Introduction

In the rapidly evolving world of electronics manufacturing, JUKI SMT machines have emerged as a cornerstone of efficiency and precision. These sophisticated devices, particularly the JUKI pick and place machines, have revolutionized the way components are assembled on printed circuit boards (PCBs). Understanding their evolution not only highlights technological advancements but also underscores their pivotal role in modern production lines.

The Evolution of JUKI SMT Machines

JUKI has been at the forefront of innovation in SMT machines for decades, continuously refining its pick and place technology to meet the demands of high-speed assembly. From early models that laid the groundwork for automated assembly to today’s advanced pick and place machine SMD solutions, JUKI has consistently pushed the envelope. Each iteration brings enhanced capabilities, improved speed, and greater precision—features that are essential in a competitive manufacturing landscape.

Why Speed Matters in Assembly

Speed is not just a luxury in SMT production; it is a necessity that can make or break a manufacturing operation. With consumer demand for faster turnaround times increasing, having an efficient pick & place system can significantly enhance throughput while maintaining quality standards. In this context, JUKI's high-speed assembly capabilities allow manufacturers to keep pace with market demands without compromising on precision or reliability.

Overview of Advanced Technologies

The landscape of SMT machines is marked by rapid advancements in technology that facilitate smarter and faster assembly processes. JUKI's incorporation of AI-driven algorithms, real-time monitoring systems, and innovative software interfaces ensures that their line SMT solutions remain cutting-edge. As these technologies evolve further, they promise to enhance not only operational efficiency but also adaptability within diverse production environments.

Understanding JUKI Pick and Place Machines

In the world of surface mount technology (SMT), JUKI pick and place machines have carved out a reputation for excellence. These machines are engineered to optimize the assembly process, ensuring that components are placed accurately and efficiently on printed circuit boards (PCBs). With an array of advanced features, JUKI machines stand out in a crowded field of SMT machines.

Features That Set JUKI Apart

What makes JUKI pick and place machines truly special? First off, their exceptional speed and precision are unmatched in the industry, allowing for rapid placement of various components. Additionally, JUKI's innovative software solutions enhance operational flexibility, enabling users to easily switch between different production runs without losing efficiency.

Another standout feature is their modular design, which allows for easy upgrades and customization as technology evolves. This adaptability means that manufacturers can keep pace with changing demands in the market while maximizing their investment in SMT equipment. Overall, these features make JUKI's pick & place offerings not just tools but integral parts of modern SMT production lines.

The Role of JUKI in SMT Production

JUKI has played a pivotal role in transforming SMT production lines into highly efficient operations. Their pick and place machine SMD capabilities allow manufacturers to streamline workflows by reducing downtime during setup and changeovers. As a result, companies leveraging JUKI technology can respond quickly to market needs while maintaining high-quality standards.

Moreover, JUKI's commitment to research and development ensures that their machines incorporate the latest advancements in automation and artificial intelligence. This focus on innovation translates into improved accuracy and consistency across production runs—key factors that enhance overall productivity in any SMT environment. Thus, choosing a JUKI pick & place machine is not just about acquiring equipment; it's about investing in future-ready technology.

Capabilities of JUKI Machines in High-Speed Assembly

Designed for rapid operation without compromising placement accuracy, these machines excel at handling both small-scale prototypes and large-volume productions alike. Their ability to manage various component sizes—from tiny SMDs to larger through-hole parts—makes them versatile assets on any line SMT setup.

Furthermore, advanced vision systems integrated into these pick & place devices ensure precise alignment before placement occurs. This attention to detail significantly reduces errors associated with misalignment or incorrect component handling during high-speed operations. In summary, the capabilities of JUKI machines empower manufacturers to achieve unprecedented levels of efficiency while maintaining stringent quality control measures throughout the assembly process.

The Anatomy of a Pick and Place Machine

When diving into the world of SMT machines, understanding the anatomy of a pick and place machine is essential. These machines are the backbone of modern assembly lines, particularly in high-speed environments. With JUKI pick and place systems leading the charge, let’s dissect what makes these machines tick.

Key Components Explained

At the heart of any pick and place machine are its key components, which work harmoniously to ensure efficiency. The feeder system is responsible for delivering SMD components accurately to the placement head, while vision systems provide real-time feedback for precise alignment. Additionally, the placement head itself is equipped with multiple nozzles that allow for rapid handling of various component sizes, making JUKI's offerings particularly versatile in any SMT production line.

Another crucial element is the conveyor system that transports PCBs through different stages of assembly. This ensures that each board moves seamlessly from one operation to another without bottlenecks or delays. Lastly, advanced software plays a pivotal role in coordinating all these components, optimizing cycle times while maintaining high accuracy—qualities that define top-tier pick and place machines.

How SMT Pick and Place Works

The operation of an SMT pick and place machine is both fascinating and intricate. It begins with loading SMD components into feeders positioned strategically along the machine’s side; this setup allows for quick access during assembly cycles. Once a PCB enters the line SMT, sensors detect its presence and relay this information to the control software.

The placement head then springs into action—using its vision system to identify component locations on both feeders and PCBs before executing precise movements to retrieve parts from their designated spots. After picking up an SMD component with vacuum suction or mechanical grippers, it swiftly places it onto the PCB at predetermined coordinates with remarkable speed and accuracy—this process can occur at lightning-fast rates thanks to JUKI's innovative engineering.

Importance of Precision in SMD Placement

Precision in SMD placement cannot be overstated; it's what separates good assembly from great assembly! In high-speed environments where JUKI pick and place machines excel, even minor misalignments can lead to significant issues down the line—including rework costs or product failures. Therefore, every aspect—from component selection through placement—is engineered for meticulous accuracy.

Moreover, precision directly impacts yield rates; higher accuracy translates into fewer defects during manufacturing processes on SMT production lines. By incorporating advanced technologies such as laser alignment systems or sophisticated algorithms within their machinery, JUKI ensures that every component lands exactly where it should be—maximizing output quality while minimizing waste.

In summary, understanding how a pick and place machine operates—and appreciating its critical components—provides insight into why manufacturers consistently choose JUKI over competitors for their assembly needs.

Exploring SMT Production Lines

In the world of electronics manufacturing, building an efficient SMT production line is crucial for maintaining competitiveness and ensuring high-quality output. A well-structured line not only optimizes workflow but also reduces waste and enhances productivity. With the right combination of technologies, including advanced JUKI pick and place machines, manufacturers can significantly streamline their assembly processes.

Building an Efficient Line SMT

Creating an efficient line SMT requires a careful balance of machinery, process management, and skilled personnel. Each component of the production line must work in harmony to ensure that the pick and place machine operates at peak performance without bottlenecks or delays. By integrating JUKI's state-of-the-art technology into the assembly process, manufacturers can achieve seamless operation from start to finish.

Moreover, choosing the right configuration for your SMT line is essential for maximizing throughput. This includes selecting appropriate feeders for different components and ensuring that your pick & place machines are equipped with advanced capabilities for handling various SMD types efficiently. An optimized layout will not only enhance speed but also reduce setup times between different production runs.

JUKI's Role in Modern SMT Lines

JUKI has established itself as a leader in providing high-quality SMT machines that are integral to modern production lines. Their pick and place machines are designed to handle a wide range of components with exceptional speed and accuracy, making them indispensable in high-volume environments. The incorporation of JUKI technology into SMT lines allows manufacturers to meet increasing demands while maintaining stringent quality standards.

Furthermore, JUKI’s innovations include features like intelligent vision systems that enhance placement precision and reduce errors during assembly. These advancements empower operators to maintain quality control even at high speeds, ensuring that every SMD is placed correctly on the PCB. As a result, JUKI plays a pivotal role in driving efficiency within modern SMT production lines.

Integrating JUKI Machines for Optimal Performance

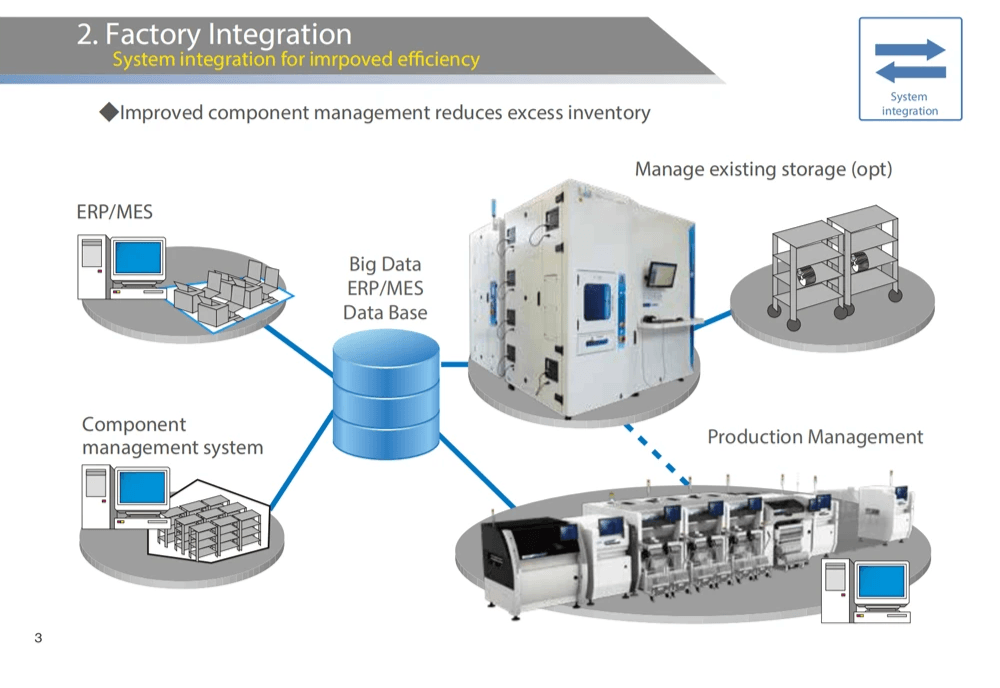

Integrating JUKI machines into your existing production setup can lead to significant improvements in overall performance. By employing sophisticated software solutions alongside their pick and place machines, manufacturers can monitor real-time data analytics that inform decision-making processes related to assembly efficiency and maintenance needs. This proactive approach ensures optimal uptime for all equipment involved in the SMT production line.

Moreover, proper training on how to utilize these advanced systems effectively is essential for achieving maximum benefits from your investment in JUKI technology. Skilled operators who understand both machine capabilities and workflow dynamics can dramatically increase productivity levels while minimizing errors during SMD placement tasks. In short, when you integrate JUKI’s cutting-edge pick & place solutions into your operations thoughtfully, you set yourself up for long-term success in the fast-paced world of electronics manufacturing.

Advantages of High-Speed Assembly

High-speed assembly is revolutionizing the electronics manufacturing landscape, and JUKI pick and place machines are at the forefront of this transformation. The ability to rapidly assemble components not only enhances efficiency but also allows manufacturers to meet increasing market demands without compromising quality. In this section, we will explore the key advantages of high-speed assembly, focusing on throughput, quality control, and economic benefits.

Increased Throughput and Efficiency

When it comes to SMT production lines, increased throughput is one of the most significant advantages provided by high-speed assembly. JUKI pick and place machines are designed for rapid operation, allowing for a higher volume of SMD components to be placed in a shorter time frame than traditional methods. This efficiency translates into shorter lead times and enables manufacturers to respond swiftly to changing market conditions or customer demands.

Moreover, the integration of advanced technologies in pick & place systems facilitates seamless workflow across the entire line SMT. With features such as intelligent component recognition and optimized placement algorithms, these machines ensure that every second counts during assembly processes. Ultimately, this leads to improved overall efficiency while minimizing downtime—an essential factor in today’s fast-paced manufacturing environment.

Quality Control in High-Speed Environments

Quality control might seem like a daunting task when dealing with high-speed assembly; however, JUKI's innovative technology ensures that precision is never sacrificed for speed. Advanced vision systems integrated into JUKI pick and place machines allow for real-time monitoring of placement accuracy during operation. This capability helps catch potential errors before they escalate into costly defects on the SMT production line.

Additionally, high-speed environments benefit from automated inspection processes that maintain stringent quality standards without slowing down production rates. These systems can identify misaligned or incorrectly placed SMD components almost instantaneously, enabling immediate corrective actions that uphold product integrity. By marrying speed with meticulous quality control measures, manufacturers can confidently produce reliable electronics that meet rigorous industry standards.

Economic Benefits of Speedy Assembly

The economic benefits derived from speedy assembly cannot be overstated; they significantly impact a company's bottom line while enhancing competitiveness in the marketplace. With increased throughput from JUKI pick and place machines comes reduced labor costs per unit produced—a crucial factor in maintaining profitability within tight margins typical in electronics manufacturing. Efficient use of resources ultimately leads to better allocation of capital towards innovation rather than merely keeping up with demand.

Furthermore, faster turnaround times enable companies to take on more projects simultaneously or respond quickly to urgent orders without sacrificing quality or reliability on their SMT production lines. As businesses scale their operations through high-speed assembly techniques like those offered by JUKI machines, they can achieve greater financial returns on investment over time while fostering long-term growth strategies within their industry sectors.

Choosing the Right Machine for Your Needs

In the world of SMT production, selecting the right pick and place machine can significantly impact your efficiency and output. With many options available, including JUKI’s renowned machines, it’s crucial to understand how they stack up against competitors. This section will guide you through comparing JUKI pick and place machines with other SMT machines, evaluating key factors for selection, and introducing Bensun Technology as your trusted partner in this journey.

Comparing JUKI with Other SMT Machines

When comparing JUKI pick and place machines to other SMT machines, several features stand out that can influence your decision. JUKI is known for its high-speed capabilities and precision in SMD placement, which are essential for modern manufacturing demands. While other brands may offer similar functionalities, JUKI often leads in terms of reliability and customer support—two critical factors when investing in a pick & place machine.

Additionally, the versatility of JUKI machines allows them to handle various components efficiently on an SMT production line. Competitors may specialize in niche applications or specific types of components but might not provide the same level of adaptability that JUKI offers across different assembly needs. This flexibility makes JUKI an attractive option for companies looking to streamline their manufacturing processes without compromising quality.

Factors to Consider in Your Selection

Selecting the right pick and place machine involves more than just brand comparison; several critical factors must be considered to ensure you make an informed choice. First, assess your production volume requirements—high-speed assembly lines benefit significantly from advanced features offered by JUKI machines that enhance throughput while maintaining accuracy during SMD placement.

Next, think about the types of components you'll be working with on your SMT production line; some pick & place systems are better suited for specific component sizes or types than others. Also consider future scalability: investing in a machine that can grow with your business needs will save time and costs down the road.

Lastly, consider support services such as training and maintenance offered by manufacturers like Bensun Technology when choosing a machine. A robust support system ensures you get maximum uptime from your equipment while minimizing disruptions during operation—a vital aspect when working within fast-paced environments typical of high-speed assembly lines.

Bensun Technology: Your Partner in Pick and Place Solutions

They offer comprehensive consultations that help businesses identify their unique requirements before recommending suitable models from brands like JUKI or others within the industry. Their expertise ensures you choose a pick & place machine that aligns perfectly with both current demands and future growth potential.

Moreover, Bensun Technology provides exceptional after-sales support including training programs designed specifically for operators using SMT pick and place systems—an invaluable resource as technology continues evolving at breakneck speed. With their assistance, you’ll not only optimize performance on your SMT production line but also foster an environment where continuous improvement becomes part of daily operations.

In conclusion, selecting the right machine is crucial for maximizing efficiency on your assembly lines; understanding how different options compare alongside expert guidance from partners like Bensun Technology can make all the difference in achieving success within today’s competitive market landscape.

Conclusion

In the ever-evolving landscape of manufacturing, JUKI technologies are paving the way for a future where speed, efficiency, and precision reign supreme. As the demand for high-quality electronic components continues to surge, JUKI pick and place machines stand at the forefront of this revolution. Their innovative designs and advanced capabilities ensure that manufacturers can keep pace with market demands while maintaining exceptional quality.

Future of JUKI Technologies in Manufacturing

The future of JUKI technologies in manufacturing looks bright as they continue to innovate and enhance their SMT machines. With ongoing advancements in automation and artificial intelligence, the potential for smarter pick and place machines is vast. Expect to see even more sophisticated features that will streamline processes in SMT production lines, making them faster and more efficient than ever before.

Maximizing Efficiency with the Right Equipment

Investing in a high-quality pick and place machine can significantly increase throughput while reducing downtime on line SMT setups. By integrating top-tier equipment like JUKI's offerings into your production line, you can achieve unparalleled levels of productivity and precision.

Why Bensun Technology Stands Out in SMT Services

Bensun Technology distinguishes itself as a premier partner for those seeking reliable solutions in SMT services, particularly when it comes to pick and place machinery. Their deep understanding of various smt machines allows them to offer tailored solutions that meet diverse manufacturing needs effectively. With a commitment to quality service and support, Bensun ensures that your investment in JUKI pick and place machines translates into real-world success.