Introduction

In the fast-paced world of electronics manufacturing, solder paste inspection has become a critical component in ensuring product quality and reliability. The advent of advanced solder paste inspection machines has revolutionized the way we approach PCB assembly, allowing for quicker detection of defects and improved overall efficiency. As technology continues to evolve, the importance of integrating effective optical inspection systems into production lines cannot be overstated.

Importance of Solder Paste Inspection

Solder paste inspection is essential for maintaining high standards in PCB assembly, as it directly impacts the performance and longevity of electronic devices. By utilizing a solder paste inspection machine, manufacturers can identify issues such as insufficient solder application or misalignment before they escalate into costly problems. This proactive approach not only enhances product quality but also fosters customer trust and satisfaction.

How Technology Transforms PCB Assembly

The integration of technology in PCB assembly has led to significant improvements in both speed and accuracy, particularly through the use of AOI (Automated Optical Inspection) systems. These sophisticated optical inspection tools allow for real-time monitoring and evaluation of solder paste application, ensuring that every component is perfectly placed and adequately prepared for soldering. As a result, manufacturers can reduce waste, minimize rework costs, and ultimately boost their bottom line.

The Role of Quality Control in Manufacturing

Implementing robust quality control measures—including regular solder flux assessments—ensures that every stage of production meets stringent industry standards. By prioritizing effective solder paste inspection methods within their quality control frameworks, manufacturers position themselves to outperform competitors while delivering reliable products to consumers.

What is Solder Paste Inspection?

Solder paste inspection is a critical process in the realm of PCB assembly that ensures the quality and reliability of electronic components. By accurately assessing the application of solder paste on printed circuit boards (PCBs), manufacturers can prevent defects that might lead to product failure. This inspection not only enhances product performance but also reduces costly rework and increases overall efficiency in manufacturing.

Definition and Purpose

At its core, solder paste inspection refers to the meticulous evaluation of solder paste deposits on PCBs before components are placed for soldering. The primary purpose is to verify that the right amount of solder paste has been applied in the correct locations, which is essential for optimal electrical connectivity and mechanical strength. Without effective solder paste inspection, issues like insufficient or excess solder can arise, leading to potential failures during operation.

Key Components of Solder Paste Inspection

The key components of a solder paste inspection machine typically include advanced imaging systems, such as AOI (Automated Optical Inspection) technology, which captures high-resolution images for analysis. These machines are equipped with sophisticated algorithms that can detect inconsistencies in the application of solder paste, including misalignment or inadequate coverage. Additionally, features like real-time data feedback and integration with production line systems enhance the effectiveness of optical inspection processes.

The Process in PCB Assembly

Incorporating solder paste inspection into PCB assembly involves several well-defined steps to ensure quality control throughout production. Initially, PCBs are cleaned and prepared before applying the solder paste using a stencil or screen printing method. Once applied, an AOI optical inspection machine scans each board to identify any discrepancies in the solder flux application—this crucial step allows manufacturers to catch potential errors early on before component placement occurs, ultimately saving time and resources while enhancing product reliability.

Types of Solder Paste Inspection Machines

In the world of PCB assembly, selecting the right solder paste inspection machine is crucial for maintaining quality and efficiency. With various technologies available, understanding these options can help manufacturers make informed decisions that enhance their production processes. This section will explore AOI inspection machines, the benefits of optical inspection systems, and a comparison between manual and automated systems.

Overview of AOI Inspection Machines

Automated Optical Inspection (AOI) machines are a cornerstone in modern solder paste inspection. These sophisticated devices utilize high-resolution cameras to capture images of PCBs and analyze them for defects in solder paste application. By employing advanced algorithms, AOI systems can detect issues such as insufficient solder flux or misalignment, ensuring that every component is positioned correctly before the assembly process continues.

The primary function of AOI inspection machines is to provide real-time feedback during production, significantly reducing the chances of defects going unnoticed. They are designed to inspect various aspects of solder paste application, including volume, shape, and placement accuracy. This capability makes AOI machines indispensable for manufacturers aiming to uphold stringent quality control standards.

Benefits of Optical Inspection Systems

Optical inspection systems offer a plethora of advantages that enhance the overall efficiency and reliability of solder paste inspection processes. One major benefit is their ability to quickly identify defects without requiring physical contact with the PCB surface; this minimizes potential damage during inspections. Additionally, these systems can operate at high speeds, allowing manufacturers to maintain rapid production rates while ensuring thorough checks.

Another key advantage is their adaptability; optical inspection systems can be programmed to recognize different types of solder flux and specific design requirements for various PCBs. This flexibility means that manufacturers can easily adjust their processes as product designs evolve or new technologies emerge in the market. Moreover, by integrating optical inspection into production workflows, companies often experience reduced rework costs due to early detection of issues.

Comparison of Manual vs. Automated Systems

Manual inspections rely heavily on human judgment which can lead to inconsistencies due to fatigue or oversight during lengthy production runs—this may result in faulty products making it through quality control checks undetected.

On the other hand, automated systems not only enhance accuracy but also improve throughput by eliminating bottlenecks associated with human involvement in inspections. While manual inspections may seem cost-effective initially due to lower upfront investment costs for equipment, they often lead to higher long-term expenses from increased defect rates and rework needs caused by less reliable assessments.

In summary, while both manual and automated systems have their place in PCB manufacturing environments, incorporating an advanced solder paste inspection machine like an AOI system offers significant advantages over traditional methods—especially when striving for excellence in quality control.

The Significance of Solder Flux

Solder flux plays a pivotal role in the effectiveness of solder paste inspection, ensuring optimal connections on printed circuit boards (PCBs). Without proper flux, solder paste may not flow correctly or adhere to surfaces, leading to defects that can compromise the entire assembly. Understanding its significance is crucial for anyone involved in PCB manufacturing and quality control.

Why Solder Flux Matters

Solder flux is essential because it cleans and prepares metal surfaces for soldering, enhancing the wetting properties of solder paste. This preparation helps prevent oxidation and ensures a strong bond between components and the PCB. In the realm of solder paste inspection, effective flux application can mean the difference between a flawless assembly and one riddled with defects.

When using a solder machine, having the right type of flux can significantly impact the performance of your optical inspection systems. If inadequate flux is applied, it may lead to poor solder joints that are difficult to detect during automatic optical inspection (AOI) processes. Therefore, understanding why solder flux matters is fundamental for achieving high-quality results in PCB assembly.

Common Types of Solder Flux

There are several types of solder flux available on the market today, each designed for specific applications in electronics manufacturing. The most common categories include rosin-based fluxes, water-soluble fluxes, and no-clean fluxes—each with its own set of advantages and ideal use cases. For instance, rosin-based flux provides excellent cleaning properties but requires thorough post-soldering cleaning; on the other hand, no-clean flux allows for minimal cleanup after application.

Incorporating these different types into your production line can enhance overall efficiency while improving outcomes during solder paste inspection processes. Selecting the right type based on your specific needs will not only optimize performance but also facilitate smoother AOI inspections by ensuring that all joints are adequately prepared for evaluation. Choosing wisely among these options can ultimately save time and resources down the line.

Impact on Solder Paste Inspection

The impact of solder flux on solder paste inspection cannot be overstated; it directly influences how well joints are inspected by machines like AOI systems. Properly applied flux ensures that there are no barriers preventing adequate adhesion or flow of the solder paste during reflow processes—this leads to better visual results when examined under an optical inspection system. Conversely, insufficient or improper use of solder flux can result in defects that may go undetected if not carefully monitored.

Moreover, when integrating a new solder machine into your production line, understanding how different types of solders interact with various forms of flux will help streamline your inspection process significantly. A well-chosen combination enhances both reliability and accuracy during inspections while reducing waste caused by faulty assemblies needing rework or replacement due to inadequate initial inspections. In short, prioritizing effective use of solder flux will yield substantial benefits in both quality control measures and overall production efficiency.

Integrating Solder Paste Inspection in Production

Integrating solder paste inspection into the production process is crucial for ensuring high-quality PCB assembly. The right solder paste inspection machine can significantly enhance the efficiency and reliability of manufacturing operations. By adopting effective optical inspection methods, manufacturers can minimize defects and improve overall product quality.

Steps to Implement Inspection Systems

The first step in implementing a solder paste inspection system is to assess the specific needs of your production line. This involves selecting a suitable solder paste inspection machine that aligns with your operational goals and budget. Once selected, it's vital to train staff on how to use the system effectively, ensuring they understand both the technology and its importance in maintaining quality control.

Next, establish a regular maintenance schedule for the optical inspection equipment to ensure optimal performance over time. Calibration of the solder paste inspection machine should also be conducted periodically to maintain accuracy in measurements. Finally, integrate data from inspections into your overall quality management system for continuous improvement.

Challenges in Optical Inspection

While optical inspection systems offer significant advantages, they are not without their challenges. One primary concern is the variability in solder flux types used across different assemblies; this can affect how well an AOI optical inspection system performs during inspections. Additionally, achieving consistent lighting conditions and camera focus can be tricky when dealing with various board designs and component placements.

Another challenge lies in interpreting results accurately; false positives or negatives may occur if settings are not properly calibrated or if there are unexpected variations in solder paste application. Furthermore, integrating these systems into existing workflows without causing disruptions can also pose logistical hurdles that must be navigated carefully.

Best Practices for Effective Inspection

To maximize the effectiveness of your solder paste inspection processes, adhere to several best practices that promote optimal results. First and foremost, regularly update your AOI optical inspection software to leverage improvements in detection algorithms and analysis capabilities. Keeping up with advancements ensures that you maintain a competitive edge while enhancing defect detection rates.

Additionally, it’s essential to create standardized procedures for using the solder paste inspection machine across all teams involved in production—this fosters consistency and reduces errors stemming from human factors. Finally, encourage open communication between operators and engineers regarding any anomalies detected during inspections; this collaboration will help refine processes further and address potential issues before they escalate.

Choosing the Right Solder Machine

Selecting the right solder machine is crucial for maintaining high standards in PCB assembly. With various options available, understanding the features and capabilities of solder paste inspection machines is essential for optimizing production quality. A well-chosen solder paste inspection system can significantly enhance manufacturing efficiency and reduce defects.

Features to Look For

When evaluating a solder paste inspection machine, several key features should be at the forefront of your decision-making process. First and foremost, consider the resolution and speed of the optical inspection system; higher resolution ensures accurate detection of defects in solder paste, while speed is vital for maintaining production flow. Additionally, look for advanced algorithms that enhance defect recognition capabilities, ensuring that even subtle issues with solder flux are identified promptly.

Another important feature is ease of integration with existing production lines; a seamless connection between your AOI inspection systems and other machinery can streamline operations significantly. The ability to handle various types of solder paste formulations is also crucial, as different projects may require specific types of flux or paste compositions. Lastly, ensure that the machine offers user-friendly software for monitoring and reporting performance metrics—this will help maintain quality control throughout your manufacturing process.

Leading Brands and Solutions

The market offers a variety of leading brands known for producing top-notch solder paste inspection machines tailored to different needs in PCB assembly. Companies such as Koh Young Technology and Viscom are recognized for their innovative AOI optical inspection systems that combine precision with efficiency to detect inconsistencies in solder paste application effectively. Other notable mentions include Omron and CyberOptics, which provide reliable solutions designed to enhance overall production quality through advanced imaging technologies.

Each brand typically offers a range of models suited for various production scales—from small-scale operations to large manufacturing facilities—allowing businesses to select an option that fits their specific requirements best. Furthermore, many manufacturers offer customizable solutions so you can tailor features according to your unique operational needs involving solder flux applications or other specialized processes related to PCB assembly.

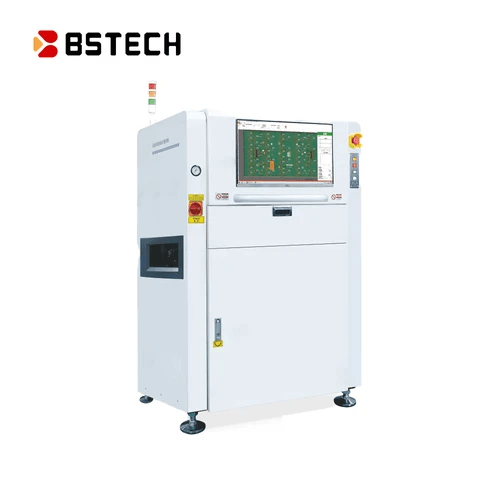

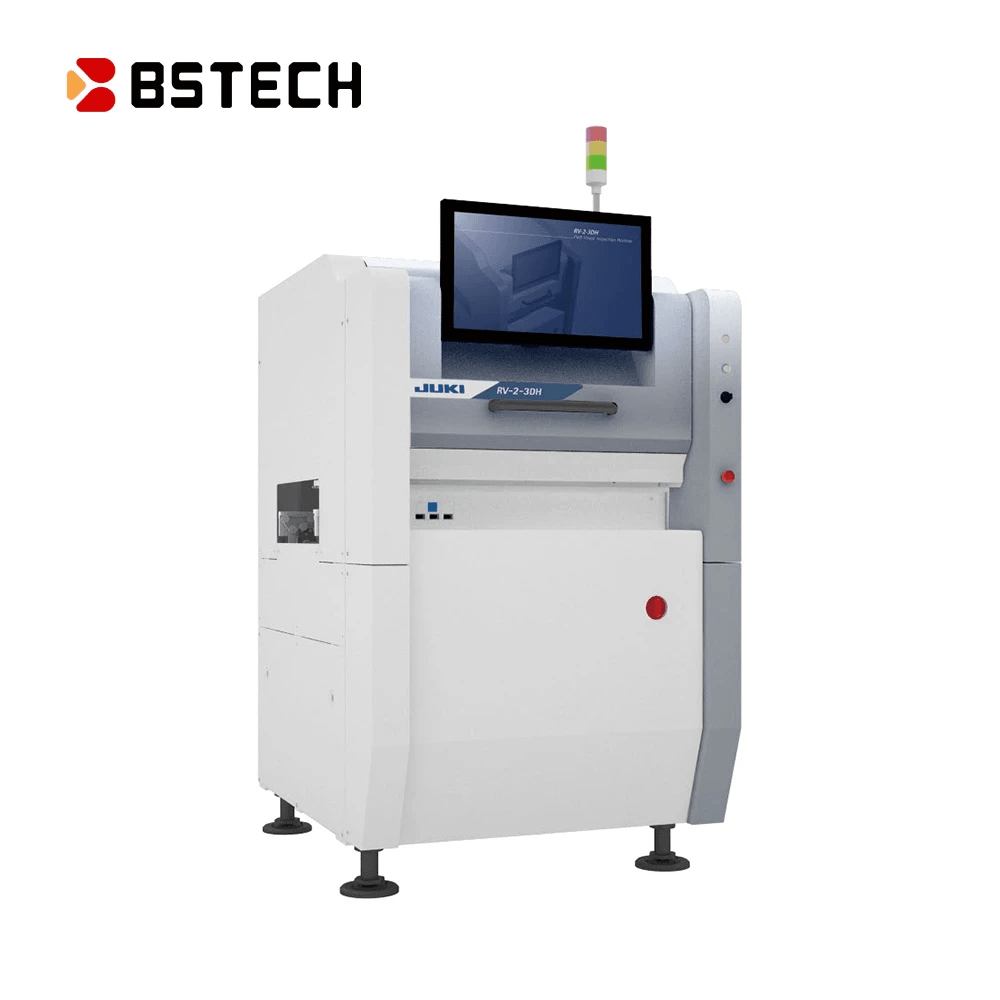

Bensun Technology: A Partner in Production

Bensun Technology stands out as a reliable partner when it comes to selecting an effective solder paste inspection machine tailored specifically for modern manufacturing demands. Their commitment to innovation ensures that their AOI optical inspection systems are equipped with cutting-edge technology capable of detecting even minute defects in both solder paste application and overall PCB quality control processes. With Bensun's expertise in integrating these systems into existing workflows, customers can expect enhanced productivity without compromising on quality.

Moreover, Bensun provides comprehensive support services ranging from installation assistance to ongoing maintenance—making them an invaluable resource throughout your production journey involving critical processes like solder flux management or automated inspections using state-of-the-art equipment designed explicitly for this purpose. By choosing Bensun Technology as your partner in production, you not only gain access to superior products but also benefit from their extensive industry knowledge aimed at optimizing every facet of your manufacturing operations.

Conclusion

In the fast-paced world of PCB assembly, solder paste inspection is not just an optional step; it's a crucial element for ensuring product quality and reliability. The integration of solder paste inspection machines into production lines has revolutionized the way manufacturers approach quality control, making it easier to catch defects early on. By leveraging advanced optical inspection technologies, companies can significantly reduce rework costs and enhance overall efficiency.

Enhancing Quality with Solder Paste Inspection

Solder paste inspection serves as a gatekeeper in the manufacturing process, ensuring that every component is correctly placed and adequately soldered. With the use of AOI (Automated Optical Inspection) systems, manufacturers can detect issues related to solder flux application or misalignment before they escalate into larger problems down the line. This proactive approach not only boosts product quality but also fosters customer trust in the brand.

Future Trends in PCB Assembly

Looking ahead, we can expect significant advancements in solder paste inspection technology that will further streamline PCB assembly processes. Innovations like AI-driven optical inspection systems are on the horizon, promising even more accurate defect detection while minimizing human error. Additionally, as manufacturers continue to embrace automation, integrating sophisticated solder machines will become commonplace, making production faster and more reliable than ever.

The Competitive Edge of Proper Inspection

Investing in high-quality solder paste inspection machines provides companies with a competitive edge in today's market. Properly implemented AOI optical inspection not only enhances product quality but also reduces time-to-market by catching errors early in production cycles. In an industry where precision is paramount, those who prioritize effective solder paste inspection will undoubtedly stand out from their competitors.