Introduction

In the fast-paced world of electronics manufacturing, the need for precision and speed has never been more critical. Enter JUKI machines, renowned for their exceptional capabilities in surface mount technology (SMT) assembly. These powerhouse devices not only optimize production processes but also redefine what it means to achieve high-quality output in the industry.

Unleashing the Power of JUKI Machines

JUKI surface mount machines are engineered to streamline operations while delivering unparalleled accuracy. With advanced features that enhance both speed and efficiency, these machines have become a staple for manufacturers looking to stay ahead of the competition. By leveraging JUKI technology, businesses can maximize their production potential and reduce downtime significantly.

Why Choose JUKI for SMT Assembly?

The answer often points to JUKI due to its proven track record of reliability and innovation. Manufacturers benefit from using JUKI feeders that complement these machines, ensuring seamless integration within their assembly lines.

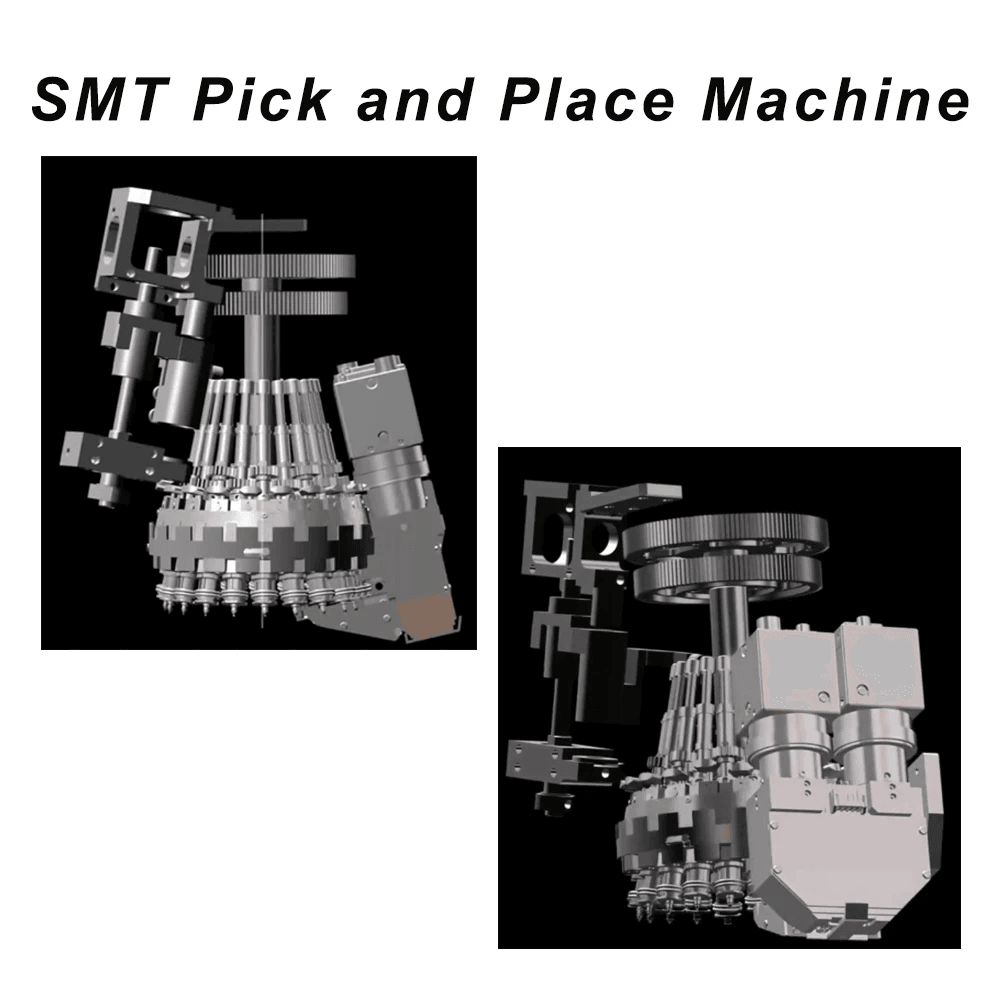

A Quick Look at JUKI Technology

JUKI's commitment to excellence is evident in its cutting-edge technology that powers its pick and place machines. These devices are designed not just for performance but also for adaptability in various manufacturing environments. Additionally, understanding the nuances of JUKI pick and place machine prices can help companies make informed decisions about investing in quality equipment that stands the test of time.

Understanding JUKI Surface Mount Machines

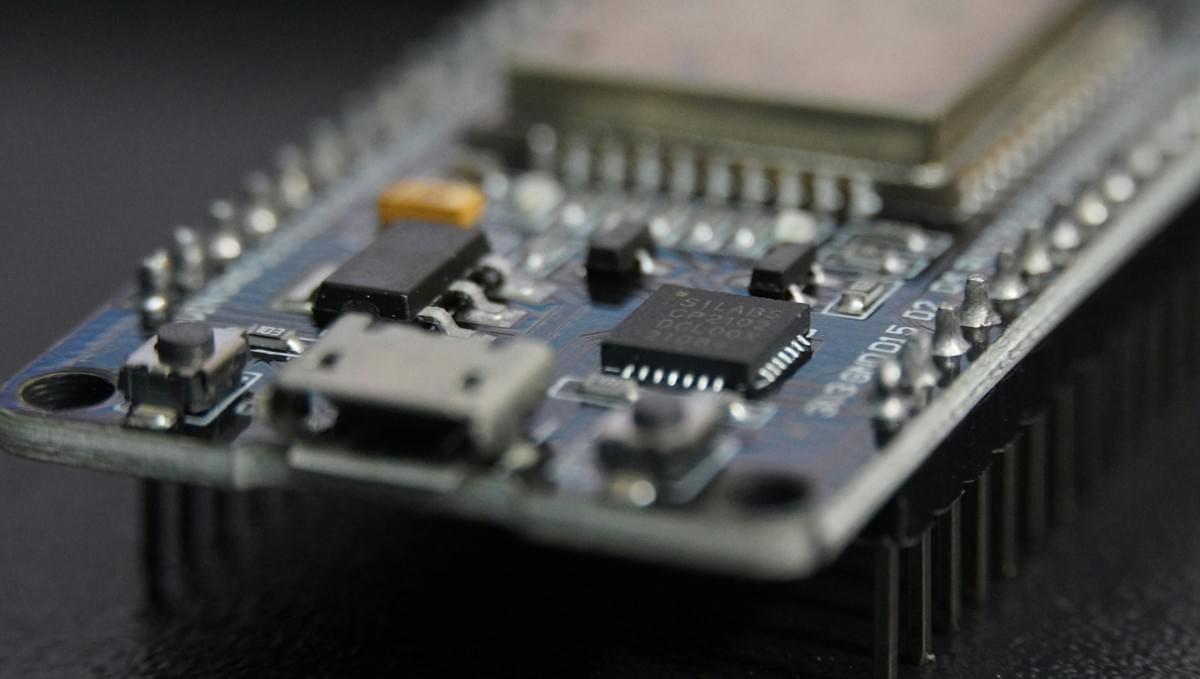

Features of JUKI Surface Mount Machines

JUKI surface mount machines boast a range of impressive features that cater to the needs of various industries. One standout characteristic is their high-speed placement capability, which allows for rapid assembly without compromising accuracy. Additionally, these machines come equipped with advanced vision systems that ensure precise component alignment and placement, making them ideal for complex circuit boards.

Moreover, JUKI feeders play a crucial role in enhancing machine efficiency by enabling quick changeovers between different component types. This flexibility is invaluable for manufacturers who need to adapt quickly to changing production demands or product designs. With options for both manual and automatic setups, JUKI surface mount machines provide an unparalleled user experience tailored to fit any production environment.

Key Benefits for Manufacturers

The advantages of using JUKI surface mount machines extend beyond just their features; they translate into significant benefits for manufacturers as well. First and foremost, the speed and accuracy facilitated by these machines lead to increased production rates—an essential factor in meeting tight deadlines and customer expectations. As we delve into “What is the top SMT machine brand?”, it becomes evident that JUKI’s reputation lies not only in its technological prowess but also in its ability to deliver results.

Another key benefit is cost-effectiveness over time; while initial investments like the JUKI Pick and Place Machine price may seem high, these systems often result in lower operational costs due to reduced labor needs and minimized material waste. Furthermore, with ongoing advancements in technology, investing in a JUKI machine means staying ahead of industry trends—ensuring your facility remains competitive now and into the future.

JUKI SMT Machines in Action

To truly appreciate the capabilities of JUKI SMT machines, one must see them in action on the factory floor. These machines are not just theoretical marvels; they have been successfully implemented across various sectors including consumer electronics, automotive components, and medical devices—showcasing their versatility across different manufacturing environments.

For example, a leading electronics manufacturer recently reported a 30% increase in output after integrating a series of JUKI surface mount machines into their assembly line—a clear testament to how effective these technologies can be when properly utilized alongside optimized processes involving JUKI feeders.

Ultimately, whether you’re considering your first investment or looking to upgrade existing equipment with what is widely regarded as one of the top SMT machine brands on the market today—JUKI provides solutions that not only meet but exceed industry standards.

The Rise of High-Speed Assembly

In the fast-paced world of manufacturing, speed is not just a luxury—it's a necessity. Companies are increasingly recognizing that the ability to produce goods quickly can significantly impact their bottom line and market competitiveness. This is where high-speed assembly comes into play, revolutionizing production lines across various industries.

Importance of Speed in Manufacturing

Speed in manufacturing translates directly to efficiency and profitability. As consumer demands grow and markets evolve, manufacturers must adapt by streamlining operations without sacrificing quality. In this context, the JUKI surface mount machine stands out as a pivotal tool for businesses aiming to increase output while maintaining high standards.

Moreover, rapid production cycles allow companies to respond swiftly to market changes and customer needs, giving them a competitive edge over slower rivals. The faster you can assemble products, the quicker you can deliver them to your customers—leading to higher satisfaction rates and repeat business. Thus, investing in high-speed assembly technologies is no longer optional but essential for survival in today's dynamic marketplace.

How JUKI Machines Enhance Production Rates

JUKI machines are engineered specifically for speed without compromising precision or reliability. With advanced features like high-speed placement capabilities and sophisticated software integration, these machines optimize every aspect of the assembly process. For instance, JUKI feeders ensure that components are delivered efficiently to the pick-and-place mechanism, drastically reducing downtime during production runs.

Additionally, innovations such as automated calibration and real-time monitoring contribute significantly to enhanced production rates with JUKI equipment. These features allow manufacturers to maintain consistent quality while ramping up output levels—a combination that makes JUKI one of the top SMT machine brands on the market today. By leveraging these advantages, businesses can achieve impressive throughput while minimizing operational costs.

Case Studies of Successful Implementations

Numerous manufacturers have successfully integrated JUKI surface mount machines into their production lines with remarkable results. One notable example involved an electronics company that faced challenges with slow assembly times due to outdated equipment. After upgrading to a state-of-the-art JUKI pick-and-place machine, they reported a 50% increase in output within just three months—a clear testament to how investing in quality machinery can pay off.

Another case study highlights how a telecommunications manufacturer improved its product cycle time by implementing JUKI feeders alongside their existing systems. By optimizing feeder usage and ensuring seamless integration with their existing workflow, they achieved faster setup times and reduced material waste significantly—demonstrating that even small enhancements can lead to substantial gains when using top-tier SMT technology.

In conclusion, embracing high-speed assembly through advanced solutions like those offered by JUKI not only boosts productivity but also positions companies favorably within competitive markets.

What is the Top SMT Machine Brand?

In the bustling world of surface mount technology (SMT), the question arises: what is the top SMT machine brand? While numerous players vie for attention, JUKI consistently stands out as a leader in innovation, performance, and reliability. The JUKI surface mount machine line offers manufacturers unparalleled efficiency and quality, making it a favorite among industry professionals.

JUKI vs. Competitors

When comparing JUKI to competitors like Panasonic and Yamaha, one quickly realizes that JUKI machines are engineered with precision and user-friendliness in mind. The JUKI Pick and Place Machine features advanced technology that enables faster placement speeds without sacrificing accuracy—a crucial factor for any manufacturer aiming to stay ahead. Furthermore, while competitors may offer similar functionalities, the seamless integration of JUKI feeders enhances overall operational efficiency, solidifying its position as a top contender in the SMT market.

Market Share and Recognition

JUKI has carved out a significant share of the global market for surface mount machines, with recognition stemming from years of reliable performance and customer satisfaction. Reports indicate that JUKI holds one of the largest shares in this competitive landscape, thanks to its commitment to innovation and quality manufacturing standards. This impressive market presence not only underscores their reputation but also highlights why many manufacturers consider them when looking for what is the top SMT machine brand.

Innovations that Set JUKI Apart

What truly sets JUKI apart from its competitors are its continuous innovations that push boundaries within SMT assembly technology. For example, advancements in their feeder systems have revolutionized how components are handled during assembly—making it easier to switch between different types without losing productivity. Moreover, their ongoing investment in R&D ensures that every new model of their surface mount machines incorporates cutting-edge features designed to enhance speed and accuracy—attributes essential for modern manufacturing environments.

JUKI Pick and Place Machine Price Analysis

When considering the investment in a JUKI pick and place machine, understanding the price structure is crucial. The cost of these machines can vary significantly based on several factors, including features, speed, and technology enhancements. Manufacturers must weigh these variables against their production needs to make an informed decision.

Factors Influencing JUKI Machine Prices

Several factors play a pivotal role in determining the price of JUKI surface mount machines. First, the model's capabilities—such as placement speed, accuracy, and component handling—can dramatically affect pricing. Additionally, optional upgrades like advanced software for better automation or enhanced JUKI feeders can add to the overall cost but may increase efficiency and output.

Another important factor is market demand; as more manufacturers seek high-speed assembly solutions, competitive pricing may fluctuate accordingly. The age of the technology also matters; newer models with innovative features typically command higher prices than their older counterparts. Ultimately, understanding these factors will help businesses gauge what they are willing to invest when searching for what is the top SMT machine brand.

Investing in Quality: Is It Worth It?

Investing in a quality JUKI pick and place machine often pays off in the long run due to increased productivity and reduced downtime. While initial costs might seem steep compared to lower-end models from other brands, the reliability and performance of JUKI machines can lead to significant savings over time. High-quality equipment minimizes maintenance issues and maximizes production rates—an essential consideration for any manufacturer aiming for success in today's competitive landscape.

Moreover, opting for top-tier machinery means fewer errors during assembly processes thanks to superior technology integration. This translates into less rework needed on defective boards, ultimately saving both time and money on labor costs associated with fixing mistakes made by inferior machines. Therefore, investing in a JUKI surface mount machine should be viewed not just as an expense but as a strategic move toward enhancing your manufacturing capabilities.

Budgeting for Your SMT Equipment

Budgeting effectively for your SMT equipment requires careful consideration of all associated costs beyond just purchasing the machine itself. When planning your budget for a JUKI pick and place machine, it's essential to account for installation fees, training expenses for staff on using advanced features like JUKI feeders effectively, and ongoing maintenance costs that come with operating sophisticated machinery over time.

Additionally, consider potential financing options that could ease upfront financial burdens while allowing you to benefit from enhanced assembly capabilities immediately. It's wise to include contingencies in your budget plan since unexpected expenses can arise during setup or initial operations that may require additional funds or resources allocated towards training staff or upgrading software systems.

In conclusion, being proactive about budgeting ensures you’re prepared not only financially but also strategically when integrating high-quality SMT equipment into your operations—a critical step toward staying competitive within your industry.

Maximizing Efficiency with JUKI Feeders

When it comes to enhancing the performance of JUKI surface mount machines, the role of JUKI feeders cannot be overstated. These feeders are essential components that ensure precise and efficient placement of components during the SMT assembly process. By leveraging advanced technology, JUKI feeders contribute significantly to overall production efficiency and quality.

Overview of JUKI Feeders

JUKI feeders are designed to work seamlessly with their range of surface mount machines, providing reliable feeding mechanisms for various component types. These feeders come in different configurations, including tape, tray, and bulk options, catering to diverse manufacturing needs. The precision engineering behind each feeder ensures that components are delivered accurately and consistently, which is crucial for maintaining high-quality standards in SMT assembly.

Tips for Optimizing Feeder Use

To maximize the potential of your JUKI feeders, consider implementing a few best practices. First, regularly calibrate your feeders to maintain accuracy in component placement; this simple step can significantly reduce errors during production runs. Additionally, organizing your component inventory effectively allows for quicker changes between jobs—this is particularly beneficial when working with multiple JUKI surface mount machines that require rapid setup adjustments.

Another tip is to utilize feeder management software that tracks usage patterns and alerts you when maintenance is needed or when stocks are low. This proactive approach not only extends the lifespan of your equipment but also minimizes downtime—an essential factor in determining what is the top SMT machine brand in terms of productivity.

Real-world Examples of Increased Efficiency

Numerous manufacturers have reported significant improvements in their assembly lines after optimizing their use of JUKI feeders alongside their pick and place machines. For instance, a leading electronics manufacturer increased its production rate by 30% after implementing a systematic feeder calibration routine across its fleet of JUKI surface mount machines. Similarly, another company noted that integrating smart feeder management software led to a 25% reduction in material waste due to better tracking and organization.

These real-world examples underline how investing time into optimizing feeder use can yield substantial returns on efficiency and productivity—factors that define what makes JUKI one of the most sought-after brands in SMT technology today.

Conclusion

In the fast-paced world of electronics manufacturing, leveraging the right technology can make all the difference. JUKI surface mount machines stand out as a beacon of innovation and reliability, providing manufacturers with a competitive edge. With their advanced features and proven performance, JUKI machines are not just tools; they are essential partners in achieving operational excellence.

A Competitive Edge with JUKI Technology

When it comes to what is the top SMT machine brand, JUKI consistently rises to the occasion. Their surface mount machines integrate cutting-edge technology that enhances speed and precision, allowing manufacturers to stay ahead of the curve. By investing in JUKI feeders and other components, businesses can optimize their assembly lines for maximum efficiency.

The reputation of JUKI as a leader in SMT technology is not merely based on marketing hype; it's backed by years of innovation and customer satisfaction. With features like automatic placement accuracy and flexibility for various component types, JUKI machines ensure that your production process remains agile and responsive to market demands. This competitive edge translates into higher productivity rates and reduced time-to-market for new products.

Investing in the Future of Assembly

Investing in a JUKI pick and place machine is an investment in your company’s future success. As manufacturing processes evolve, having reliable equipment becomes paramount for maintaining competitiveness in an ever-changing landscape. The initial cost associated with acquiring a JUKI surface mount machine often pays off through increased production rates and lower operational costs over time.

Moreover, as you consider JUKI pick and place machine prices, think about the long-term benefits rather than just upfront expenses. High-quality machinery minimizes downtime due to fewer malfunctions or maintenance issues—this means more time spent producing rather than repairing or troubleshooting equipment failures. Ultimately, choosing JUKI signals your commitment to quality and innovation within your assembly operations.

Why Bensun is Your Go-To JUKI Supplier

When it comes to sourcing your next piece of equipment from a reliable partner, look no further than Bensun for your JUKI needs. With extensive knowledge about all things related to juki feeders, we provide tailored solutions that fit your specific requirements while maximizing efficiency on the production floor. Our dedicated team ensures you receive not just equipment but also ongoing support throughout your journey with us.

Bensun understands that choosing what is the top SMT machine brand requires careful consideration—therefore we prioritize transparency regarding pricing structures like those associated with various models of JUKI pick and place machines available on our platform. Our commitment goes beyond sales; we aim to build lasting relationships where our clients feel supported every step of the way toward achieving their manufacturing goals.

In conclusion, embracing JUKI technology through Bensun can be transformative for your assembly processes—so why wait? Elevate your operations today by making informed decisions backed by expertise!