Introduction

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. Enter the Juki Pick and Place Machine, a game-changer that revolutionizes the way components are placed on printed circuit boards (PCBs). With its advanced technology, this machine not only enhances production speed but also ensures remarkable accuracy—a must-have for any modern soldering operation.

Discover the Juki Pick and Place Machine

The Juki Pick and Place Machine stands out in a crowded market with its exceptional features tailored for high-volume production. It boasts an impressive ability to handle various component sizes and types, making it versatile for different projects. Whether you’re working with small electronic devices or complex machinery, this pick & place machine adapts seamlessly to your needs.

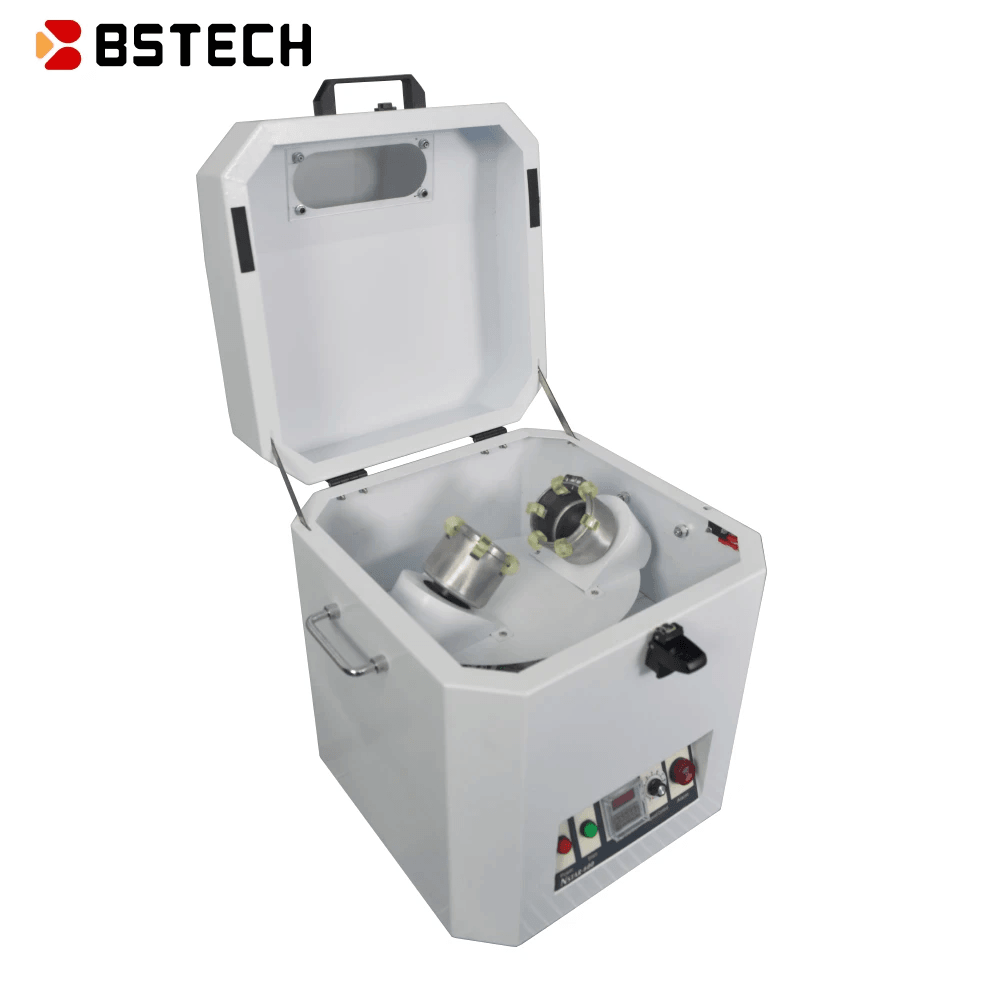

Why Choose Bensun Technology

When considering investment in a soldering machine like the Juki Pick and Place Machine, partnering with Bensun Technology is a smart choice. Their expertise in providing top-notch machinery ensures that you receive not only a quality product but also unparalleled support throughout your journey. With Bensun's commitment to customer satisfaction, you can rest assured knowing you're making a long-term investment in your production capabilities.

Unpacking Advanced Soldering Solutions

Advanced soldering solutions encompass more than just machines; they include processes like reflow soldering and essential components such as solder paste inspection systems. The integration of these technologies optimizes overall efficiency while maintaining high standards of quality control in manufacturing processes. By choosing solutions from Bensun Technology, you're not just purchasing equipment—you're investing in comprehensive systems designed to elevate your production line's performance.

Overview of the Juki Pick and Place Machine

The Juki Pick and Place Machine stands at the forefront of modern manufacturing technology, designed to streamline the assembly process with precision and efficiency. This machine is engineered to handle a variety of components, making it a versatile choice for manufacturers looking to enhance their production capabilities. By integrating advanced features, the Juki pick and place machine not only improves output but also ensures high-quality results.

Key Features and Benefits

One of the standout features of the Juki pick and place machine is its exceptional accuracy in component placement, which minimizes errors during assembly. With an impressive speed that allows for rapid production cycles, this soldering machine can significantly reduce lead times while maintaining quality standards. Additionally, its user-friendly interface simplifies operation, making it accessible for both seasoned professionals and newcomers in the field.

Another notable benefit is its adaptability; whether you're dealing with small-scale projects or large-volume productions, this machine can be configured to meet your specific needs. The integration of solder paste inspection technology enhances reliability by ensuring that each component receives optimal solder coverage before reflow soldering occurs. This feature alone can save manufacturers from costly mistakes caused by inadequate solder application.

Efficiency and Precision in Production

Efficiency is key in any manufacturing environment, and the Juki pick and place machine excels in this regard by combining speed with precision. Its advanced algorithms optimize placement strategies, allowing for quick adjustments based on component types or sizes without sacrificing accuracy. This level of efficiency translates into higher throughput rates, enabling companies to fulfill orders faster than ever before.

Moreover, precision is not just about speed; it's also about ensuring every component is placed correctly every time. The Juki's cutting-edge vision systems facilitate real-time monitoring during production runs, providing immediate feedback if any discrepancies arise during assembly processes like reflow soldering. This proactive approach helps maintain quality control throughout production cycles.

Comparative Analysis with Other Machines

When comparing the Juki pick and place machine price with other machines on the market, it's clear that you get what you pay for—exceptional quality at a competitive rate. While some budget options may seem appealing initially due to lower costs, they often lack essential features such as integrated solder paste inspection or advanced programming capabilities found in Juki models. In contrast, investing in a high-quality pick & place machine pays off through increased reliability and reduced operational costs over time.

Additionally, many alternatives struggle to match Juki's efficiency levels—especially when handling complex boards or diverse component types that require quick adaptability during production runs. Some machines may offer similar specifications on paper but fall short during practical applications due to outdated technology or inefficient workflows. Ultimately, choosing a Juki means opting for longevity and performance that outshine many competitors in today's fast-paced manufacturing landscape.

Understanding Juki Pick and Place Machine Price

When considering the investment in a Juki pick and place machine, understanding the price structure is crucial. The cost of these machines is influenced by various factors, including technology, features, and market demand. It’s essential to analyze these aspects to make an informed decision that aligns with your production goals.

Factors Influencing Pricing

The pricing of a Juki pick and place machine is determined by several key factors. First, the technological advancements integrated into the machine play a significant role; more sophisticated models equipped with advanced features like high-speed operation or enhanced solder paste inspection capabilities tend to be pricier. Additionally, brand reputation and support services also influence pricing; investing in a well-regarded brand like Juki often means better reliability and customer support down the line.

Another important consideration is the scale of production; larger operations may require more complex machines that can handle higher volumes efficiently, leading to higher costs. Furthermore, optional add-ons such as reflow soldering compatibility or specialized feeders can also increase the overall price of the pick & place machine. Therefore, understanding your specific needs will help clarify which features justify their associated costs.

Cost-Effectiveness vs. Quality

When it comes to soldering machines like those from Juki, striking a balance between cost-effectiveness and quality is paramount. While cheaper alternatives may seem appealing initially due to their lower juki pick and place machine price tags, they often compromise on performance or longevity. Investing in a high-quality machine ensures reliability in production processes, reducing downtime caused by equipment failure.

Moreover, quality machines typically come with enhanced features that improve overall efficiency—such as superior solder paste inspection systems—which can lead to significant savings over time through reduced waste and increased output consistency. In many cases, choosing quality over cost upfront translates into long-term financial benefits for businesses looking to optimize their manufacturing processes with reliable pick & place machinery.

In conclusion, while it might be tempting to opt for lower-priced options when purchasing a soldering machine, consider how much you value precision and durability in your production line before making your final decision.

Long-Term Investment Considerations

Investing in a Juki pick and place machine should be viewed as a long-term commitment rather than just an immediate expense. The initial juki pick and place machine price may appear steep compared to other options available on the market; however, this investment pays off through improved efficiency and productivity over time. By ensuring consistent performance across various manufacturing tasks—including reflow soldering—you’ll find that operational costs decrease significantly.

Further emphasizing long-term investment considerations is how well these machines integrate with modern automation systems for enhanced productivity gains—think about future-proofing your operations! Choosing equipment that seamlessly incorporates advanced technologies not only prepares you for industry advancements but also provides flexibility as your business grows or shifts direction.

Ultimately, when evaluating any potential purchase within your production setup—including machinery like the juki—consider how each piece contributes toward achieving broader business objectives over years rather than months alone.

The Role of Solder Paste Inspection

In the world of electronics manufacturing, solder paste inspection plays a pivotal role in ensuring product quality and reliability. This critical step helps detect defects early in the production process, preventing costly errors down the line. By implementing effective solder paste inspection, manufacturers can significantly reduce rework and improve overall efficiency.

Importance in the Manufacturing Process

Solder paste inspection is essential for identifying issues such as insufficient or excessive solder paste application on printed circuit boards (PCBs). These discrepancies can lead to poor electrical connections or even complete failures of electronic devices, which could be disastrous for businesses. Ultimately, a robust inspection process not only enhances product quality but also safeguards a company's reputation and bottom line.

How Juki Enhances Inspection Efficiency

Juki has integrated advanced technologies into its pick and place machines to streamline solder paste inspection processes. With high-resolution cameras and sophisticated algorithms, Juki's systems can quickly identify inconsistencies in solder application, ensuring that every component is placed correctly. This level of precision minimizes human error and maximizes production efficiency—key factors that influence juki pick and place machine price.

Integrating Inspection with the Pick and Place Machine

Integrating solder paste inspection directly into the juki pick and place machine workflow offers unparalleled advantages for manufacturers. By aligning these two processes, companies can achieve real-time feedback on their production lines, allowing for immediate corrections when needed. This seamless integration not only enhances overall productivity but also positions manufacturers to adopt more automated solutions like reflow soldering with confidence.

Enhancing Production with Reflow Soldering

Reflow soldering is a crucial process that complements the capabilities of Juki pick and place machines, creating a streamlined assembly line for electronic manufacturing. By integrating reflow soldering with the precision of Juki equipment, manufacturers can achieve higher efficiency and quality in their production processes. Not only does this combination reduce production time, but it also ensures that components are securely soldered, minimizing defects and enhancing overall product reliability.

Compatibility with Juki Equipment

The compatibility of reflow soldering with Juki pick and place machines is a game-changer for many manufacturers. Juki's advanced technology allows seamless integration between the pick & place machine and reflow ovens, ensuring that every component placed is perfectly aligned for optimal soldering results. This synergy not only simplifies the workflow but also enhances the effectiveness of solder paste inspection, as both processes work in harmony to deliver superior quality.

Process Optimization Techniques

To get the most out of your reflow soldering process alongside a Juki pick and place machine, several optimization techniques can be employed. First, adjusting temperature profiles based on specific component types can significantly improve solder joint integrity while reducing defects. Additionally, regular maintenance of both your Juki equipment and reflow oven ensures consistent performance; after all, a well-tuned machine pick and place system leads to fewer errors during production.

Real-World Success Stories

Numerous companies have experienced remarkable improvements in their production lines by adopting Juki equipment paired with effective reflow soldering strategies. For instance, one electronics manufacturer reported a 30% reduction in assembly time after integrating these technologies while maintaining high-quality standards—an impressive feat considering rising juki pick and place machine prices! Another success story highlights how implementing precise temperature controls during reflow led to significant reductions in defective products due to improper solder joints.

Conclusion

In the ever-evolving landscape of electronics manufacturing, maximizing productivity is essential for staying competitive. The Juki pick and place machine stands out as a leader in this domain, offering unmatched efficiency and precision that can significantly enhance production lines. By integrating advanced features such as solder paste inspection and reflow soldering compatibility, manufacturers can streamline operations and reduce costs.

Maximizing Productivity with Juki Machinery

The Juki pick and place machine is engineered to elevate productivity levels through its high-speed operation and accuracy. With the capability to handle complex placements seamlessly, it minimizes errors that can lead to costly rework or downtime. Investing in a Juki machine not only improves throughput but also ensures quality, making it a smart choice for any manufacturing facility focused on growth.

The Future of Automation in Soldering

As technology advances, the future of automation in soldering appears brighter than ever. Innovations in pick & place machines like those from Juki are setting new standards for efficiency while reducing labor costs and human error. As more companies adopt these technologies, we can expect significant shifts towards fully automated production lines that integrate seamlessly with processes such as reflow soldering and solder paste inspection.

Choosing the Right Partner: Bensun Technology

When selecting machinery for your production needs, partnering with a reliable provider like Bensun Technology is crucial. They not only offer exceptional products like the Juki pick and place machine but also provide invaluable support throughout the purchasing process—ensuring you understand the implications of juki pick and place machine price versus long-term benefits. With Bensun by your side, you can navigate through options confidently while enhancing your manufacturing capabilities.