Introduction

In the ever-evolving landscape of manufacturing, pick and place machines have emerged as essential tools for streamlining production processes. These sophisticated devices automate the placement of components onto printed circuit boards (PCBs), significantly enhancing efficiency and precision. But what is a pick and place machine? Understanding this technology is crucial for anyone looking to optimize their manufacturing operations.

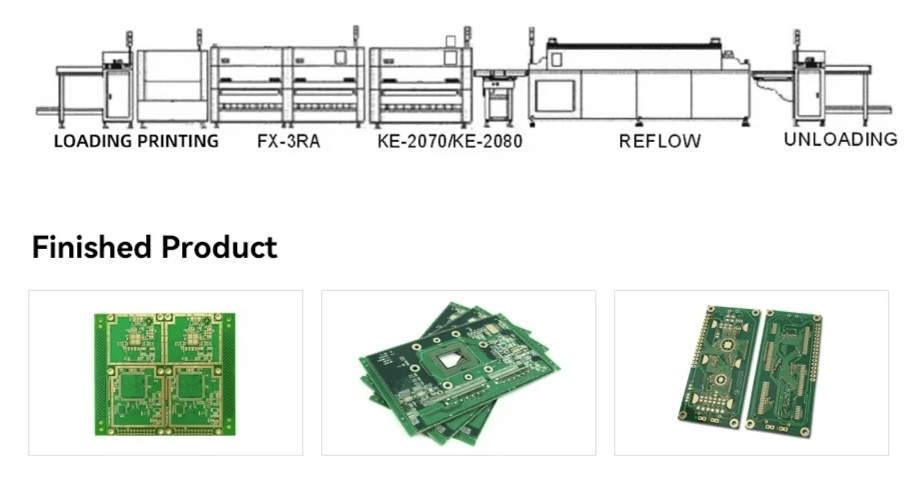

Understanding SMT Pick and Place Machines

Surface Mount Technology (SMT) pick and place machines are designed to handle the intricate task of assembling electronic components with remarkable speed and accuracy. By utilizing advanced robotics, these machines can quickly position various components on PCBs, ensuring optimal placement every time. The integration of SMT in manufacturing has transformed how products are assembled, making it vital for businesses to grasp its significance fully.

The Importance of Automation in Manufacturing

Automation plays a pivotal role in modern manufacturing, driving efficiency while reducing human error. With the implementation of SMT pick and place machines, companies can achieve higher output rates without compromising quality. As industries increasingly turn to automated solutions, understanding which robot is used for pick and place becomes essential for maintaining a competitive edge.

What to Consider When Buying Online

When venturing into the online marketplace for a pick and place machine, several factors warrant consideration to ensure you make an informed decision. First, assess your specific needs—whether you're looking at a desktop pick and place machine or an industrial model—based on your production volume and complexity. Additionally, researching reputable brands that offer support services can enhance your purchasing experience while ensuring you choose the right equipment tailored to your requirements.

What is a Pick and Place Machine?

In the world of electronics manufacturing, pick and place machines play a pivotal role in assembling printed circuit boards (PCBs). These automated devices are designed to efficiently position components onto a PCB, ensuring precision and speed that manual assembly simply can't match. So, what is a pick and place machine? It’s essentially the unsung hero behind your favorite gadgets, making sure every tiny component finds its rightful spot.

Overview of Functionality

At its core, the functionality of pick and place machines revolves around their ability to pick components from a designated area and place them onto PCBs with remarkable accuracy. This process typically involves advanced vision systems that identify component locations before robotic arms execute the task with speed and finesse. The efficiency of this pick and place machine process not only enhances production rates but also minimizes errors—an essential factor in high-stakes electronics manufacturing.

Key Components Explained

Understanding the key components of SMT pick and place machines can help demystify how they work. The primary elements include feeders that hold components, vision systems for alignment detection, robotic arms for movement, and control software for orchestrating operations seamlessly. Each part plays a crucial role in ensuring that the entire assembly process flows smoothly, transforming raw materials into fully functional electronics.

Applications in Electronics

Pick and place machines are indispensable across various applications in electronics manufacturing—from smartphones to medical devices. They excel at placing surface mount technology (SMT) components on PCBs due to their speed and accuracy, which is critical when dealing with densely packed circuits. As industries continue to innovate, these machines adapt to accommodate new technologies while maintaining their central role in efficient production lines.

Which Robot is Used for Pick and Place?

Types of Robots in SMT

The landscape of pick and place machines features several types of robots, each with its unique advantages. Articulated robots offer a high degree of flexibility, making them ideal for complex assembly tasks where movement precision is key. On the other hand, delta robots excel in speed and efficiency, often preferred in high-volume production lines due to their rapid motion capabilities.

Collaborative robots (cobots) have also made their mark in this field, working alongside human operators to increase productivity without sacrificing safety. Each type of robot brings something different to the table; thus, selecting the right one can depend on factors like production volume and complexity of the tasks involved. Ultimately, knowing what type of robot is used for pick and place applications can help manufacturers optimize their operations.

Benefits of Robotic Pick and Place Systems

Robotic pick and place systems offer a multitude of benefits that can transform manufacturing processes into streamlined operations. First off, these systems significantly reduce human error by automating repetitive tasks with pinpoint accuracy—something that’s crucial when dealing with tiny electronic components. Additionally, they boost productivity by operating continuously without fatigue or breaks, allowing businesses to meet tight deadlines more effectively.

Moreover, implementing robotic systems in your SMT pick and place machine process can lead to cost savings over time through reduced labor costs and increased throughput rates. This automation not only enhances quality control but also allows for better allocation of human resources toward more complex tasks that require critical thinking or creativity. In essence, investing in robotic technology translates into both operational efficiency and competitive advantage.

Brands Leading the Market

When exploring options for your next pick and place machine investment, familiarizing yourself with leading brands will be advantageous. Companies like Yamaha Robotics offer a range of SMT pick and place machines renowned for their reliability and ease of use—perfect for both large-scale manufacturers and smaller enterprises looking at desktop pick and place machines as viable alternatives. Another notable player is Universal Instruments; they provide customizable solutions tailored to specific production needs while maintaining high standards.

Furthermore, Panasonic has made significant strides with its advanced robotics technology aimed at enhancing automation within electronics manufacturing sectors. These brands not only deliver quality machinery but also provide comprehensive support services that ensure smooth integration into existing workflows—a must-have when considering which robot is used for pick-and-place operations! By choosing reputable brands leading the market today, you set yourself up for success as you navigate through the world of SMT.

What Are the Three Types of SMT?

Overview of Surface Mount Technology

Surface Mount Technology revolutionized the way electronic components are assembled onto circuit boards. Unlike traditional through-hole technology, where components are inserted into holes on a PCB, SMT allows components to be mounted directly on the surface, leading to more compact designs and improved performance. This efficiency is particularly beneficial for pick and place machines, which automate the placement process, enhancing speed and accuracy in production.

Differences Among the Types

The three main types of SMT include chip-on-board (COB), surface mount device (SMD), and ball grid array (BGA). COB involves directly attaching bare chips onto a PCB using conductive adhesive or soldering; it's often used in high-density applications. SMDs are pre-packaged components that can be easily handled by pick and place machines; they come in various shapes and sizes, catering to diverse electronic needs. BGAs feature an array of solder balls on their underside for attachment to PCBs; they provide excellent electrical performance but require precise alignment during placement.

Applications in Various Industries

Different types of SMT find applications across numerous industries due to their versatility and efficiency. For instance, COB is frequently utilized in LED lighting systems where space-saving is essential. SMDs dominate consumer electronics like smartphones and laptops due to their compact nature, while BGAs are preferred in high-performance computing devices such as servers and gaming consoles due to their superior thermal management capabilities.

Understanding the Pick Place Mechanism

When diving into the world of pick and place machines, one cannot overlook the intricacies of the pick place mechanism. This process is crucial for automating component assembly in electronics manufacturing, ensuring precision and efficiency. With a well-designed mechanism, these machines can significantly enhance productivity while minimizing errors.

Mechanics of the Process

The pick and place machine process begins with a robotic arm equipped with suction cups or grippers that identify and lift components from a feeder or tray. Once secured, the arm moves to a designated location on a printed circuit board (PCB) to accurately position the component before releasing it. This seamless operation is made possible by advanced sensors and software that coordinate movement, ensuring that each part is placed precisely where it needs to go.

Understanding what is a pick and place machine involves recognizing its reliance on both mechanical design and electronic control systems. The mechanics must work harmoniously to allow for quick movements without sacrificing accuracy, which is paramount in electronics assembly. As manufacturers seek to optimize their production lines, mastering these mechanical processes becomes essential.

Advantages of Efficient Mechanisms

Efficient mechanisms in SMT pick and place machines provide several advantages that can transform production capabilities. Firstly, they reduce cycle times significantly; faster placement means higher output without compromising quality. Additionally, these mechanisms minimize waste by ensuring components are placed correctly on the first attempt, reducing rework costs associated with errors.

Another key benefit of efficient mechanisms lies in their adaptability; modern pick and place machines can handle various component sizes and types with ease. This flexibility allows businesses to pivot quickly based on market demands or changes in product design without needing extensive downtime for reconfiguration. Ultimately, investing in an efficient pick place mechanism translates directly into improved profitability for manufacturers.

How It Affects Production Quality

The quality of production heavily relies on how effectively the pick place mechanism operates within SMT systems. An unreliable mechanism can lead to misalignment or improper placement of components on PCBs—issues that may not be immediately visible but can cause significant problems down the line. By ensuring precision through advanced mechanics, manufacturers can maintain high standards that meet industry regulations.

Moreover, as we explore which robot is used for pick and place tasks, it's clear that advancements in robotics contribute directly to enhanced production quality as well. High-precision robots equipped with sophisticated algorithms ensure consistent performance across numerous cycles—this consistency fortifies overall product reliability in electronics manufacturing sectors like automotive or medical devices where quality cannot be compromised.

In conclusion, understanding what is the pick place mechanism reveals its vital role in optimizing production processes while maintaining high-quality standards across industries dependent on SMT technology.

Exploring Desktop Pick and Place Machines

In the realm of manufacturing, desktop pick and place machines are becoming increasingly popular, particularly among small businesses. These compact devices offer a range of benefits that can significantly enhance production efficiency without requiring a large investment. With their ability to automate the assembly process, desktop pick and place machines allow startups to compete with larger manufacturers by streamlining operations and reducing labor costs.

Benefits for Small Businesses

One major benefit of using a desktop pick and place machine is the reduced footprint; these machines take up less space than their industrial counterparts while still delivering impressive performance. Additionally, they provide an affordable entry point into automation, enabling small manufacturers to improve their processes without breaking the bank.

Another advantage is ease of use; many desktop models come equipped with user-friendly interfaces that allow operators to quickly learn how to program them for various tasks. This means businesses can ramp up production without extensive training or technical expertise. Furthermore, desktop pick and place machines are versatile enough to handle different types of components, making them ideal for small batch runs or prototyping projects.

Popular Options on the Market

When it comes to choosing a desktop pick and place machine, several options stand out in today’s market. Brands like Neoden and Mycronic have made a name for themselves by offering reliable machines equipped with advanced features tailored for small-scale operations. These models often include multiple nozzles for different component sizes and high-speed placement capabilities, ensuring efficiency in the pick and place machine process.

Another noteworthy option is the JUKI 2020 series, which has garnered attention for its precision and adaptability in various applications within electronics manufacturing. Many users appreciate its robust software support that simplifies programming tasks—a crucial factor when considering what is a pick and place machine? Ultimately, selecting the right model will depend on your specific needs regarding throughput, component types, and budget constraints.

Comparing Desktop vs. Industrial Machines

While both desktop pick and place machines and industrial models serve similar purposes—automating assembly—their differences are significant enough to influence purchasing decisions. Industrial SMT pick and place machines typically offer higher speeds, greater accuracy, and larger component handling capacities than their smaller counterparts; however, this comes at a premium price point that may not be feasible for every business.

On the other hand, desktop models excel in flexibility; they can easily accommodate various projects without requiring extensive setup changes or large operational spaces. Additionally, maintenance costs tend to be lower with desktop units due to their simpler design compared to industrial machines that may require specialized service personnel frequently. Ultimately, understanding what are the three types of SMT can help determine which type aligns best with your production goals—whether you're looking at robust industrial solutions or nimble desktop alternatives.

Conclusion

In the fast-evolving world of manufacturing, pick and place machines are becoming indispensable. Their role in automating processes has transformed production lines, making them faster and more efficient. As we look to the future, advancements in technology promise even more innovative solutions that will enhance the capabilities of these machines.

The Future of Pick and Place Technology

The future of pick and place technology is bright, with ongoing improvements in speed, precision, and adaptability. Emerging trends like AI integration and machine learning are set to revolutionize how these systems operate, enabling them to learn from their environments for better efficiency. Additionally, as industries shift towards more sustainable practices, we can expect to see eco-friendly designs that minimize waste while maximizing output.

How Bensun Technology Meets Your Needs

Bensun Technology stands out in the realm of SMT pick and place machines by offering tailored solutions that cater to diverse manufacturing needs. With a focus on quality and performance, Bensun ensures that every machine integrates seamlessly into your production line while optimizing processes like the pick place mechanism. Whether you're looking for a desktop pick and place machine or a larger industrial model, Bensun is committed to providing exceptional support throughout your purchasing journey.

Tips for Choosing the Right Machine Online

When it comes to selecting a suitable pick and place machine online, there are several key factors to consider. First off, understand what is a pick and place machine? Familiarize yourself with its functionalities so you can match them with your specific requirements. Next, investigate which robot is used for pick and place applications; this knowledge will help you assess compatibility with your existing systems.

Moreover, take time to explore what are the three types of SMT available on the market today—each type serves different purposes across various industries. Lastly, don't overlook customer reviews or testimonials; they provide invaluable insights into the performance of specific models during real-world use cases.