Introduction

In today's fast-paced electronics landscape, understanding the intricacies of PCB SMT assembly is more crucial than ever. This method not only streamlines production but also enhances the quality and reliability of electronic devices. By diving into the essentials of SMT assembly, we can appreciate its growing significance in modern manufacturing.

Understanding PCB SMT Assembly Essentials

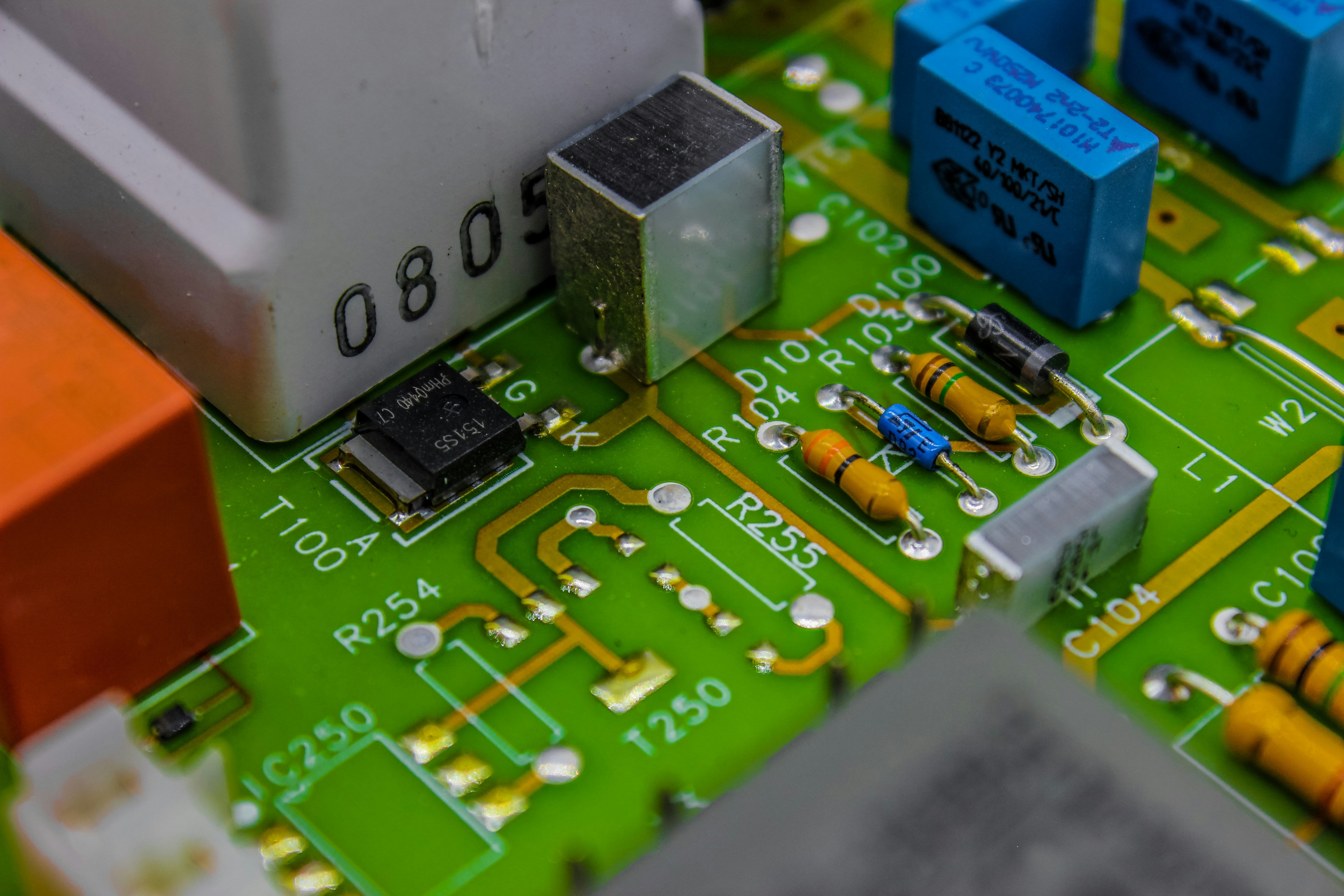

PCB SMT assembly, or Surface Mount Technology assembly, involves placing components directly onto the surface of printed circuit boards (PCBs). This process has revolutionized how electronic devices are designed and produced, allowing for more compact and efficient designs. With a firm grasp on what is SMT PCB assembly, manufacturers can leverage its advantages to improve their product offerings.

Key Benefits of Optimizing SMT Processes

Optimizing SMT processes leads to several key benefits that can significantly impact production efficiency and cost-effectiveness. For instance, it reduces manual labor costs while increasing throughput by utilizing automated equipment in the PCB SMT assembly line. Additionally, improved optimization enhances product quality by minimizing defects during the assembly process.

Exploring the SMT Assembly Process

The SMT assembly process comprises several steps that ensure components are accurately placed and soldered onto PCBs. What are the steps in the SMT assembly line? From solder paste application to component placement and reflow soldering, each stage plays a pivotal role in achieving a high-quality final product. Understanding these steps allows manufacturers to refine their techniques and select suitable PCB SMT assembly manufacturers for their needs.

What is SMT PCB Assembly?

In the world of electronics, understanding what SMT PCB assembly entails is crucial for anyone looking to delve into modern manufacturing processes. So, what is SMT PCB assembly? It refers to the method of mounting surface-mount devices (SMDs) directly onto the surface of printed circuit boards (PCBs). This innovative approach has revolutionized how electronic components are integrated, offering numerous advantages over traditional through-hole techniques.

Definition and Overview

SMT PCB assembly stands for Surface Mount Technology Printed Circuit Board Assembly. This process involves soldering components onto a PCB's surface rather than inserting them through holes, which was common in older methods. By using SMDs that are smaller and lighter than their through-hole counterparts, manufacturers can achieve higher component density and improved performance in their designs.

The SMT assembly process typically involves several steps: applying solder paste, placing components on the board, reflow soldering to secure them in place, and finally inspecting the assembled boards for quality assurance. Each of these steps plays a critical role in ensuring that the final product meets stringent quality standards while also being cost-effective and efficient.

Importance in Modern Electronics

The importance of SMT PCB assembly cannot be overstated in today's fast-paced electronics market. As devices become smaller and more complex, manufacturers need to optimize their production processes to stay competitive. By adopting SMT techniques, companies can reduce overall production costs while increasing efficiency—two factors that are vital for success.

Moreover, this technology allows for greater design flexibility since SMDs can be arranged in various configurations without sacrificing performance or reliability. The ability to produce compact designs has led to innovations across various sectors—from consumer electronics like smartphones to industrial applications such as automation equipment—making SMT an essential component of modern electronics manufacturing.

Common Applications and Industries

SMT PCB assembly finds applications across a wide range of industries due to its versatility and efficiency. Common sectors include telecommunications, automotive electronics, medical devices, consumer goods, and aerospace technology—all of which rely on high-quality PCBs for optimal functionality. Within these industries, you’ll find products like smartphones packed with features or advanced medical imaging equipment requiring precise electronic integration.

Furthermore, with the rise of IoT (Internet of Things) devices demanding compact yet powerful solutions, SMT has become even more relevant as it allows manufacturers to create intricate designs without compromising on size or weight. The adaptability offered by pcb smt assembly ensures that businesses can respond quickly to ever-evolving market demands while maintaining high standards of quality.

Differences Between SMD and SMT PCB

In the realm of electronics, understanding the distinctions between Surface Mount Devices (SMD) and Surface Mount Technology (SMT) is crucial for optimizing your PCB SMT assembly processes. While they are often used interchangeably, they refer to different aspects of electronic assembly. This section will clarify these terms and guide you on their appropriate applications in the assembly line.

Key Definitions Explained

To grasp what is SMT PCB assembly, one must first understand that SMD refers specifically to the components that are mounted directly onto the surface of a printed circuit board (PCB), while SMT encompasses the entire process of placing these components onto the board. In simpler terms, SMDs are like the actors in a play, while SMT is the stage where everything happens. This distinction lays the groundwork for understanding how each plays a role in modern electronics manufacturing.

Advantages of SMD in PCB Assembly

When considering what is the difference between SMD and SMT PCB, it’s essential to highlight that SMDs offer several advantages during PCB SMT assembly. They typically occupy less space than traditional through-hole components, allowing for more compact and efficient designs—a crucial benefit as devices continue to shrink in size. Additionally, using SMDs can enhance performance due to shorter electrical paths and reduced parasitic inductance, making them ideal for high-frequency applications.

When to Use SMD vs. SMT

The decision on when to use SMD versus other component types often hinges on specific project requirements and constraints within your PCB assembly kit. If you're working with limited space or need high-density packaging, opting for an SMD approach within your SMT assembly process could be beneficial. Conversely, if you require robust connections or are dealing with larger components that need additional mechanical support, traditional through-hole technology might still have its place alongside your PCB SMT assembly efforts.

Understanding PCB vs. PCB Assembly

In the world of electronics, distinguishing between a printed circuit board (PCB) and PCB assembly is fundamental to grasping how devices function. While both are integral to electronic products, they serve distinct purposes that affect design, production, and functionality. Let’s dive into what constitutes a PCB, the role of PCB assembly in production, and why both are crucial for the electronics industry.

What Constitutes a PCB?

A printed circuit board (PCB) is essentially the backbone of an electronic device; it provides mechanical support and electrical connectivity for various components. Made from insulating materials like fiberglass or plastic, PCBs feature conductive pathways etched onto their surface to connect different parts such as resistors, capacitors, and integrated circuits. In essence, understanding what is SMT PCB assembly requires recognizing that a bare PCB is just one piece of the puzzle—it's where all those tiny components will eventually reside.

The Role of PCB Assembly in Production

PCB assembly refers to the process where electronic components are mounted onto a bare PCB to create a functional unit ready for integration into larger devices. This process typically involves various techniques including Surface Mount Technology (SMT), which allows for efficient placement of components on both sides of the board. Without effective PCB assembly, even the most sophisticated designs would remain lifeless; thus, mastering the SMT assembly process is crucial for any manufacturer aiming for high-quality electronics.

Why Both Are Crucial for Electronics

Both PCBs and their assembly play vital roles in modern electronics—without one or the other, your favorite gadgets wouldn’t exist! The relationship between them can be likened to that of a foundation and a house: you need a sturdy base (the PCB) before you can build something functional on top (the assembled device). Understanding what is the difference between PCB and PCB assembly helps manufacturers optimize their processes and ensure quality in every step—from selecting suitable pcb smt assembly manufacturers to assembling an efficient pcb smt assembly kit.

Steps in the SMT Assembly Line

The PCB SMT assembly process is a finely-tuned operation that transforms printed circuit boards into fully functional electronic devices. Each step in the SMT assembly line plays a crucial role, ensuring that components are accurately placed and soldered onto the PCB. Understanding these steps can help manufacturers streamline their processes and improve overall efficiency.

Overview of the Assembly Process

The SMT assembly process begins with the preparation of the PCB, which includes cleaning and applying solder paste to specific pads. Following this, components are placed onto the board using automated pick-and-place machines, a vital aspect of what is SMT PCB assembly. After placement, boards undergo reflow soldering to secure components in place, followed by inspection and testing to ensure quality and functionality.

As you navigate through each stage of the assembly line, it’s essential to maintain high standards for precision and cleanliness. The entire process not only enhances productivity but also reduces errors that could lead to costly rework later on. By understanding what are the steps in SMT assembly line, manufacturers can better plan for efficiency at every turn.

Equipment Required for Each Step

To execute an efficient PCB SMT assembly process, various specialized equipment is essential at each stage of production. Initially, stencil printers apply solder paste with accuracy; this is followed by pick-and-place machines that precisely position surface mount devices (SMDs) on designated pads—this equipment is critical for high-speed operations. Finally, reflow ovens heat the assembled boards to melt solder paste and create solid electrical connections.

In addition to core machinery like printers and ovens, inspection systems such as Automated Optical Inspection (AOI) tools ensure quality control throughout production phases. Manufacturers should also consider investing in cleaning equipment post-assembly to maintain optimal performance levels during subsequent production runs. By utilizing appropriate tools tailored for each step, companies can significantly enhance their output quality while reducing waste.

Best Practices for Efficiency

Efficiency in PCB SMT assembly doesn’t just happen; it requires strategic planning and adherence to best practices throughout every stage of production. First off, maintaining an organized workspace minimizes confusion and maximizes productivity—think about layout optimization! Regular training sessions for operators ensure they are up-to-date with machine operations and troubleshooting techniques.

Another key practice involves continuous monitoring of equipment performance; predictive maintenance can prevent unexpected downtime during critical manufacturing periods. Implementing lean manufacturing principles helps eliminate unnecessary steps within your workflow—this will save time while allowing your team to focus on value-added tasks instead! Lastly, collaborating closely with reliable PCB SMT assembly manufacturers ensures access to high-quality materials like a robust pcb smt assembly kit tailored specifically for your needs.

Choosing PCB SMT Assembly Manufacturers

Selecting the right PCB SMT assembly manufacturer can be a daunting task, especially with the myriad of options available today. It's crucial to consider several factors that will not only affect your product's quality but also its time-to-market and overall cost-effectiveness. By understanding what to look for in a partner, you can ensure that your SMT assembly process runs smoothly and efficiently.

What to Consider When Selecting a Partner

When diving into the world of PCB SMT assembly, start by evaluating the manufacturer's experience and reputation in the industry. Look for companies that specialize in high-quality SMT processes and have a proven track record with clients similar to your business needs. Additionally, consider their capabilities regarding equipment and technology; manufacturers should use advanced machinery that aligns with modern standards to ensure precision in every step of the SMT assembly process.

Another critical aspect is communication; choose a partner who prioritizes transparency and keeps you informed throughout production. This includes providing updates on timelines, potential challenges, and solutions as they arise. Lastly, assess their flexibility—can they adapt to changes in design or volume? A responsive manufacturer can make all the difference when unexpected adjustments are needed during production.

Evaluating Quality vs. Cost

In PCB SMT assembly, finding the right balance between quality and cost is essential yet often tricky. While it may be tempting to go for lower prices upfront, remember that cutting corners can lead to increased costs down the line due to defects or delays. Therefore, prioritize manufacturers who demonstrate a commitment to quality assurance through certifications and rigorous testing protocols.

Consider asking for samples or prototypes before making any commitments; this will give you insight into their workmanship without fully committing your resources just yet. Furthermore, look into customer reviews or case studies showcasing past projects—these insights can provide clarity on how well they perform under various conditions while still delivering competitive pricing.

Lastly, don't shy away from negotiating terms; many manufacturers are open to discussions on bulk orders or long-term partnerships which could yield better rates without compromising quality standards.

Role of Bensun Technology in the Market

Bensun Technology has positioned itself as a leading player among PCB SMT assembly manufacturers by emphasizing both innovation and reliability in its services. With years of experience under its belt, Bensun offers comprehensive solutions tailored specifically for various industries requiring high-quality PCBA solutions at competitive prices. Their commitment to utilizing state-of-the-art machinery ensures that every step in the SMT assembly process meets industry standards while delivering exceptional results.

Moreover, Bensun understands the importance of collaboration during production phases; their team works closely with clients from initial design through final delivery ensuring transparency at every level of engagement. This proactive approach not only enhances customer satisfaction but also streamlines operations significantly—a key factor when considering what is involved in PCB vs. PCB assembly processes.

As trends evolve within electronics manufacturing—such as miniaturization or increased automation—Bensun remains adaptable by continuously upgrading technologies and methodologies used within their facilities. Choosing Bensun Technology means investing not just in quality but also future-proofing your products against rapidly changing market demands.

Conclusion

In the ever-evolving world of electronics, mastering PCB SMT assembly is not just an option; it's a necessity for staying competitive. By streamlining your SMT assembly process, you can enhance efficiency, reduce costs, and improve product quality. Understanding the nuances of what is SMT PCB assembly and its various components will empower manufacturers to make informed decisions that elevate their production capabilities.

Streamlining Your SMT Assembly Process

To truly optimize your PCB SMT assembly process, a thorough understanding of each step involved is essential. From design to final inspection, knowing what are the steps in the SMT assembly line allows for better planning and execution. Implementing best practices such as automated pick-and-place machines and real-time monitoring can significantly enhance efficiency while reducing human error.

Moreover, selecting the right PCB SMT assembly manufacturers can play a pivotal role in this optimization journey. They should be equipped with advanced technology and skilled personnel who understand the intricacies of both SMD and SMT processes. With careful evaluation, companies can ensure they partner with manufacturers capable of delivering high-quality results consistently.

Future Trends in PCB SMT Assembly

The landscape of PCB smt assembly is continually shifting due to technological advancements and market demands. One notable trend is the increasing integration of artificial intelligence into the SMT assembly process, which promises to improve precision and speed dramatically. As industries demand smaller yet more powerful devices, innovations such as flexible PCBs are also gaining traction.

Another exciting development includes advancements in materials used for SMD components that enhance thermal performance and reliability. These trends indicate a future where efficiency meets sustainability in PCB smt assembly practices—creating products that not only perform better but are also environmentally friendly. Keeping an eye on these trends will help businesses stay ahead in a competitive market.

Investing in Quality PCBA Solutions

Whether you're exploring what is the difference between SMD and SMT PCB or navigating through various pcb smt assembly kits available on the market, prioritizing quality over cost will yield greater returns on investment over time. High-quality components ensure durability and reliability—two critical factors for customer satisfaction.

Furthermore, engaging with reputable pcb smt assembly manufacturers who prioritize quality assurance processes will safeguard your investment from potential defects or failures during production runs. Investing wisely means choosing partners who understand your needs and align with your vision for excellence in electronic manufacturing. Ultimately, this commitment to quality will resonate with customers long after their first interaction with your product.