Introduction

In the fast-paced world of electronics manufacturing, the question arises: What is an insertion machine? Specifically, an insertion machine refers to a specialized device designed for placing electronic components onto printed circuit boards (PCBs) with precision and efficiency. Among these machines, the terminal inserter stands out as a crucial player in streamlining PCB assembly processes.

What Is an Insertion Machine?

An insertion machine is an automated system that facilitates the placement of various electronic components onto PCBs, significantly enhancing production capabilities. The most common type of insertion machine used in this context is the Auto Insertion Machine for PCB assemblies, which ensures high-speed and accurate component placement. By utilizing advanced technology, these machines reduce manual labor and minimize human error during assembly.

Benefits of Using Auto Insertion Machines

The benefits of using auto insertion machines are manifold; they improve overall production efficiency while maintaining high levels of accuracy. Automated Insertion Machines can handle complex tasks that would be time-consuming and error-prone if performed manually, allowing manufacturers to meet increasing demands without sacrificing quality. Moreover, these machines contribute to cost savings by reducing labor costs and minimizing material waste during the assembly process.

Bensun's Role in SMT Technology

Bensun plays a pivotal role in advancing Surface Mount Technology (SMT) through its innovative solutions tailored for PCB assembly. As a leader in providing state-of-the-art automated systems, Bensun offers reliable terminal inserters that enhance productivity and efficiency on assembly lines. By integrating cutting-edge technology into their products, Bensun helps manufacturers achieve seamless operations while adapting to evolving market needs.

Understanding Terminal Inserters

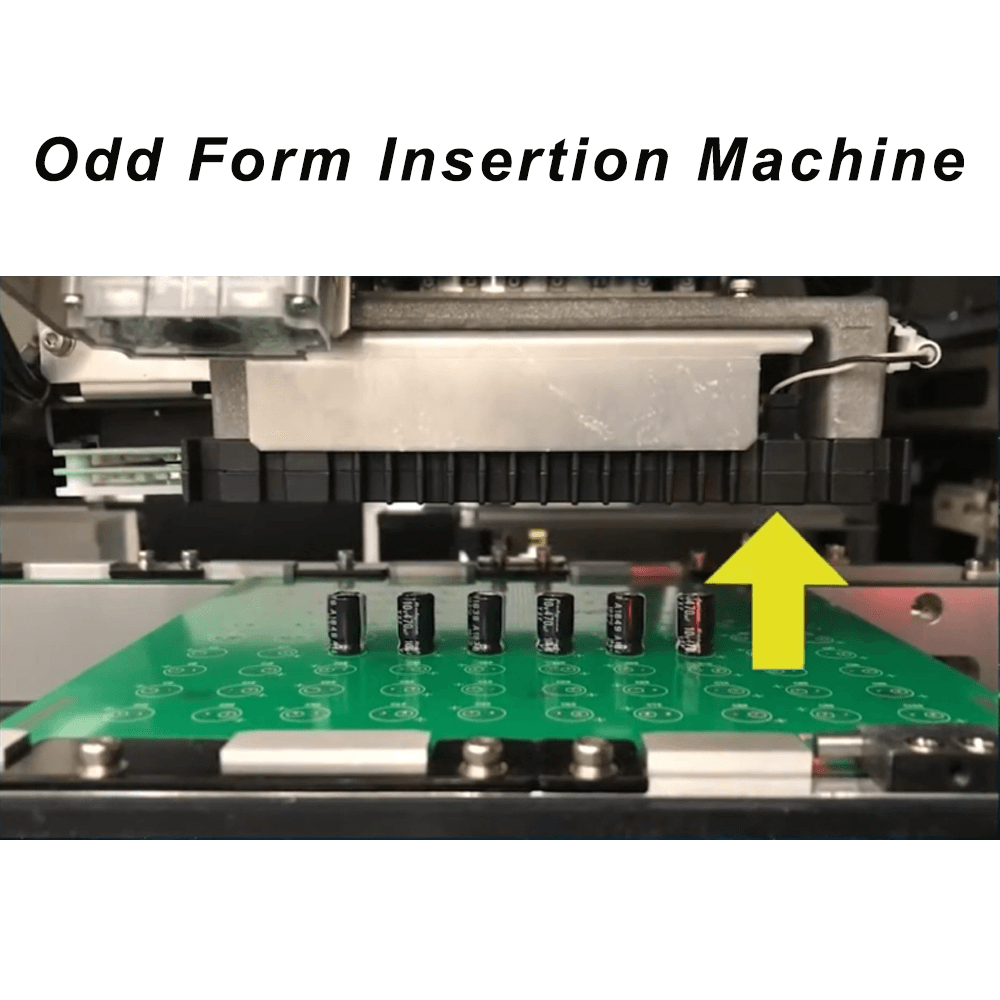

When diving into the world of PCB assembly, one cannot overlook the significance of terminal inserters. These devices are engineered to automate the insertion of components into printed circuit boards (PCBs), streamlining what was once a painstaking manual process. So, what is an insertion machine? It’s a specialized tool that enhances efficiency and accuracy in assembling electronic devices.

How Terminal Inserters Work

Terminal inserters operate through a combination of mechanical precision and automated processes. The machine feeds components from reels or trays, aligning them accurately before inserting them into designated holes on the PCB. This process significantly reduces human error and ensures each terminal is positioned correctly, which is crucial for maintaining quality in electronic assemblies.

The mechanism behind an Automated Insertion Machine involves various technologies such as vision systems for alignment and robotic arms for placement. These features allow the terminal inserter to adapt to different component sizes and types, making it versatile for various production needs. Ultimately, this automation translates to faster production times without compromising quality—perfect for modern manufacturing demands.

Key Features of Automated Insertion Machines

Automated Insertion Machines come packed with features that elevate their functionality beyond simple component placement. One standout feature is their ability to handle high-mix low-volume production runs efficiently; they can switch between different component types with minimal downtime. Additionally, many models include advanced programming capabilities that allow operators to customize settings based on specific project requirements.

Another key feature is integrated inspection systems that ensure every inserted terminal meets stringent quality standards before moving on to subsequent assembly stages. This not only enhances product reliability but also reduces waste by catching errors early in the process. With user-friendly interfaces and sophisticated data tracking systems, these machines make it easier than ever for manufacturers to keep tabs on production metrics.

Common Applications in PCB Assembly

The versatility of terminal inserters makes them indispensable in numerous applications within PCB assembly environments. From consumer electronics like smartphones and tablets to industrial equipment and automotive electronics, these machines play a critical role in ensuring components are inserted accurately and efficiently. Their ability to handle varying shapes and sizes of terminals means they can cater to diverse industries with unique requirements.

In addition, Auto Insertion Machines are frequently utilized in medical device manufacturing where precision is paramount due to regulatory standards and safety concerns. The consistency offered by automated insertion not only speeds up production but also assures compliance with rigorous industry guidelines—something manual processes struggle with under pressure. As technology continues evolving, so too will the applications for terminal inserters within PCB assembly lines.

Advantages of Automated Insertion Machines

In the fast-paced world of electronics manufacturing, automated insertion machines have become essential tools for efficiency and productivity. These machines, particularly terminal inserters, offer a multitude of benefits that enhance the overall assembly process. From improved precision to cost savings, understanding these advantages can help businesses make informed decisions about their production capabilities.

Enhanced Precision and Accuracy

One of the standout features of an automated insertion machine is its ability to deliver enhanced precision and accuracy in PCB assemblies. Unlike manual processes, where human error can lead to misalignment or faulty connections, a terminal inserter ensures that components are placed with exact specifications every time. This level of accuracy not only minimizes defects but also increases the reliability of the final product.

Automated insertion machines utilize advanced technology such as vision systems and precise mechanical movements to achieve this high level of accuracy. The result? A significant reduction in rework costs and an increase in overall production quality. For manufacturers looking to maintain a competitive edge, investing in an Auto Insertion Machine for PCB assemblies is a no-brainer.

Increased Production Speed

In today’s market, speed is often just as important as quality when it comes to manufacturing electronics. Automated insertion machines allow for rapid assembly processes that far surpass manual methods. By utilizing terminal inserters, companies can streamline their production lines and drastically reduce cycle times.

These machines are designed for high throughput without sacrificing quality, enabling manufacturers to meet tight deadlines while maintaining exceptional standards. With quick setup times and minimal downtime between runs, an Automated Insertion Machine can significantly boost overall productivity levels. It’s clear that when speed matters most, these machines are invaluable assets on the assembly line.

Cost Efficiency and Reduced Labor

Cost efficiency is another compelling advantage offered by automated insertion machines like terminal inserters. By automating labor-intensive tasks traditionally performed by workers, companies can reduce labor costs significantly while reallocating human resources to more strategic roles within the organization. This shift not only enhances productivity but also fosters a more innovative work environment.

Moreover, automated systems minimize material waste due to their precision placement capabilities—saving money on both components and rework expenses associated with errors in manual assembly processes. With lower operational costs and increased profitability potential, investing in an Auto Insertion Machine for PCB assemblies becomes a smart financial decision for any forward-thinking manufacturer seeking long-term success.

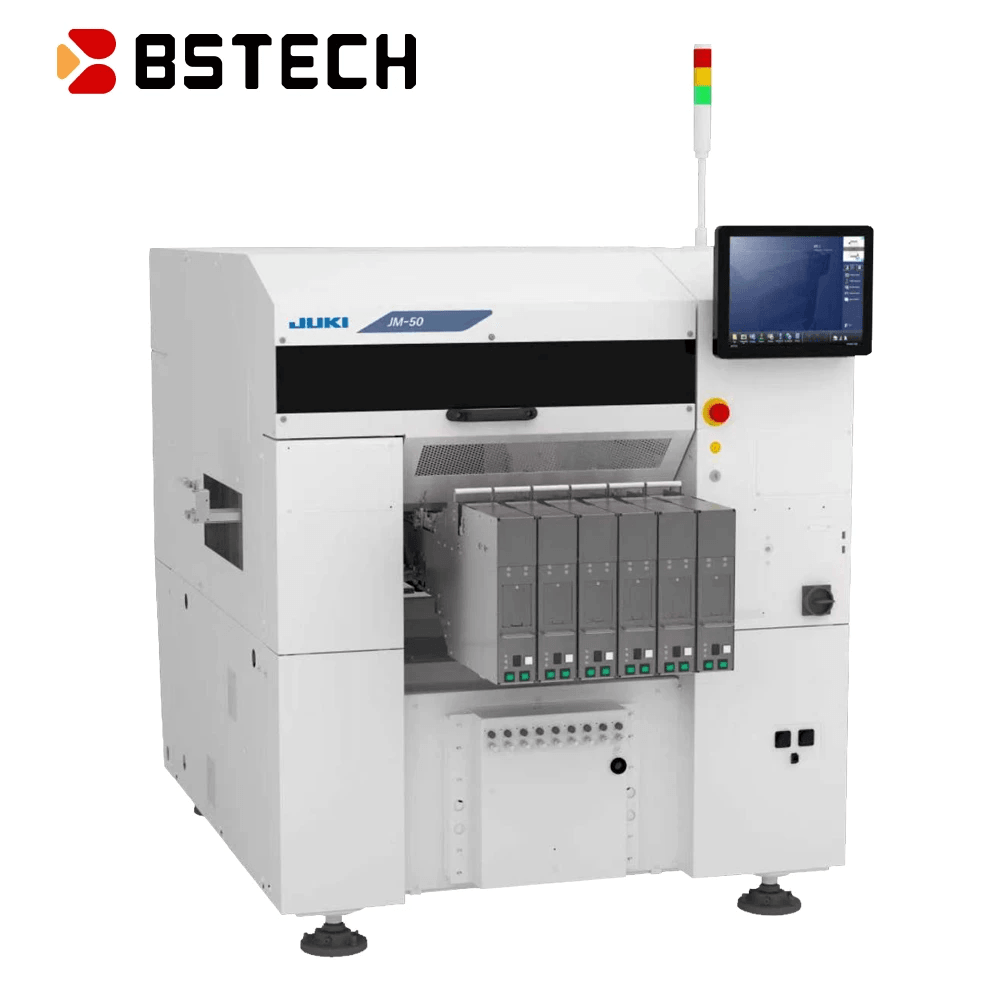

JUKI's JM-50 Insertion Machine

When it comes to the world of PCB assembly, JUKI's JM-50 insertion machine is a game changer. This automated insertion machine is designed for precision and efficiency, making it a top choice for manufacturers looking to enhance their production lines. With its innovative features tailored for terminal insertion, this machine represents a significant step forward in SMT technology.

Features of JUKI's JM-50

The JM-50 boasts a variety of features that set it apart from other auto insertion machines on the market. One notable aspect is its ability to handle various component types, including both through-hole and surface mount devices, ensuring versatility in PCB assemblies. Additionally, the machine incorporates advanced vision systems that enhance accuracy during the insertion process, minimizing errors and improving overall quality.

Another key feature is its user-friendly interface, which allows operators to easily program and adjust settings based on specific production needs. This flexibility makes the JM-50 suitable not just for high-volume runs but also for those more intricate high-mix low-volume productions that require quick changes between different component types. Furthermore, with its robust construction and reliable performance, this automated insertion machine promises longevity and reduced maintenance downtime.

Why It's Ideal for High-Mix Low-Volume Production

In today's fast-paced electronics market, manufacturers often face challenges when dealing with high-mix low-volume production runs. The JUKI JM-50 shines in this environment due to its adaptability; it can quickly switch between different terminal inserter configurations without extensive retooling or setup time. This feature allows companies to maintain productivity while catering to diverse customer demands without sacrificing quality.

Moreover, the speed at which this auto insertion machine operates does not compromise precision—each component is inserted accurately every time thanks to sophisticated algorithms that guide placement based on real-time feedback from sensors. As a result, businesses can achieve shorter lead times while ensuring their product quality remains top-notch—a crucial factor in maintaining competitive advantage in the electronics industry.

Lastly, with its compact design and efficient use of floor space, the JM-50 fits seamlessly into existing production lines without requiring extensive renovations or expansions. This makes it an attractive option for companies looking to optimize their operations without incurring significant overhead costs.

How JUKI's Machine Stands Out

What truly sets JUKI's JM-50 apart from other automated insertion machines is its blend of cutting-edge technology and practical functionality tailored specifically for PCB assembly processes. Unlike many competitors that focus solely on speed or volume output, JUKI has prioritized an integrated approach that emphasizes both efficiency and accuracy—essential qualities when considering what an insertion machine should deliver.

Additionally, the company’s commitment to ongoing innovation means that users benefit from regular software updates and enhancements that keep their machinery at the forefront of technology advancements in SMT manufacturing. This proactive approach ensures customers remain competitive by leveraging new capabilities as they become available.

Finally, JUKI’s exceptional after-sales support adds another layer of distinction; customers receive comprehensive training programs alongside responsive technical assistance whenever needed—an essential factor when investing in an automated insertion machine like the JM-50 for PCB assemblies.

The Evolution of SMT Technology

The evolution of Surface Mount Technology (SMT) has been a remarkable journey, marked by significant advancements that have transformed the way electronic components are assembled. From the early days of manual assembly to today's sophisticated automated solutions, the landscape of PCB manufacturing has changed dramatically. Understanding this evolution provides valuable insights into how terminal inserters and Auto Insertion Machines for PCB assemblies have become critical in modern production environments.

Historical Advances in SMT Equipment

In the beginning, PCB assemblies relied heavily on manual labor and rudimentary tools for component placement and soldering. As technology progressed, the introduction of automated machinery revolutionized the industry, allowing for faster production times and improved accuracy. Notably, the development of Automated Insertion Machines enabled manufacturers to efficiently place components with precision that was previously unattainable in manual processes.

The 1990s saw a surge in innovations within SMT equipment, leading to more compact and versatile machines capable of handling various component types and sizes. These advances paved the way for terminal inserters designed specifically for high-speed insertion tasks, further enhancing productivity on assembly lines. Today’s equipment boasts features like vision systems and real-time monitoring that ensure optimal performance and quality control during production.

Transitioning from Manual to Automated Processes

The shift from manual assembly to automated processes was driven by a need for efficiency and consistency in PCB manufacturing. Early adopters quickly recognized that employing an Automated Insertion Machine could drastically reduce human error while increasing throughput rates—an essential factor when meeting market demands. As manufacturers began integrating terminal inserters into their workflows, they experienced not only enhanced precision but also significant cost savings over time.

This transition wasn't merely about adopting new machines; it required a cultural shift within organizations as well. Workers needed training to operate these advanced systems effectively, leading to a new generation of skilled technicians proficient with high-tech equipment like Auto Insertion Machines for PCB assemblies. The result was an industry-wide transformation where automation became synonymous with quality assurance and operational excellence.

The Future of Assembly Line Automation

Looking ahead, the future of assembly line automation promises even more exciting developments as technology continues to evolve at an unprecedented pace. Innovations such as artificial intelligence (AI) integration into Automated Insertion Machines will likely enhance decision-making capabilities on the factory floor—predicting maintenance needs or optimizing workflows based on real-time data analysis is just around the corner!

Moreover, we can expect further improvements in terminal inserter designs that will accommodate increasingly complex circuit boards while maintaining speed and accuracy levels previously thought unattainable. With sustainability becoming a key focus across industries, future machines may also incorporate eco-friendly practices aimed at reducing waste during production processes.

As we venture further into this era of automation, one thing is certain: companies like Bensun are poised to lead this charge by continuously innovating within SMT technology frameworks while ensuring their clients remain competitive in an ever-evolving marketplace.

Choosing the Right Automated Insertion Machine

Selecting the right automated insertion machine can feel like finding a needle in a haystack, especially with so many options available. It’s essential to understand your specific needs and how different machines, including terminal inserters and auto insertion machines for PCB assemblies, can meet those requirements. This section will guide you through the critical factors to consider when making your choice.

Factors to Consider

When evaluating an automated insertion machine, first consider the scale of your production. Are you focused on high-mix low-volume production or mass manufacturing? Understanding your production volume will help you determine if you need a versatile terminal inserter or a more specialized automated insertion machine tailored for specific tasks.

Next, assess the types of components you'll be working with. Different machines handle varying sizes and shapes of components; some are better suited for through-hole components while others excel with surface-mounted devices. Compatibility with your existing PCB designs is crucial—after all, what is an insertion machine worth if it can't handle your parts?

Lastly, think about your budget and total cost of ownership. While initial purchase price is important, don't overlook factors like maintenance costs, energy consumption, and potential downtime. A cost-efficient automated insertion machine may save you money upfront but could lead to losses if it frequently malfunctions or lacks support.

Comparing Different Brands and Models

Once you've established your criteria, it's time to dive into comparing different brands and models of terminal inserters and auto insertion machines for PCB assemblies. Each manufacturer has its unique features that cater to various production needs—some may offer advanced automation capabilities while others focus on user-friendly interfaces.

Look at customer reviews and case studies; they provide invaluable insights into real-world performance that specifications alone can't convey. Additionally, consider the flexibility each model offers; machines that can adapt to changing production demands will provide long-term value as technology evolves.

Don’t forget about warranty terms and service packages when comparing models! A great warranty can save significant costs down the line if issues arise during operation.

The Importance of After-Sales Support

After-sales support is often an overlooked aspect when choosing an automated insertion machine but should never be underestimated! Reliable after-sales service ensures that any hiccups during operation are swiftly addressed without causing major disruptions in your assembly line workflow.

When selecting a terminal inserter or any other type of automated insertion machine for PCB assemblies, inquire about training programs offered by manufacturers as well as access to technical support teams post-purchase. Having knowledgeable staff available can make all the difference when troubleshooting unexpected challenges or optimizing performance settings.

Finally, ensure that replacement parts are readily available from suppliers or manufacturers so that maintenance doesn't turn into a lengthy ordeal down the road! An efficient after-sales support system not only enhances productivity but also provides peace of mind knowing you're covered in case anything goes awry.

Conclusion

In wrapping up our exploration of insertion machines, it’s clear that these devices play a crucial role in modern PCB assembly. Understanding what an insertion machine is and how it functions can significantly enhance the efficiency of production lines. As we’ve seen, automated insertion machines, particularly terminal inserters, offer a plethora of benefits that make them indispensable in today’s manufacturing landscape.

Key Takeaways on Insertion Machines

First and foremost, terminal inserters are designed to streamline the assembly process by automating the insertion of components into printed circuit boards (PCBs). This automation not only boosts precision but also accelerates production speed while reducing labor costs—key factors for any manufacturer looking to stay competitive. Ultimately, investing in an auto insertion machine for PCB assemblies is not just about keeping up; it’s about leading the charge toward greater efficiency and innovation.

The Future of Terminal Inserters

Looking ahead, the future of terminal inserters appears bright as technology continues to evolve at a rapid pace. We can expect advancements that will further enhance the capabilities of automated insertion machines, making them even more versatile and efficient for various applications. With trends leaning toward miniaturization and increased complexity in electronic designs, terminal inserters will undoubtedly adapt to meet these new challenges head-on.

How Bensun Enhances PCB Assembly Efficiency

Bensun stands out in this dynamic landscape by offering state-of-the-art solutions tailored for modern assembly needs. Their commitment to innovation ensures that their automated insertion machines not only meet industry standards but often exceed them—providing unmatched reliability and performance. By choosing Bensun's offerings, manufacturers can significantly enhance their PCB assembly efficiency while staying ahead of the competition.