Introduction

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) has emerged as a cornerstone for efficiency and precision. This technology allows for the assembly of electronic components directly onto the surface of printed circuit boards, significantly reducing production time and improving reliability. At the forefront of this innovation is JUKI, a name synonymous with quality in industrial machinery, particularly with their groundbreaking model, the JUKI ISM3600.

Understanding Surface Mount Technology

Surface Mount Technology revolutionizes how electronic devices are assembled by allowing components to be mounted directly onto the PCB's surface rather than through holes. This method not only saves space but also enhances electrical performance due to shorter connections and reduced signal interference. As manufacturers strive for compact designs and higher functionality, SMT has become an essential practice in modern electronics production.

The Role of JUKI in SMT

JUKI has established itself as a leader in SMT solutions with its innovative range of industrial machines designed for high-speed assembly processes. The company's commitment to quality and technological advancement ensures that their equipment meets the rigorous demands of today's electronics manufacturers. Among these offerings, the JUKI ISM3600 stands out as a prime example of how JUKI continues to push the boundaries of what's possible in SMT.

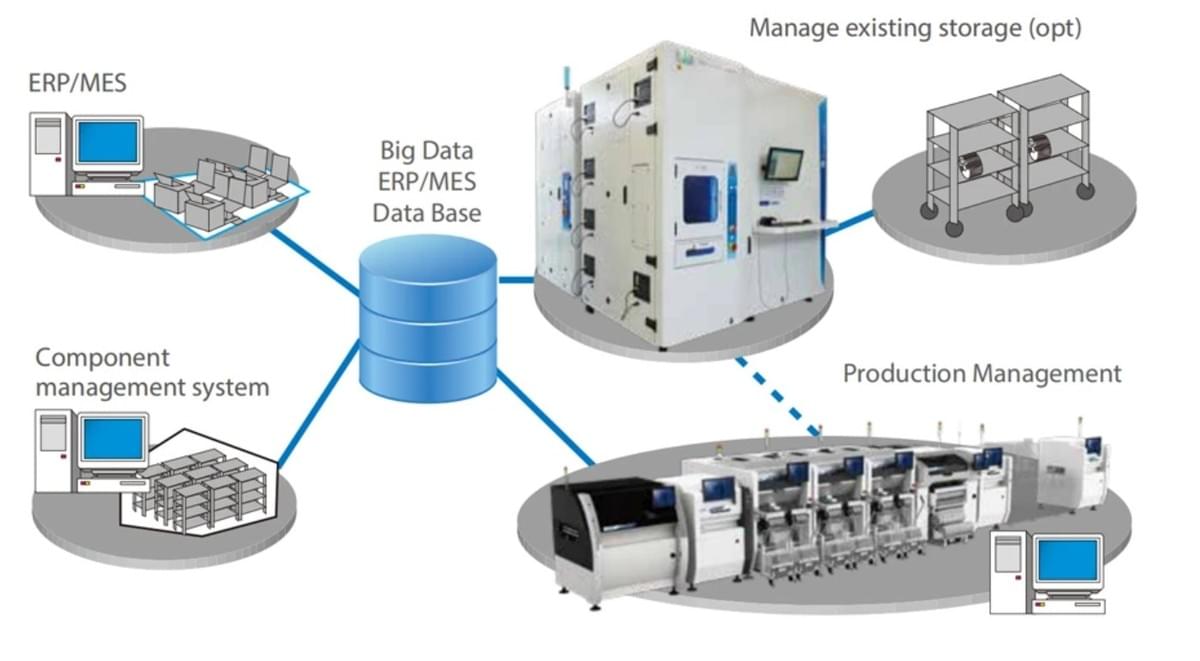

Overview of ISM3600 Features

The JUKI ISM3600 boasts an impressive array of features that cater specifically to the needs of modern manufacturing environments. With advanced pick-and-place capabilities, it can handle various component sizes while maintaining exceptional accuracy and speed. Additionally, its user-friendly interface and integration with automated systems make it a top choice for companies looking to enhance their production lines without sacrificing quality or efficiency.

What is the JUKI ISM3600?

The JUKI ISM3600 is a cutting-edge machine that embodies the pinnacle of Surface Mount Technology (SMT) innovation. Designed by JUKI, a leader in industrial machinery, this model enhances production efficiency and quality in electronics manufacturing. With its advanced features and capabilities, the JUKI ISM3600 stands out as a preferred choice for many companies looking to optimize their assembly lines.

An Introduction to JUKI

JUKI has been at the forefront of industrial machine manufacturing for decades, earning a reputation for reliability and technological advancement. Established in Japan, the company has continually pushed boundaries to provide high-performance solutions tailored to various industries. The introduction of the JUKI ISM3600 is yet another testament to their commitment to innovation and excellence in SMT.

Key Specifications of ISM3600

The JUKI ISM3600 boasts impressive specifications that cater to modern manufacturing needs. It features high-speed placement capability with an accuracy that ensures precise component positioning on printed circuit boards (PCBs). Additionally, it supports a wide range of components, making it versatile enough for various applications within the electronics sector.

Unique Advantages of the ISM3600

What sets the JUKI ISM3600 apart from other juki industrial machines is its blend of speed, precision, and user-friendly interface. This machine not only accelerates production but also reduces errors through its advanced visual inspection systems that catch inconsistencies before they become costly mistakes. Furthermore, its modular design allows easy upgrades and maintenance—making it an intelligent investment for businesses aiming for long-term growth in SMT capabilities.

The Importance of SMT in Electronics

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled, making it a cornerstone of modern electronics manufacturing. Unlike traditional methods that require drilling holes into circuit boards, SMT allows for components to be mounted directly on the surface, resulting in a more compact and efficient design. This innovation not only streamlines production but also enhances the overall performance of electronic devices.

What is Surface Mount Technology?

Surface Mount Technology (SMT) is a method that involves placing electronic components directly onto the surface of printed circuit boards (PCBs). This technique utilizes smaller components with leads that are soldered to pads on the PCB, allowing for greater flexibility in design and layout. The JUKI ISM3600 leverages this technology to provide high-speed assembly and superior accuracy, making it an essential tool for manufacturers looking to stay competitive.

Benefits of SMT over Traditional Methods

The benefits of SMT over traditional through-hole methods are numerous and compelling. For starters, SMT enables higher component density, which means more functionality can fit into smaller devices—think smartphones and wearables! Additionally, because the JUKI industrial machines like the ISM3600 use advanced pick-and-place mechanisms, they significantly reduce labor costs while increasing production speed and consistency.

How SMT Enhances Production Efficiency

When it comes to enhancing production efficiency, SMT stands head and shoulders above older techniques. The streamlined process reduces assembly time by allowing multiple components to be placed simultaneously with precision—a feature prominently highlighted in JUKI industrial machines like the ISM3600. Furthermore, automated visual inspection systems ensure quality control at every step, minimizing errors and waste while maximizing output.

Key Components of the JUKI ISM3600

The JUKI ISM3600 stands out in the world of Surface Mount Technology (SMT) thanks to its carefully engineered components that enhance efficiency and precision. This section delves into three critical elements: the pick and place mechanism, the reflow soldering process, and the significance of visual inspection systems. Understanding these components will help you appreciate how the JUKI industrial machine elevates production capabilities.

Pick and Place Mechanism in JUKI ISM

At the heart of the JUKI ISM3600 is its advanced pick and place mechanism, designed for speed and accuracy. This system utilizes high-precision robotics that swiftly picks up components from feeders and places them onto PCBs with remarkable precision, reducing cycle times significantly. With its ability to handle a wide variety of component sizes and types, the JUKI ISM ensures flexibility in production runs while maintaining superior placement accuracy.

Moreover, this mechanism is equipped with intelligent vision systems that enable real-time adjustments during operation. The result? Enhanced reliability in component placement that minimizes errors often associated with manual processes. When it comes to SMT, having a robust pick and place system like that found in the JUKI industrial machine is crucial for achieving high-quality results.

Reflow Soldering Process Explained

Once components are placed on a PCB using the JUKI ISM3600's sophisticated pick and place mechanism, they must be soldered securely to ensure durability and functionality. The reflow soldering process employed by this machine is both efficient and effective; it involves heating solder paste on a PCB until it melts, forming reliable electrical connections as it cools down again.

The design of the reflow oven within the JUKI industrial machine allows for precise temperature control across multiple zones, ensuring uniform heating throughout each assembly batch. This meticulous approach not only enhances solder joint quality but also reduces defects associated with traditional soldering methods. In short, reflow soldering within the context of SMT has never been more advanced than with the capabilities offered by the JUKI ISM3600.

Importance of Visual Inspection Systems

In any manufacturing process where precision is key—especially in electronics—the importance of visual inspection systems cannot be overstated. The JUKI ISM3600 incorporates cutting-edge visual inspection technology designed to identify defects or misalignments before they escalate into costly errors downstream in production lines. By employing automated optical inspection (AOI), this system can detect issues such as missing components or incorrect placements quickly.

Furthermore, these visual inspection systems contribute significantly to overall quality assurance processes within any SMT setup using a JUKI industrial machine like the ISM3600. They provide real-time feedback that allows operators to make immediate adjustments if necessary—ensuring only top-quality products reach consumers' hands while minimizing waste and rework costs along the way. In essence, integrating robust visual inspection systems into your SMT operations not only streamlines production but also enhances product reliability.

Bensun Technology's Offerings

Bensun Technology is at the forefront of providing comprehensive solutions for industries utilizing Surface Mount Technology (SMT). Their offerings cater to a diverse range of needs, ensuring that businesses can optimize their production processes with JUKI industrial machines like the ISM3600. From complete production lines to flexible leasing options, Bensun is committed to supporting companies in achieving their manufacturing goals.

Complete Production Line Solutions

Bensun Technology specializes in creating complete production line solutions tailored for the JUKI ISM3600 and other JUKI industrial machines. These solutions encompass everything from component placement to final assembly, ensuring a seamless workflow that maximizes efficiency. By integrating advanced technology and automation, Bensun helps clients streamline their operations and reduce lead times significantly.

With the JUKI ISM3600 at the heart of these production lines, manufacturers can benefit from high-speed performance and precision placement capabilities. This not only enhances product quality but also allows businesses to scale their operations effectively. Moreover, Bensun’s expertise ensures that each line is optimized for specific requirements, adapting to various industry standards and customer demands.

Short-Term Equipment Leasing Options

For companies looking to maintain flexibility without a long-term commitment, Bensun Technology offers short-term equipment leasing options that include the JUKI ISM series. This approach allows businesses to access state-of-the-art JUKI industrial machines without significant upfront investment while still enjoying top-tier technology for their SMT needs. Whether it’s for a temporary project or testing new products, this leasing model provides an ideal solution.

Leasing equipment like the JUKI ISM3600 enables manufacturers to respond swiftly to market changes or fluctuations in demand without being tied down by ownership costs. Clients can easily upgrade or switch out machinery as needed, keeping pace with technological advancements in electronics manufacturing. In addition, this flexibility allows companies to focus on innovation rather than maintenance of outdated equipment.

Contract Processing and PCBA Manufacturing

Bensun Technology also excels in contract processing and Printed Circuit Board Assembly (PCBA) manufacturing services using the reliable JUKI ISM3600 system. By outsourcing these critical processes, companies can leverage Bensun's expertise while freeing up internal resources for core business activities. This partnership model helps clients achieve high-quality assemblies with consistent results every time.

The use of advanced features within the JUKI industrial machine ensures that every PCB produced meets stringent quality standards required in today’s competitive landscape. With a focus on precision and efficiency, Bensun provides tailored solutions that cater specifically to customer requirements across various industries—from automotive electronics to consumer gadgets. Ultimately, this collaboration fosters innovation while reducing time-to-market for new products.

Real-World Applications of JUKI ISM3600

The JUKI ISM3600 has made significant waves across various industries, showcasing its versatility and efficiency in surface mount technology (SMT). As manufacturers seek to enhance their production capabilities, the JUKI industrial machine stands out as a go-to solution for businesses aiming to streamline their assembly processes. From consumer electronics to automotive components, the applications of the JUKI ISM3600 are vast and impactful.

Industries Benefiting from SMT

Numerous industries have embraced SMT, with electronics manufacturing leading the charge. The telecommunications sector relies heavily on compact and efficient components, making the JUKI ISM3600 an ideal choice for producing high-density circuit boards. Additionally, medical device manufacturers appreciate the precision and reliability that this JUKI industrial machine offers in assembling critical electronic components essential for patient care.

Moreover, the automotive industry has seen a shift towards more sophisticated electronic systems in vehicles, which necessitates advanced manufacturing techniques like those provided by the JUKI ISM3600. The ability to handle intricate designs while maintaining quality control is paramount in this sector. As industries evolve and demand smarter solutions, SMT continues to play a crucial role in meeting these challenges head-on.

Case Studies of Successful Implementations

One notable case study involves a leading consumer electronics company that adopted the JUKI ISM3600 to improve its production line efficiency significantly. By integrating this advanced machine into their workflow, they reported a 30% increase in output while reducing defects by nearly 25%. This transformation not only enhanced their product quality but also allowed them to respond more swiftly to market demands.

Another example comes from an automotive parts manufacturer that utilized the JUKI industrial machine for assembling complex control units. With its exceptional pick-and-place capabilities and reflow soldering process, they were able to produce high-quality components at a fraction of previous costs. These success stories highlight how organizations are leveraging the power of SMT through machines like the JUKI ISM3600 to stay competitive.

Future Trends in Surface Mount Technology

Looking ahead, several trends are emerging within surface mount technology that promise exciting advancements for machines like the JUKI ISM3600. One key trend is miniaturization; as devices become smaller yet more powerful, manufacturers will increasingly rely on sophisticated SMT solutions to meet these demands without compromising performance or reliability.

Additionally, automation and artificial intelligence are set to revolutionize how we approach manufacturing processes within SMT environments. The integration of smart technologies into machines like those offered by JUKI industrial could lead to even higher efficiencies and lower operational costs across various sectors.

Finally, sustainability is becoming a focal point as companies strive for greener manufacturing practices; thus innovations surrounding energy-efficient machines will likely gain traction in future developments of equipment such as the JUKI ISM3600.

Conclusion

As we wrap up our exploration of the JUKI ISM3600 and its pivotal role in surface mount technology (SMT), it’s clear that JUKI has made significant strides in enhancing manufacturing processes across various industries. The JUKI ISM3600 stands as a testament to innovation, blending advanced technology with user-friendly features that streamline production. With its robust capabilities, the JUKI industrial machine not only meets but often exceeds the expectations of modern electronics manufacturers.

The Impact of JUKI on SMT

JUKI's contribution to SMT is nothing short of transformative, revolutionizing how electronic components are assembled. By integrating precision engineering with cutting-edge technology, the JUKI ISM3600 has set new benchmarks for efficiency and reliability in production lines. This impact resonates through reduced cycle times, improved quality control, and greater adaptability to evolving market demands.

Why Choose JUKI Industrial Machines

When it comes to selecting industrial machines for SMT applications, choosing JUKI is an investment in quality and performance. The reputation of JUKI industrial machines is built on years of excellence and innovation, making them a preferred choice among manufacturers worldwide. With features like intuitive operation and advanced automation, the JUKI ISM3600 provides unparalleled value that translates directly into enhanced productivity.

Embracing Innovation with Bensun Technology

Partnering with Bensun Technology offers a unique opportunity to leverage the full potential of the JUKI ISM3600 within your production environment. Their comprehensive solutions include everything from complete production line setups to flexible leasing options tailored for businesses of all sizes. By embracing these innovations alongside top-tier machinery like the JUKI industrial machine, companies can stay ahead in a competitive landscape while optimizing their operational efficiency.