Introduction

In the world of electronics, understanding the intricacies of PCB assembly is essential for anyone looking to create reliable and efficient devices. But what does PCB assembly mean? Simply put, it refers to the process of connecting electronic components onto a printed circuit board (PCB) to form a functional unit. This foundational step in electronics manufacturing not only involves technical know-how but also highlights the importance of quality in PCB design.

Understanding PCB Assembly Basics

At its core, PCB assembly is about transforming a mere blueprint into a working piece of technology. This involves various methods such as surface mount technology (SMT) and through-hole technology, each with its own set of advantages and applications. By grasping these basics, one can appreciate how assembled PCBs play a pivotal role in modern electronics.

Importance of Quality in PCB Design

Quality assurance in PCB design cannot be overstated; it directly influences the performance and longevity of electronic products. High-quality PCBs reduce the risk of failures, ensuring that devices operate reliably under different conditions. When considering assembled PCB manufacturers, it's crucial to prioritize those that adhere to strict quality standards during both design and manufacturing phases.

Selecting the Right Components

Selecting the right components is vital for successful PCB assembly and overall product functionality. The components chosen must not only fit within the design specifications but also meet performance criteria for durability and efficiency. By carefully evaluating options from various assembled PCB manufacturers, you can ensure that your final product meets industry standards while maximizing cost-effectiveness.

What Does PCB Assembly Mean?

When diving into the world of electronics, you might wonder, What does PCB assembly mean? At its core, PCB assembly refers to the process of connecting electronic components to a printed circuit board (PCB) to create a functional device. This process is crucial for transforming a bare PCB into an assembled PCB that can perform specific tasks in various electronic applications.

Definition and Purpose of PCB Assembly

PCB assembly is the intricate dance of placing and soldering components onto a circuit board. The primary purpose is to ensure that all parts work harmoniously together within an electronic system. By assembling PCBs, manufacturers create reliable products ranging from simple gadgets to complex machinery, making it essential for modern technology.

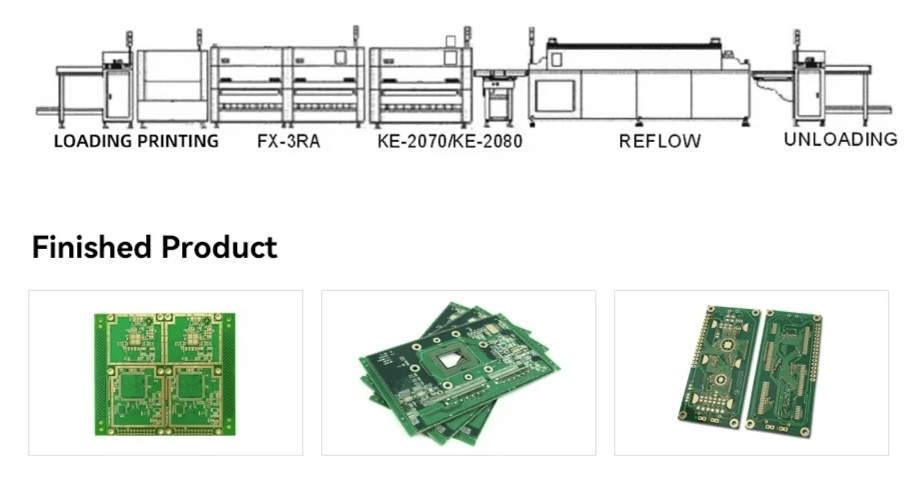

Key Steps in the Assembly Process

Assembling a PCB involves several key steps that contribute to its overall functionality and quality. First, components are sourced and organized according to the design specifications—this step is critical for ensuring everything fits perfectly on the board. Next comes placement, where components are positioned accurately on the board before soldering them in place, followed by inspection and testing to ensure reliability and performance.

Common Terms in PCB Manufacturing

Navigating the world of PCB manufacturing can be tricky without knowing some common terms associated with it. For instance, solder mask refers to a protective layer preventing solder from bridging between conductive paths during assembly. Other terms include silkscreen, which indicates component labels on the board, and vias, tiny holes that connect different layers of a multi-layered assembled PCB—essential for complex designs.

How Do You Assemble a PCB?

Assembling a PCB may sound like rocket science, but with the right tools and a clear process, it can be as straightforward as pie. Whether you're diving into the world of electronics or just curious about what does PCB assembly mean, understanding how to assemble a PCB is essential for creating functional electronic devices. This section will guide you through the necessary tools, a step-by-step assembly process, and best practices to ensure your project is a success.

Tools Required for Assembly

To embark on your PCB assembly journey, you'll need some essential tools at your disposal. First up is a soldering iron—this trusty device melts solder to create electrical connections between components on the assembled PCB. Alongside that, you'll want solder wire, tweezers for precise placement of tiny components, and wire cutters to trim excess leads after soldering.

Don’t forget about safety goggles to protect those peepers from accidental splashes of molten solder! A multimeter is also crucial for testing connections and ensuring everything functions as expected. Lastly, having an anti-static wrist strap can save your assembled PCB from any unwanted static electricity damage during assembly.

Step-by-Step Assembly Process

Now that you've gathered your tools, let’s break down how do you assemble a PCB step by step! Start by carefully reviewing the schematic and layout of your design; this ensures you know where each component goes. Next, place all components onto the board according to their designated spots—this is where those tweezers come in handy!

Once everything is positioned correctly on the board, it’s time to fire up that soldering iron! Begin by heating each connection point and applying solder until each joint looks shiny and solid—voilà! After soldering all components onto your assembled PCB, use your multimeter to check for continuity and ensure there are no short circuits before powering it up.

Best Practices for Effective Assembly

To elevate your PCB assembly game further, consider these best practices for effective assembly that will keep you ahead of the curve! First off, always double-check component orientation—placing polarized components backward can lead to failure faster than you can say what is assembly layer in PCB?

Another tip? Keep your workspace organized; clutter can lead to mistakes like misplacing small parts or mixing up similar-looking components. Lastly, don’t rush through the process; patience pays off when it comes to achieving high-quality results in both assembly and functionality of what is PCB design and assembly.

What Is the Assembly Layer in PCB?

When diving into the world of printed circuit boards (PCBs), understanding the assembly layer is crucial. The assembly layer refers to the specific arrangement and integration of components on a PCB, which plays a pivotal role in ensuring that the board functions as intended. This layer is central to what does PCB assembly mean, as it encompasses all elements necessary for creating a fully operational electronic device.

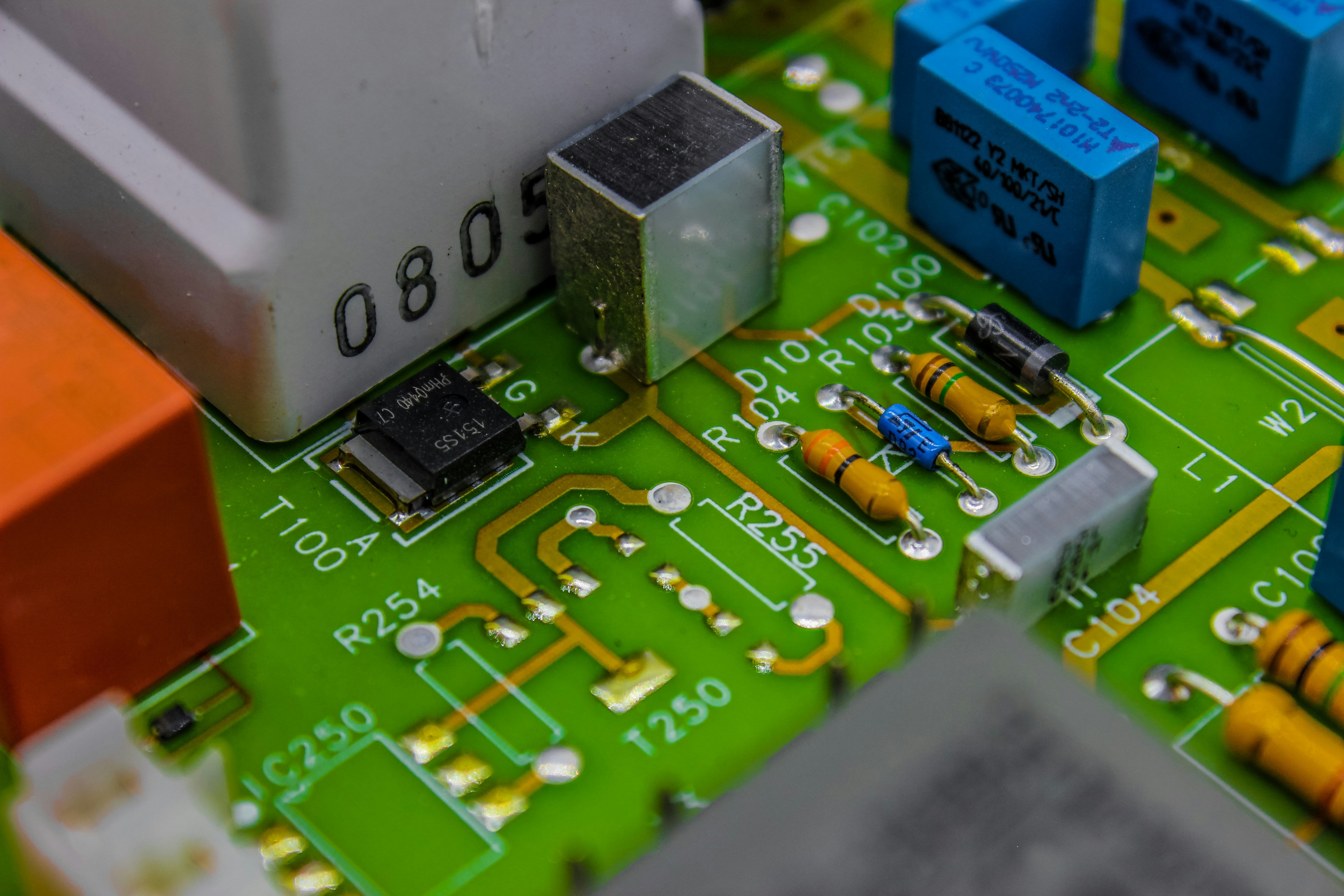

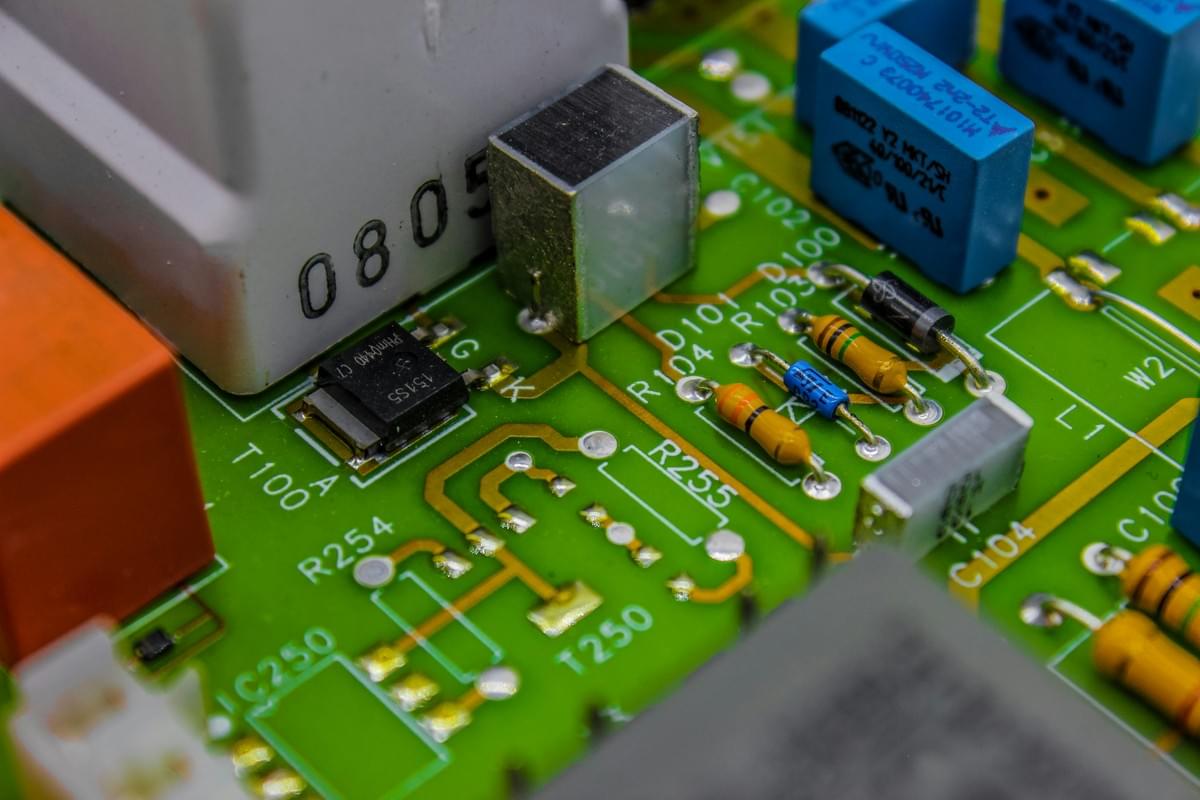

Understanding PCB Layers and Their Functions

PCBs are typically made up of multiple layers, each serving distinct functions that contribute to overall performance. The assembly layer specifically involves placing various components such as resistors, capacitors, and integrated circuits onto the board's surface. This process ensures that electrical connections are made correctly, allowing for efficient signal transmission and power distribution throughout the assembled PCB.

In essence, understanding these layers helps clarify how do you assemble a PCB effectively. Each layer must be designed with precision to accommodate the specific requirements of both electrical pathways and component placement. By grasping this concept, designers can create PCBs that not only meet functional needs but also optimize space and enhance reliability.

Importance of Layers in PCB Design

The importance of layers in PCB design cannot be overstated; they dictate not just functionality but also manufacturability. Layers allow designers to separate different types of signals—such as power and ground—thereby reducing interference and enhancing performance. For assembled PCB manufacturers, this means a more straightforward assembly process with fewer errors during production.

Moreover, having multiple layers can lead to more compact designs without sacrificing quality or performance. This compactness is particularly beneficial in today's electronics landscape where space is at a premium. Therefore, understanding what is assembly layer in PCB design helps streamline both manufacturing processes and end-product efficiency.

How Layers Impact Assembly and Functionality

Layers significantly impact both assembly procedures and overall functionality by dictating how components interact within an electronic device. A well-structured layered design reduces complexity during assembly; it allows for automated processes that enhance speed while minimizing potential errors during what is PCB design and assembly stages.

Additionally, each layer's configuration influences thermal management—a critical aspect when considering high-performance applications like computers or mobile devices where heat dissipation can affect reliability over time. Therefore, knowing how layers impact these factors provides insight into selecting assembled PCB manufacturers who prioritize quality control throughout their production processes.

What Is PCB Design and Assembly?

PCB design and assembly are fundamental processes in electronics that ensure devices function correctly and efficiently. Understanding the intricacies of these processes can significantly impact the performance of an assembled PCB. So, let’s dive into what makes PCB design and assembly tick.

Overview of PCB Design Principles

At its core, PCB design involves creating a blueprint for electronic circuits that will be fabricated onto a board. Key principles include ensuring signal integrity, minimizing electromagnetic interference, and optimizing component placement to enhance performance. When considering what does PCB assembly mean in this context, it’s clear that thoughtful design is crucial for successful assembly and functionality of the final product.

Moreover, attention to detail during the design phase can prevent costly errors during assembly. This means selecting appropriate materials, understanding layer stack-ups, and adhering to industry standards—all vital for producing high-quality assembled PCBs. Ultimately, strong design principles pave the way for efficient manufacturing processes down the line.

Integrating Design and Assembly for Efficiency

Integrating design with assembly is essential for streamlining production workflows in PCB manufacturing. Efficient collaboration between designers and assemblers helps identify potential issues early on, reducing delays caused by rework or redesigns later in the process. When you ask how do you assemble a PCB effectively? The answer often lies in how well these two stages communicate throughout development.

By aligning both disciplines from the outset, manufacturers can optimize layouts to facilitate easier handling during assembly—think reduced soldering time or fewer complex connections to manage. This integration not only enhances productivity but also ensures that assembled PCBs meet quality standards right out of the gate. After all, when design meets practicality seamlessly, everyone benefits.

Role of Software in PCB Design

Software plays an indispensable role in modern PCB design by providing tools that simplify complex tasks like schematic capture and layout creation. Advanced software solutions help engineers simulate circuit behavior before physical prototypes are built—saving time and resources while improving overall reliability of assembled PCBs. Additionally, using dedicated software allows designers to easily incorporate changes based on feedback from assemblers or manufacturers.

Many tools also offer features that facilitate communication between teams involved in both designing and assembling PCBs through shared databases or real-time updates on modifications made during development phases. This level of transparency ensures everyone is on the same page regarding what needs to be done when it comes time for actual production runs at assembled PCB manufacturers’ facilities. In short, leveraging cutting-edge software not only boosts efficiency but ultimately leads to better-designed products ready for market demands.

Selecting Assembled PCB Manufacturers

Choosing the right assembled PCB manufacturer can make or break your project. With a multitude of options available, it's crucial to consider several factors that can influence both the quality of your PCB assembly and the overall success of your product. From production capabilities to customer service, each aspect plays a vital role in ensuring you receive high-quality assembled PCBs that meet your specifications.

Factors to Consider When Choosing a Manufacturer

When selecting an assembled PCB manufacturer, start by evaluating their experience in the industry and their reputation among previous clients. A manufacturer with a proven track record in PCB manufacturing will likely understand what does PCB assembly mean and how to deliver quality results consistently. Additionally, consider their technological capabilities—do they use advanced machinery and software for both design and assembly?

Next, assess their ability to provide customized solutions tailored to your specific needs. This is particularly important when you're looking at what is PCB design and assembly; manufacturers should be able to adapt designs efficiently without compromising on quality or function. Lastly, don't overlook customer support—having responsive communication can ease any concerns during the assembly process.

Bensun Technology: A Trusted Partner

Bensun Technology stands out as a reliable partner for those seeking high-quality assembled PCBs. With years of experience in the field of PCB manufacturing, they have honed their processes to ensure that every step—from design to final assembly—meets stringent quality standards. Their expertise in what is assembly layer in PCB ensures that all layers are correctly integrated for optimal performance.

Moreover, Bensun Technology prides itself on using cutting-edge technology for both design and manufacturing processes, making them well-equipped to handle complex projects efficiently. They also offer excellent customer service, providing clients with timely updates throughout the entire process of assembling a PCB. By choosing Bensun Technology as your manufacturer, you’re not just getting an assembled PCB; you’re gaining a partner committed to your project's success.

Evaluating Quality and Service Offerings

Evaluating an assembled PCB manufacturer's quality and service offerings involves looking beyond just pricing; it requires an analysis of their certifications and adherence to industry standards as well. High-quality manufacturers will often have ISO certifications or other relevant accreditations that demonstrate their commitment to excellence in both design and assembly processes.

Additionally, inquire about testing procedures they implement post-assembly; thorough testing ensures reliability before products reach consumers' hands—essentially answering how do you assemble a PCB effectively while maintaining quality control throughout the process? Finally, consider reading reviews or seeking testimonials from past customers; this can provide valuable insights into what you might expect regarding service levels when working with them.

Conclusion

In the realm of electronics, understanding PCB assembly is crucial for ensuring functionality and reliability in devices. From grasping what PCB assembly means to mastering how to assemble a PCB, each aspect plays a vital role in the overall success of electronic projects. As we’ve explored, the integration of design and assembly along with selecting the right assembled PCB manufacturers can significantly impact quality and performance.

Key Takeaways on PCB Assembly

To sum up, PCB assembly is not just about putting components together; it’s a meticulous process that requires attention to detail at every stage. Knowing how to assemble a PCB effectively involves understanding various tools and best practices that enhance efficiency and reduce errors. Additionally, recognizing what an assembly layer in PCB entails helps in creating designs that are not only functional but also optimized for manufacturing.

Future Trends in PCB Design and Manufacturing

As technology advances, we can expect several trends to shape the future of PCB design and manufacturing. Innovations such as automated assembly processes, 3D printing of PCBs, and increased use of AI in design will transform how assembled PCBs are produced. Furthermore, sustainability will play an increasingly important role as manufacturers seek eco-friendly materials and processes while maintaining high-quality standards.

Resources for Further Learning on PCB Assembly

For those eager to dive deeper into the world of assembled PCBs, numerous resources are available online that cover everything from basic concepts to advanced techniques. Websites like IPC.org provide valuable industry standards and guidelines on what is PCB design and assembly. Additionally, forums such as EEVblog offer community insights where aspiring engineers can ask questions about how do you assemble a PCB or explore experiences with different assembled PCB manufacturers.