Introduction

In the fast-paced world of electronics, SMT manufacturing has become a cornerstone of modern production. As technology evolves, the demand for efficient circuit board assembly processes continues to rise, emphasizing the need for streamlined operations that enhance productivity and quality. Understanding the essentials of printed circuit assembly is crucial for both seasoned professionals and newcomers in the industry.

Understanding SMT Manufacturing Essentials

Surface Mount Technology (SMT) manufacturing is a sophisticated process that involves mounting electronic components directly onto the surface of printed circuit boards (PCBs). This approach not only reduces space but also improves performance and reliability compared to traditional methods. To truly grasp SMT manufacturing, one must delve into its various stages, from component selection to final assembly, ensuring that each element contributes to a high-quality circuit card assembly.

The Importance of Circuit Board Assembly

The significance of circuit board assembly cannot be overstated; it serves as the backbone for virtually all electronic devices we rely on today. Printed circuit board assembly transforms raw materials into functional units that power everything from smartphones to industrial machinery. By focusing on efficient PCB assembly practices, manufacturers can enhance their product offerings while meeting stringent market demands.

Streamlining PCB Assembly for Efficiency

Streamlining PCB assembly is essential for optimizing production workflows and minimizing costs in SMT manufacturing environments. Techniques such as automation and lean methodologies can significantly reduce waste while improving turnaround times without sacrificing quality. Embracing these strategies not only boosts efficiency but also positions companies competitively within an ever-evolving landscape of electronic components and technologies.

Key Components of SMT Manufacturing

In the realm of SMT manufacturing, understanding the key components is crucial for achieving optimal performance and efficiency. Each element plays a significant role in the overall process, from the electronic components that power devices to the meticulous methods used in circuit card assembly. This section dives deep into these essential aspects, shedding light on their individual importance and interconnectivity.

Overview of Electronic Components

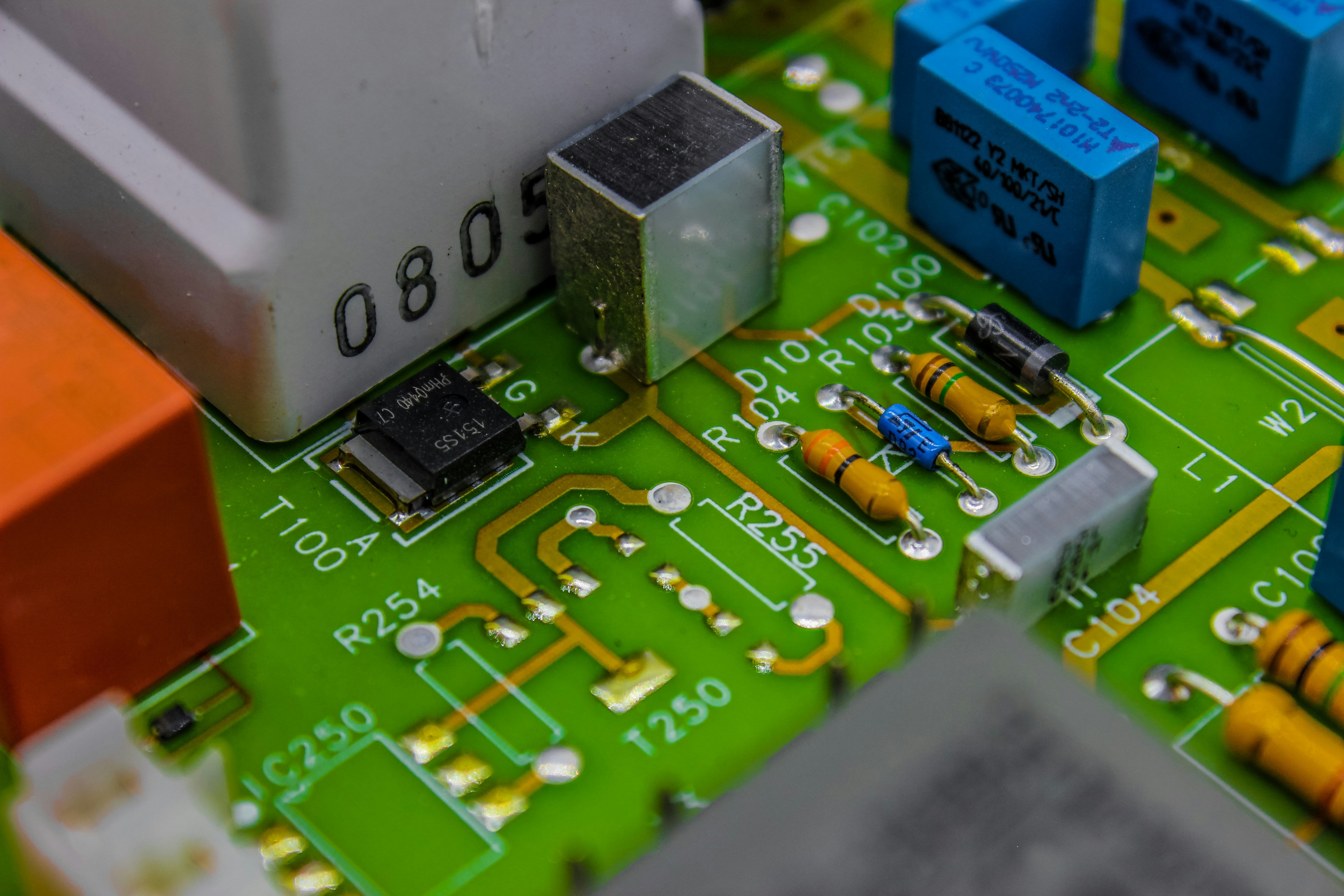

Electronic components are the building blocks of any circuit board, serving as vital elements that facilitate various functions within electronic devices. These include resistors, capacitors, diodes, and integrated circuits—each contributing uniquely to the overall performance of a printed circuit board assembly (PCB). In SMT manufacturing, selecting high-quality electronic components is paramount; they directly influence reliability and efficiency in circuit board assembly.

The integration of these components must be done with precision during PCB assembly to ensure that each part functions optimally within its designated role. For instance, resistors manage current flow while capacitors store energy for quick release when needed. Understanding how these electronic components interact helps manufacturers streamline processes and enhance product quality.

Role of Circuit Card Assembly

Circuit card assembly (CCA) serves as a critical phase in SMT manufacturing where electronic components are mounted onto a PCB to create functional assemblies. This process involves placing components accurately on the board's surface using specialized machinery like pick-and-place systems before soldering them into place through reflow techniques. The efficiency of circuit card assembly significantly affects production timelines and costs.

Moreover, CCA requires skilled technicians who ensure that each component is correctly aligned and securely attached to prevent future failures in operation. Effective management during this stage can reduce waste and improve yield rates—two key metrics for any successful PCB assembly operation. With advancements in technology, automation is increasingly playing a role in enhancing accuracy during circuit card assembly.

Importance of Printed Circuit Board Assembly

Printed circuit board assembly (PCBA) is where all the magic happens; it transforms raw materials into fully functional electronic products ready for market distribution. The importance of PCBA cannot be overstated—it’s not just about assembling parts but ensuring that every connection is flawless for optimal device functionality. In SMT manufacturing, effective PCB assembly processes lead to higher product reliability and customer satisfaction.

Furthermore, PCBA encompasses various stages including soldering techniques such as wave soldering or reflow soldering which are critical for establishing strong electrical connections between components on the board. Quality control during this phase ensures defects are minimized before products reach consumers, ultimately safeguarding brand reputation in competitive markets. As technology evolves, so do methods used in printed circuit board assembly—paving the way for innovations that enhance both speed and quality.

Best Tools for SMT Process Optimization

In the fast-paced world of SMT manufacturing, having the right tools can make a world of difference. From precision machines to quality inspection systems, optimizing your circuit board assembly process is essential for achieving high-quality printed circuit assembly. Let's dive into some top picks and benefits that can enhance your PCB assembly workflow.

Top Picks for Pick and Place Machines

When it comes to pick and place machines, efficiency and accuracy are paramount in circuit card assembly. Leading options like the Yamaha YSM Series and Panasonic NPM Series stand out for their speed and flexibility in handling various electronic components. These machines not only boost productivity but also ensure that components are placed with pinpoint accuracy on the printed circuit board, reducing the likelihood of errors during assembly.

Moreover, modern pick and place machines come equipped with advanced software that allows for real-time monitoring and adjustments during operation. This capability is particularly beneficial in high-volume production environments where quick changes may be necessary to adapt to different PCB designs or component types. Investing in top-tier pick and place technology ultimately translates to smoother operations, faster turnaround times, and enhanced overall quality in your SMT manufacturing process.

Benefits of Reflow Soldering Machines

Reflow soldering machines play a critical role in ensuring strong connections between electronic components on a circuit board. These machines use controlled heat profiles to melt solder paste applied to the printed circuit assembly before cooling it down to form solid joints between components and pads on the PCB. The precision of reflow soldering minimizes defects such as cold solder joints or bridging while maximizing reliability.

One significant advantage of modern reflow soldering systems is their ability to handle various types of solder materials, making them versatile tools for different applications within SMT manufacturing. Additionally, many models feature advanced temperature profiling capabilities that allow manufacturers to optimize their processes according to specific component requirements or product designs. This adaptability leads not only to improved quality but also supports efficient production lines tailored for diverse electronic projects.

Essential Visual Inspection Systems

To maintain high standards in PCB assembly, implementing effective visual inspection systems is crucial within SMT manufacturing environments. These systems utilize advanced imaging technology—such as 2D or 3D inspection—to detect defects early in the production process before they escalate into larger issues downstream. By identifying problems like misaligned components or insufficient solder coverage at this stage, manufacturers can save time and resources while ensuring product integrity.

Furthermore, integrating automated optical inspection (AOI) systems enhances consistency compared to manual inspections by providing faster feedback loops on quality control measures throughout circuit card assembly processes. The data gathered from these inspections can also inform future improvements by highlighting recurring issues or trends related to specific electronic components used across multiple projects. Ultimately, investing in robust visual inspection solutions fortifies overall product reliability while streamlining workflows within printed circuit board assembly operations.

Enhancing Workflow in PCB Assembly

In the fast-paced world of SMT manufacturing, enhancing workflow is crucial for maximizing productivity and ensuring high-quality output. By focusing on techniques that streamline processes, implementing lean principles, and embracing automation, companies can significantly improve their circuit board assembly operations. This section delves into effective strategies to optimize workflow in printed circuit assembly.

Techniques for Improving Efficiency

Improving efficiency in circuit board assembly begins with a thorough analysis of existing workflows to identify bottlenecks and redundancies. Techniques such as 5S methodology—Sort, Set in order, Shine, Standardize, Sustain—can help organize the workspace and promote a culture of continuous improvement among teams handling electronic components. Additionally, adopting real-time monitoring systems allows manufacturers to track production metrics closely and make informed adjustments swiftly.

Another effective strategy is cross-training employees across different roles within the PCB assembly line. This not only enhances flexibility but also fosters a collaborative environment where team members can share insights on improving processes involving printed circuit board assembly. Furthermore, utilizing visual management tools ensures everyone is aware of production targets and status updates at a glance.

Finally, regular feedback loops can help teams refine their methods continuously. By encouraging open communication about challenges faced during circuit card assembly processes, organizations can implement solutions faster and enhance overall efficiency in SMT manufacturing.

Implementing Lean Manufacturing Principles

Lean manufacturing principles are essential for any organization looking to optimize its PCB assembly process by eliminating waste while maximizing value. The core idea revolves around creating more value for customers with fewer resources by streamlining operations involved in printed circuit board assembly. Key lean tools like Value Stream Mapping (VSM) help visualize the flow of materials and information throughout the manufacturing process.

One significant aspect of lean implementation is focusing on just-in-time production techniques that align inventory levels with actual demand for electronic components used in circuit board assemblies. This minimizes excess inventory costs while ensuring that necessary parts are available when needed without delays or interruptions in production flow. Moreover, engaging employees at all levels fosters a culture where everyone contributes ideas toward continuous improvement efforts.

Lastly, incorporating kaizen events—short-term projects aimed at specific improvements—can drive rapid enhancements within the PCB assembly line by addressing targeted issues identified through ongoing assessments using lean principles. Ultimately, these methods lead not only to cost savings but also improved quality outcomes within SMT manufacturing environments.

Role of Automation in Circuit Board Assembly

Automation plays an increasingly vital role in enhancing workflow efficiency within circuit board assembly processes across various industries today. By integrating advanced technologies like robotics and artificial intelligence into SMT manufacturing practices, companies can achieve greater precision while reducing human error associated with manual tasks involved in electronic component placement or soldering activities during printed circuit board assembly.

Moreover, automated systems facilitate faster processing times by handling repetitive tasks such as pick-and-place operations more efficiently than human workers alone could manage without fatigue or loss of focus over extended periods—ensuring consistent quality throughout the entire production cycle of PCB assemblies! Additionally, real-time data analytics provided by automated solutions enable manufacturers to monitor performance metrics instantaneously; this allows them to make swift adjustments whenever necessary based on actual conditions rather than relying solely on historical data trends alone.

In conclusion, embracing automation not only streamlines workflows but also empowers teams working on complex projects related to circuit card assemblies across varied applications—from consumer electronics all the way through industrial machinery! As technology continues evolving rapidly within this space alongside growing demands from customers worldwide seeking innovative solutions tailored specifically for their needs—those who adapt will undoubtedly thrive!

Quality Control in SMT Manufacturing

Quality control is the backbone of successful SMT manufacturing, ensuring that every circuit card assembly meets high standards. In the world of printed circuit assembly, even a minor defect can lead to significant performance issues, making rigorous quality measures essential. By establishing robust quality control processes, manufacturers can guarantee reliability and longevity for their electronic components.

Establishing Standards for Electronic Components

Establishing stringent standards for electronic components is crucial in SMT manufacturing. These standards dictate the specifications and tolerances that each component must meet before being used in circuit board assembly. By adhering to these guidelines during printed circuit board assembly, manufacturers can reduce the likelihood of defects and ensure that all electronic components function seamlessly together.

Moreover, industry certifications such as IPC-A-610 provide a framework for evaluating the quality of solder joints and overall assembly integrity. This not only improves product reliability but also enhances customer satisfaction as clients receive high-quality circuit board assemblies tailored to their needs. Ultimately, setting these standards fosters a culture of excellence within PCB assembly operations.

Testing Methods for Circuit Board Assembly

Testing methods play a critical role in maintaining quality throughout the PCB assembly process. From automated optical inspection (AOI) to functional testing, various techniques are employed to identify defects early on in circuit card assembly. Implementing these testing procedures ensures that any issues with electronic components are caught before they escalate into costly problems.

In addition to AOI, X-ray inspection has become increasingly popular for detecting hidden solder joint defects within multilayer printed circuit boards. These advanced testing methods not only enhance reliability but also provide manufacturers with valuable data to improve future production runs in SMT manufacturing. By continuously refining their testing protocols, companies can achieve higher levels of efficiency and quality assurance.

Quality Assurance in PCB Manufacturing

Quality assurance is an ongoing commitment within PCB manufacturing that encompasses every stage from design to final inspection. It involves systematic monitoring and evaluation processes aimed at ensuring that all aspects of circuit board assembly meet established standards consistently over time. This proactive approach helps identify potential weaknesses early on and allows manufacturers to implement corrective actions swiftly.

An integral part of this process includes regular audits and reviews of both internal practices and supplier performance concerning electronic components used in production. Additionally, fostering a culture where employees are trained on best practices related to quality control plays a significant role in enhancing overall product integrity during printed circuit board assembly operations. As a result, companies engaged in SMT manufacturing can confidently deliver reliable products while maintaining customer trust.

Collaborating with Bensun Technology

In the ever-evolving landscape of SMT manufacturing, collaboration with specialized partners like Bensun Technology can significantly enhance your circuit board assembly processes. With a focus on innovation and efficiency, partnering with experts allows companies to leverage advanced techniques and tailored solutions that meet their unique needs in printed circuit assembly. This section delves into the custom solutions offered by Bensun Technology, the benefits of contract processing, and how to effectively utilize full production line services.

Custom Solutions for SMT Manufacturing

Bensun Technology excels in providing custom solutions tailored specifically for the intricate demands of SMT manufacturing. Whether you require specialized equipment or unique configurations for your electronic components, their expertise ensures that your circuit card assembly meets industry standards while optimizing performance. By offering bespoke designs in printed circuit board assembly, they help businesses reduce waste and improve overall efficiency in their PCB assembly operations.

Moreover, these custom solutions are not just about meeting current needs; they are designed with future scalability in mind. As technology advances and market demands shift, having a partner who can adapt and modify your circuit board assembly processes is invaluable. This adaptability allows businesses to stay competitive without constantly overhauling their entire production systems.

Benefits of Contract Processing

Contract processing offers a multitude of advantages for companies involved in SMT manufacturing, particularly when it comes to managing costs and resources efficiently. By outsourcing certain aspects of circuit card assembly to Bensun Technology, businesses can focus on their core competencies while benefiting from reduced overhead expenses associated with maintaining an extensive in-house operation. This strategic move enables companies to allocate more resources toward innovation while ensuring high-quality printed circuit board assembly.

Additionally, contract processing provides access to advanced technologies and skilled labor that may otherwise be unavailable or too costly for smaller firms to implement independently. With dedicated teams specializing in various facets of PCB assembly processes, Bensun ensures that quality control measures are consistently upheld throughout production runs. This level of expertise not only enhances product reliability but also fosters trust among clients who rely on precision-engineered electronic components.

Leveraging Full Production Line Services

When it comes to maximizing productivity within SMT manufacturing environments, leveraging full production line services from Bensun Technology can be a game-changer for many organizations. These comprehensive services encompass everything from initial design consultations through final inspection stages of circuit board assembly—streamlining the entire process under one roof enhances communication and minimizes delays often caused by coordinating multiple vendors.

Moreover, utilizing full production line services means integrating cutting-edge technologies at every step—from automated pick-and-place machines to sophisticated reflow soldering systems—ultimately resulting in higher throughput rates and lower defect levels within printed circuit board assemblies. The synergy created through this holistic approach not only improves operational efficiency but also elevates product quality across all electronic components produced.

In conclusion, collaborating with Bensun Technology offers substantial advantages across various dimensions of SMT manufacturing—from custom solutions tailored for specific needs to efficient contract processing models and comprehensive full production line services that streamline operations. Such partnerships pave the way for enhanced innovation while ensuring that your PCB assembly processes remain competitive in an increasingly demanding market landscape.

Conclusion

In the rapidly evolving landscape of SMT manufacturing, innovation is not just a buzzword; it's a necessity. The integration of advanced technologies and methodologies has revolutionized circuit card assembly, enabling manufacturers to produce more efficient and reliable printed circuit assemblies. As we move forward, these innovations will continue to shape the future of electronic components and their applications.

Innovations Driving SMT Manufacturing Forward

The latest advancements in SMT manufacturing are transforming how we approach circuit board assembly. From smart pick-and-place machines that optimize component placement to sophisticated software that enhances design accuracy, these innovations are crucial for improving production speed and quality. Moreover, new materials and techniques in printed circuit board assembly allow for more compact designs without sacrificing performance or reliability.

The Impact of Automation on Efficiency

Automation is a game-changer in the realm of PCB assembly, significantly enhancing efficiency across various stages of production. By automating repetitive tasks such as soldering and inspection, manufacturers can reduce human error while increasing throughput rates. This shift not only streamlines the entire process but also allows skilled workers to focus on more complex tasks that require critical thinking and creativity.

Future Trends in Circuit Board Assembly

Looking ahead, several trends are set to redefine circuit board assembly practices in SMT manufacturing. The rise of Industry 4.0 technology promises greater connectivity between machines, leading to smarter factories with real-time data analytics capabilities. Additionally, sustainability will play an increasingly vital role as manufacturers seek eco-friendly materials and processes in their printed circuit assembly efforts.