Introduction

In the rapidly evolving world of electronics, SMD PCB assembly has emerged as a crucial component of modern manufacturing processes. Understanding SMD (Surface Mount Device) technology is essential for anyone looking to grasp the intricacies of contemporary circuit design and production. This introduction will explore what SMD on PCB entails, its significance in the electronics industry, and an overview of its diverse applications.

Understanding SMD PCB Assemblies

SMD PCB assemblies refer to printed circuit boards that utilize surface mount technology to house electronic components. Unlike traditional methods, where components are inserted through holes in the board, SMD components are mounted directly onto the surface, allowing for more compact designs and efficient layouts. This fundamental shift in assembly techniques has paved the way for smaller and more powerful electronic devices.

Importance of SMD in Electronics

The importance of SMD in electronics cannot be overstated; it has revolutionized how devices are designed and manufactured. As consumer demand for smaller gadgets with enhanced functionality grows, SMD technology offers manufacturers a pathway to achieve these objectives without compromising on performance or reliability. Furthermore, the efficiency gained through SMD assembly translates into cost savings—making it an attractive option for businesses aiming to stay competitive.

Overview of SMD PCB Applications

SMD PCB applications span a wide range of industries, from consumer electronics to medical devices and automotive systems. This versatility stems from the ability to integrate numerous components into tight spaces while maintaining high performance levels—a necessity in today's miniaturized tech landscape. Whether it's smartphones or sophisticated medical equipment, understanding how do you put SMD components on a PCB is key to unlocking innovative solutions across various sectors.

What is SMD on PCB?

Surface Mount Device (SMD) technology has revolutionized the world of printed circuit boards (PCBs). As the name suggests, SMD components are mounted directly onto the surface of a PCB, allowing for a more compact and efficient design compared to traditional methods. This section will delve into what SMD means in the context of PCBs, highlighting its defining characteristics, differences from through-hole technology, and the many benefits it offers.

Definition and Key Characteristics

SMD refers to electronic components that are designed to be soldered directly onto the surface of PCBs rather than through holes drilled into them. These components come in various shapes and sizes but generally feature small footprints that contribute to space-saving designs. Key characteristics include their lightweight nature, reduced assembly time, and compatibility with automated assembly processes—making them ideal for modern electronic devices.

Differences Between SMD and Through-Hole

When comparing SMD with traditional through-hole technology, there are several notable differences. First off, through-hole components require drilling holes into the PCB for insertion, while SMDs sit flat on top—this not only saves space but also allows for higher component density on boards. Additionally, while through-hole parts often provide greater mechanical stability due to their leads extending through the board, SMDs offer better performance at high frequencies and lower inductance due to their shorter electrical paths.

Benefits of Using SMD Components

The advantages of using SMD components in PCB assembly are numerous and compelling. For starters, they enable manufacturers to create smaller devices without compromising functionality—a crucial factor in today’s fast-paced tech landscape where miniaturization is key. Furthermore, because they can be assembled using automated processes like pick-and-place machines, companies benefit from increased efficiency and reduced labor costs during production; this ultimately impacts smd pcb assembly price positively by lowering overall manufacturing expenses.

What is SMD Assembly?

SMD assembly refers to the process of placing Surface Mount Devices (SMDs) onto printed circuit boards (PCBs). This technique has revolutionized electronic manufacturing by allowing for more compact designs and improved performance. Understanding what SMD assembly entails is crucial for anyone involved in electronics, from hobbyists to industry professionals.

The Process Explained

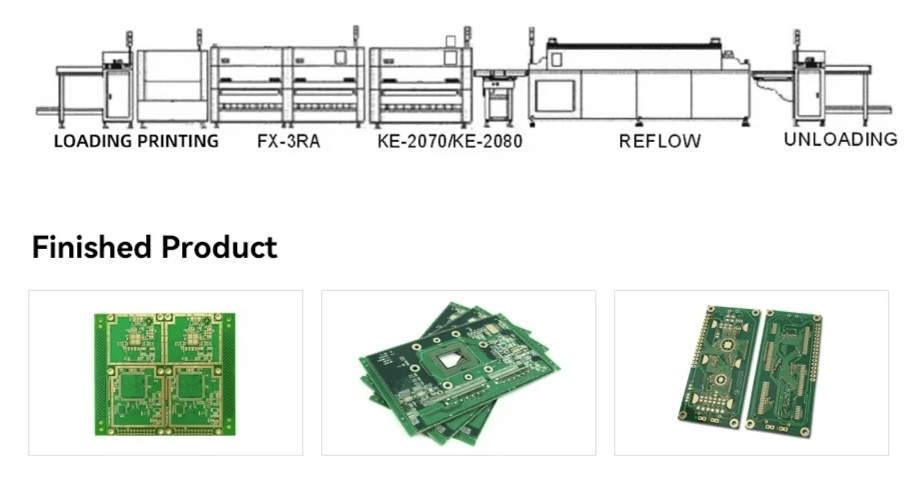

The SMD assembly process begins with designing a PCB layout that accommodates various SMD components. Once the design is complete, the next step involves applying solder paste to the designated pads on the PCB where the components will be placed. After that, SMD components are accurately positioned on these pads using automated pick-and-place machines or manual methods, followed by a reflow soldering process that permanently bonds them to the PCB.

This meticulous sequence ensures that each component is securely attached and electrically connected, which is vital for optimal performance in electronic devices. Additionally, understanding how do you put SMD components on a PCB can significantly enhance your efficiency during assembly. Each stage of this process plays an essential role in achieving high-quality results in smd pcb assembly.

Tools and Equipment Used

To execute an effective SMD assembly, a variety of specialized tools and equipment are required. First and foremost are pick-and-place machines that automate the positioning of components onto PCBs with remarkable precision and speed. Other essential tools include stencil printers for applying solder paste, reflow ovens for heat treatment during soldering, and inspection equipment like AOI (Automated Optical Inspection) systems to ensure quality control.

Additionally, hand tools such as tweezers and soldering irons may be used for manual adjustments or repairs during the assembly process. The right combination of these tools not only streamlines production but also helps in reducing smd pcb assembly price by minimizing errors and enhancing throughput efficiency. Therefore, equipping your workspace with proper tools is vital for successful SMD PCB assemblies.

Role of a Surface Mount (SMT) PCB Assembly Manufacturer

A Surface Mount (SMT) PCB Assembly Manufacturer plays a pivotal role in bringing designs to life through efficient production processes tailored specifically for SMD technology. These manufacturers are experts at managing everything from initial design consultations to final product testing, ensuring quality at every step of what is the PCB assembly process? They leverage advanced machinery and skilled technicians to create reliable assemblies that meet industry standards.

Moreover, partnering with experienced smd pcb assembly manufacturers can lead to significant advantages such as reduced lead times and cost-effective solutions tailored to specific project needs. Their expertise not only simplifies complex tasks but also ensures compliance with regulatory requirements while providing insights into future trends within surface mount technology. So when you're considering who should handle your next project, remember that choosing an established SMT manufacturer can make all the difference in achieving high-quality results.

How Do You Put SMD Components on a PCB?

Step-by-Step Assembly Guide

The first step in the SMD PCB assembly process involves preparing your PCB design files, ensuring they are optimized for surface mount technology. Once your design is finalized, you'll need to print solder paste onto the pads where the SMD components will be placed; this is typically done using a stencil and squeegee method for precision. After applying solder paste, place your SMD components accurately on the pads using either manual placement or automated pick-and-place machines.

Next up in this guide is reflow soldering, where you heat the board in an oven to melt the solder paste and secure the components in place—this step solidifies what is often seen as an art form in surface mount (SMT) PCB assembly. After cooling down, inspect your assembly visually or via automated optical inspection systems to ensure everything looks good before moving on to functional testing of your assembled board. Following these steps will help streamline what could otherwise be a complex process into manageable tasks.

Common Methods and Techniques

There are several methods and techniques employed during SMD PCB assembly that can greatly influence efficiency and quality. One popular technique involves using stencils for applying solder paste; this ensures even distribution of solder across all pads—critical for reliable connections when mounting various SMD components. Another method involves utilizing pick-and-place machines that automate component placement; these machines can significantly speed up production while maintaining high accuracy.

Additionally, wave soldering may be used as an alternative method when dealing with mixed technology boards containing both through-hole and surface mount devices. Understanding these common methods allows manufacturers to choose what best suits their specific needs while keeping an eye on factors like smd pcb assembly price and production timelines. Ultimately, selecting appropriate techniques will enhance not just productivity but also product reliability.

Quality Control Measures

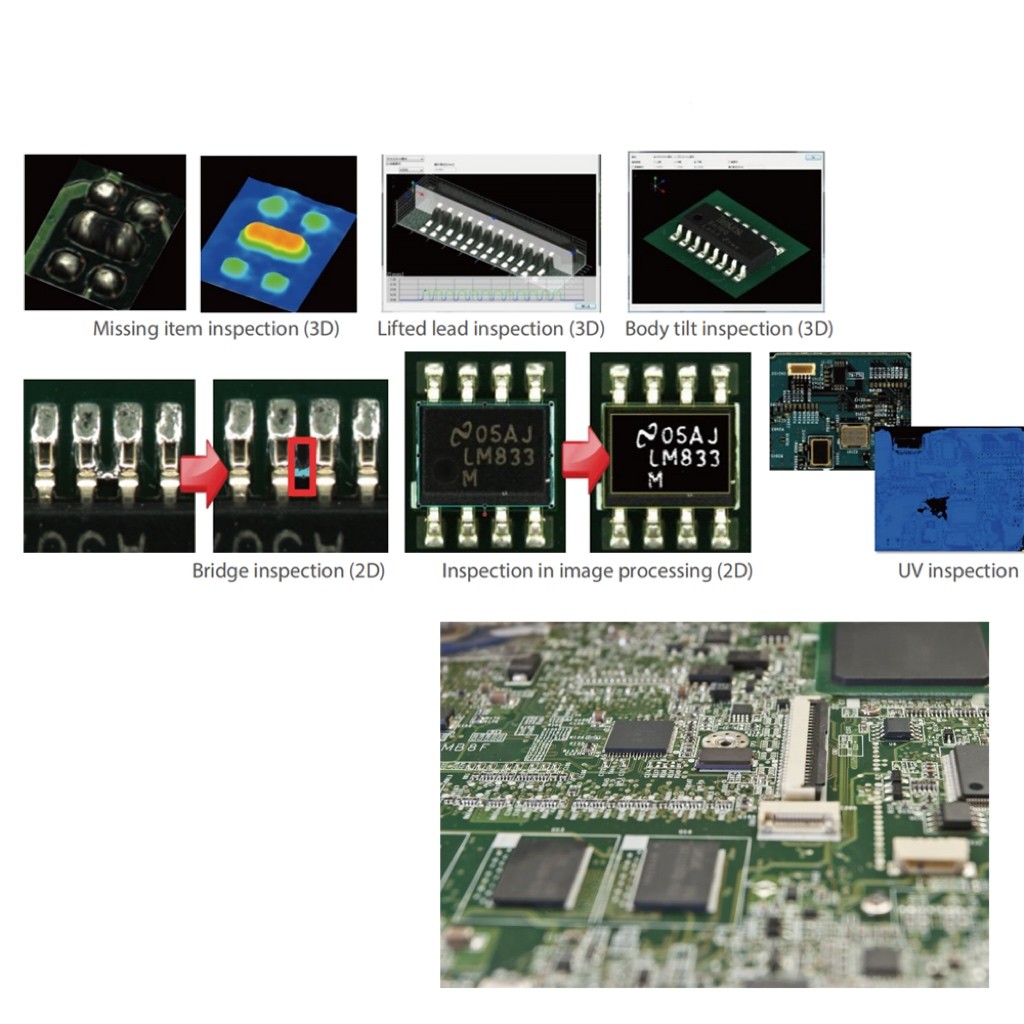

Quality control measures are vital throughout every stage of the SMD assembly process to ensure that only top-notch products reach customers' hands. First off, implementing regular inspections during various stages—from initial component sourcing through final testing—can help catch defects early before they become costly issues later on down the line. This includes visual inspections of component placement accuracy as well as functional tests post-assembly to verify circuit performance.

Moreover, employing automated inspection systems such as X-ray or AOI (Automated Optical Inspection) will provide another layer of assurance regarding connection integrity within your smd pcb assembly projects—especially important when dealing with densely populated boards or complex designs! Finally, maintaining clear documentation throughout each phase helps track any discrepancies that may arise during production runs and aids in continuous improvement efforts among smd pcb assembly manufacturers.

What is the PCB Assembly Process?

The PCB assembly process is a vital journey that transforms a conceptual design into a tangible product ready for the market. It encompasses several stages, from initial design to final production, ensuring that each component, especially SMD components, is placed precisely on the printed circuit board (PCB). Understanding this process is crucial for anyone involved in electronics manufacturing and design.

Stages from Design to Production

The first stage in the PCB assembly process starts with designing the schematic and layout of the circuit board. This involves selecting appropriate components, including SMD components, and arranging them on the PCB in a way that optimizes performance and space. Once the design is finalized, it moves into prototyping—creating a sample board to test functionality before mass production begins.

After prototyping, which often involves testing various iterations of SMD PCB assembly designs for reliability and efficiency, we transition into production. This phase includes fabricating the PCBs and assembling them using specialized equipment designed for surface mount technology (SMT). Each step must be meticulously followed to ensure high-quality results; otherwise, you might end up with more headaches than working devices!

Importance of Prototype Testing

Prototype testing is an essential part of the PCB assembly process that cannot be overlooked. It allows manufacturers to identify any issues with SMD component placement or overall board functionality before moving on to full-scale production. By catching problems early during this phase—like incorrect soldering techniques or faulty components—companies can save time and money in their smd pcb assembly endeavors.

Moreover, thorough testing can provide valuable insights into how well your design performs under real-world conditions. Whether it's thermal testing or signal integrity analysis, each test contributes significantly to refining your final product. Ultimately, prototype testing ensures that when you do launch your SMD assemblies into production, they are reliable and ready for consumer use.

SMD PCB Assembly Price Considerations

When it comes to pricing for SMD PCB assembly services, several factors come into play that can affect overall costs significantly. The complexity of your design—including how many layers your PCB has or how many different types of SMD components are used—can influence price points dramatically. Additionally, choosing between different smd pcb assembly manufacturers may yield varying quotes based on their capabilities and technologies.

Another key consideration is volume: higher quantities typically lower per-unit costs due to economies of scale in manufacturing processes. However, investing in quality during this stage pays off; opting for cheaper solutions might lead you down a path filled with defects or failures later on! So while cost matters in choosing an SMT PCB Assembly Manufacturer, balancing quality against price should be your guiding principle.

Leading SMD PCB Assembly Manufacturers

In the world of electronics, choosing the right SMD PCB assembly manufacturer can significantly impact your project's success. With a plethora of options available, understanding the strengths and specializations of various manufacturers is essential. This section delves into some leading players in the SMD PCB assembly industry, spotlighting Bensun Technology and providing tips on selecting the right partner for your needs.

Overview of Top Industry Players

The market for SMD PCB assembly is filled with remarkable companies that excel in various aspects of surface mount technology. Notable industry leaders include Jabil, Flextronics, and Foxconn, each known for their innovative approaches and commitment to quality. These manufacturers not only provide high-quality assemblies but also contribute significantly to advancements in what is SMD on PCB? technology through research and development.

Many top-tier SMD PCB assembly manufacturers focus on specific sectors such as automotive, telecommunications, or consumer electronics. Their expertise allows them to cater precisely to diverse customer requirements while ensuring efficiency and reliability in production processes. By leveraging state-of-the-art equipment and skilled personnel, these companies streamline what is the PCB assembly process? from design to delivery.

When evaluating potential partners in your search for an SMD PCB assembly manufacturer, consider their track record with similar projects. Look for testimonials or case studies that highlight their capabilities in handling complex assemblies and meeting tight deadlines without compromising quality standards. The reputation of these leading players often reflects their ability to adapt swiftly to technological changes while maintaining competitive smd pcb assembly prices.

Spotlight on Bensun Technology

Bensun Technology has carved a niche for itself within the realm of SMD PCB assembly manufacturers by emphasizing quality and customer satisfaction above all else. Specializing in surface mount (SMT) technology, they offer a comprehensive range of services from prototyping to full-scale production runs tailored specifically for diverse industries. Their commitment to excellence makes them a go-to choice when asking yourself: What is SMD assembly?

What sets Bensun apart from its competitors is its state-of-the-art facilities equipped with advanced machinery designed explicitly for efficient SMT processes. They utilize cutting-edge techniques during what is the PCB assembly process?, ensuring that every component meets stringent quality control measures before reaching customers' hands. Furthermore, Bensun's team comprises experienced professionals dedicated to guiding clients through every step involved in how do you put SMD components on a PCB?

With competitive pricing structures that cater well to startups as well as established enterprises alike, Bensun Technology provides an attractive option when considering smd pcb assembly price factors without sacrificing performance or reliability. Their extensive experience ensures they can handle any challenges that may arise during production while maintaining a focus on delivering exceptional results consistently.

How to Choose the Right Manufacturer

Selecting an appropriate manufacturer for your SMD PCB assembly needs requires careful consideration of several factors beyond just pricing alone—though it does play an important role! Start by evaluating each company's experience level within your specific industry sector; this can greatly influence their understanding of unique challenges related specifically to what is SMD on PCB?.

Next up: assess their technological capabilities! A reputable manufacturer should possess modern equipment capable of executing advanced techniques involved in what is SMD assembly?. Additionally, inquire about their quality assurance protocols—after all; no one wants subpar products when dealing with sensitive electronic components!

Lastly—and perhaps most importantly—don’t forget about communication! Partnering with someone who values transparency throughout how do you put SMD components on a PCB? will ensure smooth collaboration throughout every stage—from initial design discussions through final delivery milestones ensuring everything aligns perfectly according expectations set forth initially!

Conclusion

In wrapping up our exploration of SMD PCB assemblies, it's clear that understanding the nuances of surface mount technology is essential for anyone involved in electronics manufacturing. From defining what SMD on PCB means to delving into the intricacies of SMD assembly, we've covered a lot of ground. This knowledge not only enhances your design capabilities but also empowers you to make informed decisions when selecting SMD components and manufacturers.

Key Takeaways on SMD PCB Assemblies

SMD PCB assembly offers a myriad of advantages, including compact designs and improved performance over traditional through-hole methods. Understanding what is SMD assembly helps you appreciate its efficiency in modern electronics production, where speed and precision are paramount. Additionally, knowing how do you put SMD components on a PCB can significantly impact the quality and reliability of your final product.

Future Trends in Surface Mount Technology

The future of surface mount technology (SMT) seems bright, with continuous advancements in miniaturization and automation driving innovation in the field. Emerging trends suggest that we will see even more sophisticated techniques for placing and soldering components on PCBs as manufacturers seek to reduce costs associated with SMD PCB assembly price fluctuations. Moreover, sustainability will likely play an increasing role as companies strive to adopt eco-friendly practices while maintaining high standards in their production processes.

Final Thoughts on Choosing SMD Assemblies

When it comes to choosing SMD assemblies, selecting the right manufacturer is crucial for ensuring quality and reliability in your electronic products. Researching various SMD PCB assembly manufacturers can help you identify those who offer competitive pricing without compromising on performance or service quality. Ultimately, understanding what is the PCB assembly process will guide you toward making choices that align with both your technical needs and budgetary constraints.