Introduction

In the fast-paced world of electronics manufacturing, understanding the nuances of pick and place machines is essential for achieving optimal efficiency and precision. These machines play a pivotal role in PCB assembly, automating the placement of components with remarkable accuracy. As we delve into this topic, we will explore various types of machines, including automatic pick and place machines and their manual counterparts, as well as desktop options that cater to different production needs.

Understanding Pick and Place Machines

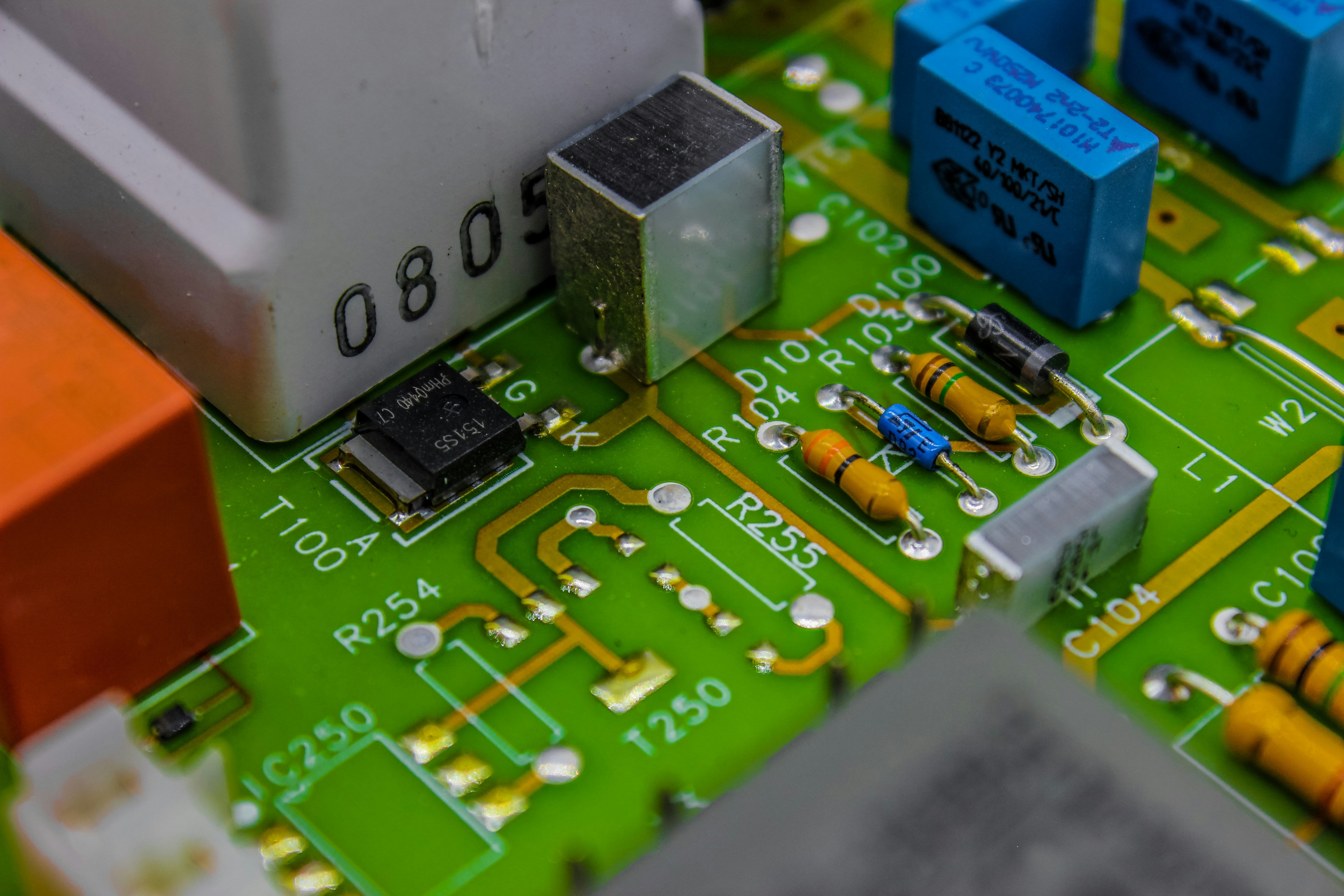

Pick and place machines are the backbone of surface mount technology (SMT) in PCB assembly. They are designed to swiftly pick up electronic components from a feeder or tray and accurately position them onto a circuit board, ensuring high-speed production without compromising quality. From automatic pick and place machines that streamline large-scale operations to manual pick and place machines suited for smaller tasks, each type serves a unique purpose in the manufacturing process.

The Importance of PCB Design

A well-thought-out PCB design is crucial for maximizing the efficiency of any pick and place machine. Proper layout not only facilitates easier component placement but also minimizes potential errors during assembly. By considering factors such as component size, orientation, and spacing during the design phase, manufacturers can significantly enhance the performance of their SMT pick and place machines.

Analyzing Machine Performance

To ensure that your investment in an automatic pick and place machine pays off, analyzing machine performance is vital. Key performance indicators (KPIs) such as speed, accuracy, and uptime can provide insights into how well a machine operates under various conditions. Utilizing appropriate tools for performance analysis allows manufacturers to troubleshoot common issues effectively while optimizing workflows for better productivity.

What is a Pick and Place Machine?

Basics of Functionality

At its core, a pick and place machine operates by using robotic arms to pick components from their trays and place them on designated spots on the PCB. This functionality is crucial for achieving high-speed assembly while maintaining accuracy, which is essential in today's fast-paced electronics market. The automatic pick and place machine utilizes advanced vision systems to identify component types and orientations, ensuring that each piece lands exactly where it should.

The beauty of this technology lies in its ability to handle various component sizes and shapes, making it versatile for different projects. With an automatic pick and place machine, you can significantly reduce manual labor costs while speeding up production times—two factors that are critical in staying competitive within the industry. As such, these machines have become indispensable tools for SMT (Surface Mount Technology) manufacturers.

Types of Pick and Place Machines

Pick and place machines come in several varieties tailored to different needs—from high-speed models designed for mass production to more compact options suited for smaller runs or prototyping. Automatic pick and place machines dominate the market due to their efficiency; they can assemble PCBs at rates far exceeding manual methods. On the other hand, manual pick and place machines still hold value for those who prefer hands-on control or are working with lower volumes.

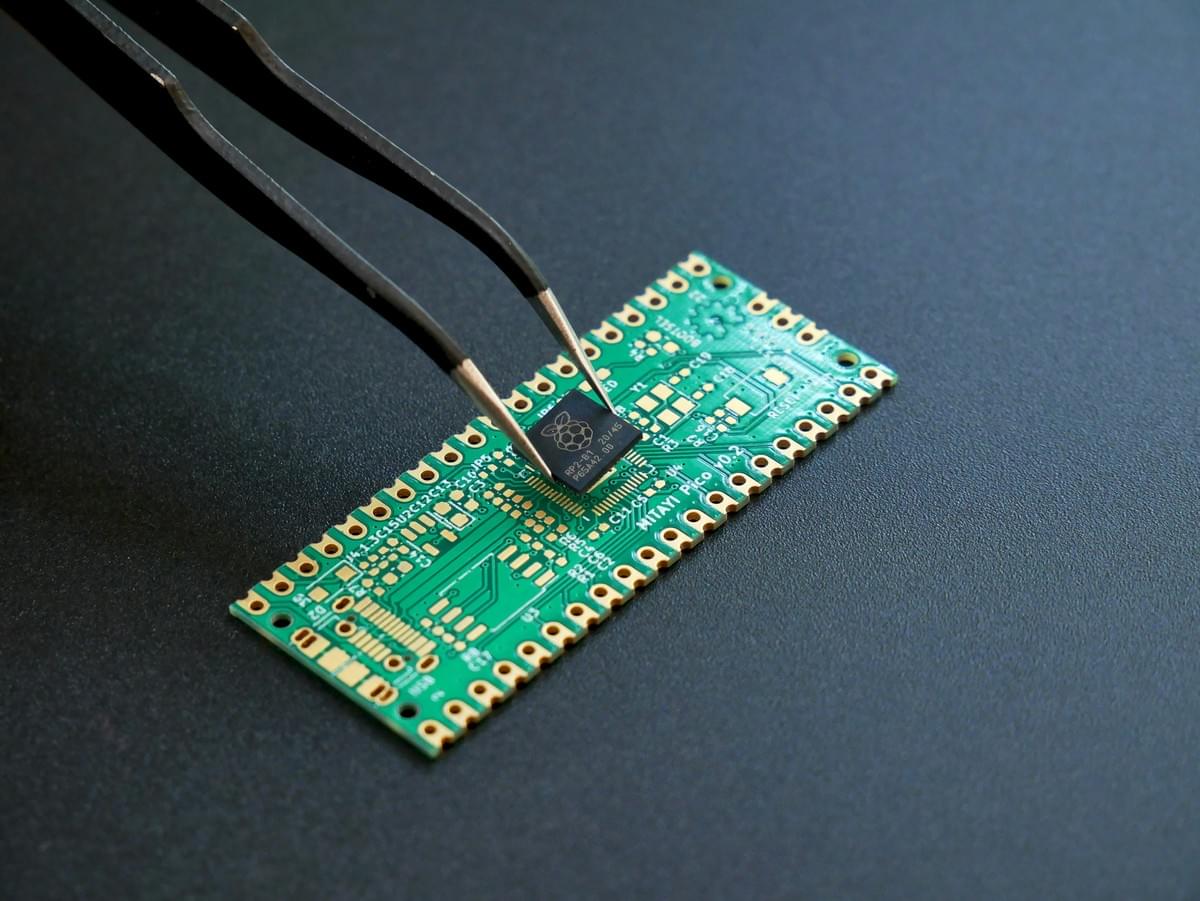

For those looking into specific applications, there are also desktop pick and place machines that fit snugly into home workshops or small labs without sacrificing performance. These models often feature user-friendly interfaces that make them accessible even for beginners in PCB assembly. Whether you opt for an automatic or manual solution largely depends on your production scale, budget considerations—including automatic pick and place machine price—and specific project requirements.

Overview of Desktop and Manual Options

Desktop pick and place machines have gained popularity among hobbyists due to their compact size yet impressive capabilities—perfect for small-scale projects or prototypes where space is at a premium. These machines typically offer many features found in larger units but at a more manageable price point, making them ideal for startups or individual users looking to get into PCB assembly without breaking the bank.

On the flip side, manual pick and place machines provide flexibility that some operators prefer when dealing with unique components or low-volume tasks requiring careful attention to detail. While they may not match the speed of their automated counterparts, they allow users greater control over placement accuracy—a vital aspect when working with intricate designs or sensitive electronics.

Choosing between these options ultimately boils down to your specific needs: whether you prioritize speed with an automatic model or value hands-on precision with a manual one will dictate your choice among SMT pick and place machine manufacturers available today.

Key Features of Automatic Pick and Place Machines

Automatic pick and place machines are revolutionizing the way we approach PCB assembly, offering a plethora of features that enhance production capabilities. These machines are designed to automate the placement of electronic components onto printed circuit boards, streamlining processes that were once labor-intensive. Understanding their key features can help you make an informed decision when selecting a machine for your specific needs.

Speed and Efficiency Factors

The ability to rapidly position components on PCBs means faster turnaround times for production runs, which is crucial in today's fast-paced market. Moreover, these machines often come equipped with advanced software that optimizes the assembly process, ensuring efficiency that manual pick and place machines simply can't match.

In terms of efficiency, many SMT pick and place machine manufacturers focus on reducing cycle times while maximizing output. This is achieved through high-speed feeders and precise movement systems that allow for quick adjustments during operation. As a result, businesses can see significant improvements in their overall productivity without compromising quality.

For those considering an automatic pick and place machine price comparison against desktop or manual options, the initial investment may seem higher; however, the long-term savings in labor costs and increased throughput often justify this expense. Ultimately, investing in speed and efficiency translates into better profit margins for manufacturers looking to scale their operations.

Precision in PCB Assembly

Precision is paramount when dealing with delicate electronic components; automatic pick and place machines excel in this area as well. With advanced vision systems integrated into these machines, they can accurately identify component placement locations down to micrometers—something that manual methods struggle to achieve consistently. This level of precision not only minimizes errors but also enhances the reliability of finished products.

Additionally, many modern automatic pick and place machines come equipped with features like real-time feedback loops that constantly monitor placement accuracy during operation. If a misalignment occurs, these systems can make immediate adjustments without halting production entirely—ensuring that every board meets stringent quality standards. Such capabilities are particularly beneficial when assembling complex PCBs with tiny components that require meticulous handling.

The combination of speed and precision makes these machines indispensable for high-volume manufacturing environments where even minor defects can lead to significant losses down the line. For businesses aiming for excellence in PCB assembly processes, investing in an automatic pick and place machine is a strategic move towards achieving superior quality control.

Versatility in Component Handling

One of the standout features of automatic pick and place machines is their versatility when it comes to handling different types of components—be it surface mount devices (SMDs), through-hole parts or odd-shaped items like connectors or sensors. This flexibility allows manufacturers to use one machine across various projects without needing multiple setups or dedicated equipment for each component type—a common limitation seen with manual pick and place machines.

Moreover, many desktop pick and place machine models have been designed specifically for small-scale operations or prototyping while still offering impressive versatility compared to traditional methods. They can easily switch between different component sizes by adjusting settings or swapping out feeders without extensive downtime—a feature highly valued by smaller manufacturers who need adaptability at an affordable price point.

As technology advances further into areas such as AI-driven assembly techniques or modular designs tailored specifically for unique applications within industries like automotive electronics or consumer gadgets—the versatility factor will only continue expanding its importance among SMT pick-and-place solutions available today. Choosing a machine capable of adapting quickly ensures you remain competitive regardless of shifting market demands.

PCB Design Considerations

Designing for efficiency in the realm of PCB assembly is crucial, especially when integrating an automatic pick and place machine into your workflow. The layout of your PCB can significantly impact how well these machines perform, ultimately affecting production speed and accuracy. By considering design elements that facilitate smooth operation, you can enhance the overall effectiveness of your assembly process.

Designing for Pick and Place Efficiency

When creating a PCB layout, it’s essential to prioritize features that enhance the functionality of a pick and place machine for PCB assembly. This includes ensuring adequate spacing between components to allow for easy access by the machine’s placement heads. Additionally, using standard component sizes can minimize complications during assembly and help maintain a competitive automatic pick and place machine price by reducing customization needs.

Another critical aspect is to utilize appropriate pad sizes that align with the specifications of your chosen SMT pick and place machine manufacturers. Proper pad design ensures secure component placement while minimizing potential misalignments during operation. Ultimately, an efficient design not only streamlines the assembly process but also contributes to higher yield rates in production.

Component Placement Strategies

Strategically placing components on a PCB can significantly influence the performance of both manual and desktop pick and place machines. It’s advisable to group similar components together to optimize the picking sequence, which reduces cycle time during assembly operations. For instance, placing passive components near each other can minimize travel time between placements for automatic machines.

Furthermore, consider placing larger components first before smaller ones in your layout strategy; this helps prevent obstruction during placement operations—an important factor when using an automatic pick and place machine. Utilizing a systematic approach in component placement not only enhances efficiency but also allows for easier troubleshooting down the line if issues arise with specific parts or connections.

Schematic to Layout Conversion

The transition from schematic design to layout is where many designers encounter challenges that can affect their choice between desktop or manual pick and place machines later on. A smooth conversion requires careful attention to detail; ensure that all connections are correctly represented before finalizing your layout for production use with an SMT pick and place machine manufacturers’ specifications in mind.

Using advanced software tools designed specifically for this purpose can streamline this process significantly; they often include features that automatically adjust component placements based on predefined rules suitable for automated systems like an automatic pick and place machine. Ultimately, achieving an accurate schematic-to-layout conversion will set a solid foundation for efficient PCB manufacturing processes while keeping costs manageable regarding equipment investment.

Analyzing Performance: Metrics and Tools

In the world of automated PCB assembly, understanding performance metrics is crucial for ensuring that your pick and place machine operates at peak efficiency. With the right tools and indicators, manufacturers can fine-tune their processes to maximize productivity while minimizing costs. This section will delve into key performance indicators, useful analysis tools, and common troubleshooting techniques that every operator should know.

Key Performance Indicators for SMT Machines

These metrics often include placement accuracy, cycle time, and yield rate, which collectively provide a comprehensive view of machine performance. For instance, a high placement accuracy is vital for ensuring that components are correctly positioned on the PCB during assembly—after all, even a minor misalignment can lead to significant issues down the line.

Another critical KPI is cycle time—the total time taken by the machine to complete a specific task or batch of PCBs. This metric directly affects production speed and efficiency; thus, manufacturers often seek machines with shorter cycle times without compromising quality. Lastly, yield rate reflects the percentage of functional boards produced versus those that failed testing; improving this KPI can significantly reduce costs associated with rework or scrap.

Tools for Performance Analysis

To effectively measure these KPIs in an automatic pick and place machine environment, various tools are available to operators and engineers alike. Software solutions designed specifically for SMT machines offer real-time analytics that help track performance metrics continuously throughout production cycles. These tools not only provide instant feedback but also allow users to generate detailed reports pinpointing areas needing improvement.

Additionally, many modern desktop pick and place machines come equipped with built-in diagnostic features that alert users to potential problems before they escalate into costly downtime or defective products. Utilizing these advanced capabilities ensures smoother operation while enhancing overall productivity levels in PCB assembly processes. Furthermore, integrating data from multiple sources can create a more robust analysis framework—allowing manufacturers to make informed decisions based on comprehensive insights.

Troubleshooting Common Issues

Despite best efforts in monitoring performance metrics through advanced tools and KPIs, issues may still arise with both manual pick and place machines as well as more complex automatic systems. Common problems include component misalignment during placement or inconsistent soldering results due to improper settings or maintenance lapses. Identifying these challenges quickly is essential for maintaining production flow.

To troubleshoot effectively, operators should first consult their machine’s user manual for recommended maintenance schedules or operational guidelines tailored specifically for their model type—be it an automatic pick and place machine or a desktop version designed for smaller tasks. Regular cleaning of nozzles and feeders can prevent material jams while ensuring optimal component handling throughout the assembly process.

Moreover, establishing clear protocols for error detection can help minimize downtime; implementing regular training sessions ensures staff remain adept at identifying anomalies early on before they impact overall output quality significantly.

Choosing the Right Manufacturer

Selecting the right manufacturer for your pick and place machine is crucial for ensuring efficiency and quality in PCB assembly. With numerous options available, it’s important to evaluate both the capabilities of the machines and the reliability of their manufacturers. This section will guide you through identifying top SMT pick and place machine manufacturers, understanding pricing dynamics, and highlighting Bensun Technology's role in providing effective PCB solutions.

Top SMT Pick and Place Machine Manufacturers

Companies like Yamaha, Juki, and ASM are well-known for their automatic pick and place machines that cater to various production scales—from high-speed assembly lines to smaller desktop pick and place machines. Each manufacturer offers unique features tailored to different needs, making it essential to assess what aligns best with your specific requirements.

In addition to these giants, there are also emerging players that provide competitive options in the market. For instance, some manufacturers focus on crafting manual pick and place machines designed for hobbyists or small-scale operations looking for cost-effective solutions without compromising on performance. Evaluating these diverse offerings allows businesses of all sizes to find a suitable match that balances quality with budget considerations.

Ultimately, choosing a reputable manufacturer not only guarantees access to cutting-edge technology but also ensures ongoing support through maintenance services and spare parts availability. Investing time in researching SMT pick and place machine manufacturers can lead you toward a partner who understands your needs for efficient PCB assembly.

Evaluating Automatic Pick and Place Machine Prices

Understanding automatic pick and place machine prices is vital when budgeting for your PCB assembly setup. Prices can vary significantly based on factors such as automation level, speed capabilities, component handling versatility, and additional features like vision systems or software integration. While high-end models may come with a hefty price tag, they often deliver greater efficiency over time—ultimately justifying the investment.

It’s essential to consider not just the upfront costs but also potential long-term savings associated with operational efficiency. For example, an automatic pick and place machine might have higher initial costs compared to a manual option but could drastically reduce labor expenses while increasing production speed—resulting in quicker return on investment (ROI). Additionally, be sure to factor in maintenance costs when evaluating overall pricing; some models may require more frequent servicing than others.

Lastly, don’t hesitate to reach out directly to manufacturers or authorized distributors for quotes tailored specifically to your needs; this can help clarify any discrepancies you encounter while browsing online listings of automatic pick and place machine prices. By thoroughly analyzing costs against performance expectations, you’ll be better equipped to make an informed decision that fits your budget without sacrificing quality.

The Role of Bensun Technology in PCB Solutions

Bensun Technology has carved out an impressive niche within the realm of PCB solutions by offering reliable automatic pick and place machines suited for various applications—from prototyping runs using desktop models all the way up through large-scale manufacturing setups requiring advanced automation features. Their commitment extends beyond simply selling equipment; they prioritize customer satisfaction by providing comprehensive support throughout every stage of use—from installation guidance through troubleshooting assistance.

One standout aspect of Bensun Technology is their focus on integrating user-friendly interfaces into their systems which makes it easier even for those new to automated processes or unfamiliar with complex machinery—this ensures smoother transitions from manual operations towards fully automated workflows within PCB assembly environments! Furthermore, they offer competitive pricing structures that cater not only large enterprises but also smaller businesses seeking effective solutions without breaking their budgets.

In summary, partnering with Bensun Technology means gaining access not only state-of-the-art equipment but also valuable expertise aimed at optimizing production efficiency while minimizing downtime during operation—a win-win situation indeed! As you navigate through choices available among SMT pick-and-place machine manufacturers consider how well each aligns with both immediate goals as well as longer-term visions within electronics manufacturing processes.

Conclusion

In the fast-paced world of electronics manufacturing, maximizing efficiency with automated systems is not just a luxury; it's a necessity. An automatic pick and place machine can significantly streamline the PCB assembly process, allowing for higher output and reduced labor costs. By integrating these machines into production lines, manufacturers can optimize workflows and enhance overall productivity.

Maximizing Efficiency with Automated Systems

The integration of an automatic pick and place machine into your operations can lead to remarkable gains in efficiency. These machines are designed to handle component placement with speed and precision that far surpasses manual methods or even desktop pick and place machines. With their ability to work continuously without fatigue, they ensure that production lines remain active longer, ultimately boosting output.

Moreover, investing in an automatic pick and place machine often pays off in the long run by minimizing errors during assembly. This reduction in mistakes leads to fewer reworks and defects, which directly impacts profitability. When evaluating options such as automatic pick and place machine price versus performance, remember that the initial cost is often outweighed by the savings generated through increased operational efficiency.

The Future of PCB Manufacturing Technology

Looking ahead, the future of PCB manufacturing technology is bright with advancements in automation shaping the landscape. The evolution of SMT pick and place machine manufacturers continues to push boundaries, resulting in machines that are faster, smarter, and more adaptable than ever before. Features like artificial intelligence integration will further enhance precision while allowing for greater versatility in handling various component types.

As technology progresses, we can expect even more sophisticated desktop pick and place machines to emerge on the market catering to smaller operations without sacrificing quality or speed. This democratization of technology means that even small-scale manufacturers can access tools previously reserved for large enterprises. Ultimately, this trend toward innovation will continue to transform how PCBs are assembled across industries.

Final Thoughts on Selecting the Right Machine

When it comes time to select a pick and place machine for PCB assembly, several factors should be considered beyond just price alone—though understanding automatic pick and place machine prices is essential! Evaluate your specific needs regarding production volume, complexity of designs, and types of components used before making a decision.

Additionally, researching SMT pick and place machine manufacturers will give you insight into reliability based on user reviews and industry reputation—don't shy away from reaching out for demonstrations or consultations! Remember that whether you opt for a manual pick and place machine or dive straight into automation with an advanced model depends largely on your operational goals; choose wisely!