Introduction

In the fast-paced world of electronics, choosing the right SMT supplier can make or break a project. The SMT industry is fraught with challenges that can impact not only production timelines but also product quality and overall cost efficiency. Understanding these factors is crucial for making informed decisions in SMT manufacturing, ensuring that your production runs smoothly and effectively.

Importance of Choosing the Right SMT Supplier

Selecting an appropriate SMT supplier is paramount for any business involved in electronics manufacturing. A reliable partner can provide not just equipment but also expertise that enhances your overall production capabilities. In a competitive landscape where every detail counts, the right supplier becomes an invaluable asset in achieving success in SMT production.

Overview of SMT Manufacturing Challenges

The journey through SMT manufacturing is often riddled with obstacles, from sourcing quality components to managing intricate assembly processes. Manufacturers face pressure to reduce lead times while maintaining high standards of quality—an endeavor that requires adept handling of various challenges within the SMT industry. Understanding these hurdles allows businesses to better navigate their options when selecting an SMT supplier.

Key Factors to Consider in SMT Production

When evaluating potential suppliers, several key factors come into play that can significantly influence your decision-making process. These include the supplier's experience within the SMT industry, their quality assurance practices, and the range of technologies they have at their disposal for effective production solutions. By focusing on these critical elements, you can align your needs with a supplier capable of supporting your goals in SMT manufacturing.

Evaluating Supplier Experience

When it comes to selecting the right SMT supplier, experience is a crucial factor that often sets the best apart from the rest. The SMT industry is constantly evolving, and suppliers with a rich history in SMT manufacturing can offer insights and expertise that newer entrants simply cannot match. A well-established supplier will not only understand the nuances of SMT production but also have refined their processes through years of practical application.

Years in SMT Industry

The number of years an SMT supplier has been active in the industry can be a strong indicator of their reliability and capability. Suppliers with extensive experience are likely to have encountered various challenges in SMT manufacturing, allowing them to develop effective solutions over time. This depth of knowledge can translate into smoother production processes, reduced lead times, and ultimately, better products for your business.

Notable Clients and Projects

A supplier's portfolio speaks volumes about their expertise in SMT production. Notable clients and high-profile projects showcase a company's ability to handle diverse requirements and complex demands in the SMT industry. When considering an SMT supplier, look for case studies or testimonials from clients that highlight successful collaborations; these will give you confidence in their ability to deliver quality results tailored to your needs.

Industry Certifications and Compliance

In an era where quality assurance is paramount, industry certifications serve as proof of a supplier's commitment to excellence in SMT manufacturing practices. Certifications such as ISO 9001 or IPC standards indicate adherence to recognized benchmarks within the industry, ensuring that your chosen supplier meets stringent quality control measures. Furthermore, compliance with these standards not only enhances credibility but also reassures you that your products will be manufactured consistently at high quality levels.

Quality Assurance Practices

In the world of SMT manufacturing, quality assurance is not just a checkbox; it's the backbone of reliable production. Choosing an SMT supplier with robust quality assurance practices ensures that your products meet industry standards and customer expectations. A commitment to quality can significantly reduce defects, enhance reliability, and ultimately lead to greater customer satisfaction in the competitive SMT industry.

Testing and Inspection Protocols

An effective SMT supplier will have rigorous testing and inspection protocols in place throughout the smt production process. From initial component verification to final product testing, each stage should be meticulously monitored to catch any potential issues early on. This proactive approach not only minimizes waste but also enhances overall efficiency, ensuring that your products are built to last.

Certifications like ISO and IPC

Certifications such as ISO and IPC are critical indicators of a supplier's commitment to quality in the SMT industry. These certifications demonstrate adherence to international standards for quality management systems and electronic manufacturing processes, respectively. When evaluating potential suppliers, look for those who proudly display these certifications as a testament to their dedication to excellence in smt manufacturing.

Reputation for Reliability

A solid reputation for reliability is essential when selecting an SMT supplier; after all, you want partners who deliver consistently high-quality results without fail. Researching client testimonials, case studies, and industry reviews can provide valuable insight into a supplier’s track record in smt production. A reliable partner not only meets deadlines but also stands by their work—essential qualities in today’s fast-paced manufacturing landscape.

Range of Equipment and Technology

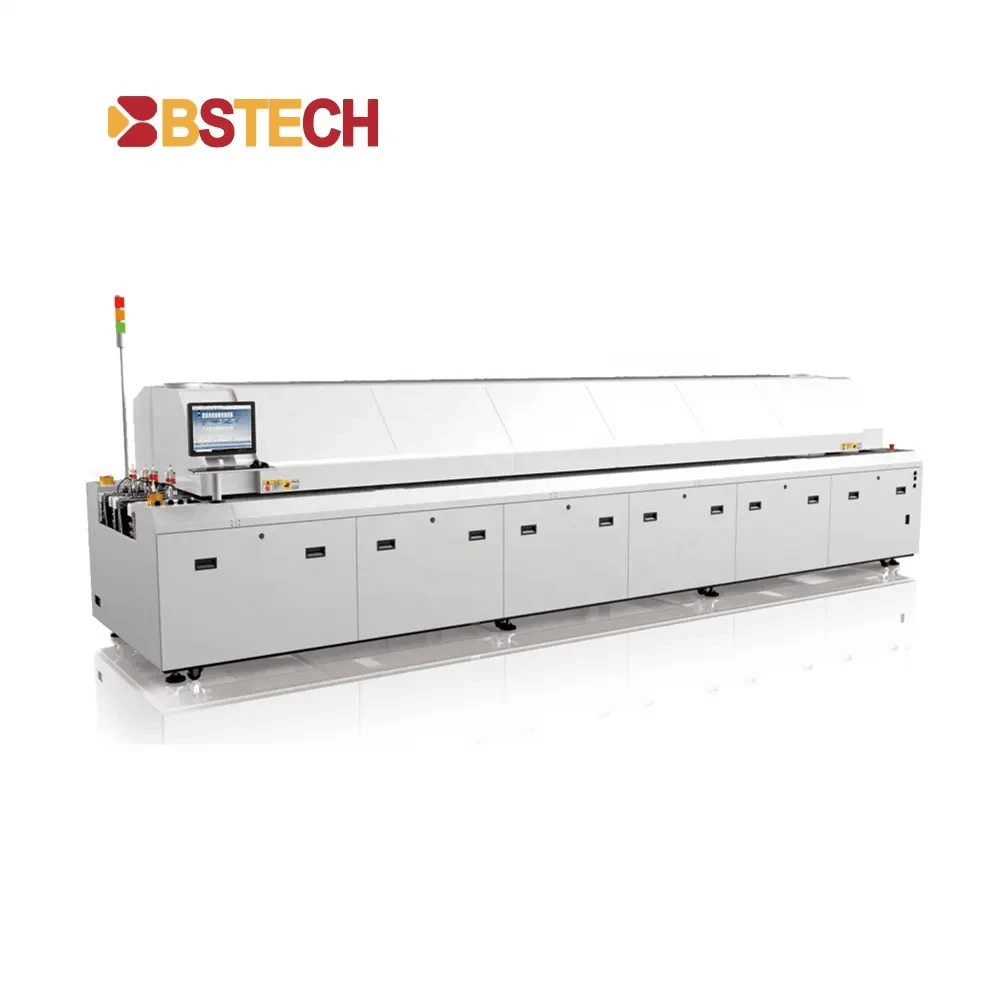

When it comes to SMT manufacturing, the range of equipment and technology available can significantly influence production efficiency and quality. A reliable SMT supplier will offer a comprehensive suite of machinery designed to meet various needs in the SMT industry. From pick-and-place machines to reflow ovens, understanding the types of equipment offered is crucial for any business looking to optimize its SMT production.

Types of SMT Production Equipment Offered

The types of SMT production equipment provided by suppliers can vary widely, but key categories include solder paste printers, pick-and-place machines, and inspection systems. Each piece plays a vital role in ensuring that components are placed accurately on printed circuit boards (PCBs). By choosing an SMT supplier that offers a diverse array of equipment, manufacturers can effectively streamline their operations and enhance overall productivity.

In addition to standard machinery, some suppliers may also provide specialized equipment for niche applications within the SMT industry. This could include automated optical inspection (AOI) systems or selective soldering machines tailored for specific project requirements. Understanding these offerings allows businesses to select an SMT supplier that aligns with their unique manufacturing needs.

Advanced Technologies in Use

The integration of advanced technologies into SMT manufacturing processes is transforming how companies operate within the industry. Suppliers that leverage cutting-edge innovations such as robotics, artificial intelligence (AI), and machine learning can offer significant advantages in terms of speed and precision. These technologies not only improve throughput but also enhance quality control measures throughout the production cycle.

Moreover, advancements like Industry 4.0 connectivity allow manufacturers to monitor their processes in real-time, providing valuable data insights for continuous improvement. An experienced SMT supplier will be at the forefront of adopting these technologies, ensuring that clients benefit from increased efficiency and reduced waste during their manufacturing processes. As you evaluate potential partners in the SMT industry, consider how well they incorporate these advanced technologies into their offerings.

Customization Options Available

Customization is increasingly important in today’s diverse market landscape; therefore, selecting an SMT supplier that offers tailored solutions can be a game-changer for many manufacturers. Whether it’s adapting existing machinery or creating bespoke setups designed specifically for unique projects, flexibility is key in modern SMT production environments. Suppliers who understand this need will often provide options for modifying equipment configurations or software interfaces based on client specifications.

Additionally, customization extends beyond just machinery; it includes support services like training programs tailored to specific operational needs or ongoing maintenance plans suited to varying production scales. By prioritizing suppliers who offer these options, businesses can ensure smoother integration into their existing workflows while maximizing output efficiency across all stages of production within the SMT industry.

In conclusion, evaluating a potential partner's range of equipment and technology is essential when selecting an appropriate SMT supplier for your manufacturing needs. With advancements driving change at every turn within this dynamic market space, having access to diverse tools along with customization capabilities will set your operation up for success now and into the future.

Support and Service Offerings

In the competitive world of SMT manufacturing, selecting a supplier that offers robust support and service is crucial for maintaining production efficiency. A reliable SMT supplier should not only provide top-notch equipment but also ensure that clients have access to ongoing assistance tailored to their specific needs. This commitment to support can significantly impact the overall success of SMT production processes.

Availability of Technical Support

When evaluating an SMT supplier, one of the most critical aspects is the availability of technical support. A responsive support team can help troubleshoot issues quickly, minimizing downtime in your SMT manufacturing operations. Look for suppliers who offer multiple channels for communication—such as phone, email, or live chat—to ensure you can reach them whenever a challenge arises.

Additionally, consider whether the technical support team has experience in the SMT industry and understands the intricacies of your specific production requirements. Having knowledgeable personnel available can make all the difference when it comes to resolving complex issues efficiently. Ultimately, strong technical support fosters a partnership where both parties work together to optimize SMT production outcomes.

Maintenance and Repair Services

Regular maintenance and timely repairs are essential components of successful SMT manufacturing operations. An effective SMT supplier should provide comprehensive maintenance services that help keep equipment running smoothly over time. This proactive approach not only extends the lifespan of machines but also reduces unexpected breakdowns that could disrupt production schedules.

Moreover, inquire about the availability of on-site repair services versus remote assistance options when evaluating potential suppliers. On-site repairs can save valuable time during critical situations where every minute counts in your manufacturing process. By ensuring your chosen supplier prioritizes maintenance and repair services, you enhance your operational efficiency while minimizing disruptions in your workflow.

Training for Equipment Use

Training is often an overlooked aspect when considering an SMT supplier; however, it plays a vital role in maximizing productivity within your manufacturing environment. A reputable supplier should offer comprehensive training programs designed to help your staff become proficient in using their equipment effectively. This investment in training ensures that employees are well-versed in operational best practices and safety protocols associated with SMT production.

Additionally, consider whether training sessions are available both on-site and online to accommodate different learning preferences among staff members. Continuous education opportunities from your supplier can further enhance skills over time as new technologies emerge within the SMT industry landscape. Prioritizing proper training ultimately empowers teams to operate machinery confidently while optimizing performance throughout various stages of production.

Cost-Efficiency and Flexibility

In the fast-evolving world of SMT manufacturing, cost-efficiency and flexibility are critical factors that can make or break a partnership with an SMT supplier. The ability to adapt to changing demands while maintaining budget constraints is essential for companies striving to stay competitive in the SMT industry. By understanding various pricing structures and options available, businesses can make informed decisions that align with their production goals.

Pricing Models and Payment Options

When evaluating potential SMT suppliers, one must consider the different pricing models they offer. Some suppliers may provide fixed pricing, which can help in budgeting for long-term projects, while others may have variable pricing based on volume or specific services rendered in SMT production. Additionally, flexible payment options such as installment plans or deferred payments can ease financial burdens and allow companies to allocate resources more effectively within the ever-competitive SMT industry.

Rental vs. Purchase Options

Choosing between renting or purchasing equipment is a significant decision for any business involved in SMT manufacturing. Renting allows companies to access advanced technology without committing large capital upfront, making it ideal for short-term projects or testing new processes in SMT production. On the other hand, purchasing equipment might be more cost-effective in the long run for businesses with consistent needs; understanding your operational requirements will clarify which option best suits your strategy within the dynamic landscape of the SMT industry.

Value for Money in SMT Manufacturing

Ultimately, value for money is paramount when selecting an SMT supplier; it's not just about getting the lowest price but ensuring that quality and service match your investment. An effective supplier will deliver reliable performance alongside competitive pricing structures that reflect their commitment to excellence in SMT manufacturing practices. By focusing on long-term relationships rather than short-lived deals, companies can ensure they receive not only great products but also ongoing support that enhances overall value.

Conclusion

In the ever-evolving landscape of the SMT industry, selecting the right SMT supplier is crucial for achieving success in SMT manufacturing. The key selection criteria outlined—supplier experience, quality assurance practices, equipment range, support services, and cost-efficiency—serve as a roadmap to navigate this complex terrain. By prioritizing these factors, businesses can ensure they partner with a supplier that not only meets their immediate needs but also aligns with their long-term goals in SMT production.

Recap of Key Selection Criteria

When evaluating an SMT supplier, it’s essential to consider their experience within the SMT industry and any notable projects they've undertaken. Quality assurance practices should also be scrutinized; certifications like ISO and IPC can indicate a commitment to excellence in SMT manufacturing. Additionally, assessing the range of equipment and technology available can help ensure that your chosen partner is equipped to handle diverse production demands efficiently.

Importance of Long-Term Supplier Relationships

Building a long-term relationship with an SMT supplier can yield significant benefits for your business in the competitive world of SMT manufacturing. Such partnerships foster trust and collaboration, allowing for smoother communication and quicker resolutions to issues that may arise during production. Moreover, established relationships often lead to better pricing models and greater flexibility in adapting to changing market conditions or technological advancements.

Future Trends in SMT Production and Partnerships

Looking ahead, trends such as automation and smart manufacturing are set to reshape the landscape of the SMT industry significantly. Suppliers who embrace advanced technologies will likely become invaluable partners as companies seek innovative solutions for efficient production processes. As businesses continue to prioritize sustainability alongside efficiency in their operations, selecting an adaptable and forward-thinking SMT supplier will be key in navigating these future challenges successfully.