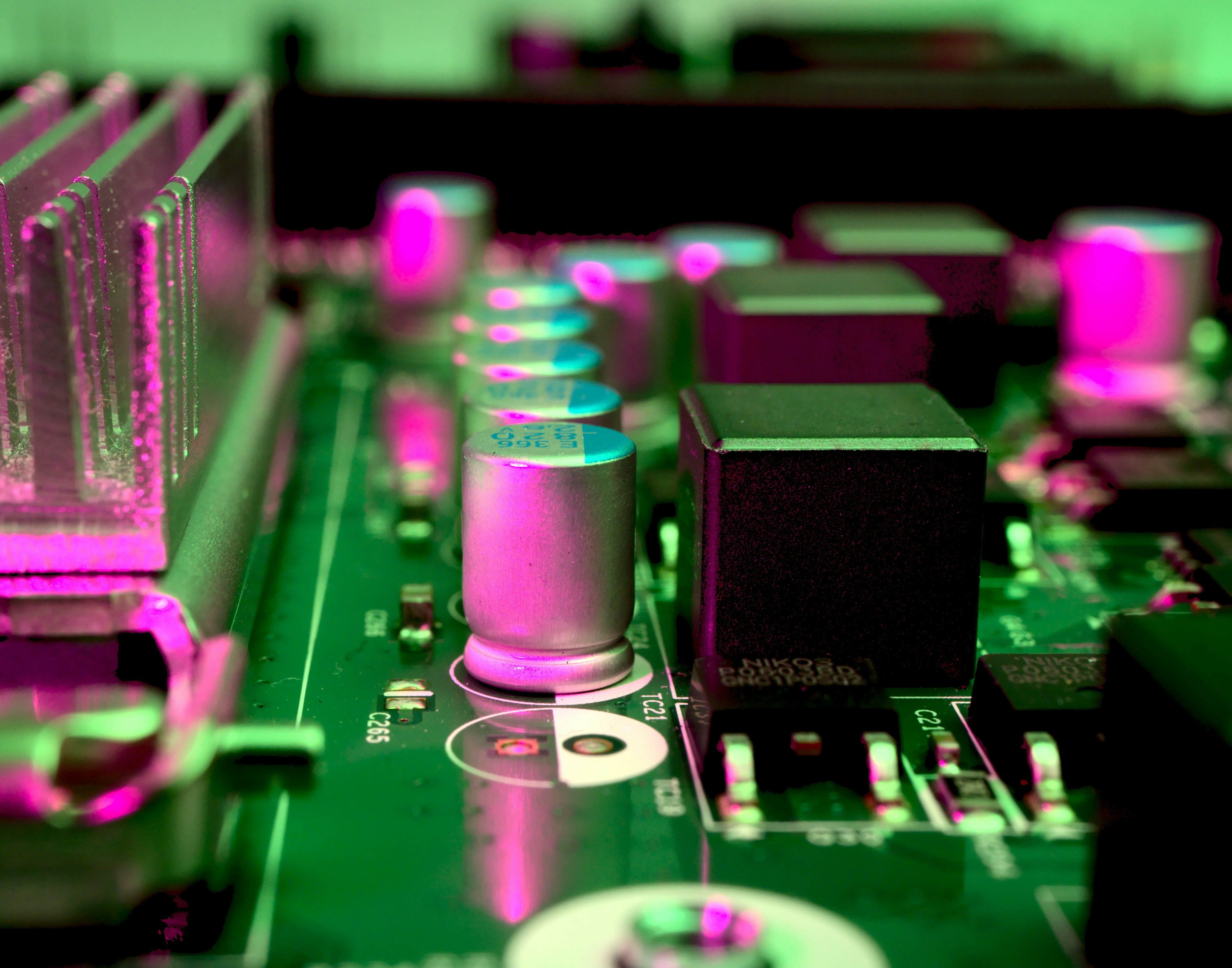

SMT PCB board assembly involves placing surface mount components directly onto the printed circuit board (PCB), eliminating the need for through-hole technology. This method not only streamlines production but also enhances performance by reducing the distance between components, which is vital for high-speed applications. By grasping the fundamentals of printed circuit assembly, manufacturers can better appreciate how SMT technology optimizes both functionality and cost-effectiveness in PCB fab and assembly.

Importance of Quality in PCB Manufacturing

Quality assurance in PCB manufacturing and assembly cannot be overstated; it is essential to ensure reliability and longevity in electronic products. Flaws or defects in a printed circuit assy can lead to catastrophic failures, affecting everything from consumer electronics to critical medical devices. Therefore, investing time and resources into quality control measures during each stage of the PCB manufacturing assembly process is not just prudent—it's necessary.

Key Components of Printed Circuit Assembly

A successful printed circuit assembly relies on several key components that work together seamlessly to create a functional product. These include various types of resistors, capacitors, integrated circuits, and connectors that are meticulously placed on the pcb assembly board during production. Understanding these components' roles helps manufacturers optimize their processes while ensuring that every aspect of their pcb fab and assembly meets industry standards.

What is SMT Technology?

Surface Mount Technology (SMT) has revolutionized the way we approach PCB manufacturing and assembly. This innovative method involves mounting electronic components directly onto the surface of a circuit board, allowing for more compact designs and improved performance. As technology continues to evolve, understanding SMT's role in printed circuit assembly becomes crucial for anyone involved in electronics.

Definition and Overview

SMT is defined as a technique that enables the attachment of components to the surface of a printed circuit board (PCB), rather than inserting them through holes as in traditional methods. This process not only streamlines production but also enhances the reliability of the circuit board by minimizing potential weak points. The result is a more robust PCB assembly board that meets modern demands for efficiency and miniaturization.

Benefits of SMT in PCB Assembly

The benefits of SMT in PCB assembly are numerous, making it a preferred choice among manufacturers. First, it allows for higher component density, which means more functions can be packed into smaller devices—perfect for today’s compact gadgets. Additionally, SMT reduces manufacturing costs due to shorter production times and less material waste during the PCB fab and assembly process.

Another significant advantage is improved electrical performance; components mounted on an SMT PCB board typically exhibit better signal integrity thanks to shorter lead lengths. Moreover, this technology facilitates automated processes, which enhance precision during production while minimizing human error—a crucial factor in quality control within PCB manufacturing assembly.

Common Applications of SMT

SMT technology finds its place across various industries due to its versatility and efficiency in printed circuit assy applications. It’s commonly used in consumer electronics like smartphones and laptops where space is at a premium but functionality must remain high. Beyond consumer goods, SMT is also prevalent in automotive electronics, medical devices, and telecommunications equipment—areas where reliability is paramount.

Moreover, industries engaged in rapid prototyping often rely on SMT because it enables quick adjustments during product development without extensive retooling or delays associated with traditional methods. As such, understanding common applications of SMT helps businesses leverage its advantages effectively while ensuring their products meet industry standards.

Essential Equipment for PCB Assembly

In the world of printed circuit assembly, having the right equipment is crucial for achieving high-quality results. Each piece of machinery plays a unique role in ensuring that the SMT PCB board is assembled accurately and efficiently. From placing components to inspecting the finished product, let's explore some essential equipment that drives successful PCB manufacturing and assembly.

JUKI Pick and Place Machines

JUKI pick and place machines are renowned for their precision in placing components on a circuit board. These machines automate the process, allowing for faster production rates while minimizing human error—a win-win scenario for any PCB fab and assembly operation. With advanced vision systems, JUKI machines can identify component placement errors in real-time, ensuring that every SMT PCB board meets stringent quality standards.

Moreover, these pick and place machines are designed to handle a variety of component sizes and shapes, making them versatile tools in printed circuit assy processes. Their ability to adapt to different production needs means they can be utilized across various industries, from automotive to consumer electronics. Investing in JUKI technology enhances efficiency while maintaining the integrity of your PCB manufacturing assembly.

Visual Inspection Machines

Visual inspection machines play an indispensable role in quality control during printed circuit assembly processes. These innovative devices utilize high-resolution cameras and advanced algorithms to detect defects such as misaligned components or soldering issues on the SMT PCB board before they become costly problems down the line. By integrating visual inspection into your PCB manufacturing and assembly workflow, you can significantly reduce rework costs and improve overall product reliability.

These machines provide a level of scrutiny that manual inspections simply cannot match, making them essential for maintaining high standards in printed circuit assy operations. Additionally, many visual inspection systems offer real-time feedback to operators, enabling immediate corrective actions if defects are detected during production runs. This proactive approach ensures that only top-quality products leave your facility.

Reflow Ovens and Their Role

Reflow ovens are a cornerstone of any efficient PCB assembly board process, responsible for soldering surface-mounted components onto the circuit board through controlled heating cycles. The reflow process involves melting solder paste applied earlier during assembly; once cooled, it creates strong electrical connections between components on the SMT PCB board—vital for functionality!

Modern reflow ovens come equipped with sophisticated temperature profiling capabilities that allow manufacturers to fine-tune their processes based on specific materials used in their PCBs. This precision helps prevent common issues like solder bridging or insufficient wetting during soldering—a critical aspect of maintaining quality throughout your pcb fab and assembly operations. In essence, reflow ovens not only enhance productivity but also ensure robust performance of finished products.

The PCB Manufacturing Process

The PCB manufacturing process is a complex journey that transforms an electronic design into a functional product. It encompasses various stages, from the initial design phase to the final assembly of the printed circuit assembly (PCA). Understanding this process is crucial for anyone involved in electronics, as it ensures high-quality output and efficient production.

From Design to Fabrication

The journey begins with a detailed design phase, where engineers create schematics and layouts for the circuit board. This involves using advanced software tools to ensure that every component fits perfectly on the PCB assembly board. Once the design is finalized, it moves to fabrication, where layers of materials are etched and processed to form the actual circuit board.

During fabrication, multiple steps are executed meticulously, including drilling holes for components and applying copper traces. These processes must adhere to strict specifications to ensure functionality and reliability in the final product. By integrating SMT technology during this stage, manufacturers can optimize space on the circuit board while enhancing performance.

The Role of Circuit Boards

Circuit boards serve as the backbone of electronic devices, providing pathways for electrical signals between components. In printed circuit assembly, these boards are not just passive carriers; they actively influence performance through their layout and material properties. The choice of materials used in PCB manufacturing and assembly can significantly impact durability and signal integrity.

Moreover, circuit boards come in various types—single-sided, double-sided, or multi-layered—each suited for different applications based on complexity and size requirements. As technology advances, so do circuit boards; innovations like flexible PCBs allow for more versatile designs in compact spaces. Ultimately, understanding the role of these boards helps manufacturers produce reliable products that meet consumer demands.

Quality Control in PCB Manufacturing Assembly

Quality control is paramount throughout every phase of PCB manufacturing assembly to ensure that each smt pcb board meets industry standards. This involves rigorous testing at various stages—from initial fabrication checks to final inspections before shipping out products. Implementing effective quality control measures can prevent costly errors down the line.

Common quality assurance practices include visual inspections using specialized machines and automated testing methods like flying probe testers or boundary scan tests. These techniques help identify defects early on while ensuring that each printed circuit assy operates as intended under real-world conditions. By prioritizing quality control within pcb fab and assembly processes, manufacturers can build trust with clients while minimizing returns due to faults.

Best Practices for Efficient Assembly

In the world of PCB manufacturing and assembly, efficiency is key to ensuring high-quality printed circuit assembly while keeping costs manageable. Adopting best practices not only streamlines production but also enhances the overall performance of the circuit board. Let’s dive into some essential strategies that can elevate your PCB assembly board processes.

Optimizing Production Line Setup

A well-organized production line setup is crucial for effective SMT PCB board assembly. By strategically placing equipment such as pick and place machines and reflow ovens, you can minimize unnecessary movement and reduce cycle times. Additionally, implementing a lean manufacturing approach helps eliminate waste, ensuring that each step in the printed circuit assy process adds value to the final product.

To further enhance efficiency, consider using digital tools to monitor production flow in real-time. This allows for quick adjustments based on demand fluctuations or potential bottlenecks in your PCB fab and assembly operations. Ultimately, an optimized setup leads to faster turnaround times without compromising quality—an essential aspect of successful PCB manufacturing and assembly.

Importance of Cleanliness and Maintenance

Cleanliness in the environment where SMT PCB board assembly takes place cannot be overstated; it’s foundational to producing reliable printed circuit assemblies. Dust, debris, or contaminants can lead to defects on the circuit board that may go unnoticed until it’s too late—resulting in costly rework or even product failure in the field. Regular cleaning schedules should be established alongside routine maintenance checks for all machinery involved in PCB manufacturing.

Moreover, maintaining equipment not only prolongs its lifespan but also ensures consistent performance during production runs. A well-maintained pick and place machine or reflow oven operates more efficiently, leading to fewer errors during printed circuit assy processes. In essence, cleanliness combined with diligent maintenance creates a solid foundation for achieving high standards in PCB manufacturing assembly.

Training Staff for Precision in Assembly

Investing time and resources into training staff is vital for achieving precision during SMT PCB board assembly operations. Skilled technicians who understand the nuances of working with complex printed circuit assemblies can identify potential issues before they escalate into significant problems down the line. Providing ongoing education about new technologies or techniques used within your PCB fab and assembly processes keeps your team at the forefront of industry advancements.

Furthermore, fostering a culture that values attention to detail encourages employees to take pride in their work—leading to higher quality outputs across all stages of printed circuit assy production. When staff members are well-trained and confident in their abilities, it translates directly into improved efficiency on the production floor as well as enhanced product reliability post-assembly. Ultimately, investing in human capital is one of the smartest moves you can make within your PCB manufacturing landscape.

Bensun Technology: A Leader in SMT Solutions

In the ever-evolving landscape of PCB manufacturing and assembly, Bensun Technology stands out as a beacon of innovation and reliability. With a strong commitment to quality and efficiency, Bensun has positioned itself as a leader in providing SMT (Surface Mount Technology) solutions that cater to a wide array of industries. Their expertise in printed circuit assembly ensures that every circuit board produced meets the highest standards of functionality and durability.

Overview of Bensun's Offerings

Bensun offers an impressive range of services designed to streamline the PCB manufacturing process while maintaining exceptional quality. Their portfolio includes advanced SMT PCB board assembly, where precision meets speed, ensuring rapid production without compromising on quality. By leveraging state-of-the-art technology, Bensun provides tailored solutions for printed circuit assy that address specific client needs across various sectors.

The company prides itself on its robust capabilities in both design and fabrication, offering comprehensive support from concept to completion. Whether it's developing prototypes or scaling up production runs, Bensun has the tools and expertise to handle it all efficiently. Clients can expect not only high-quality circuit boards but also innovative approaches that enhance their overall manufacturing experience.

Contract Manufacturing Services

Bensun's contract manufacturing services are designed for businesses seeking reliable partners in PCB fab and assembly processes. By outsourcing their printed circuit assembly needs to Bensun, companies can focus on their core competencies while benefiting from expert handling of their circuit board production requirements. This partnership model allows clients to scale operations quickly without the burden of investing heavily in equipment or personnel.

The flexibility offered by Bensun’s contract services means they can accommodate everything from small batch orders to large-scale productions seamlessly. Their experienced team ensures that each phase of the PCB manufacturing assembly is executed with precision, adhering strictly to industry standards for quality control. This dedication not only enhances product reliability but also fosters long-term relationships built on trust and mutual success.

Flexible Solutions for Diverse Industries

One of the standout features of Bensun Technology is its ability to provide flexible solutions tailored specifically for diverse industries such as automotive, telecommunications, consumer electronics, and medical devices. Each sector has unique requirements when it comes to SMT PCB board specifications; thus, understanding these nuances is crucial for successful outcomes in printed circuit assy projects.

Bensun’s adaptability ensures they can meet varying demands without sacrificing quality or performance—whether it's high-speed data transfer circuits or intricate medical device assemblies requiring stringent regulations compliance. Their commitment extends beyond just delivering products; they aim to be strategic partners who help clients navigate the complexities of modern PCB manufacturing challenges effectively.

In summary, partnering with Bensun Technology means accessing top-tier SMT solutions backed by years of industry experience and innovation-driven practices that prioritize quality at every step—from design through PCB fab and assembly processes.

Conclusion

In the ever-evolving landscape of electronics, the significance of selecting the right PCB manufacturing partner cannot be overstated. A reliable partner ensures that your printed circuit assembly meets stringent quality standards while also adhering to timelines and budget constraints. With numerous options available, it’s essential to evaluate potential partners based on their expertise in SMT PCB board technology and their ability to deliver consistent results.

Choosing the Right PCB Manufacturing Partner

When it comes to choosing a partner for your PCB manufacturing and assembly needs, consider factors such as experience, technology capabilities, and customer support. Look for companies that specialize in SMT PCB board processes, as they will have the necessary equipment and know-how to handle complex designs efficiently. Additionally, a good partner should offer flexibility in services to accommodate varying production volumes without compromising quality.

Emphasizing Quality in Assembly Processes

Quality should be at the forefront of any printed circuit assy operation. Implementing strict quality control measures throughout the PCB manufacturing assembly process can significantly reduce defects and enhance product reliability. Engaging in regular audits and inspections ensures that every circuit board produced meets industry standards, ultimately leading to greater customer satisfaction and loyalty.

Future Trends in SMT PCB Technologies

The future of SMT PCB technologies is bright, with innovations continuously shaping how we approach printed circuit assembly. Emerging trends such as automation, artificial intelligence integration, and advanced materials are set to revolutionize the efficiency and effectiveness of PCB fab and assembly processes. As these technologies evolve, manufacturers must stay ahead of the curve by investing in cutting-edge solutions that enhance productivity while maintaining high-quality standards.